No AFM Air-box top

#1

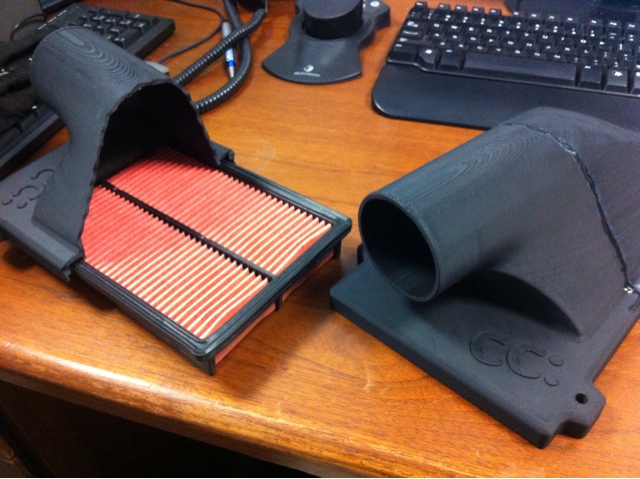

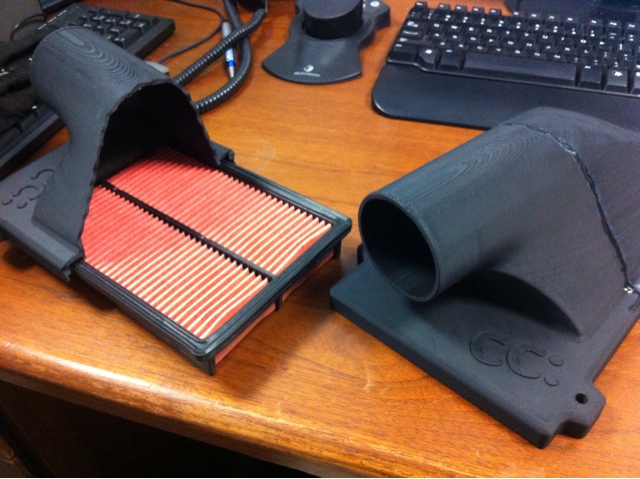

I removed my AFM for megasquirt, so I built a new air-box top to keep the airbox.

I drew it up in SolidWorks and printed it off with our Stratasys 3d printer. The big Fortus machine is busy for the next month, so I chopped the part in half (virtually) so it fit on the smaller machine and then glued it back together when it was done. Because Prototype.

I'll sand it down and hit it with some Satin black paint - but that'll happen some other time. I have a TT this weekend.

The spare piece in the pic sitting on the filter is a failed print. It makes a cool cut-away to show the inside, though.

Maybe I'll investigate 'Randall' intakes next and make up something that will pull in low pressure air.

I don't think something like this would have a market, but I could make up a mold and try a few in carbon or fiberglass if there's interest.

I drew it up in SolidWorks and printed it off with our Stratasys 3d printer. The big Fortus machine is busy for the next month, so I chopped the part in half (virtually) so it fit on the smaller machine and then glued it back together when it was done. Because Prototype.

I'll sand it down and hit it with some Satin black paint - but that'll happen some other time. I have a TT this weekend.

The spare piece in the pic sitting on the filter is a failed print. It makes a cool cut-away to show the inside, though.

Maybe I'll investigate 'Randall' intakes next and make up something that will pull in low pressure air.

I don't think something like this would have a market, but I could make up a mold and try a few in carbon or fiberglass if there's interest.

Last edited by vortexblue; 08-24-2012 at 10:07 AM.

#3

Hey Emilio - I've used NDA's in the past for people with prototypes. Drop me a note!

I've had a few questions about the process and the parts.

The machine I used on for this particular model was an older Dimension machine. It uses ABS plastic and a support material that dissolves in a water-based solution. This machine is outdated, and this particular one is built from old parts... it's really just for the employees fun.

The newer versions of the machine use a ABS/ PC blend and the material is more flexible and has a kind of satin 'sheen' to it.

There are larger versions of the machine (Fortus line) that can do different materials such as PC and Ultem. I plan on making a throttlebody adapter out of ultem to see how well it'll hold up on a daily driver motor. I've heard of companies like Edelbrock using it to create a full intake manifold and bolt it onto a motor on a flowbench. They can get meaningful numbers off the bench before they get to the machining/ casting phase.

I bolted the airbox top on last night and took it for a ride. With out a dyno, I have 0 numbers for you, but the part didn't implode under vacuum; so I guess it's successful.

I've had a few questions about the process and the parts.

The machine I used on for this particular model was an older Dimension machine. It uses ABS plastic and a support material that dissolves in a water-based solution. This machine is outdated, and this particular one is built from old parts... it's really just for the employees fun.

The newer versions of the machine use a ABS/ PC blend and the material is more flexible and has a kind of satin 'sheen' to it.

There are larger versions of the machine (Fortus line) that can do different materials such as PC and Ultem. I plan on making a throttlebody adapter out of ultem to see how well it'll hold up on a daily driver motor. I've heard of companies like Edelbrock using it to create a full intake manifold and bolt it onto a motor on a flowbench. They can get meaningful numbers off the bench before they get to the machining/ casting phase.

I bolted the airbox top on last night and took it for a ride. With out a dyno, I have 0 numbers for you, but the part didn't implode under vacuum; so I guess it's successful.

#6

Sure. I would just need to edit the solid model file.

The ABS can be sanded and glued and epoxied and body-fillered... anything that you can do with a normal piece of ABS. The 3d printer is just awesome for doing *most* of your work. The prints on the big machine can get pricy, but they'd be ready to use right off the machine.

If you're going to google this stuff for your own info, look for FDM - fused deposition modeling. This is like a hot-glue gun with brains. It'll make strong parts like we'll need in a car application. The other types of SLA's will look prettier due to their layer resolution, but the materials are not nearly as strong.

The ABS can be sanded and glued and epoxied and body-fillered... anything that you can do with a normal piece of ABS. The 3d printer is just awesome for doing *most* of your work. The prints on the big machine can get pricy, but they'd be ready to use right off the machine.

If you're going to google this stuff for your own info, look for FDM - fused deposition modeling. This is like a hot-glue gun with brains. It'll make strong parts like we'll need in a car application. The other types of SLA's will look prettier due to their layer resolution, but the materials are not nearly as strong.

#7

heres' some more 3d printed junk in my noob intro:

https://www.miataturbo.net/meet-gree...-miatas-47122/

https://www.miataturbo.net/meet-gree...-miatas-47122/

#8

Hey Chris, I think there might very well be a market for this for folks going MS but not going turbo (like the guy with the Supercharger). Have you contacted the DIY guys?

You never know. My little bit of garage piddling from 20 years ago turned into an international avionics company. I could scarcely have imagined.

BTW, check into Virtual Dyno.

You never know. My little bit of garage piddling from 20 years ago turned into an international avionics company. I could scarcely have imagined.

BTW, check into Virtual Dyno.

Thread

Thread Starter

Forum

Replies

Last Post

bigmackloud

Miata parts for sale/trade

19

01-08-2021 11:24 AM

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM

russian

Miata parts for sale/trade

6

10-08-2015 03:01 PM