what material for flat underbody?

#25

there is no doubt a flat underbody would be beneficial on a street car, however you probably wouldn't notice it at all unless it were on a track car. Also, I doubt anyone that serious would be doing just a flat underbody alone. We're talking about adding splitters, diffusers, and wings, which could mask the effects of just one of the pieces of aero

#29

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

#31

there is no doubt a flat underbody would be beneficial on a street car, however you probably wouldn't notice it at all unless it were on a track car. Also, I doubt anyone that serious would be doing just a flat underbody alone. We're talking about adding splitters, diffusers, and wings, which could mask the effects of just one of the pieces of aero

I did light under paneling with corrugated plastic. Of the two 24x36" sheets I got initially, most of it went to underpaneling instead of rad ducting (the original intention)

ClubRicer.net.. I mean ClubRoadster.net is not giving me any usable feedback. Probably because these aren't "nice" pieces.

Simply ziptied on, seems to be holding up so far, only daily driving so far.. Few pics. This project started from a blown radiator.

Front, covering only the front sub.

Rear, 24" x 36" piece

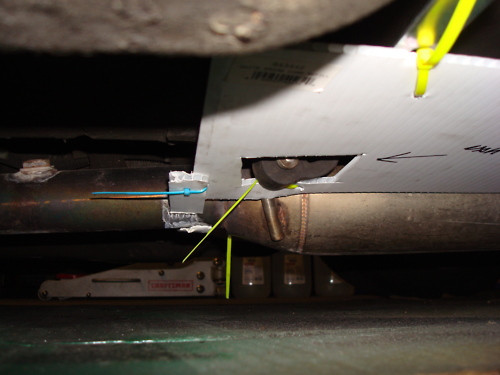

It starts a few inches ahead of where the floor ends, in line with the plastic bolts the tie down the plastic fuel filter cover. This pic has another piece intentionally sitting on the mid-pipe to see if it'd catch fire or merely just melt as I anticipated.

Minimal gap between exh pipe and corrugated plastic:

No signs of melting aside from the aforementioned piece, which was to be expected.

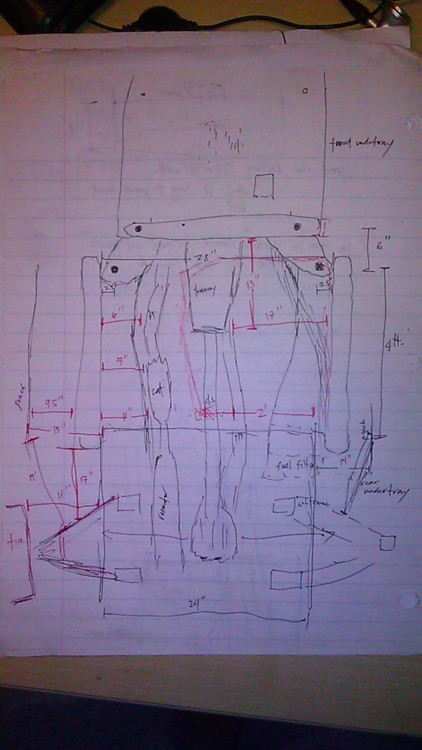

Top piece goes under front sub.. I cut out an outline for the front jack point and a rectangle slit for oil changes. Oil temps are within normal operating range. Oil pan surface temps were not recorded pre- or post-... I don't think it's an issue.

Bottom piece is pre- and post- radiator, guiding the air upwards to an eventual vented hood.

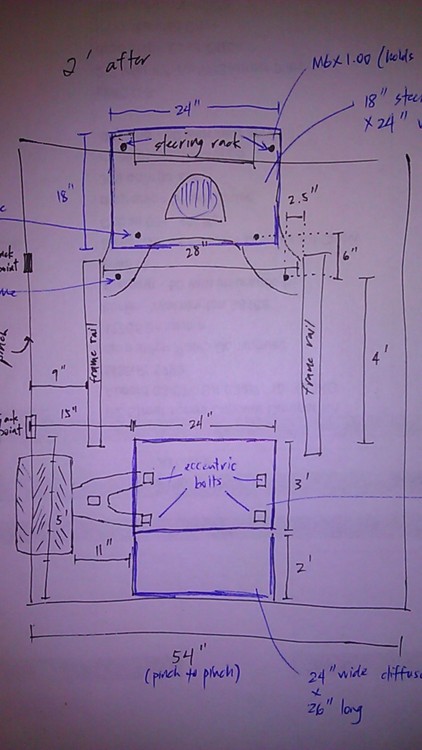

24" wide x 36" long, meets the floor and 5" past the rear eccentric bolts/subframe to mate along with the Lexan diffuser (also a prototype).

Never bothered to record differential casing temperatures before adding these. I believe there is still enough airflow in the tunnel for it to cool the diff. After a 30 minute drive, diff casing is at 170 degree temps using an infrared thermo. Just in case exhaust piping was affecting readings, I took a reading of the subframe (110 degree) and the exhaust pipe ("Hi")-- probably somewhere 200+

This is what I have on the front end:

It is at 75-80mm ground clearance, undertray surface is 115mm above ground. Yes, this creates a low pressure region right behind the front-most airdam, and it would be better if it were lower or at least inline with the front subframe, but for clearance issues, I am testing to see how low it can go without scraping it too much. The front-most airdam is more easily disposable than another splitter/undertray.

I've also been doing some non-traditional coast down tests with variations and also between 3.5" pinch vs 3.75"/4.00" pinch heights.

Would appreciate some criticism-- already observing positive subjective and objective results and already have plans for more aero work...

Some sketches/measurements for some brainstorming.

(p.s. sorry for the long post, and this was the most recent thread on this topic)

#32

these guys do alot of areo mods and there are tons f write ups on under body trays:

http://ecomodder.com/forum/

http://ecomodder.com/forum/

#35

yea, I bought 10 sheets of 24x48 (4mm thickness) for $70 shipped. 4mm seems pretty good, Its thin enouugh for things that don't need to be particularly rigid, but can be doubled or even tripled up for a splitter. Since its vertically stiff, sealing up the rows with some foam or something for the sort, could make for nice material to do a diffuser also. Either way, depending on the way you orient it, you can go from something that is stiff, to something that is bendable and durable!

#36

Elite Member

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

yea, I bought 10 sheets of 24x48 (4mm thickness) for $70 shipped. 4mm seems pretty good, Its thin enouugh for things that don't need to be particularly rigid, but can be doubled or even tripled up for a splitter. Since its vertically stiff, sealing up the rows with some foam or something for the sort, could make for nice material to do a diffuser also. Either way, depending on the way you orient it, you can go from something that is stiff, to something that is bendable and durable!

I have a boner.

I am not the fabrication lord so stuf like this that is cheap and easy to work with is my type of material. ---- yeah.

Link please!

#37

http://www.corrugatedplastics.net/4m...ticSheets.html

Easy to work with is an understatement, I made the undertray in less than an hour. a dremel with a plastic cutting wheel will make you into an arteest in no time!

Easy to work with is an understatement, I made the undertray in less than an hour. a dremel with a plastic cutting wheel will make you into an arteest in no time!

#39

How do people secure the undertray to their car?

I'm half way through building mine and my plan was to epoxy bolts underneath the car fit the tray into place, use nylock nuts then cut the bolts down to length for minimal cost and ease of removal.

But then I realised that id possibly have to tie these nuts with wire to go on the track. so I decided to look into other ways.

If anyone has a good cheap solution (not cable ties...) please share.

I'm half way through building mine and my plan was to epoxy bolts underneath the car fit the tray into place, use nylock nuts then cut the bolts down to length for minimal cost and ease of removal.

But then I realised that id possibly have to tie these nuts with wire to go on the track. so I decided to look into other ways.

If anyone has a good cheap solution (not cable ties...) please share.

#40

I epoxied the bolt on the coroplast. The undertray is in the bumper, so just put the bolts down. The good thing here, is if it comes loose I am not leaving bolts on the track. A nut is a lot less likely to damage a tire than a bolt. And also, its less likely for the undertray to fall off since the bolt is still going through the bumper hole.

Not sure why you have to tie the nut with wire? Stock miata has plenty of bolts going straight into metal. You can use a locking flange nut if you are worried they will fall out.

Not sure why you have to tie the nut with wire? Stock miata has plenty of bolts going straight into metal. You can use a locking flange nut if you are worried they will fall out.