Cost Effectiveness of different ECUs

#101

Supporting Vendor

iTrader: (33)

Join Date: Jul 2006

Location: atlanta-ish

Posts: 12,659

Total Cats: 134

I sincerely doubt I'm misunderstanding, since you just repeated the same thing again.

I'd like you to provide specific examples of why the MS3X is more powerful than the EMS-4 for a 4-cylinder forced induction application (i.e. the relevant application for this thread and this forum in general).

I'm not crass enough to refuse to tune Megasquirts like some idiots across the country, but I do think that it lacks a couple of major features that the AEM supports. I've played with both and I think the EMS-4 is the superior ECU for our application.

I'd like you to provide specific examples of why the MS3X is more powerful than the EMS-4 for a 4-cylinder forced induction application (i.e. the relevant application for this thread and this forum in general).

I'm not crass enough to refuse to tune Megasquirts like some idiots across the country, but I do think that it lacks a couple of major features that the AEM supports. I've played with both and I think the EMS-4 is the superior ECU for our application.

I downloaded AEMTuner and a Miata example project, looked through it and read through the manual a bit. I think this product is better directly compared to MS2 than MS3X.

Here is a list of the things I quickly found where MS3X has the advantage over EMS-4. I only listed things that I felt may benefit a Miata type application. Please feel free to look over the list and let me know if I made any errors regarding the capabilities of EMS-4.

MS3X advantages:

-MS3X is natively compatible with 99-05 Miata crank trigger pattern and does not require installation of a new trigger disc (though MS3X is compatible with higher tooth count trigger wheels if desired).

-2 or 3 stage fueling with 2 stages sequential, vs only a single stage

-if only 4 fuel channels are being used, the remaining 6 can be reassigned as additional digital or PWM high current outputs

-programmable injector response curves, including trims for small pulsewidths for superior idle and light load characteristics with large injectors. each injector can have an individual response curve if needed.

-model based acceleration enrichment

-6x6 trim table per cylinder for fuel

-6x6 trim table per cylinder for ignition

-closed loop EGO per cylinder, if o2 sensors are installed per cylinder

-3 step launch (vs 2)

-much larger I/O, with separate inputs and outputs (where the AEM uses the same pins, so assigning an analog input removes a general purpose output)

-integrated a/c control with feed forward closed loop idle kick

-integrated cooling fan control with feed forward close loop idle kick

-native support of water/meth injection, multiple strategies

-native support of multiple stages of nitrous and progressive nitrous, multiple strategies

-native support of fuel pump control (instead of having to purpose a general purpose output for pump control)

-antilag support

-dual fuel support, with switchable maps for fuel, ignition, afr, ae, boost, rev limit

-E85/flex fuel sensor support

-trims for fuel pressure and fuel temperature

-AFR safety system, with programmable limiter if AFR is out of target

-sophisticated support for up to 2 knock sensors, integrated into software, with programmable level, bandpass frequency, and response

-logic ignition outputs can be inverted in software to natively support CDI ignition

-native support of basic traction control (driven wheel vs undriven wheel)

-"perfect run" feature to aid in consistent launch behavior

-MS3X has a lower price point

-MS3X can be built from a parts kit at an even lower price point

That is what I found at first glance, so my list may not be perfect. I apologize if I missed any features with the AEM system, and of course welcome feedback.

#102

Megasquirt-3 MS3 Ignition Settings

There are some OEM-style things it doesn't currently do, like trying to record a table of knock limit timing, but it's a significant jump from the KnockSenseMS, and a bit more sophisticated than what we put in the MSPNP.

#104

The knock control board just hit the market yesterday. You can see the details on it here:

Megasquirt-3 MS3 Ignition Settings

There are some OEM-style things it doesn't currently do, like trying to record a table of knock limit timing, but it's a significant jump from the KnockSenseMS, and a bit more sophisticated than what we put in the MSPNP.

Megasquirt-3 MS3 Ignition Settings

There are some OEM-style things it doesn't currently do, like trying to record a table of knock limit timing, but it's a significant jump from the KnockSenseMS, and a bit more sophisticated than what we put in the MSPNP.

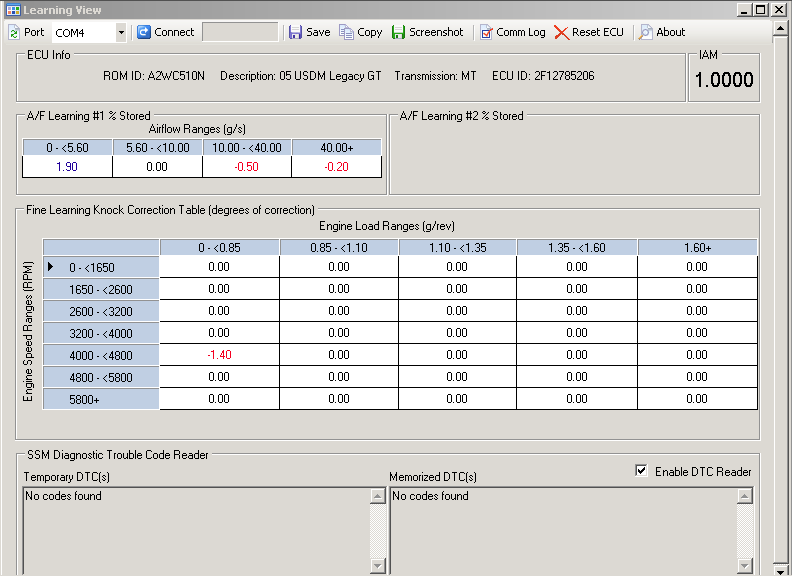

how much trouble would you get into reverse-engineering the subaru ecu knock control code?

Its one of the best Ive seen

#107

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

In general, I like the AEM because while it may not have the expansive featureset (I'd love to have stuff like more I/Os and the PW-dependent injector offsets), the features that it does have are both important and mature. MS1 had EBC too, but that doesn't mean it was worth using.

#111

Do the MS3 or the AEM do knock windowing?

Or do they just look at the overall noise level?

Windowing improves the discrimination of knock vs. the background noise level. I wrote down several ideas for discrimination schemes.

One of them is to look at the delta in noise level in-window vs. out-of-window - not just to look at in-window noise and ignore out-of-window noise, and compare this to a 2D table vs. RPM.

Note that in all cases there needs to be bandpass filtering to only listen to the knock frequency of 6.5 kHz ish.

Or do they just look at the overall noise level?

Windowing improves the discrimination of knock vs. the background noise level. I wrote down several ideas for discrimination schemes.

One of them is to look at the delta in noise level in-window vs. out-of-window - not just to look at in-window noise and ignore out-of-window noise, and compare this to a 2D table vs. RPM.

Note that in all cases there needs to be bandpass filtering to only listen to the knock frequency of 6.5 kHz ish.

#115

Because fuel temperature trims are cheaper to test out. About the only way to make certain your knock detection can distinguish knock at high load and RPM is to load up an engine on the dyno and give it too much timing. GM appears to have trashed at least half a dozen LS1 motors in dyno testing to get their ECU's knock detection to the level it's at now (reportedly, that is one of the best knock detection systems out there). So far, we've only sent one engine to the scrapyard testing the knock module out.

Thread

Thread Starter

Forum

Replies

Last Post

Motorsport-Electronics

ECUs and Tuning

0

09-05-2015 08:02 AM

AlwaysBroken

Engine Performance

4

09-04-2015 01:35 PM