Pneumatic Sequential Shifter

#101

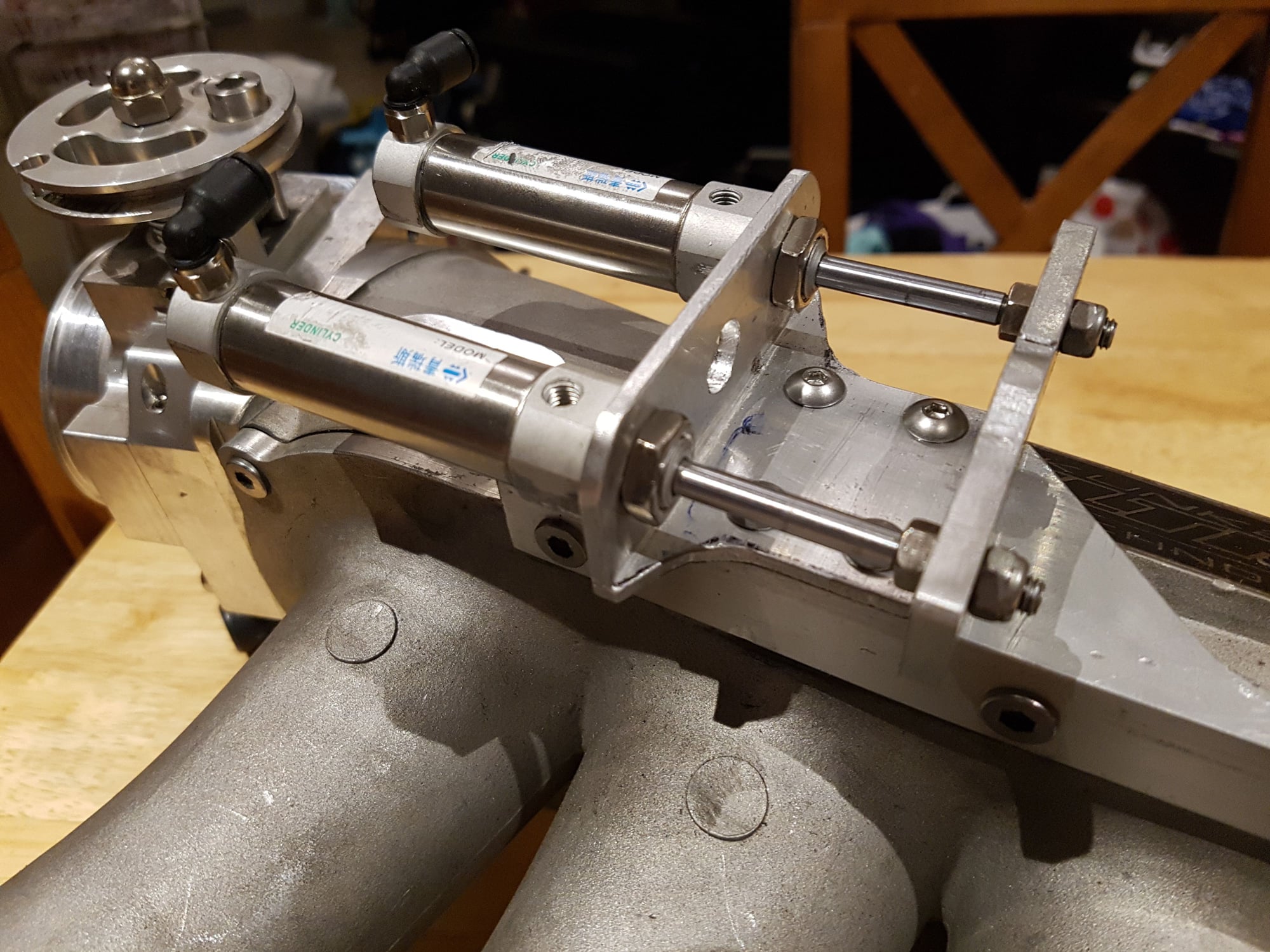

I've been thinking about throttle blips on downshifts and came up with a fairly simple idea. Since I already have compressed air onboard I may as well use the small air cylinders I ebayed when I started the project.

I'm using the air cylinders to push the throttle cable outer sleave backwards to open the throttle plate. They have enough strength to punch open the throttle nice and fast and will return to a closed position under the spring power from the throttle. This should work so that if the shift controller loses power or there is air pressure loss, I'm not going to be ontrack with a throttle that is stuck open. It also means I can have my foot on the throttle and the blip will just add some extra throttle without too much feedback through the pedal... I think.

The next step is to hook it up to the arduino shift controller and start decoding the CANbus so that I can test how responsive it is. I'll wire up a button on the dash that will trigger a throttle blip up to a set rpm, say 6000 and try to hold there by cycling the pneumatics on and off. This will test both the speed of the cylinders and the delay from reading the CANbus rpm. (It should be 20ms)

#102

I've been thinking about throttle blips on downshifts and came up with a fairly simple idea. Since I already have compressed air onboard I may as well use the small air cylinders I ebayed when I started the project.

I'm using the air cylinders to push the throttle cable outer sleave backwards to open the throttle plate. They have enough strength to punch open the throttle nice and fast and will return to a closed position under the spring power from the throttle. This should work so that if the shift controller loses power or there is air pressure loss, I'm not going to be ontrack with a throttle that is stuck open. It also means I can have my foot on the throttle and the blip will just add some extra throttle without too much feedback through the pedal... I think.

The next step is to hook it up to the arduino shift controller and start decoding the CANbus so that I can test how responsive it is. I'll wire up a button on the dash that will trigger a throttle blip up to a set rpm, say 6000 and try to hold there by cycling the pneumatics on and off. This will test both the speed of the cylinders and the delay from reading the CANbus rpm. (It should be 20ms)

I'm using the air cylinders to push the throttle cable outer sleave backwards to open the throttle plate. They have enough strength to punch open the throttle nice and fast and will return to a closed position under the spring power from the throttle. This should work so that if the shift controller loses power or there is air pressure loss, I'm not going to be ontrack with a throttle that is stuck open. It also means I can have my foot on the throttle and the blip will just add some extra throttle without too much feedback through the pedal... I think.

The next step is to hook it up to the arduino shift controller and start decoding the CANbus so that I can test how responsive it is. I'll wire up a button on the dash that will trigger a throttle blip up to a set rpm, say 6000 and try to hold there by cycling the pneumatics on and off. This will test both the speed of the cylinders and the delay from reading the CANbus rpm. (It should be 20ms)

#103

My other design was a rotary cam sitting over the throttle wheel that engages a pin that sits in a slotted hole in the throttle wheel. When the cam rotates it pulls the throttle open with it but allows the throttle to rotate independently. I could then drive the cam wheel via a thottle cable and remote pneumatic air cylinder, but this would have created the loose throttle cable problem you mention and also the potential for it to bind and jam. So I went back to my first idea which looks fairly inelegant but it's nice and simple and safe. The only issue I can see will be rubbing the throttle cable on things as it moves forwards and backwards.

Thread

Thread Starter

Forum

Replies

Last Post

jonboy

Suspension, Brakes, Drivetrain

14

03-29-2020 09:49 AM

Long_av8r

Suspension, Brakes, Drivetrain

17

01-12-2018 11:12 AM

dieselmiata

Suspension, Brakes, Drivetrain

5

08-16-2014 02:47 PM