How-to: VVT oil feed

#1

I thought I might contribute to the Miata community by writing a short guide on how to plumb the turbo oil supply for 01-05 VVT engines.

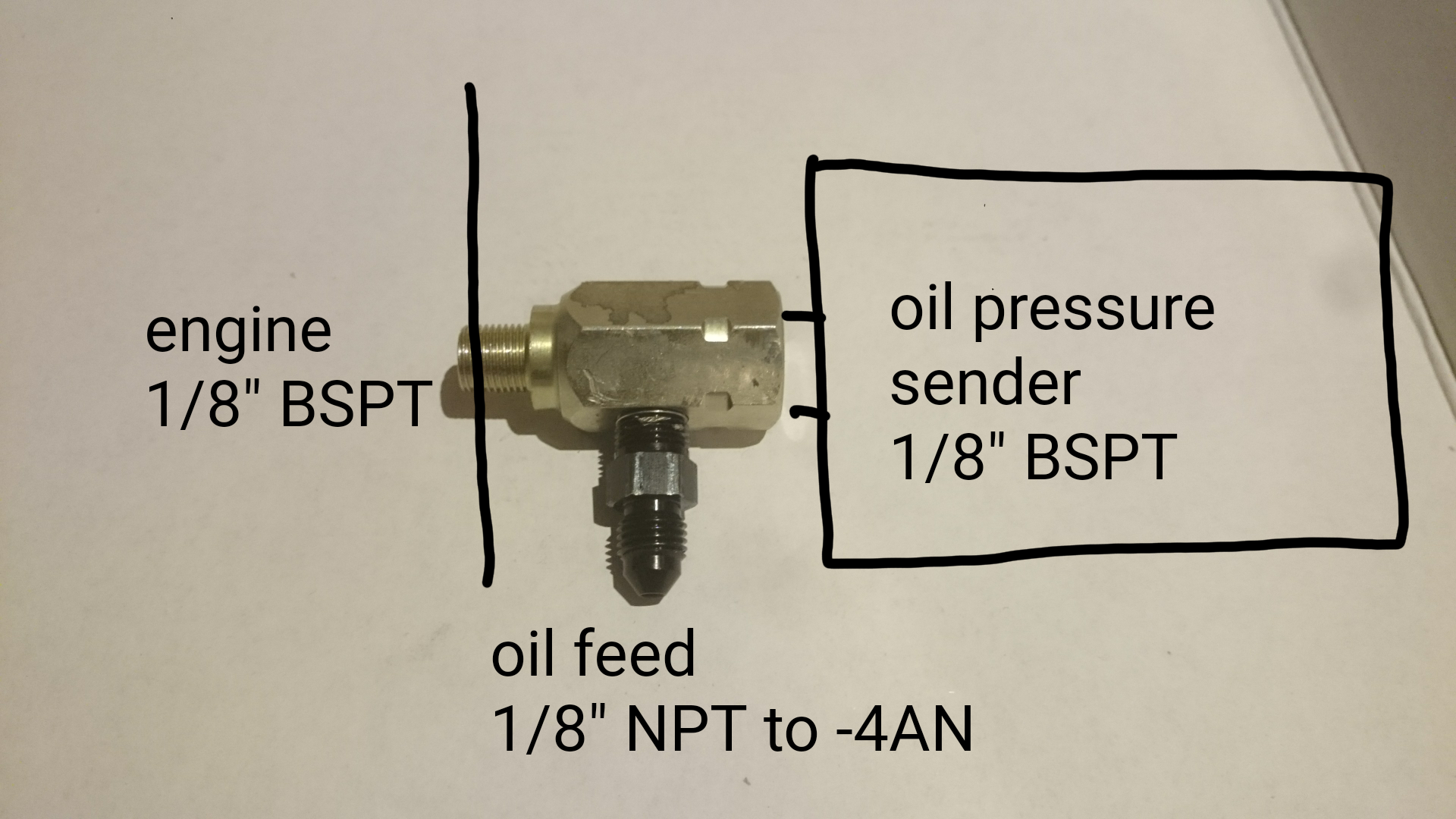

Why not tee into the oil pressure sender on the passenger side like everyone else does, you might ask. Well, there are various reasons. First, I did not only have a hard time sourcing an 1/8" BSPT T-fitting with an 1/8" NPT port, I also didn't like the idea of having the heavy, big-*** NA oil pressure sender hanging that far off the engine. To me this is asking for trouble when the fitting's material fails, causing immediate loss of oil pressure.

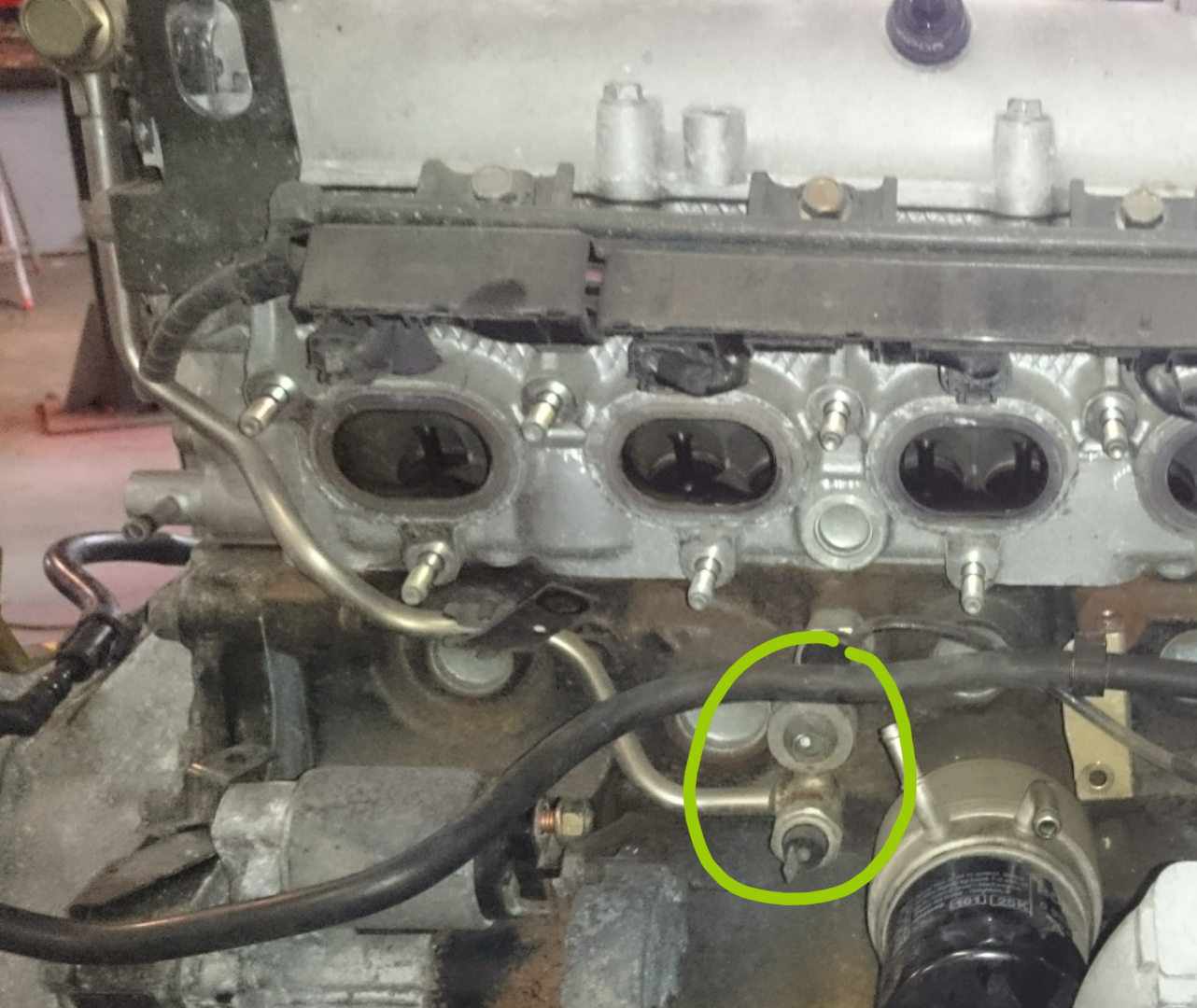

So I went looking somewhere else. Following the oil line routing from the area where everybody else used to source their turbo oil (green circle), I saw the VVT system obtains its oil from the same port as the oil pressure sender (just follow the hard line to the top left corner). So no matter where I tap into (oil pressure sender via T-fitting, or at the VVT mechanism, the VVT solenoid would always see the same oil pressure.

Basically you get two spots to tap into. The first one is near the firewall at the rear end of the VVT hard line. There is an unused passage on the back where one can drill & tap.

However, while reducing the length of the oil supply, the line still has to run behind the engine. This makes it not only hard to check for damage, but will also increase the risk of having the SS braided line cut its way through wires etc. Luckily there is another possible location on the front of the VVT mechanism, where you can tap into. It's clean, it's short, it's perfect.

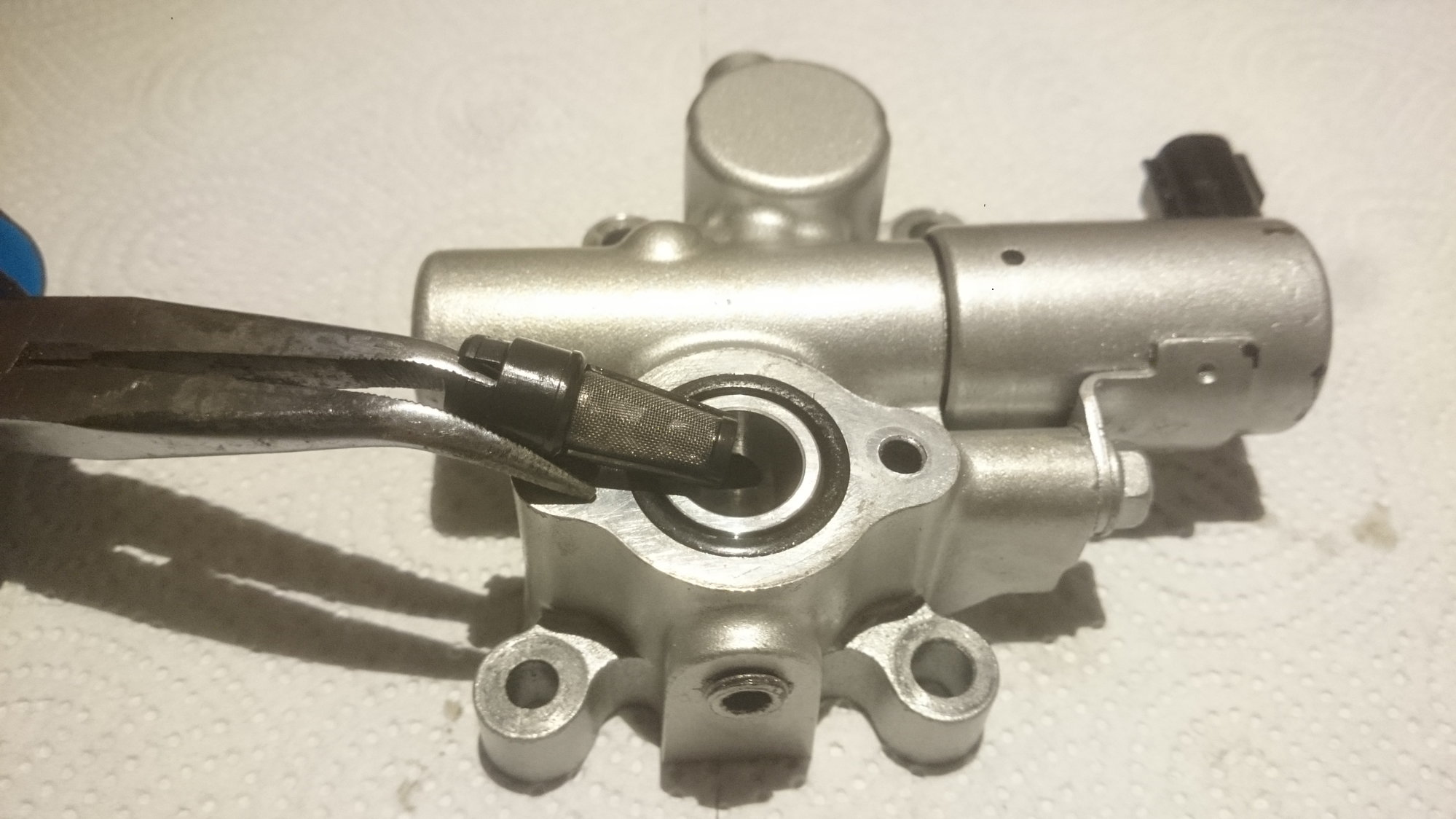

for obvious reasons you'll have to remove the VVT mechanism. It is very sensitive to dirt, so Mazda put in a little extra filter. Remember to use a clean work space! To begin with, remove that filter.

Inside the port you'll see an orifice on the top. This lets oil pass into the VVT actuator. On the bottom of this photo you can see a plug.

This is where we will tap into. Remove the plug with a hex wrench.

The plug is an 1/8" BSPT screw. It is slightly tapered. We will use an 1/8" NPT to -4AN adapter instead. Because once some dude dropped some other dude's tea into the ocean, NPT and BSPT threads are very similar, but not identical. They are both tapered and measure 27 and 28 threads per inch respectively.

since the overall deptch of the thread is only 14 mm, we can run a 1/8" NPT tap into the 1/8" BSPT thread. NPT-to-AN adapters are far easier to find than BSPT.

basically you have two choices. The 90° adapter with a straight fitting "might" be able to run underneath the VVT hardline, but I didn't want to take any chances. It's better to use that one when tapping into the other end of the VVT hardline (near the firewall). The straight adapter with the 90° fitting on the right runs over the hardline while not interfering with it. That's the one you want.

Grease the tap to catch most metal shavings. Repeatedly remove the tap to clean out shavings. Don't run the tap too far. Since NPT threads are tapered you need a tight fit with your adapter in order to seal well. Regularly check and tap some more if your adapter is tight while still having some threads sticking out.

Using Teflon tape, mount the adapter. The 90° fitting is mounted in this picture to check whether it clears the hardline.

It does!

So there you have it: The shortest, cleanest VVT turbo oil supply in the Miata world. Contrary to the picture, the SS braided line doesn't touch anything and runs perfectly straight to the EFR turbo.

Last edited by Eunos91; 07-24-2018 at 04:15 AM.

#2

side not: i haven't run the engine yet, but as I said, it shouldn't really matter whether one gets the oil at the oil pressure sender or at the VVT mechanism. While researching "my" method I discovered that others have gone this route before. Samwu8k tapped into the rear end, while Rev and JamesGSY tapped into the front end like I did. James reported some VVT noise later, but I'm certain that was causes by other unknown issues. Rev confirmed he has been successfully running that approach for 18 months.

#7

Resurrection here, run into any issues with the oil feed in this location?

I have my Journal bearing T25 being fed from this location and I am getting turbo seal leakage. I am not saying this is the cause, but just trying to track down some facts while i trouble shoot. It was a rebuilt turbo, oil drain 10an above oil level etc.

Side note- i was able to find a BSPT to 4AN fitting on Mcmaster Carr 1/4"7/16"-20UNF1/8____BSPTZinc-Plated Steel4,500 psi @ 72° F4545K1624.47

I have my Journal bearing T25 being fed from this location and I am getting turbo seal leakage. I am not saying this is the cause, but just trying to track down some facts while i trouble shoot. It was a rebuilt turbo, oil drain 10an above oil level etc.

Side note- i was able to find a BSPT to 4AN fitting on Mcmaster Carr 1/4"7/16"-20UNF1/8____BSPTZinc-Plated Steel4,500 psi @ 72° F4545K1624.47

Last edited by muthagoose; 10-02-2018 at 09:58 AM.

#8

Great idea, seems much cleaner than running the line tapped off the pressure sender hole around the back of the engine.

I would use a steel or SS fitting for the initial takeoff. High vibration does a job on little bity aluminum fittings.

Would love to hear Savington s take on it as his kit is the EFR standard.

Is the VVT oil feed line restricted at all? Seems like a plenty large tube to supply both, as the turbo is a restricted feed?

I would use a steel or SS fitting for the initial takeoff. High vibration does a job on little bity aluminum fittings.

Would love to hear Savington s take on it as his kit is the EFR standard.

Is the VVT oil feed line restricted at all? Seems like a plenty large tube to supply both, as the turbo is a restricted feed?

#9

Elite Member

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

Resurrection here, run into any issues with the oil feed in this location?

I have my Journal bearing T25 being fed from this location and I am getting turbo seal leakage. I am not saying this is the cause, but just trying to track down some facts while i trouble shoot. It was a rebuilt turbo, oil drain 10an above oil level etc.

Side note- i was able to find a BSPT to 4AN fitting on https://www.mcmaster.com/catalog/124/2151/4"7/16"-20UNF1/8____BSPTZinc-Plated Steel4,500 psi @ 72° F4545K1624.47

I have my Journal bearing T25 being fed from this location and I am getting turbo seal leakage. I am not saying this is the cause, but just trying to track down some facts while i trouble shoot. It was a rebuilt turbo, oil drain 10an above oil level etc.

Side note- i was able to find a BSPT to 4AN fitting on https://www.mcmaster.com/catalog/124/2151/4"7/16"-20UNF1/8____BSPTZinc-Plated Steel4,500 psi @ 72° F4545K1624.47

#13

Haven't run into any issues so far. Also I fail to understand what the difference between teeing off at the beginning and the end of the VVT feed tube really is . Both happens before the VVT mechanism, so there shouldn't be any difference in cam shaft lubrication or pressure to the VVT actuator?

#14

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

The difference is the oil pressure sender port supplying oil to two lines directly vs the vvt hardline being asked to now support two lines. One results in more overall flow and least pressure drop to both supplies, and applies engine oil pressure directly to both lines. The other gives the vvt oil supply a lower pressure bypass route directly at the vvt actuator.

#15

Small correction on the 1/8 in. BSP thread; I am pretty damn sure BSP is a straight thread, no taper, that's the difference between BSP and NPT. As a result, BSP relies on a O-ring, or crushable washer, like a Stat_o_seal, etc. unlike the taper thread NPT. I like your thread, well photo'ed and all. I also agree with your thoughts on that big NA oil pre. sender hanging off the block, just waiting to vibrate itself to failure. For that reason, while I did tap my turbo oil feed there, I used an BSP / AN3 fitting at the block, and with a 12 in. AN3 line relocated the sender to the side of the engine bay, and located the "T" there. Well done post, my man!

#16

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,224

Total Cats: 1,146

Yes but on VVT engines, the oil pressure switch, which is where everyone T's off of for their turbo, has already gone through the VVT hard line banjo bolt. So the argument is that there's relatively no difference between T'ing it at the beginning of the hard vs. the end of the hardline.

I completely understand not wanting to use one of the galley plugs on the head, since those are post-head restrictor at the top of the block, but the VVT line is unrestricted for it's entire length, and gets it's oil directly from the filter, which get's it's oil directly from the oil pump.

I completely understand not wanting to use one of the galley plugs on the head, since those are post-head restrictor at the top of the block, but the VVT line is unrestricted for it's entire length, and gets it's oil directly from the filter, which get's it's oil directly from the oil pump.

#17

Small correction on the 1/8 in. BSP thread; I am pretty damn sure BSP is a straight thread, no taper, that's the difference between BSP and NPT. As a result, BSP relies on a O-ring, or crushable washer, like a Stat_o_seal, etc. unlike the taper thread NPT. I like your thread, well photo'ed and all. I also agree with your thoughts on that big NA oil pre. sender hanging off the block, just waiting to vibrate itself to failure. For that reason, while I did tap my turbo oil feed there, I used an BSP / AN3 fitting at the block, and with a 12 in. AN3 line relocated the sender to the side of the engine bay, and located the "T" there. Well done post, my man!

#18

Half related to the thread.

Does the NB8B have a different casting for the oil feed on the engine to allow for the banjo fitting of the VVT?

Or does it use a pressure sender with a longer thread to take the banjo into account?

In my mind i'm wondering why people use the T piece on non-vvt blocks instead of just using a banjo there.

Surely the casting is different, or i'm missing something else?

Edit:

Ignore, just found some pics from different angles.

It's not just a standard banjo fitting, it's a weirdly unique banjo at block, then pressure sender feed port attached to the banjo fitting.

so yeah, ignore the above post

Does the NB8B have a different casting for the oil feed on the engine to allow for the banjo fitting of the VVT?

Or does it use a pressure sender with a longer thread to take the banjo into account?

In my mind i'm wondering why people use the T piece on non-vvt blocks instead of just using a banjo there.

Surely the casting is different, or i'm missing something else?

Edit:

Ignore, just found some pics from different angles.

It's not just a standard banjo fitting, it's a weirdly unique banjo at block, then pressure sender feed port attached to the banjo fitting.

so yeah, ignore the above post

Thread

Thread Starter

Forum

Replies

Last Post