heat + plastic dipstick = engine fire!

#21

I took this apart last night and noted that all of the studs were also backing out; and noticed that the threads were damaged due to the flange vibration. I checked my build notes and it shows that I torqued the studs in at 30#, dry; and then torqued the crimp nuts in at 35#. I couldn't reach the bottom 2 with a socket, so these were tightened with an end wrench, "tight".

The car was not street tested, and I figure that the two events that I attended prior to the failure consisted of an accumulated 4 1//2 to 5 hours of on track time.

The downpipe is quite heavy and is unsupported until the first OEM exhaust hanger prior to the rear axel. The suggestion of an exhaust brace at the forward section of the downpipe looks to be a very good solution.

I will also replace the steel studs, crimp nuts and also use nord lock washers.

What is the concensus for stud material? steel, stainless; I'd rather not buy the expensive Inconel unless it's necissary.

What do you think of Handyman's suggestion of resbond to lock the studs? (I worry about dis-assembly at later date). Sorry Hus, I don't know what a CHRA is or how to saftey wire it.

Sav: I will take off the heat shield... and replace it with a nomex jock strap? like Hus suggested.

Thx for your help and solutions. cj

The car was not street tested, and I figure that the two events that I attended prior to the failure consisted of an accumulated 4 1//2 to 5 hours of on track time.

The downpipe is quite heavy and is unsupported until the first OEM exhaust hanger prior to the rear axel. The suggestion of an exhaust brace at the forward section of the downpipe looks to be a very good solution.

I will also replace the steel studs, crimp nuts and also use nord lock washers.

What is the concensus for stud material? steel, stainless; I'd rather not buy the expensive Inconel unless it's necissary.

What do you think of Handyman's suggestion of resbond to lock the studs? (I worry about dis-assembly at later date). Sorry Hus, I don't know what a CHRA is or how to saftey wire it.

Sav: I will take off the heat shield... and replace it with a nomex jock strap? like Hus suggested.

Thx for your help and solutions. cj

#22

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,203

Total Cats: 1,138

The CHRA is your Center House Rotating Assembly. From front to back on your turbo you have your compressor housing, CHRA, and Turbine housing.

The compressor housing is what the hot side intercooler pipe and air filter bolt to.

The CHRA is what the oil feed/drain and water feed/drain bolt to, and both ends have wheels on the end that stick into the two housings.

Turbine housing is what bolts to your manifold and downpipe.

The CHRA is held to the turbine housing and compressor housing with 4-6 bolts depending on turbo size. With Hustler's V-bands on the manifold and downpipe, he destroyed a CHRA by having these bolts back out/stretch. He bought inconel bolts to stop the stretching, and safety wired them to stop them from backing out.

This is certainly a "buy it and leave it" solution, probably the best you can do.

The exhaust clamp will go a long way to reduce your failures, along with placing inconel and locking hardware everywhere you can.

The compressor housing is what the hot side intercooler pipe and air filter bolt to.

The CHRA is what the oil feed/drain and water feed/drain bolt to, and both ends have wheels on the end that stick into the two housings.

Turbine housing is what bolts to your manifold and downpipe.

The CHRA is held to the turbine housing and compressor housing with 4-6 bolts depending on turbo size. With Hustler's V-bands on the manifold and downpipe, he destroyed a CHRA by having these bolts back out/stretch. He bought inconel bolts to stop the stretching, and safety wired them to stop them from backing out.

This is certainly a "buy it and leave it" solution, probably the best you can do.

The exhaust clamp will go a long way to reduce your failures, along with placing inconel and locking hardware everywhere you can.

#25

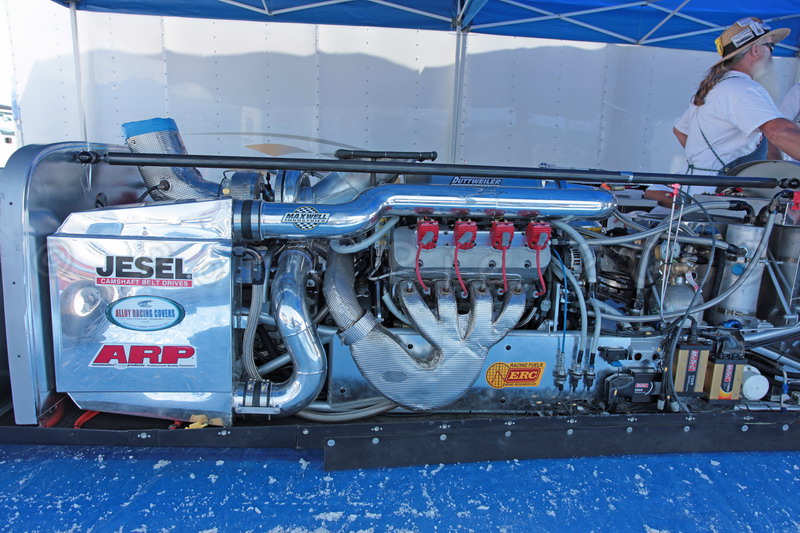

In the pictured cases, the components are better described as insulators rather than shields. Rather than trying to protect external items from frying, the intent is to retain as much heat energy as possible for use in the turbine. I think Andrew's point is that extra stuff (such a shields) = weight = bad. In addition, shields make inspection harder. In many cases, you are better off moving heat sensitve components away from heat sources rather than shielding the heat source.

But, we digress.

To OP, if you want to know why you should look into Inconel, Google "Creep" or "Thermal Creep."

But, we digress.

To OP, if you want to know why you should look into Inconel, Google "Creep" or "Thermal Creep."

#26

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

I'm just saying that I don't think they do nearly as good a job as individually wrapping each line in Firesleeve or reflective heat sleeve. If you want to effectively keep specific items cool (heater hoses, lower coolant hose, oil/water lines, brake MC reservoir), then wrap those specific items.

#27

Those are some well insulated pipes!

Guys, I wonder if it is more the vibration rather than the heat that rattled these bolts loose.

The nord lock washers aren't going to fit onto the flange as they are too large in diameter.

As suggested, I think that safety wire is the fix. The nuts are too small for me to drill out a corner, but I can replace the stud/nut assy with hex head bolts; drill and then tie the wire... then also weld up a DP brace.

I think that's what I'll try... and of course I'll leave the heat shield off so that I can inspect on a regular basis.

Guys, I wonder if it is more the vibration rather than the heat that rattled these bolts loose.

The nord lock washers aren't going to fit onto the flange as they are too large in diameter.

As suggested, I think that safety wire is the fix. The nuts are too small for me to drill out a corner, but I can replace the stud/nut assy with hex head bolts; drill and then tie the wire... then also weld up a DP brace.

I think that's what I'll try... and of course I'll leave the heat shield off so that I can inspect on a regular basis.

#34

I have given so much latitude for lewd innuendo in this post...

It might not matter now, but I did mean to say a "hex head bolt"; ARP 8m 24mm x 1.25 black oxide with an expanded shoulder and a 10mm head... I think it's a better way than a stud + nut as it can be easily drilled and wired.

... it's a lot of work to keep your dipstick from getting flamed.

It might not matter now, but I did mean to say a "hex head bolt"; ARP 8m 24mm x 1.25 black oxide with an expanded shoulder and a 10mm head... I think it's a better way than a stud + nut as it can be easily drilled and wired.

... it's a lot of work to keep your dipstick from getting flamed.

#35

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,203

Total Cats: 1,138

My point was you most likely can't get a bolt into all those holes. That's why the studs come in from the back.

A lot of us have studs that protrude exactly 0mm past the nuts.

Put that in your sig and smoke it.

A lot of us have studs that protrude exactly 0mm past the nuts.

Put that in your sig and smoke it.

Thread

Thread Starter

Forum

Replies

Last Post