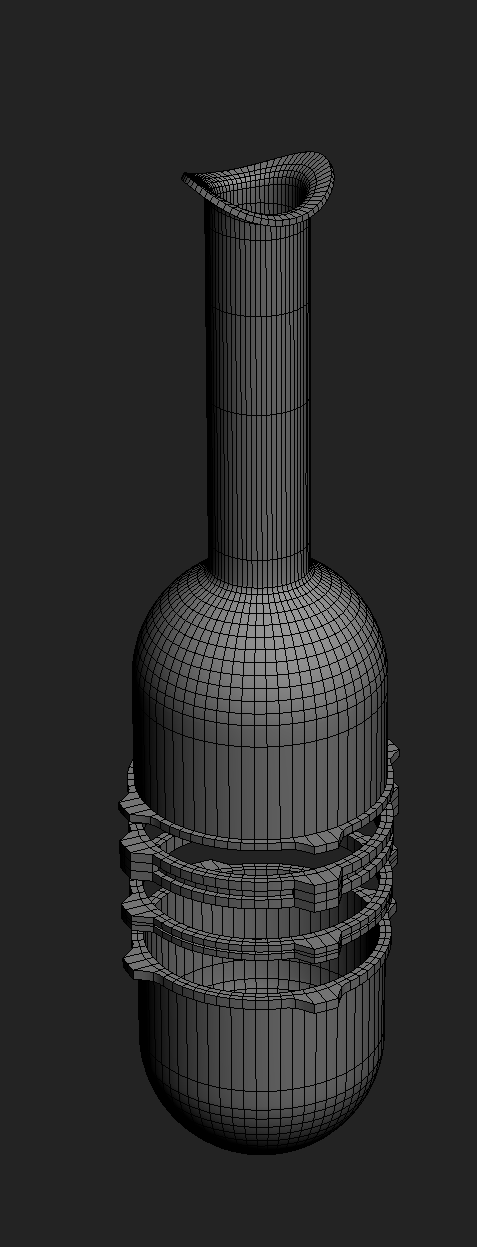

3d printed intake for N/A NA miatas

#343

Finished my intake installation today. Ended up using a 60 degree that I had to add 15 degrees by cutting the end at a slant, a 2.75 stainless coupler and a 45 degree elbow. I don't have a hood latch obviously. Total lenght is 20". I think it will make a little more power than using a 90 degree elbow. I also had to cut the hood a bit to make it fit.

#344

Finished my intake installation today. Ended up using a 60 degree that I had to add 15 degrees by cutting the end at a slant, a 2.75 stainless coupler and a 45 degree elbow. I don't have a hood latch obviously. Total lenght is 20". I think it will make a little more power than using a 90 degree elbow. I also had to cut the hood a bit to make it fit.

#345

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Looks great. I mocked up that location this weekend while I had the hood latch off.

At some point I am going to be doing multiple days of dyno testing with a bunch of parts and I will a/b that location with the stock hole.

Someone on miata.net had their printed plastic duct fail. It warped and shrank until it was a really narrow opening. I haven't tested aluminum radiator surface temps, it might be a good idea to throw a small piece of something like header wrap between the duct and the top of the radiator to force a gap.

At some point I am going to be doing multiple days of dyno testing with a bunch of parts and I will a/b that location with the stock hole.

Someone on miata.net had their printed plastic duct fail. It warped and shrank until it was a really narrow opening. I haven't tested aluminum radiator surface temps, it might be a good idea to throw a small piece of something like header wrap between the duct and the top of the radiator to force a gap.

#347

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

If you already have an air gap a small piece of heat reflective foil is good added insurance. If you don't have any, I can cut off a scrap piece and throw it in an envelope for you. The pictures of that guy's warped intake freaked me out. I suspect that his printer used PLA instead of ABS but either way, ~200F radiator surface is pushing the limits of ABS plastic.

#348

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Audio recording of my helmholtz resonator:

https://i.imgur.com/PqzYNpL.png

This is within 5hz of the frequency the calculator predicted. I think I am going to tweak it slightly to put the center at 3700rpm

https://i.imgur.com/PqzYNpL.png

This is within 5hz of the frequency the calculator predicted. I think I am going to tweak it slightly to put the center at 3700rpm

#350

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I am hoping by the summer. I just got 12 cartridge heaters and a screw in thermocouple from mcmaster carr. I need to take measurements off of them and then finish the cad work on the molds. Once the molds are done, I should be able to make them a lot faster than with the silicone molds I was using before. I am going to switch to prepreg, and the self heating aluminum molds can be run hotter than the oven I built, the layup time with prepreg is short, and the cure time with pre-preg at about 250F is much faster as well.

#352

I was originally on the list for one of these, then life happened and I needed to change direction with my modifications.

Will you have a kit available for NAs that still need to use the MAF? I was originally building for CSP, but I'll be forced to content myself with STS for now, and the MAF must be retained.

ETA: Just looked through the thread again, saw you had a NA with stock ECU early on in development. However, still interested to know if you plan on having a kit available or if I'd need to piece things together.

Will you have a kit available for NAs that still need to use the MAF? I was originally building for CSP, but I'll be forced to content myself with STS for now, and the MAF must be retained.

ETA: Just looked through the thread again, saw you had a NA with stock ECU early on in development. However, still interested to know if you plan on having a kit available or if I'd need to piece things together.

#355

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I was originally on the list for one of these, then life happened and I needed to change direction with my modifications.

Will you have a kit available for NAs that still need to use the MAF? I was originally building for CSP, but I'll be forced to content myself with STS for now, and the MAF must be retained.

ETA: Just looked through the thread again, saw you had a NA with stock ECU early on in development. However, still interested to know if you plan on having a kit available or if I'd need to piece things together.

Will you have a kit available for NAs that still need to use the MAF? I was originally building for CSP, but I'll be forced to content myself with STS for now, and the MAF must be retained.

ETA: Just looked through the thread again, saw you had a NA with stock ECU early on in development. However, still interested to know if you plan on having a kit available or if I'd need to piece things together.

#358

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

There isn't any room just after the intake filter in the pipe. The air filter flange fits almost directly against the bottom of the radiator support bar.

In practice, that IAT location has been great. Way less issues with heat soak than when I had it in the engine bay. The temps it reads are comparable to what I measured sticking a thermocouple in open air nearby.

In practice, that IAT location has been great. Way less issues with heat soak than when I had it in the engine bay. The temps it reads are comparable to what I measured sticking a thermocouple in open air nearby.