Artech Downpipe crack. Will a repair hold up?

#41

No problem, I know that sucks having to keep pulling it! When I was turbo I always ran mild steel 16 gauge as it was cheap and reliable and no brace required because wall thickness was like .065". But alas my exhaust system probably weighed at least twice what yours does and certainly was not as pretty!

#42

Elite Member

Thread Starter

iTrader: (5)

Join Date: Aug 2011

Location: South Jersey

Posts: 1,512

Total Cats: 30

No problem, I know that sucks having to keep pulling it! When I was turbo I always ran mild steel 16 gauge as it was cheap and reliable and no brace required because wall thickness was like .065". But alas my exhaust system probably weighed at least twice what yours does and certainly was not as pretty!

#43

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

My recommendation is to add a brace to take the load off the downpipe. If that was 16 gauge mild steel tube it wouldn't be cracking since it could handle that load no problem. But it would be heavy and not as pretty. If you want thin wall stainless, you can't put huge loads on it and expect it to last.

#54

Really, that's weird. Every welding specification I've ever read requires that the material fail in the base metal and not in the weld.

When I worked at Honda we did lots of testing for this exact thing, the tensile specimen was always required to fail in the base metal. If the specimen failed in the weld or in the HAZ then the test was considered a failure.

I don't doubt Abe's skills at all. But in my experience, a failure straight through the weld bead is a big no-no.

When I worked at Honda we did lots of testing for this exact thing, the tensile specimen was always required to fail in the base metal. If the specimen failed in the weld or in the HAZ then the test was considered a failure.

I don't doubt Abe's skills at all. But in my experience, a failure straight through the weld bead is a big no-no.

#56

Really, that's weird. Every welding specification I've ever read requires that the material fail in the base metal and not in the weld.

When I worked at Honda we did lots of testing for this exact thing, the tensile specimen was always required to fail in the base metal. If the specimen failed in the weld or in the HAZ then the test was considered a failure.

I don't doubt Abe's skills at all. But in my experience, a failure straight through the weld bead is a big no-no.

When I worked at Honda we did lots of testing for this exact thing, the tensile specimen was always required to fail in the base metal. If the specimen failed in the weld or in the HAZ then the test was considered a failure.

I don't doubt Abe's skills at all. But in my experience, a failure straight through the weld bead is a big no-no.

#57

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Then why did it also fail the second weld with a nice fat filler mound there.

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

#58

Elite Member

Thread Starter

iTrader: (5)

Join Date: Aug 2011

Location: South Jersey

Posts: 1,512

Total Cats: 30

Then why did it also fail the second weld with a nice fat filler mound there.

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

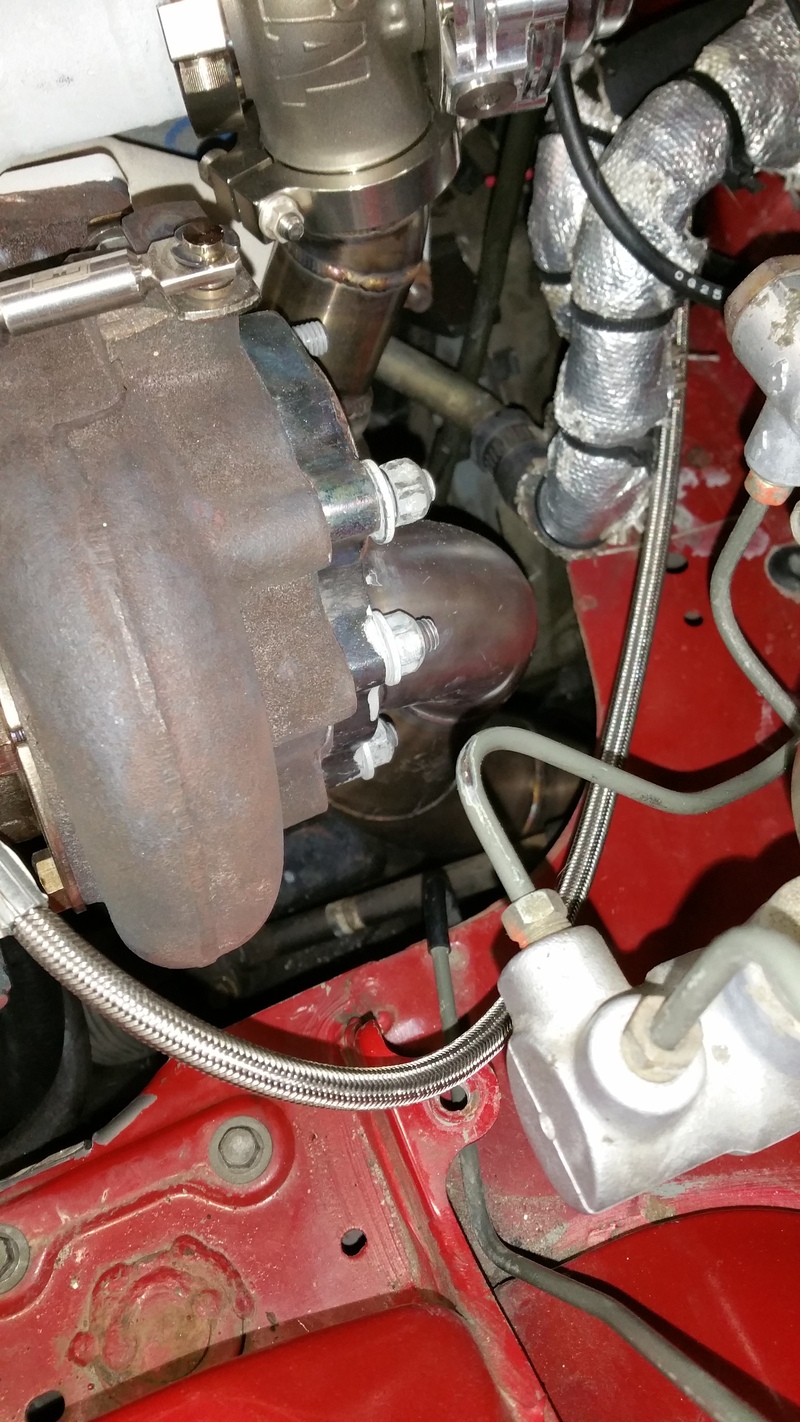

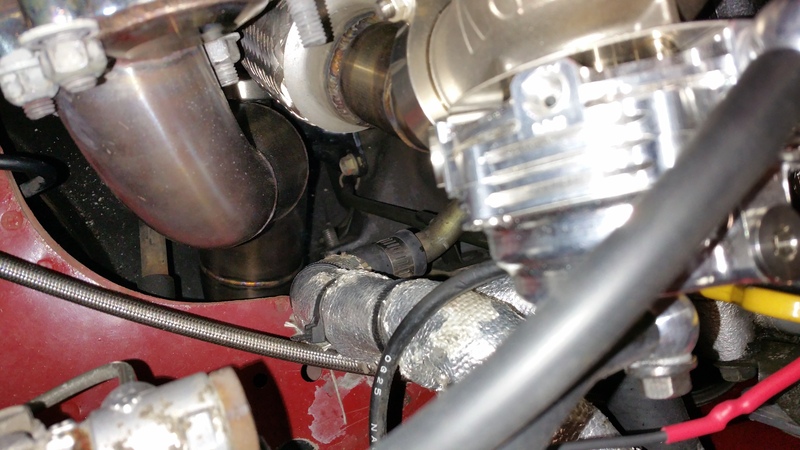

The only thing I noticed when removing the downpipe yesterday was that the exhaust seemed to be pulling down on the back side of the downpipe. I'm assuming that was putting stress on the weld that cracked and thats why it split. I fully plan to add a brace and see what happens this time.

In other news, i'm now a pro at pulling my downpipe. Literally had it out in like 20 mins yesterday compared to 2 hours the first time (Granted, the anti-seize was still fresh on the downpipe hardware)

#60

Then why did it also fail the second weld with a nice fat filler mound there.

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

This is scary. I've welded a bunch of downpipes with no filler, no reinforcements, no flexes (basically any 'street car' setup i've done), and I'm a far inferior welder to abe, while using inferior material (vibrant bends instead of beautiful steam pipe bends).

SO something's off with the car, not the pipe. What that is, I dunno.

How buzzy is your car? Running a chinese flywheel/clutch?

But I dunno. Seems to me something is putting really high stress in that spot. Hence why I recommended a brace.

Random though, but if his EGT's were really high for some reason, would that contribute to this failure?