Post your DIY aero pics

#806

Heya all, I have been working on a custom 3D printed wing for my car. I don't have to pay for the cost to print since I have a 3D printer so it's just material costs (around $70 for the plastic used). I also wanted to trial a custom wing profile that I found on the NACA site that is designed for a very low drag to downforce ratio. It should suit the tracks I run on without creating massive downforce or requiring a very high speed.

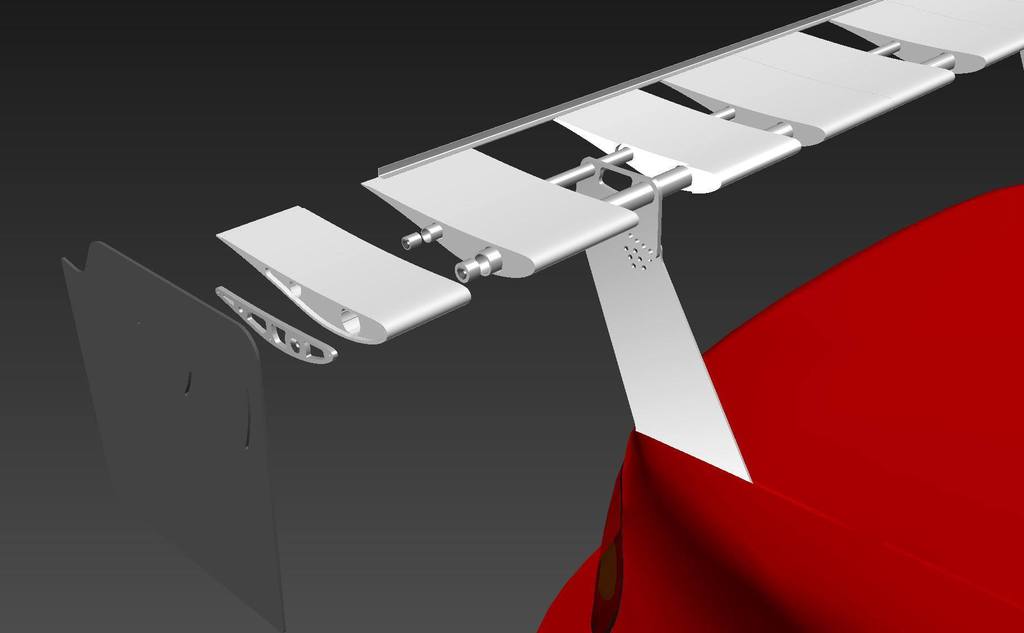

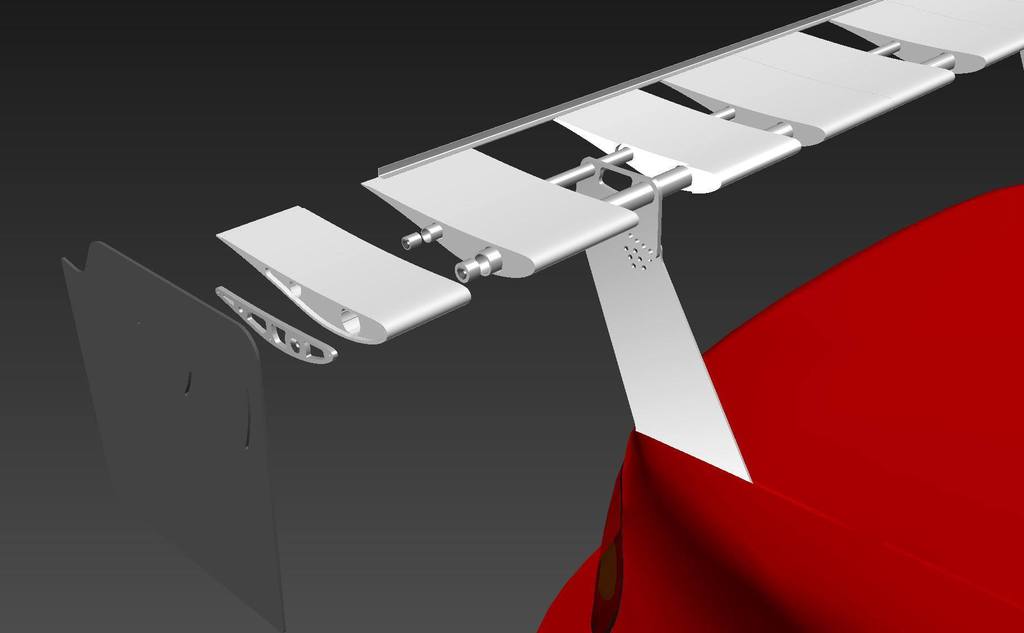

The initial 3D design breakdown:

Print time for each section is around 10 hours, so a total of approx 110 hours of printing. I managed to get nearly 2 completed each day so I printed all sections in a week.

Here is a shot of it in parts getting assembled. The 12 plastic sections slot onto two ally rails that then get clamped at the ends with the brackets that mount the end plates. The main support brackets also slot onto the rails and are keyed into the plastic.

I have yet to test the wing at speed but it all feels pretty solid on the car other than a bit of sideways wobble. I think I might have cut too much metal out of the main vertical supports and will probably make some solid versions instead which should help the overall wing rigidity. The actual 3D parts have an internal honeycomb structure making them very strong but light. All up there is around 1.8kgs of plastic but next time I think I could reduce the infill even more to reduce weight and printing materials required.

The photos below are the first install. I'll add a gurney / wickerbill which is a 10 x 10 mm ally angle and also angle the wing a bit more for my first test.

The endplates are a similar design to what Ryan (ThePass) has made for the COT wing. They are a little smaller and the angles are based on my wing profile so I hope I got the concept correct. Thanks Ryan for inspiring me to develop DIY aero!

The initial 3D design breakdown:

Print time for each section is around 10 hours, so a total of approx 110 hours of printing. I managed to get nearly 2 completed each day so I printed all sections in a week.

Here is a shot of it in parts getting assembled. The 12 plastic sections slot onto two ally rails that then get clamped at the ends with the brackets that mount the end plates. The main support brackets also slot onto the rails and are keyed into the plastic.

I have yet to test the wing at speed but it all feels pretty solid on the car other than a bit of sideways wobble. I think I might have cut too much metal out of the main vertical supports and will probably make some solid versions instead which should help the overall wing rigidity. The actual 3D parts have an internal honeycomb structure making them very strong but light. All up there is around 1.8kgs of plastic but next time I think I could reduce the infill even more to reduce weight and printing materials required.

The photos below are the first install. I'll add a gurney / wickerbill which is a 10 x 10 mm ally angle and also angle the wing a bit more for my first test.

The endplates are a similar design to what Ryan (ThePass) has made for the COT wing. They are a little smaller and the angles are based on my wing profile so I hope I got the concept correct. Thanks Ryan for inspiring me to develop DIY aero!

Last edited by Madjak; 04-14-2015 at 02:16 AM.

#808

I haven't weighted it yet but it's very light. I could easily hold it in position with one hand whilst drilling the mounting holes in the boot. I think the ally would be 2kgs so around 3.5kgs total. I'm not that calibrated to weight so I'd have to weight it properly to know.

For reference, how heavy are the APR GT250 wings?

For reference, how heavy are the APR GT250 wings?

#809

I haven't weighted it yet but it's very light. I could easily hold it in position with one hand whilst drilling the mounting holes in the boot. I think the ally would be 2kgs so around 3.5kgs total. I'm not that calibrated to weight so I'd have to weight it properly to know.

For reference, how heavy are the APR GT250 wings?

For reference, how heavy are the APR GT250 wings?

__________________

#810

#812

I have my CAD profiles somewhere and can load up the NACA profile vs the COT profile vs mine... I've just had a computer rebuild so I'll have to retrieve them off my old drive.

Does anyone have a photo of the APR GT250 wing without endplates? I think my wing should be pretty close to that design. I was looking for one when designing the profile and I don't think I ever found one.

#814

They are hosted on Box.com (similar to dropbox) with a public share. I need to get my act together and register for an online photo host. Maybe you have a firewall that blocking your access.

EDIT: Uploaded the images to a photo site and they should now work better... I hope

EDIT: Uploaded the images to a photo site and they should now work better... I hope

Last edited by Madjak; 04-14-2015 at 02:17 AM.

#816

__________________