Godless Commie's ungodly turbo project - R2S Progressive Twin Turbo

#82

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,043

Total Cats: 6,607

But, having re-read this thread a second time, I realize that I was confused earlier. When I saw the post about an ignition module, I assumed that Hakan was trying to use this inline with the ignition coils.

That would be bad.

I understand now that he'd previously been given incorrect advice to attempt to use an ignition module as a general-purpose relay driver,

#83

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

Quick update:

I increased my speed by a little and raised the boost by a lot today.

Learned a few cool things.

The fact that I have two wastegates is an incredible advantage.

Keeping the IWG open below 100 kPa helps a great deal with fuel economy, but "when" below that 100 kPa level I close it causes major changes in how the car drives.

In essence, I am using the IWG as a SC bypass, where the turbos just freewheel if I have a certain level of vacuum in the IM.

Playing with the said threshold, I set it to close at 50 kPa. The car becomes incredibly responsive, and I see 15 psi boost pretty much right away.

15 psi at 2500 rpm in 3rd gear just launches the car!

Raising the IWG opening threshold allows me to drive the car in a more sane manner at slow speeds.

It just allows more throttle input in off freeway driving, just like a SC setup.

I'll keep playing with that threshold - I am doing it at large increments now, I will be fine tuning it once I find the best "zone" for my liking.

There was another major revelation regarding the "handshake" between the two turbos...

My approach to the transition phase was wrong.

I was under the impression compression bypass (LP bypass which stops the compounding stage and clears the way for the larger LP turbo to provide boost on its own) had to happen slightly AFTER the HP - LP transition.

I get a dip in boost if I do that. Pressure gauge drops to 100 kPa for about 1/2 second, and then boost kicks in (again), but climbs slowly this time, not unlike a late spooling single turbo.

Opening LP bypass a little BEFORE the HP - LP transition eliminates that dip, and it becomes more seamless.

There is also a problem with the LP bypass vacuum actuator - it tends to stick half open every now and then for some reason, which creates a hindrance for the larger turbo.

I got beautiful results once I opened it fully.

Need to take care of that.

I still have very few miles and SAE 30 break in oil in the engine, so my high RPM and high boost experimentation is somewhat limited at this time.

One thing is certain; I still need to pull fuel at low RPM-high load areas...

I'll keep playing with the system as I accrue miles and switch over to synthetic oil, but damn.. It's a lot of fun already!

I increased my speed by a little and raised the boost by a lot today.

Learned a few cool things.

The fact that I have two wastegates is an incredible advantage.

Keeping the IWG open below 100 kPa helps a great deal with fuel economy, but "when" below that 100 kPa level I close it causes major changes in how the car drives.

In essence, I am using the IWG as a SC bypass, where the turbos just freewheel if I have a certain level of vacuum in the IM.

Playing with the said threshold, I set it to close at 50 kPa. The car becomes incredibly responsive, and I see 15 psi boost pretty much right away.

15 psi at 2500 rpm in 3rd gear just launches the car!

Raising the IWG opening threshold allows me to drive the car in a more sane manner at slow speeds.

It just allows more throttle input in off freeway driving, just like a SC setup.

I'll keep playing with that threshold - I am doing it at large increments now, I will be fine tuning it once I find the best "zone" for my liking.

There was another major revelation regarding the "handshake" between the two turbos...

My approach to the transition phase was wrong.

I was under the impression compression bypass (LP bypass which stops the compounding stage and clears the way for the larger LP turbo to provide boost on its own) had to happen slightly AFTER the HP - LP transition.

I get a dip in boost if I do that. Pressure gauge drops to 100 kPa for about 1/2 second, and then boost kicks in (again), but climbs slowly this time, not unlike a late spooling single turbo.

Opening LP bypass a little BEFORE the HP - LP transition eliminates that dip, and it becomes more seamless.

There is also a problem with the LP bypass vacuum actuator - it tends to stick half open every now and then for some reason, which creates a hindrance for the larger turbo.

I got beautiful results once I opened it fully.

Need to take care of that.

I still have very few miles and SAE 30 break in oil in the engine, so my high RPM and high boost experimentation is somewhat limited at this time.

One thing is certain; I still need to pull fuel at low RPM-high load areas...

I'll keep playing with the system as I accrue miles and switch over to synthetic oil, but damn.. It's a lot of fun already!

#84

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

One more thing...

I also found ot a recirculating BOV is not one hundred per cent quiet.

I am thinking about welding a cage and stuffing some steel wool in the pipe between the BOV and the intake.

Should I?

I also found ot a recirculating BOV is not one hundred per cent quiet.

I am thinking about welding a cage and stuffing some steel wool in the pipe between the BOV and the intake.

Should I?

#87

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

So I had a minor accident.

Got rear ended in traffic, and the car needs to be parked in a body shop for a few days...

Fascia panel damage around the trunk lock area, plus scratches an whatnot on the bumper.

Oh, and the small turbo just stopped working.

I had the car in the garage, tuning the 3500 rpm vibrations out by playing with the preload on the upright supports, and heard a strange rattle as I was blipping the throttle in neutral.

I had a hard time pinpointing it as it was echoing throughout the whole assembly, all the way down to the resonator...

Checked everything, put the car back together and noticed no boost at all on the way home. It was perfect on the way to the garage!

Then the rattle became more noticeable...

I immediately bypassed the small turbo both on the exhaust an inlet side and drove it that way.

There is no smoke from the tailpipe, and I take that as a good sign.

I did, however, notice black soot around the oil inlet on the small turbo when I got back home today.

My plan is removing ALL of the turbo assembly, installing my NA header back in the car and taking it to the body shop sans the turbo stuff, so I can disassemble the turbos on the bench and take those in for a close inspection while the accident evidence is being removed.

I must have screwed something up badly for a turbo to last only 650 miles.

Nothing a new cartridge and/or housing can't fix.

And, I can't afford being without a car these days. I have to take my 83 year old mother to the hospital every day for radiotherapy.

Damn.

On a brighter note, season 2 of my show started today, and my other show will be aired soon, too.

Got rear ended in traffic, and the car needs to be parked in a body shop for a few days...

Fascia panel damage around the trunk lock area, plus scratches an whatnot on the bumper.

Oh, and the small turbo just stopped working.

I had the car in the garage, tuning the 3500 rpm vibrations out by playing with the preload on the upright supports, and heard a strange rattle as I was blipping the throttle in neutral.

I had a hard time pinpointing it as it was echoing throughout the whole assembly, all the way down to the resonator...

Checked everything, put the car back together and noticed no boost at all on the way home. It was perfect on the way to the garage!

Then the rattle became more noticeable...

I immediately bypassed the small turbo both on the exhaust an inlet side and drove it that way.

There is no smoke from the tailpipe, and I take that as a good sign.

I did, however, notice black soot around the oil inlet on the small turbo when I got back home today.

My plan is removing ALL of the turbo assembly, installing my NA header back in the car and taking it to the body shop sans the turbo stuff, so I can disassemble the turbos on the bench and take those in for a close inspection while the accident evidence is being removed.

I must have screwed something up badly for a turbo to last only 650 miles.

Nothing a new cartridge and/or housing can't fix.

And, I can't afford being without a car these days. I have to take my 83 year old mother to the hospital every day for radiotherapy.

Damn.

On a brighter note, season 2 of my show started today, and my other show will be aired soon, too.

#88

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,043

Total Cats: 6,607

Sucks to hear that, dude.

I have such a difficult time picturing you having a mother. I always assumed that you were assembled in a factory in Azerbaijan out of Soviet missile parts and deceased James Bond villains.

I have such a difficult time picturing you having a mother. I always assumed that you were assembled in a factory in Azerbaijan out of Soviet missile parts and deceased James Bond villains.

#91

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

And, I promptly failed to see a problem..

Given my lack of experience with turbos, it is entirely possible for me to miss a glaring clue.

I am just not well versed in the art of reading tea leaves in the form of a disassembled turbo. Yet.

That's why I will be hauling them to the folks who gave me this stuff come Monday.

There is no shaft play.

(I do know journal bearing turbos have about a mm or so play which is taken up by pressurized oil. There is no play beyond that)

I can't see any scratches, gouging, cracks or broken anything.

Both shafts spin freely, too.

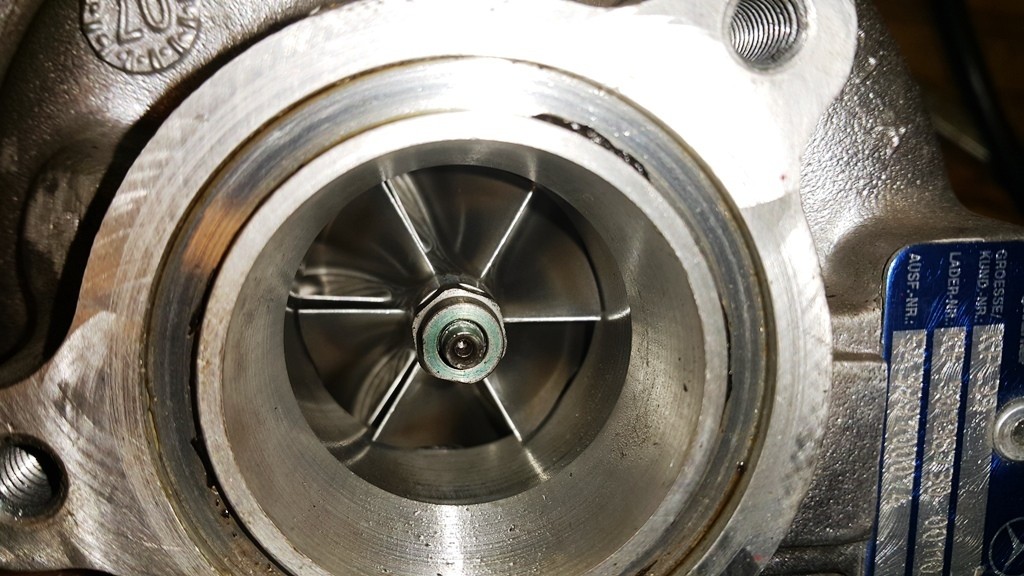

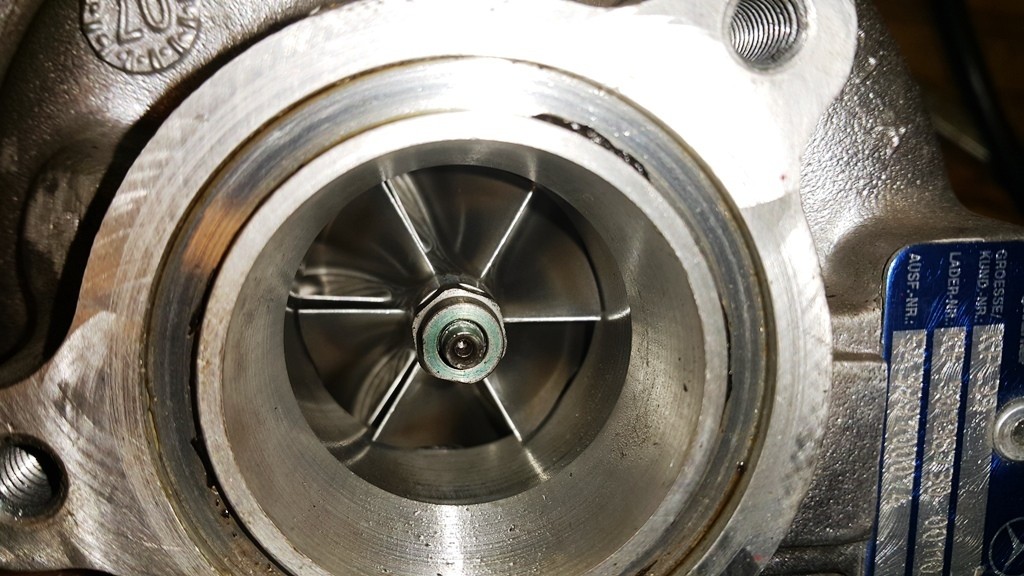

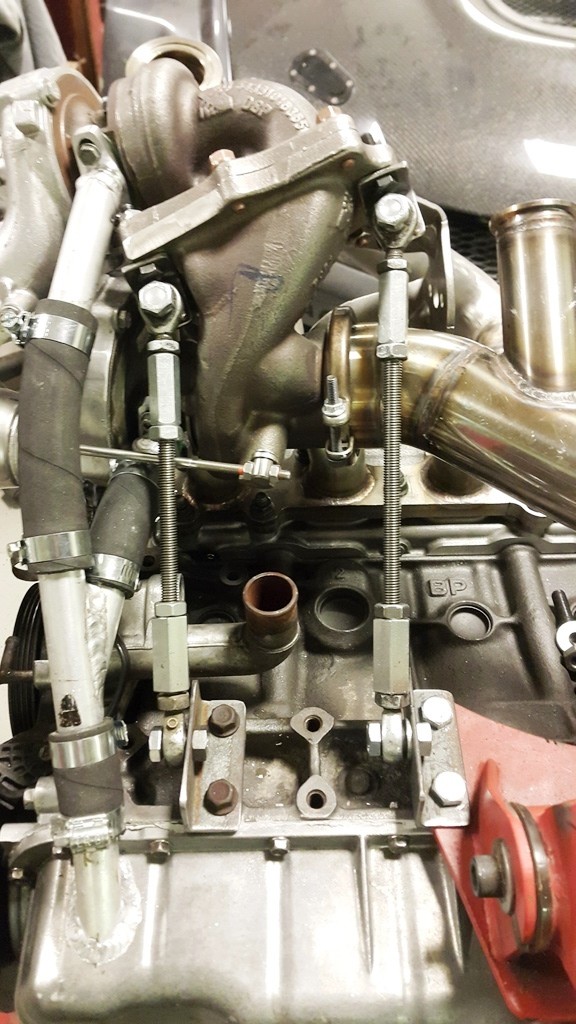

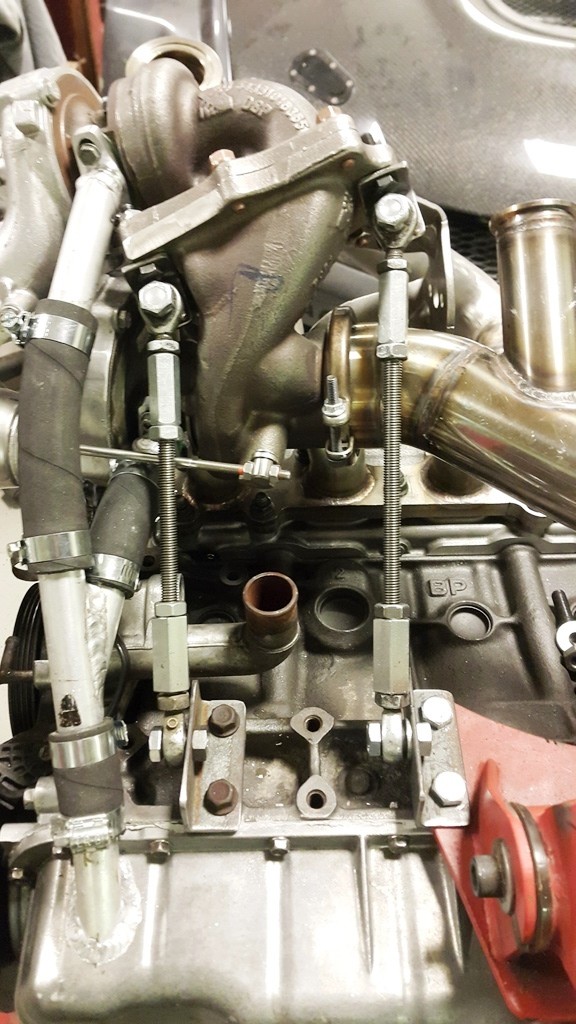

Here, see for yourself:

Little turbo (KP39 - turbinho)

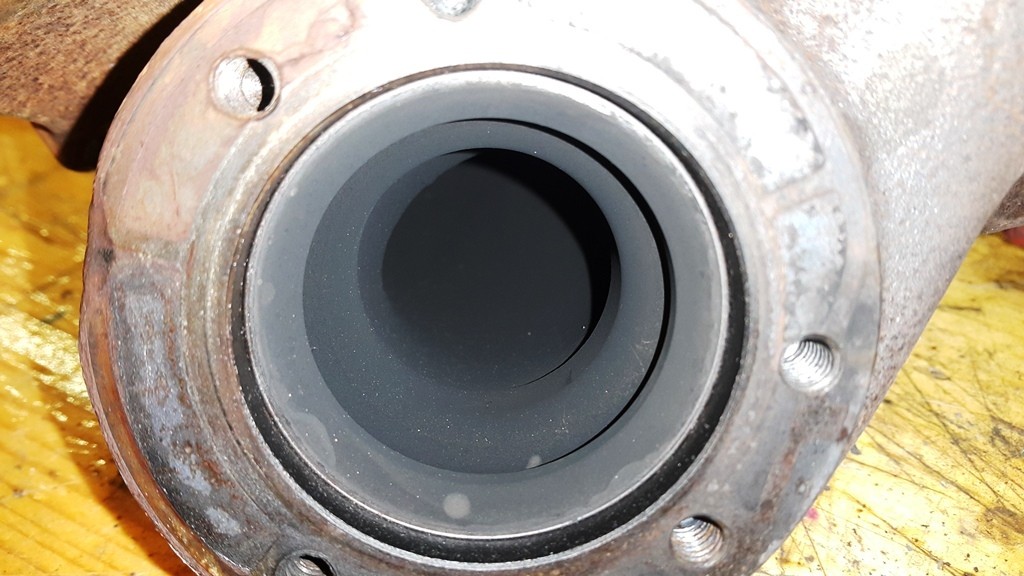

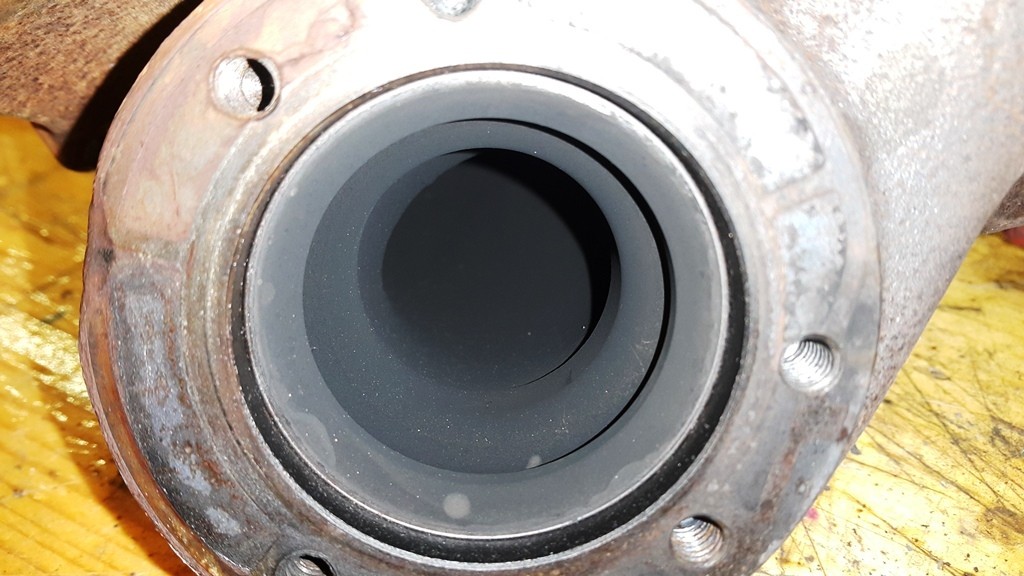

Big turbo (K04) Looks cleaner, haven't used much yet..

I found a mistake by yours truly here:

I had not used locktite on these bolts, 2 of them loosened up a little.

You can clearly see the exhaust leak...

I avoided cleaning anything so I would not be destroying clues during the proper inspection...

Given my lack of experience with turbos, it is entirely possible for me to miss a glaring clue.

I am just not well versed in the art of reading tea leaves in the form of a disassembled turbo. Yet.

That's why I will be hauling them to the folks who gave me this stuff come Monday.

There is no shaft play.

(I do know journal bearing turbos have about a mm or so play which is taken up by pressurized oil. There is no play beyond that)

I can't see any scratches, gouging, cracks or broken anything.

Both shafts spin freely, too.

Here, see for yourself:

Little turbo (KP39 - turbinho)

Big turbo (K04) Looks cleaner, haven't used much yet..

I found a mistake by yours truly here:

I had not used locktite on these bolts, 2 of them loosened up a little.

You can clearly see the exhaust leak...

I avoided cleaning anything so I would not be destroying clues during the proper inspection...

#92

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I also put the car back together so I could drive it...

Just used the old header and downpipe assembly and cobbled together a rudimentary air intake...

Packed all vacuum lines aside, and flipped over the main check valve to prevent a vacuum leak.

I left the oil feed lines in place, and used an M10 bolt to deadhead and tie both feed lines together.

I also made a sturdy plug for the oil drain inlet on the pan, made sure it is bulletproof.

It is not pretty, but it drives...

(AFR reads really lean with this header, like 2 points lean...)

Just used the old header and downpipe assembly and cobbled together a rudimentary air intake...

Packed all vacuum lines aside, and flipped over the main check valve to prevent a vacuum leak.

I left the oil feed lines in place, and used an M10 bolt to deadhead and tie both feed lines together.

I also made a sturdy plug for the oil drain inlet on the pan, made sure it is bulletproof.

It is not pretty, but it drives...

(AFR reads really lean with this header, like 2 points lean...)

#93

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I have a frequency question.

With a pretty hefty mass dangling off one side of the engine, I am getting a pretty noticeable vibration/buzz at around 3500 RPM.

I had to deal with a similar issue when I had my hotside MP62, and the solution was replacing a worn rubber insulator on the bottom support and giving it just the right amount of preload.

Since I had anticipated such an issue, I had incorporated two (dissimilar size and orientation) adjustable supports for the turbo assembly.

Here are the said supports:

I was able to tune out the better part of the vibration by preloading the supports one full turn of the long adjusting nut. That had felt a little excessive at the time, yet pretty much all preload was gone (meaning, I could almost spin the nuts by hand) when I removed them just a couple days later...

That got me thinking.

I also spoke with @TurboTim, and he confirmed it would be good practice to use a damping element such as a rubber isolator in those supports.

Turns out he had seen this sort of vibration/buzz issues with some turbo setups in the past.

So, in my quest for proper rubber isolators, I found and bought these:

They all have metal faces, and I would find a way to protect them from the heat...

BUT

I also came across these gems...

Bought them right away.

Now, do you guys think I should use the rubber isolators, or the springs?

I personally believe the springs would do a great job of retaining preload on those supports.

Or, I could do a combination (think of the rubber strap with lead beads used on a brake disc on a lathe..)

They all have M10 studs or threads, so combining them in a number of ways is possible.

What do you think?

With a pretty hefty mass dangling off one side of the engine, I am getting a pretty noticeable vibration/buzz at around 3500 RPM.

I had to deal with a similar issue when I had my hotside MP62, and the solution was replacing a worn rubber insulator on the bottom support and giving it just the right amount of preload.

Since I had anticipated such an issue, I had incorporated two (dissimilar size and orientation) adjustable supports for the turbo assembly.

Here are the said supports:

I was able to tune out the better part of the vibration by preloading the supports one full turn of the long adjusting nut. That had felt a little excessive at the time, yet pretty much all preload was gone (meaning, I could almost spin the nuts by hand) when I removed them just a couple days later...

That got me thinking.

I also spoke with @TurboTim, and he confirmed it would be good practice to use a damping element such as a rubber isolator in those supports.

Turns out he had seen this sort of vibration/buzz issues with some turbo setups in the past.

So, in my quest for proper rubber isolators, I found and bought these:

They all have metal faces, and I would find a way to protect them from the heat...

BUT

I also came across these gems...

Bought them right away.

Now, do you guys think I should use the rubber isolators, or the springs?

I personally believe the springs would do a great job of retaining preload on those supports.

Or, I could do a combination (think of the rubber strap with lead beads used on a brake disc on a lathe..)

They all have M10 studs or threads, so combining them in a number of ways is possible.

What do you think?

#94

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,775

Total Cats: 358

I use that style of rubber isolator to mount my coils, they work decently. Be aware that the metal parts are molded into the rubber, so tightening them with any amount of torque may make it difficult to take apart. You have nothing good to grab on to on the rubber side. You may need to replace them everytime you take them apart.

#95

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I use that style of rubber isolator to mount my coils, they work decently. Be aware that the metal parts are molded into the rubber, so tightening them with any amount of torque may make it difficult to take apart. You have nothing good to grab on to on the rubber side. You may need to replace them everytime you take them apart.

#96

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

Still working on the active louver system.

Ran into a minor problem.. Vacuum actuator opens the louvers beautifully, but does not have enough muscle to close it all the way.

Bottom side of the individual slats are heavier, and all connecting hardware is on the bottom side, as well, so "pulling" them up requires more force than closing.

So, I decided to us a 12V linear actuator and design a strange circuit to operate the thing with proper delays...

Order placed.

I should receive everything in a couple weeks, which means I'll be finishing this thing after my ski trip.

Details and pics will follow.

Ran into a minor problem.. Vacuum actuator opens the louvers beautifully, but does not have enough muscle to close it all the way.

Bottom side of the individual slats are heavier, and all connecting hardware is on the bottom side, as well, so "pulling" them up requires more force than closing.

So, I decided to us a 12V linear actuator and design a strange circuit to operate the thing with proper delays...

Order placed.

I should receive everything in a couple weeks, which means I'll be finishing this thing after my ski trip.

Details and pics will follow.