RWyatt's "It's takin forever" Build Thread

#301

Thanks for the info curly.

I was afraid that the 5 bolt flange would be non-standard and you confirmed that (damn).

They offer the same turbo, but with a v-band adapter - just a freakin plate with the bolt pattern for the flange on one side and a v-band on the other side. If i get that one i have a 50/50 chance that my FM downpipe flange will work with the adapter removed. If not, i could put the adapter back on and cobble together a v-band solution to the FM exhaust.

I was afraid that the 5 bolt flange would be non-standard and you confirmed that (damn).

They offer the same turbo, but with a v-band adapter - just a freakin plate with the bolt pattern for the flange on one side and a v-band on the other side. If i get that one i have a 50/50 chance that my FM downpipe flange will work with the adapter removed. If not, i could put the adapter back on and cobble together a v-band solution to the FM exhaust.

#303

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,184

Total Cats: 1,135

Has anyone made a VTCS solenoid and actuator work with a VICS? It seems silly. It's not a variable thing, it's just on/off. The VTCS bracket would just need to be tweaked, I think the actual solenoid is the same, or a new bracket made. And the VTCS actuator would have to be shortened. Worth a shot, cause yeah, often you have to buy the entire VICS manifold.

#304

I never thought about the possiblity of using a VTCS solenoid/actuator. I was this close to trying to make an actuator from an electronic push-pull solenoid connected directly to the VICS butterflys. Now, I don't have to deal with that hassle.

Anyway, with so many folks gutting their VICS IM's, it's a mystery why no one just has the actuator/solenoid just laying around collecting dust.

PS - good news! I scored a new job 2 weeks ago, so my cash-flow deficit will soon be resolved. That means I can START BUYING STUFF again!! First on the list is the new turbo, and the AN lines for the oil/water feed for the turbo, and the heater core. My new target "Miata running date" is end of March.

Anyway, with so many folks gutting their VICS IM's, it's a mystery why no one just has the actuator/solenoid just laying around collecting dust.

PS - good news! I scored a new job 2 weeks ago, so my cash-flow deficit will soon be resolved. That means I can START BUYING STUFF again!! First on the list is the new turbo, and the AN lines for the oil/water feed for the turbo, and the heater core. My new target "Miata running date" is end of March.

#307

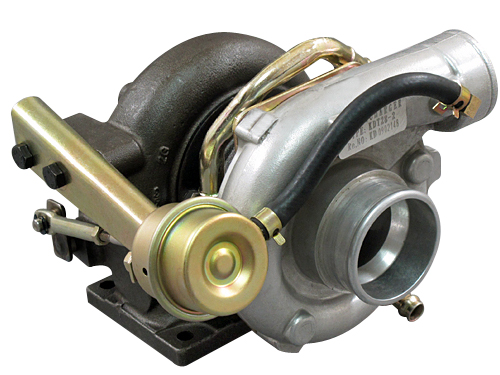

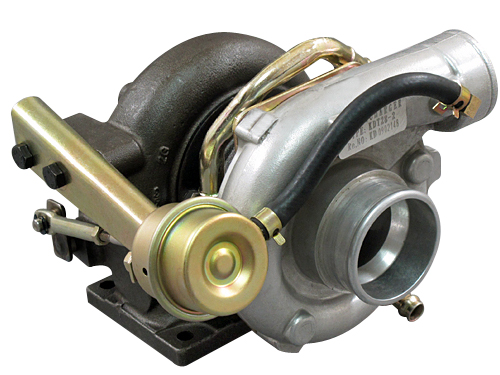

I just pulled the trigger on this;

It's a T28-clone from CX Racing: oil/water cooled, 0.86 A/R turbine, journal bearing turbo with a funky mounting for the WG (bracket is on the turbine housing allowing "infinite" choices for clocking the compressor housing).

I'm rolling the dice on whether the 5-bolt pattern on the exhaust-side will mate with the cast FM downpipe elbow that I have from the 2560. If not, I'm hoping that something like this will help;

I won't be hurt (I hope) by having to use a V-band downpipe to get to my exhaust.

It's a T28-clone from CX Racing: oil/water cooled, 0.86 A/R turbine, journal bearing turbo with a funky mounting for the WG (bracket is on the turbine housing allowing "infinite" choices for clocking the compressor housing).

I'm rolling the dice on whether the 5-bolt pattern on the exhaust-side will mate with the cast FM downpipe elbow that I have from the 2560. If not, I'm hoping that something like this will help;

I won't be hurt (I hope) by having to use a V-band downpipe to get to my exhaust.

#308

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,184

Total Cats: 1,135

Your the 4th person to want to try that turbo. I think Blaen99 and I were the first two. The size does make it a great option for an ebay turbo. However mine was sent directly to Abe, and neither of us could find a downpipe flange that worked, except the included one, which was crap.

#309

Your the 4th person to want to try that turbo. I think Blaen99 and I were the first two. The size does make it a great option for an ebay turbo. However mine was sent directly to Abe, and neither of us could find a downpipe flange that worked, except the included one, which was crap.

#311

Test-fitted the new churbo. AN lines for the heater core made. Need a 30-degree fitting for the water return from the turbo to get that completed;

Also ordered an oil return kit from CX Racing for their turbo and, wouldn't you know it, they botched it. The flange is 1/4" too small. I'm not even going to bother trying to get that fixed through them, I can find a flange on Fleabay for less hassle.

Anyway, next steps...the WG flange should come in next week, then comes the adventure of making a functional downpipe. THAT should be fun!

Also ordered an oil return kit from CX Racing for their turbo and, wouldn't you know it, they botched it. The flange is 1/4" too small. I'm not even going to bother trying to get that fixed through them, I can find a flange on Fleabay for less hassle.

Anyway, next steps...the WG flange should come in next week, then comes the adventure of making a functional downpipe. THAT should be fun!

#313

Been assembling parts lately. The WG flange came in late last week and I just got a weld-on v-band adapter for it yesterday. The flange and adapter are going to the welder on Monday so I should be able to start making progress on the exhaust.

I've got a 90* v-band downpipe coming in midweek from Himni Racing, so that'll get me from the turbo, to the exhaust pipe. My plan is to hack up my Flyin Miata exhaust at the Himni downpipe and weld on a v-band flange to complete the exhaust. We'll see how that works out.

I did a test-fit of the engine in the chassis (again) and made some "clearance cuts" in the deck so the downpipe won't rub (I'll check again after the flange comes back from the welder).

As far as the oil return is concerned...I tried to deal with CX Racing on their crap, but the customer service was so bad that it wasn't worth the effort to continue. I got a flange that fits off ebay in 2 days. I'm waiting on fittings so that I can make the oil drain lines. With that, the water and oil lines on the engine should be complete.

I'm going to try something a little bit different...one time before when I pulled the engine I had a water leak that was hell to find (one of those little hoses that go to the oil warmer had a pinhole leak). Anyway, the last time the engine was out (for the failed rebuild) I wanted to use an Autozone pressure tester to check for leaks but none one the adapters fit the water neck on my Fleabay aluminum radiator.

So, I got the bright idea of; a) eliminating those pesky oil warmer hoses, and b) incorporating a valved, quick-release somewhere in the water system so that I can hook up a pressure tester. What I've done is to cut off the outlet at the back of the head that supplied the oil warmer line, tap it for 3/8 NPT (shown);

...and put in a 90* Jiffy-Tite valved, male quick release (not shown) fitting back there. The fitting just clears the water neck for the reroute. The idea is that I can use a female fitting with a barbed hose fitting and a length of hose into a tee with a dial gauge and a Schrader valve. Then I can pressurize the water system (in the car, full of water) with any old air supply and check for leaks at my leisure.

We'll see how well that works...

PS - I have a "hard stop" for this build now. The car has to be able to get to an Emissions Test Station before the end of March so I can get it registered. So it's going to be Fast 'N Furious until then. It won't be pretty, but it will be running.

I've got a 90* v-band downpipe coming in midweek from Himni Racing, so that'll get me from the turbo, to the exhaust pipe. My plan is to hack up my Flyin Miata exhaust at the Himni downpipe and weld on a v-band flange to complete the exhaust. We'll see how that works out.

I did a test-fit of the engine in the chassis (again) and made some "clearance cuts" in the deck so the downpipe won't rub (I'll check again after the flange comes back from the welder).

As far as the oil return is concerned...I tried to deal with CX Racing on their crap, but the customer service was so bad that it wasn't worth the effort to continue. I got a flange that fits off ebay in 2 days. I'm waiting on fittings so that I can make the oil drain lines. With that, the water and oil lines on the engine should be complete.

I'm going to try something a little bit different...one time before when I pulled the engine I had a water leak that was hell to find (one of those little hoses that go to the oil warmer had a pinhole leak). Anyway, the last time the engine was out (for the failed rebuild) I wanted to use an Autozone pressure tester to check for leaks but none one the adapters fit the water neck on my Fleabay aluminum radiator.

So, I got the bright idea of; a) eliminating those pesky oil warmer hoses, and b) incorporating a valved, quick-release somewhere in the water system so that I can hook up a pressure tester. What I've done is to cut off the outlet at the back of the head that supplied the oil warmer line, tap it for 3/8 NPT (shown);

...and put in a 90* Jiffy-Tite valved, male quick release (not shown) fitting back there. The fitting just clears the water neck for the reroute. The idea is that I can use a female fitting with a barbed hose fitting and a length of hose into a tee with a dial gauge and a Schrader valve. Then I can pressurize the water system (in the car, full of water) with any old air supply and check for leaks at my leisure.

We'll see how well that works...

PS - I have a "hard stop" for this build now. The car has to be able to get to an Emissions Test Station before the end of March so I can get it registered. So it's going to be Fast 'N Furious until then. It won't be pretty, but it will be running.

#314

Good stuff arriving every day.

- Turbo flange w/ v-band flange welded on and v-band downpipe;

- Brand new, correct NSS switch (after getting the wrong part from Rock Auto).

- Fittings and hose for the turbo oil drain.

- SS brake lines all around (yeah, I know...not necessary).

- New O2 sensor.

Have to measure up the FM exhaust for where to cut and weld on (or take it to the welding shop and have it welded on - I have zero skill in that department) the v-band flange. That'll complete the exhaust.

Time to get busy...

- Turbo flange w/ v-band flange welded on and v-band downpipe;

- Brand new, correct NSS switch (after getting the wrong part from Rock Auto).

- Fittings and hose for the turbo oil drain.

- SS brake lines all around (yeah, I know...not necessary).

- New O2 sensor.

Have to measure up the FM exhaust for where to cut and weld on (or take it to the welding shop and have it welded on - I have zero skill in that department) the v-band flange. That'll complete the exhaust.

Time to get busy...

#315

So, today was a busy day.

Fit the downpipe onto the turbo flange and test-fit the engine (again) to check for clearance;

Still have to make another clearance cut;

This will have to be welded up, but I don't have the equipment, or the skills to do that. I'll have to figure out something.

Anyway, cut the flange off the FM downpipe, I'll have a v-band welded on the pipe.

Checked it outside the car to see what it looks like;

Blurry, but you get the idea. Looks like this'll work. I'll get a v-band welded onto that and we'll see how this fits next week.

Then, up on the hoist to tighten all of the suspension bolts. This is the first time that the car has actually moved in 6 months!;

Also, removed the stock sway bar mounts (ordered the beefier mounts from Fab9) and took off the grungy old brake lines;

...to make way for the new lines from 949 Racing.

My goal is to test-fire the engine by Monday - we'll see how well that goes.

Fit the downpipe onto the turbo flange and test-fit the engine (again) to check for clearance;

Still have to make another clearance cut;

This will have to be welded up, but I don't have the equipment, or the skills to do that. I'll have to figure out something.

Anyway, cut the flange off the FM downpipe, I'll have a v-band welded on the pipe.

Checked it outside the car to see what it looks like;

Blurry, but you get the idea. Looks like this'll work. I'll get a v-band welded onto that and we'll see how this fits next week.

Then, up on the hoist to tighten all of the suspension bolts. This is the first time that the car has actually moved in 6 months!;

Also, removed the stock sway bar mounts (ordered the beefier mounts from Fab9) and took off the grungy old brake lines;

...to make way for the new lines from 949 Racing.

My goal is to test-fire the engine by Monday - we'll see how well that goes.

#316

Got the v-band on the downpipe welded earlier this week. Today was the test fit. As you can see (below), the downpipe sits about 10* below the horizontal;

A quick cut with the angle grinder and...

Now, I just have to get this welded together and my exhaust system SHOULD be in business.

In other news, I just bought a (cheapo) flux-core welder from HF. I won't be doing any super-duty welding with it. It's mostly just to learn with. I think my first real welding trial will be to plug up the hole I made cutting the deck to clear the new downpipe.

A quick cut with the angle grinder and...

Now, I just have to get this welded together and my exhaust system SHOULD be in business.

In other news, I just bought a (cheapo) flux-core welder from HF. I won't be doing any super-duty welding with it. It's mostly just to learn with. I think my first real welding trial will be to plug up the hole I made cutting the deck to clear the new downpipe.

#317

It's gettin' real now! Put all of the accessories onto the engine and mounted the trans;

Then after a mighty struggle (freakin trans got hung up on the heat shield during install and I couldn't free it up until I put the car on the lift - took almost 2 hours, lots of cussin' and just about my last bit of energy to get it done) dropped the engine/trans into place.

I had just about enough energy left to install the reinforced sway bar mounts before calling it a night.

Today;

- Connect up and test the electrics

- Connect the fuel lines

- Install the radiator and water lines

- Install the I/C

...if all goes well, I'll try to fire it up for the first time tonight.

Then after a mighty struggle (freakin trans got hung up on the heat shield during install and I couldn't free it up until I put the car on the lift - took almost 2 hours, lots of cussin' and just about my last bit of energy to get it done) dropped the engine/trans into place.

I had just about enough energy left to install the reinforced sway bar mounts before calling it a night.

Today;

- Connect up and test the electrics

- Connect the fuel lines

- Install the radiator and water lines

- Install the I/C

...if all goes well, I'll try to fire it up for the first time tonight.

#318

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Good luck, have a fire extinguisher nearby.

Swap out the HF flux core wire with that welder. Go buy some Lincoln wire (or other good name brand wire), it will weld a lot better.

Swap out the HF flux core wire with that welder. Go buy some Lincoln wire (or other good name brand wire), it will weld a lot better.

#319

Didn't get much of anything done that I wanted to. Got hung up screwing around with some wiring. But I did manage to clean most of the grunge out of the gas tank - that was fun.

So the engine is sitting all nice 'n pretty in it's place. Most of the piping is still out of place, but it's not so big of a job any more.

Here's a gratuitous shot of the new sway bar mount and de-rusted radiator mount;

Tomorrow, after work, it's back to the grindstone...

So the engine is sitting all nice 'n pretty in it's place. Most of the piping is still out of place, but it's not so big of a job any more.

Here's a gratuitous shot of the new sway bar mount and de-rusted radiator mount;

Tomorrow, after work, it's back to the grindstone...

#320

Test-fitted the IC last night;

Day-um son! almost looks like a real car.

Also installed the "custom" V-banded FM downpipe and it fit like a glove! I've got to fab up a support bracket, but I think it'll get the job done.

Tonight's work'll be to get the top end of the engine done (injectors, fuel rail, upper IM, etc), get the radiator in and test the electrical system - make sure I don't short something out.

I also discovered where an errant pigtail came from...somehow in the struggle to get the engine/trans into the chassis, I managed to scrape off the wires from the speed sensor. I must have dorked it up pretty good because the casing from the sensor has a slight crack in it. Just something else to have to replace! It's not a show-stopper right now, more of an annoyance.

Day-um son! almost looks like a real car.

Also installed the "custom" V-banded FM downpipe and it fit like a glove! I've got to fab up a support bracket, but I think it'll get the job done.

Tonight's work'll be to get the top end of the engine done (injectors, fuel rail, upper IM, etc), get the radiator in and test the electrical system - make sure I don't short something out.

I also discovered where an errant pigtail came from...somehow in the struggle to get the engine/trans into the chassis, I managed to scrape off the wires from the speed sensor. I must have dorked it up pretty good because the casing from the sensor has a slight crack in it. Just something else to have to replace! It's not a show-stopper right now, more of an annoyance.