Miata LFX Swap (Singular Motorsports & Good-Win Racing)

#1302

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Maybe eventually? Right now my full attention is on solving the problems I need to solve to make this car work and achieve the goals set out. Trying to sell the solutions I come up with would be a distraction. Later, once everything is proved out and goals are met, maybe I take the time to adjust designs to work for a broader range of options, work out costing and manufacturing, etc. etc. I certainly have the foundation for it, drawings and detailed notes on everything that would make it possible. But the time for that isn't now.

#1304

While you are working on your hubs, be sure to put those ABS tone rings back in! Traction Control is coming your way if I can get it properly sorted. That ABS signal per wheel should do the trick! All the ECU needs is 10 teeth per revolution so 44t should give us some crazy good resolution to work with.

Ordering info for the tone rings for your V8R axles from DSS

QTY 2 / ITEM - 10.50 21.00T / PN - ABS-1204 / DESC - ESCORT 97-03 ALL MODELS ABS RINGS 44T

Ordering info for the tone rings for your V8R axles from DSS

QTY 2 / ITEM - 10.50 21.00T / PN - ABS-1204 / DESC - ESCORT 97-03 ALL MODELS ABS RINGS 44T

Last edited by griff; 05-22-2020 at 07:02 AM.

#1305

If you want a very similar weight clutch setup and dont care about the bearing and the LFX auto flex plate will engage the starter quartermaster will make you a twin disk clutch and flywheel setup of similar weight for about $800 (including a hydraulic throwout bearing). They just use the flex plate for the starter and give you a flywheel thats only as large as the 7.5" clutch and you just sandwich the flex plate between the flywheel and crank. Now if there's no suitable flexplate you have to go that pimpy full custom way.

#1306

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

While you are working on your hubs, be sure to put those ABS tone rings back in! Traction Control is coming your way if I can get it properly sorted. That ABS signal per wheel should do the trick! All the ECU needs is 10 teeth per revolution so 44t should give us some crazy good resolution to work with.

Ordering info for the tone rings for your V8R axles from DSS

QTY 2 / ITEM - 10.50 21.00T / PN - ABS-1204 / DESC - ESCORT 97-03 ALL MODELS ABS RINGS 44T

Ordering info for the tone rings for your V8R axles from DSS

QTY 2 / ITEM - 10.50 21.00T / PN - ABS-1204 / DESC - ESCORT 97-03 ALL MODELS ABS RINGS 44T

#1307

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Left side of car is finished cutting. Before I start welding stuff in I have to cut the other side to match.

Still early days on this project but getting pretty excited for how it's going to turn out. Approaching this from the standpoint of picking the wheel and tire I want to be on, placing the chassis where I want it relative to that, and just making everything else work around that. It's the right way to do it... but certainly intrusive. The list of items and areas that have to be cut, modified, relocated, reinforced, etc. has grown substantially from what I had in mind going into it.

Still early days on this project but getting pretty excited for how it's going to turn out. Approaching this from the standpoint of picking the wheel and tire I want to be on, placing the chassis where I want it relative to that, and just making everything else work around that. It's the right way to do it... but certainly intrusive. The list of items and areas that have to be cut, modified, relocated, reinforced, etc. has grown substantially from what I had in mind going into it.

#1308

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Rode the struggle bus today. Those of you who are machinists will be saying "yeah duh!"

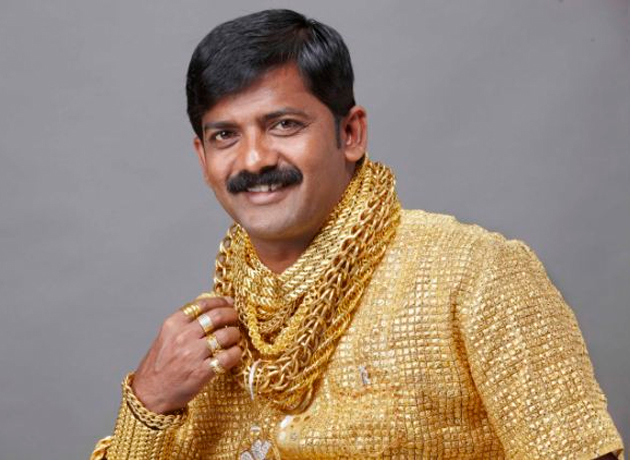

Transmission adapter plate came back fresh from anodizing today. Unwrapped it like it was Christmas to find... instead of gold, it was brown. The anodizer had told me that Type III hard anodizing comes out a shade or two darker than normal Type II... but assured me it would just be "darker gold". Not much that can be done now, it's a precision part so I'm not going to have it stripped/blasted and redone just for a color change, and I know, I know, you'll never see it once it's in the car, but I was stoked to get this part I have months of time into nicely finished in a sexy color, so the "wood brown" as I'm affectionately calling it now was a bummer.

So OK, moving on. Since the plate is back I'll take a break tonight from working on the chassis and do some final fit checks with the transmission. Ah, but that's no good either because Type III anodizing adds up to 0.004" thickness (which the anodizer didn't feel like mentioning when I specifically asked if there were any factors I should consider for choosing between Type II and III) and when we're talking about a hole with two walls that's almost a hundredth of an inch. So none of the alignment dowels fit any more. Doh!

I've got some reamers on the way to correct the holes so I'll have it sorted out soon enough. C'est la vie.

Transmission adapter plate came back fresh from anodizing today. Unwrapped it like it was Christmas to find... instead of gold, it was brown. The anodizer had told me that Type III hard anodizing comes out a shade or two darker than normal Type II... but assured me it would just be "darker gold". Not much that can be done now, it's a precision part so I'm not going to have it stripped/blasted and redone just for a color change, and I know, I know, you'll never see it once it's in the car, but I was stoked to get this part I have months of time into nicely finished in a sexy color, so the "wood brown" as I'm affectionately calling it now was a bummer.

So OK, moving on. Since the plate is back I'll take a break tonight from working on the chassis and do some final fit checks with the transmission. Ah, but that's no good either because Type III anodizing adds up to 0.004" thickness (which the anodizer didn't feel like mentioning when I specifically asked if there were any factors I should consider for choosing between Type II and III) and when we're talking about a hole with two walls that's almost a hundredth of an inch. So none of the alignment dowels fit any more. Doh!

I've got some reamers on the way to correct the holes so I'll have it sorted out soon enough. C'est la vie.

Last edited by ThePass; 05-28-2020 at 03:26 AM.

#1314

Couple of bits of info for ya...

ATS V injectors 12622473 provide 128lb/hr (30% more fuel) and fit perfectly. (Have not run yet)

The HPFP 12666366 (new number for the pump you have) will not work in a LFX head with a Mace oversized fuel lobe cam. You will either need to machine down the mating surface of the pump or add a spacer inside the plunger so that it will stay in contact.

Hope all is well and look forward to the updates on Hyper!

ATS V injectors 12622473 provide 128lb/hr (30% more fuel) and fit perfectly. (Have not run yet)

The HPFP 12666366 (new number for the pump you have) will not work in a LFX head with a Mace oversized fuel lobe cam. You will either need to machine down the mating surface of the pump or add a spacer inside the plunger so that it will stay in contact.

Hope all is well and look forward to the updates on Hyper!

#1315

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

The past month has seen a lot of sidetracks. I've had the plan for this big wheel project largely figured out, but left a few details open ended until I got in there and really had a chance to look at things from every angle. Now that I'm there and gone over things a dozen times I've decide to change the configuration a bit from what I was originally planning. That means a few more custom parts. One or two things I'm not ready to take the cover off yet until I'm sure they'll all come together the way I have envisioned, but most importantly several things require machining that up until now I'd have to send out for. Every time I have to send out for machining there's a big stop and wait in the project, and finally I decided I need to have some machining capability in-house.

So off I went on a giant sidetrack shopping for a vertical mill and metal lathe. Didn't have the budget for a new mill, so scoured Craigslist until I found a nice ACRA unit with everything I wanted. Then I had to get it from LA to San Diego, then rent a forklift and get it in the building, then get the shop area wired up for 3 phase power, then get tooling etc. for it. Just finishing that up, with the last part of that project being a new DRO system on the way and then I should be ready to start cutting with it. I also have an order in for a Precision Matthews lathe, which should be coming in another couple weeks. There will undoubtedly still be some machining jobs I need to send out for, but with this equipment I should be able to tackle probably 75% of the machining work that I come across needing to do. So while it's caused a delay up front I'm excited to have cut down on delays in the future.

Also in June, I got word of an MSM that a guy needed to sell. He said it had a blown head gasket. He'd already bought a new truck and didn't want to deal with it. So I went up to see it, it was in great condition. Price was too good to pass up, and at a glance I had my doubts that the issue was actually the head gasket, so I brought it home in the trailer. Last weekend I did water pump/timing belt/tstat/etc. and now it runs great. Still needs a new soft top and a few other details, but now I officially have another turbo Miata.

A few more pieces of the puzzle arrived during all that.

Aluminum driveshaft to transfer things between the Jerico yoke and Getrag diff:

New rear friction rings which will go on new 5 lug rotor hats:

So off I went on a giant sidetrack shopping for a vertical mill and metal lathe. Didn't have the budget for a new mill, so scoured Craigslist until I found a nice ACRA unit with everything I wanted. Then I had to get it from LA to San Diego, then rent a forklift and get it in the building, then get the shop area wired up for 3 phase power, then get tooling etc. for it. Just finishing that up, with the last part of that project being a new DRO system on the way and then I should be ready to start cutting with it. I also have an order in for a Precision Matthews lathe, which should be coming in another couple weeks. There will undoubtedly still be some machining jobs I need to send out for, but with this equipment I should be able to tackle probably 75% of the machining work that I come across needing to do. So while it's caused a delay up front I'm excited to have cut down on delays in the future.

Also in June, I got word of an MSM that a guy needed to sell. He said it had a blown head gasket. He'd already bought a new truck and didn't want to deal with it. So I went up to see it, it was in great condition. Price was too good to pass up, and at a glance I had my doubts that the issue was actually the head gasket, so I brought it home in the trailer. Last weekend I did water pump/timing belt/tstat/etc. and now it runs great. Still needs a new soft top and a few other details, but now I officially have another turbo Miata.

A few more pieces of the puzzle arrived during all that.

Aluminum driveshaft to transfer things between the Jerico yoke and Getrag diff:

New rear friction rings which will go on new 5 lug rotor hats:

#1319

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

I'm really privileged to have a great work space at our new building where I can fit stuff like this, but all of the tooling and equipment is my own, funded by me. We'd have to be doing production with this stuff for the company to justify the cost, whereas if I buy it then it's OK that it be used as much or as little as needed. There's certainly benefits for the biz; the more I can do in house the better when it comes to working with and adjusting prototypes, etc. but the main motivation for buying most of the stuff is to add more tools to my belt so to speak and further progress Hyper.

#1320

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

I've been running a wave rotor shape for about three years now. Inspired by none other than mountain and dirt bikes. One of a few tricks I've been playing with to cut weight in the rear rotor... finding the fine line between too much mass (heavy) and too little (overheating).

Last edited by ThePass; 07-11-2020 at 01:34 AM.