What is wrong with this turbo?

#21

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Is there supposed to be a gasket between the turbo and that fitting? Can I disassemble and just use some permatex gasket maker?

As the motor warmed up it was fine until about 160deg. Then I started to get some white smoke from the tail pipe then smoke from the turbo, im assuming as the oil leaked out into the hot side.

As the motor warmed up it was fine until about 160deg. Then I started to get some white smoke from the tail pipe then smoke from the turbo, im assuming as the oil leaked out into the hot side.

#23

Just checked the FM install directions looks like they recommend "smearing sealant" on the gasket and fitting before install. So I'm guessing A there is none there or B in the disassemble/reassemble process the seal was ruined.

They Do recommend a Gasket part number 02-70510. I'm wondering if I can get that locally or if I have to get it from them. I'd really like to be doing break in this weekend!!

They Do recommend a Gasket part number 02-70510. I'm wondering if I can get that locally or if I have to get it from them. I'd really like to be doing break in this weekend!!

Last edited by Sensei; 04-14-2017 at 12:56 PM. Reason: discovered new info

#25

Called Flying Miata- I love that company they are so great and so patient. They gave me a Mazda part number. Ordered the gasket from the local Mazda dealer they said hopefully they get it tomorrow morning! FM also said I could use the permatex only as a short term solution. When I get the paper gasket to coat both sides with permatex And it should be good to go!

The smoke in the exhaust seems to happen about the same time as the oil leak from the return line so the two may be related, but then again I'm certain the rings aren't seated properly yet, and being as the car has only been to 180 once I'm guessing the smoke may be related to that also. I guess I'll know for sure when the gasket gets installed.

The smoke in the exhaust seems to happen about the same time as the oil leak from the return line so the two may be related, but then again I'm certain the rings aren't seated properly yet, and being as the car has only been to 180 once I'm guessing the smoke may be related to that also. I guess I'll know for sure when the gasket gets installed.

#27

They don't. I called flying Miata and told them I needed the gasket asap they checked napa, autozone etc and they said the fastest way to get it would be to use the gasket for a msm oil pick up. And that I should be able to get it at the dealer faster than they could get it to me.

Did i I mention how awesome flying Miata is?

Did i I mention how awesome flying Miata is?

#31

Got the new gasket in today, coated both sides with permatex as reccomended by FM. Fired it up and it appears to be all good. Unfortunately my tuning laptop took a poop, so no break in today. I also noticed a possible leak from the heater core. I'll see if a new worm type clamp does the trick.

#32

HDX Swaging Tool HDX053 at The Home Depot - Mobile

#33

I got one and used it before dropping the motor in, unfortunately the deformation was maybe 2 inches back and the flare section on the tool couldn't reach back far enough to fix it 100%. I got about 80% fixed, if the problem persists with the new clamp I'll pull the hose and add some sealant.

#36

Damn those are nice! How do they compare to t bolts? There's a place local that sells t bolts of all sizes but their hours aren't ideal. I hate worm gears, but right now it's what I got, plan to upgrade once it's all running. The t bolts and worm, gears I like that they can be installed without removing the hose.

#37

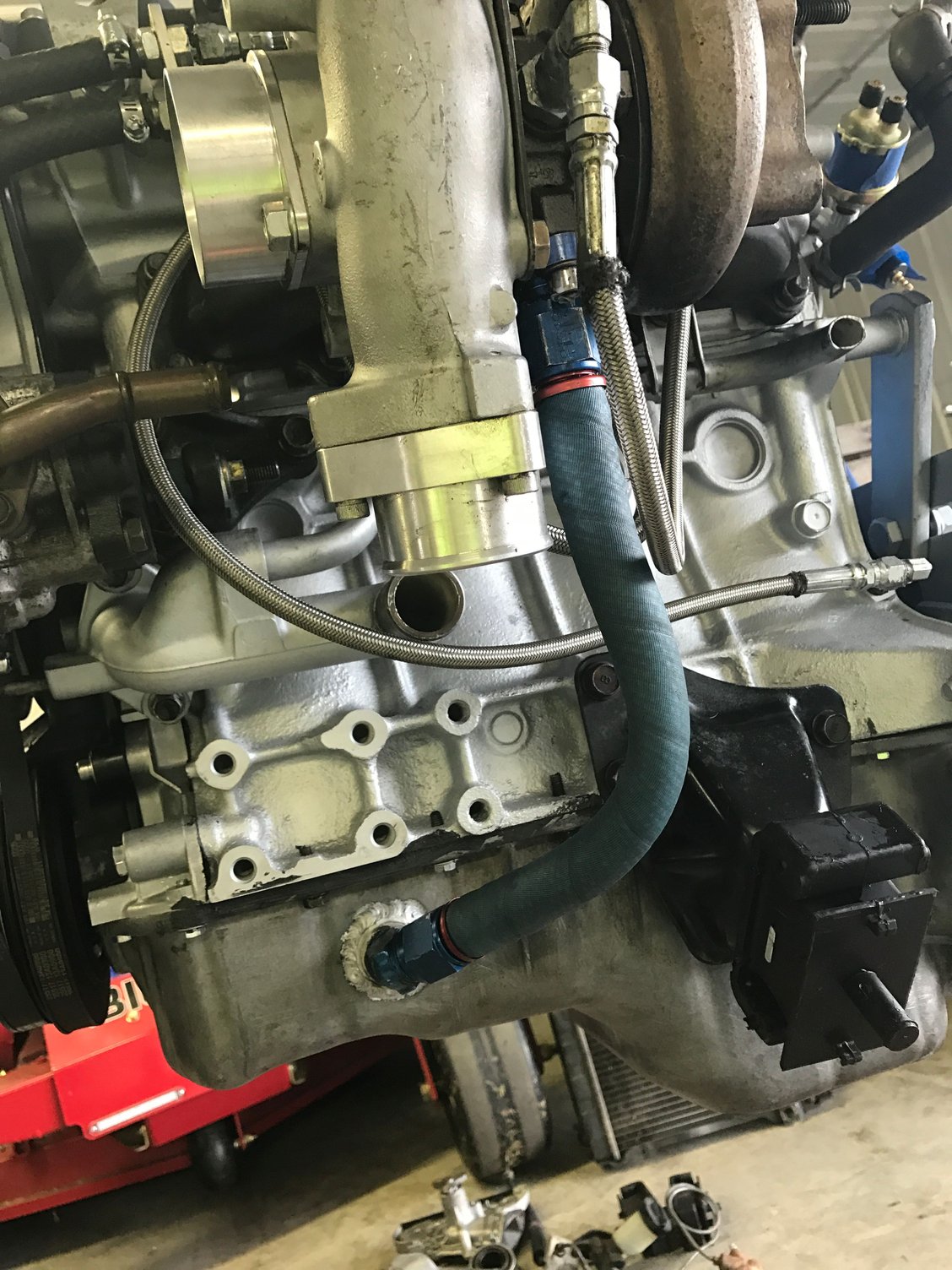

Fired up the car, still smoking and leaking oil once the car gets over 160. Removed the return and feed lines to check for obstruction, nothing obvious. It looks like the oil feed hose may be leaking at the fitting, and there does not appear to be a restrictor in the line so maybe that's the problem? Too much oil pressure?

#39

The turbo is a Garett 2560. I pulled the oil feed line and it does not appear to have any restriction. I'm not sure yet how to tell if the turbo has a restrictor in it or not yet, but if it does not I'm thinking this may be caused by oil blow by. According to Garett the turbo should see 40-45psi at max rpm, but I'm getting 60psi at start up tapering to 40 at idle. It could be a hot side seal, but if the seal is shot I feel like there should be some shaft play. The shaft is solid, no wiggle no nada.