Moderate Power on 1999

#41

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

Vlad,

Here are my settings. Getting better and better. I am also adding a little prime pulse to try to cause the first firing to be sooner. Takes so long to tune when you get one try per day (cold first start).

I think if had as much as you on the cold end, I'd flood for sure.

I included the ASE because I have been adding that and it helps. In other words, the crank pulses are not bad, but the follow-on is less than ideal.

Here are my settings. Getting better and better. I am also adding a little prime pulse to try to cause the first firing to be sooner. Takes so long to tune when you get one try per day (cold first start).

I think if had as much as you on the cold end, I'd flood for sure.

I included the ASE because I have been adding that and it helps. In other words, the crank pulses are not bad, but the follow-on is less than ideal.

#44

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

Here is the list of items for the next steps:

Find latency on old and new coils

Coolant Reroute

Roll Cage

Chassis Braces (full set from MSM)

CAN -Serial interface for LC-2 input

Indicator lights for

1. Logging

2. AFR Warning: I think this is +5V

3. 235* Coolant

Switch for Logging

Switch and input jack for music

Key Switch for EBC

Switch for LC-2 power?

New boost Gauge

Label gauges

Foamectomy

Install Hella Horns

*edit* Install Tow Hooks

EBC

COP and harness simplification

Heat Shield?

Rebuild Exhaust Manifold

Return Style Fuel set-up and adj VE Table? OR 625cc EV-14 Inj

O2 Sensor Bung for Dyno

*edit* Properly mount ECU

Catch can? Unlikely

Dyno Tune

Question 1:

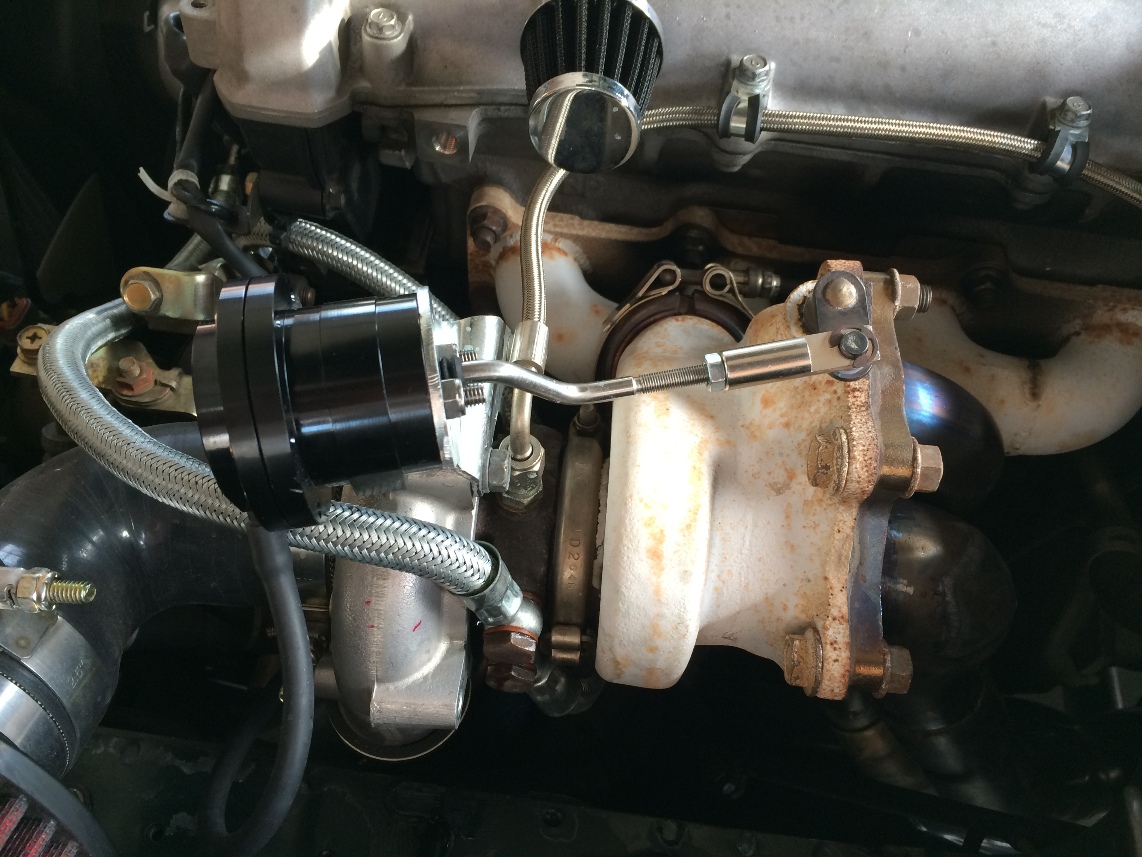

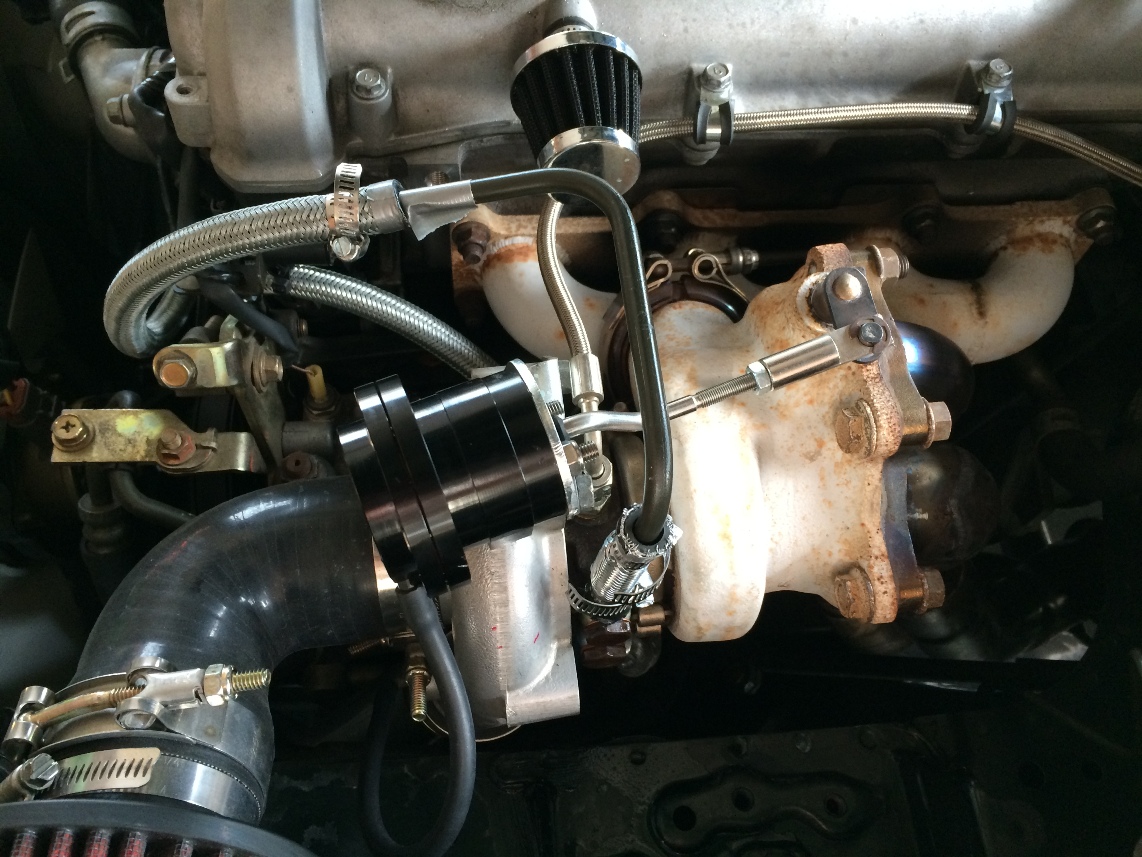

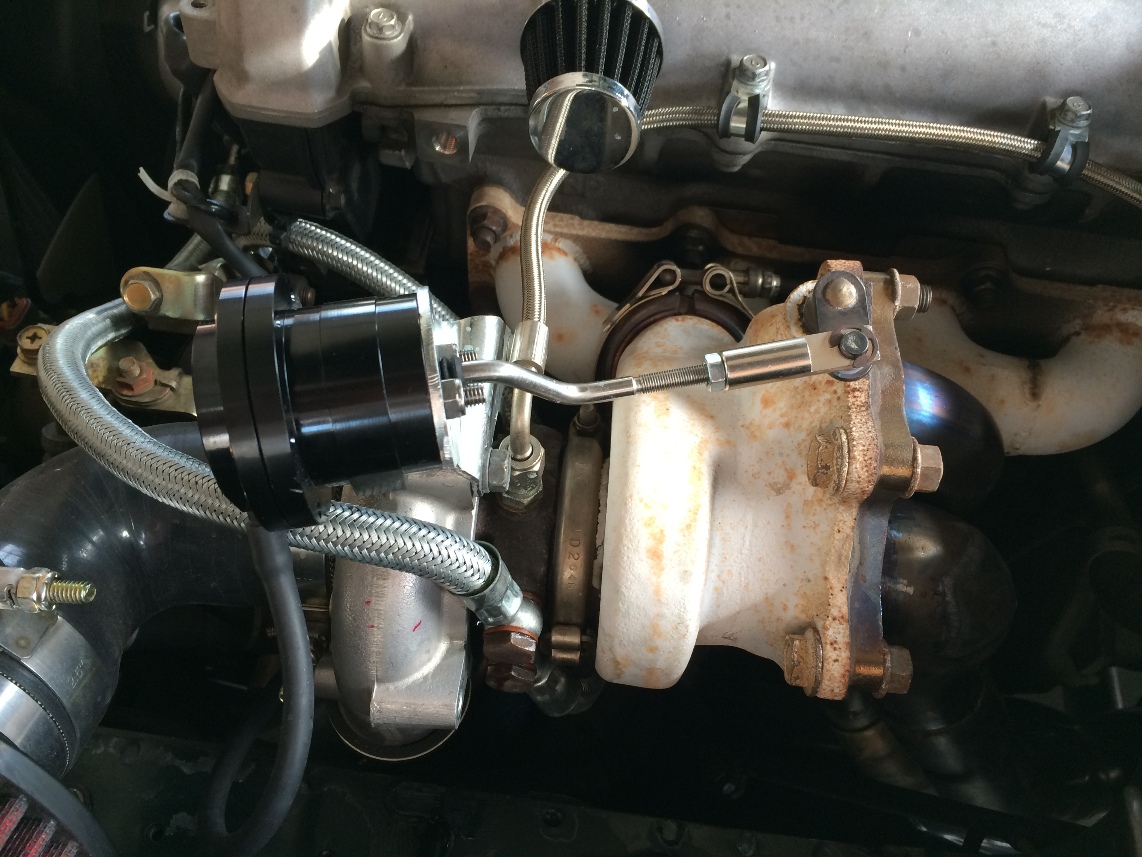

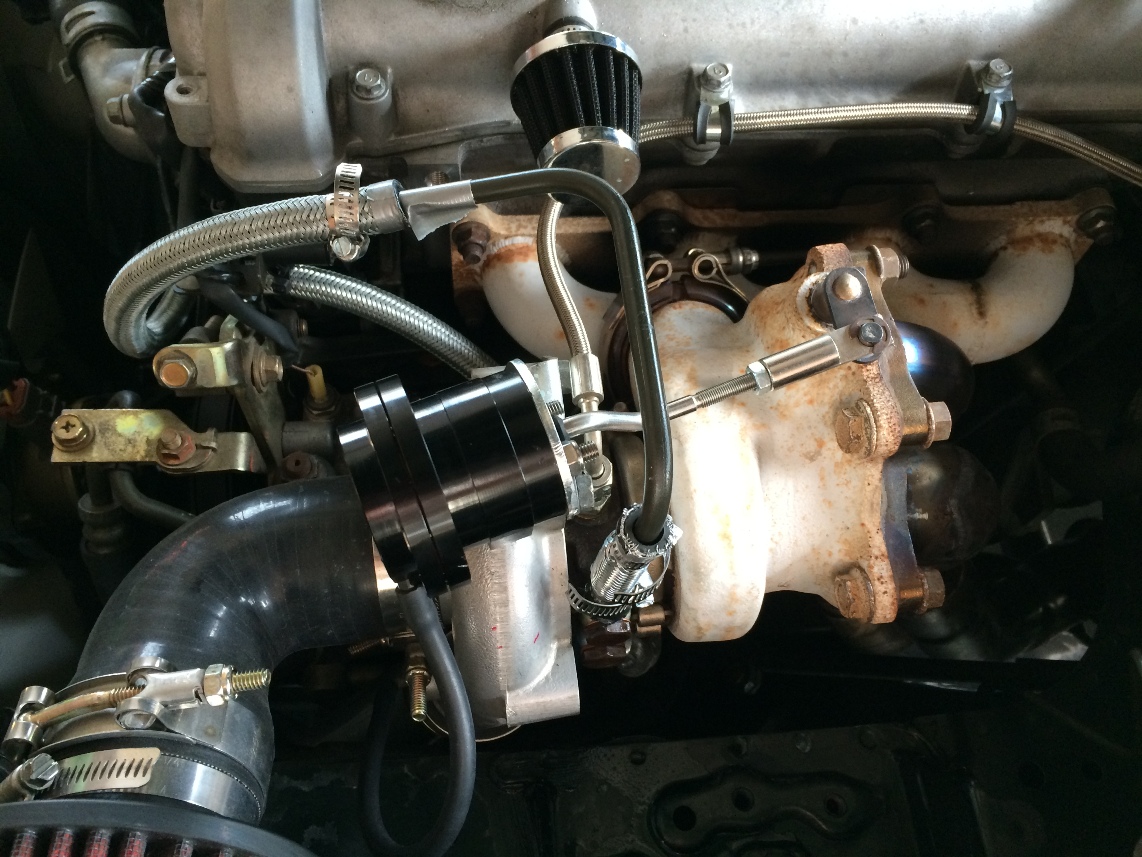

Referring to the following picture:

My question is, with the clearances I have (minimum 3" around hot stuff), and that I may (I hope) track the car, should I:

1) Ceramic Coat the downpipe

2) Add heat shield

In other words, should I bother with the heat shield given the clearances I have, or should I view it as cheap insurance. So far, on the street, the adhesive on the 3M +33 tape has not even softened (holding the lines together). What do you say Sixshooter?

Question 2:

I did get rise in CLT in summer with A/C on and boost. I never saw IAT go more than 11*F over ambient, though street only. Do you think the coolant re-route will fix this, or should I look into bypassing some air around the FMIC and more directly to the radiator?

Question 3:

I was going to go to return type fueling as I have the yellow tops. I wanted to increase the knowledge base with a before and after info on injector / fuel heat soak with both systems. However, it looks like the EV-14 injectors from the Mustang have pretty much obsoleted the Yellow Tops as the cheap, go-to injectors. Should I just skip the fuel modification and get the EV-14's?

DNM

Find latency on old and new coils

Coolant Reroute

Roll Cage

Chassis Braces (full set from MSM)

CAN -Serial interface for LC-2 input

Indicator lights for

1. Logging

2. AFR Warning: I think this is +5V

3. 235* Coolant

Switch for Logging

Switch and input jack for music

Key Switch for EBC

Switch for LC-2 power?

New boost Gauge

Label gauges

Foamectomy

Install Hella Horns

*edit* Install Tow Hooks

EBC

COP and harness simplification

Heat Shield?

Rebuild Exhaust Manifold

Return Style Fuel set-up and adj VE Table? OR 625cc EV-14 Inj

O2 Sensor Bung for Dyno

*edit* Properly mount ECU

Catch can? Unlikely

Dyno Tune

Question 1:

Referring to the following picture:

My question is, with the clearances I have (minimum 3" around hot stuff), and that I may (I hope) track the car, should I:

1) Ceramic Coat the downpipe

2) Add heat shield

In other words, should I bother with the heat shield given the clearances I have, or should I view it as cheap insurance. So far, on the street, the adhesive on the 3M +33 tape has not even softened (holding the lines together). What do you say Sixshooter?

Question 2:

I did get rise in CLT in summer with A/C on and boost. I never saw IAT go more than 11*F over ambient, though street only. Do you think the coolant re-route will fix this, or should I look into bypassing some air around the FMIC and more directly to the radiator?

Question 3:

I was going to go to return type fueling as I have the yellow tops. I wanted to increase the knowledge base with a before and after info on injector / fuel heat soak with both systems. However, it looks like the EV-14 injectors from the Mustang have pretty much obsoleted the Yellow Tops as the cheap, go-to injectors. Should I just skip the fuel modification and get the EV-14's?

DNM

Last edited by DNMakinson; 12-24-2014 at 07:54 PM. Reason: The List Grows

#48

I had high CLTs right after I put my turbo in. I put the under tray back on, installed a 180* tstat, sealed off the top of the rad to the support, and put on the aluminum plate from BEGi that goes around the hood latch area. I was getting even hotter than you, now I stay steady at 190*. Occasionally I'll see a higher temp right before the thermostat first opens, but drops within seconds when it does.

#51

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

No pics, but a brief update. Finally go around to changing out the bad WGA, though letting boost run up to 11 psi at redline has been fun. Now I'm at a steady 9 with the spring in the Kinugawa actuator.

Unfortunately, I damaged my coolant line (likely at the crimp end), so I'm down until I replace the line. I will likely go with some other arrangement as this had too tight a bend, hence the damage.

Pretty sure I through away the banjo tubes that came on the turbo, so using that is not an option.

Unfortunately, I damaged my coolant line (likely at the crimp end), so I'm down until I replace the line. I will likely go with some other arrangement as this had too tight a bend, hence the damage.

Pretty sure I through away the banjo tubes that came on the turbo, so using that is not an option.

#52

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

Here are a couple of shots. First is the addition of the Kinugawa WGA. It was supposed to be shipped with a 0.5 BAR actuator add-on to the 1.0 in the housing. Instead they shipped a separate 1.5 BAR. They took care of the problem right away.

Second shot is where I got a Banjo to barb from Flyin Miata and some brake line to add in a hard section. Worked well except I have to replace the cheap clamps with something better.

This has gotten a new item to my list: Install hard lines for coolant and oil feed. I will need to borrow or purchase a 37* flaring tool, and then weld in -6AN fittings to the mixing manifold and the return neck (well, what will be left of the return neck after we cut it down). I will have to decide how I want to run the coolants and then I'll know to get Banjo, straight adaptors, or one of each; with -6AN males for the CHRA.

Second shot is where I got a Banjo to barb from Flyin Miata and some brake line to add in a hard section. Worked well except I have to replace the cheap clamps with something better.

This has gotten a new item to my list: Install hard lines for coolant and oil feed. I will need to borrow or purchase a 37* flaring tool, and then weld in -6AN fittings to the mixing manifold and the return neck (well, what will be left of the return neck after we cut it down). I will have to decide how I want to run the coolants and then I'll know to get Banjo, straight adaptors, or one of each; with -6AN males for the CHRA.

#53

I always run through a thought experiment when thinking of modifying my setup. I want to use the heater core outlet as the water source, maybe from the bypass line itself, then have the turbo return the coolant through a -AN bung welded to the mixing manifold.

I think full-race told me -8AN or -10 AN is the largest they've put on EFR's then space is quite limited.

If I recall the heater core hoses are -12AN equiv.

Sorry, just thinking/typing out loud when I hear about cleaning up plumbing

I think full-race told me -8AN or -10 AN is the largest they've put on EFR's then space is quite limited.

If I recall the heater core hoses are -12AN equiv.

Sorry, just thinking/typing out loud when I hear about cleaning up plumbing

#54

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

No worries, P, help yourself.

So what I'm thinking on front outlet is to cut it off and weld a plate that is even with the plastic cover. To that, weld the -6AN bung for the feed. Alternatively, leave the outlet a little longer and mount the bung to the side for a straight in approach of the hard line.

So what I'm thinking on front outlet is to cut it off and weld a plate that is even with the plastic cover. To that, weld the -6AN bung for the feed. Alternatively, leave the outlet a little longer and mount the bung to the side for a straight in approach of the hard line.

#55

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

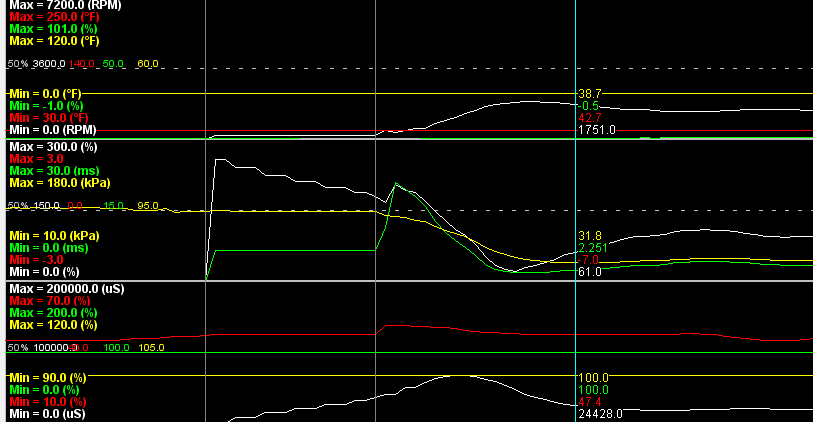

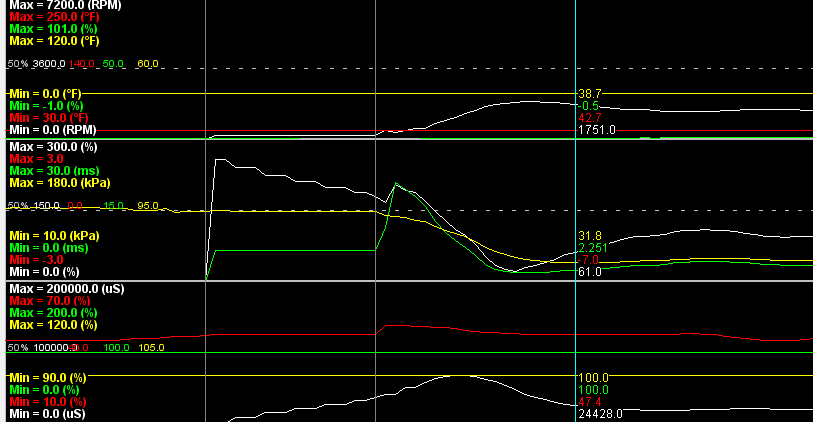

Here is my first start this morning. Time between faint timelines is 1.25 seconds, so about 6 events. This is getting real close. Using batch inj during start, EAE is tamed, I'm pretty happy with cold start progress:

The hesitation at the transition was nearly imperceptible (in the RPM trace).

The hesitation at the transition was nearly imperceptible (in the RPM trace).

#59

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

I hated what batch did to my hot starts so much that I went back to sequential. At 70* this evening, it was 4 max, and very smooth. In the AM we will see how it does at 30*. I'll just edit this post then.

*EDIT* next AM at 35*, cranked and stalled. Then cranked and ran with struggling. Unfortunately, we may br get any more cold weather this year.

I will post my settings next week, when I have a variety of starts on logs.

*EDIT* next AM at 35*, cranked and stalled. Then cranked and ran with struggling. Unfortunately, we may br get any more cold weather this year.

I will post my settings next week, when I have a variety of starts on logs.

Last edited by DNMakinson; 03-30-2015 at 09:23 PM.