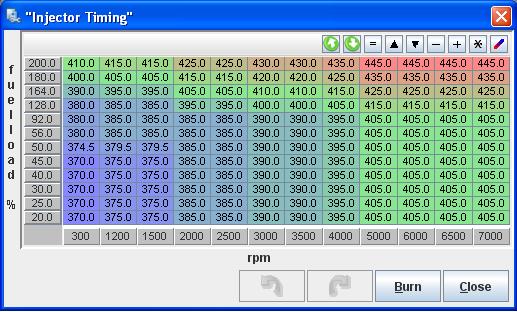

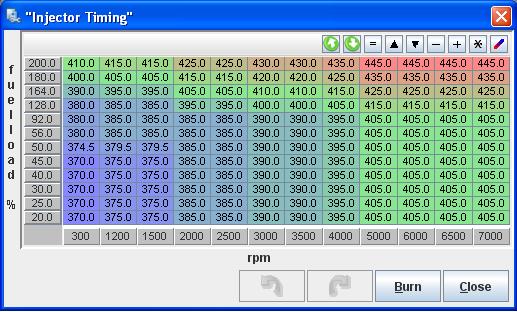

MS2/3 Injection timing maps for sequential injection

#21

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,501

Total Cats: 4,080

the term timing makes complete sense if you understand the function.

when I use injector timing, I use end of squirt. The table represents the exact degree the crank is sitting at when I expect the fuel to be completly done squirting, I timed it against the intake cam, where I want my fuel to be there before it open.

because my fuel load is based on map density, so 200% = 200kPa.

when I use injector timing, I use end of squirt. The table represents the exact degree the crank is sitting at when I expect the fuel to be completly done squirting, I timed it against the intake cam, where I want my fuel to be there before it open.

because my fuel load is based on map density, so 200% = 200kPa.

#24

can i ask you guys slightly offtopic question.

i'm trying to wrap my head around this injector timing as it applies to 2-profile cams. seems to me that the biggest gains from tuning would be for the lower rpm low profile (0 deg), but how would you optimize that without blowing up the high profile?

I ask because I'm thinking about building a ve head swap sr20.

SR16VE

Intake Low: Opens at 0deg before TDC, Closes at 20deg After BDC

Intake High: Opens at 40deg before TDC, Closes at 60deg After BDC

Exhaust Low: Opens at 64deg before BDC, Closes at 0deg After TDC

Exhaust High: Opens at 70deg before BDC, Closes at 30deg After TDC

ref: http://www.sr20-forum.com/vvl/14455-...tml#post188551

i'm trying to wrap my head around this injector timing as it applies to 2-profile cams. seems to me that the biggest gains from tuning would be for the lower rpm low profile (0 deg), but how would you optimize that without blowing up the high profile?

I ask because I'm thinking about building a ve head swap sr20.

SR16VE

Intake Low: Opens at 0deg before TDC, Closes at 20deg After BDC

Intake High: Opens at 40deg before TDC, Closes at 60deg After BDC

Exhaust Low: Opens at 64deg before BDC, Closes at 0deg After TDC

Exhaust High: Opens at 70deg before BDC, Closes at 30deg After TDC

ref: http://www.sr20-forum.com/vvl/14455-...tml#post188551

#25

Hustler, fuel load is synonymous with kPa.

Anyways, something that is not entirely clear: The -350deg used as a static value as referenced from the sequential example at DIYAutotune is refferenced to TDC as zero. It looks like the table values are the absolute of this value. Is that correct. So -350deg static would be the same as populating the entire table with 350. Setting all values to 350 in the table and working from there towards either map above seems like the best way to go. Checking to see if you need more or less fuel and dialing back when more fuel is wanted until it again wants more fuel. If unsure, it seems like farther before TDC is a good way to go.

My 2 cents on theory. This really should be almost solely based on RPM, as that will determine how much time you have to inject. Fuel load (kPa/boost) isn't really going to change things much. Actually, higher boost won't atomize the fuel as well as deep vacuum, so injecting slightly earlier with higher kPa will make sure the fuel gets drawn in in and atomize a bit better. The injection timing map should increase from left to right predominantly.

Anyways, something that is not entirely clear: The -350deg used as a static value as referenced from the sequential example at DIYAutotune is refferenced to TDC as zero. It looks like the table values are the absolute of this value. Is that correct. So -350deg static would be the same as populating the entire table with 350. Setting all values to 350 in the table and working from there towards either map above seems like the best way to go. Checking to see if you need more or less fuel and dialing back when more fuel is wanted until it again wants more fuel. If unsure, it seems like farther before TDC is a good way to go.

My 2 cents on theory. This really should be almost solely based on RPM, as that will determine how much time you have to inject. Fuel load (kPa/boost) isn't really going to change things much. Actually, higher boost won't atomize the fuel as well as deep vacuum, so injecting slightly earlier with higher kPa will make sure the fuel gets drawn in in and atomize a bit better. The injection timing map should increase from left to right predominantly.

Thread

Thread Starter

Forum

Replies

Last Post