Anyone running VVT on Haltek?

#1

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Does it suck less than MS3?

I don't really know much of anything but I downloaded the software and looked at the configs and I see it seems to be a hold duty type, with a PID set that can be modified off coolant temp plus a long term trim? That looks to be a million times better than MS3, which I can't get to control 100% worth a ******* ****.

Like I said, I don't know anything about haltek, but I got the software and picked a ECU and made a new tune and enabled cam control I/O without reading a manual, enough so I can see how it is tuned. The only thing I don't see is a way to disable the VVT below a set RPM, is that a thing?

My complaints with MS3 are pretty simple. If I enable VVT at all coolant temps it's impossible to tune because you have one set of PID values, so I only run it when it's goood and hot which for my street car is a ******* waste. Haltek has PID off coolant temp, I believe this will fix that 100%

Next, MS3 won't let me kill VVT at idle. 95% of the time it's fine, but sometimes I can't get the valve to not chatter at 100% duty to the valve. I've tried heavier oil, a different actuator/head, and a bunch of crazy lying to the controller to make it stop without much luck. I'd really, really like to completely stop oil to the valve at idle, or even purposefully run it negative duty (per the hold duty programmed) so that I am really, really sure it's fully retarded and locked up. I also think this could help the ******* horrible chatter some VVT cars seem to have on startup. Don't see how you can stop the engine with oil still potentially in the actuator and have it lock out like it's supposed to for startup. OEM has to do something different. I don't get the startup slap if I don't run VVT for a drive or two.

Does Haltek do anything like that, or could it be made to without help from the higher ups?

Also, if you're running Haltek and VVT on a miata, do you like? Follows pretty close to target, doesn't wildly oscillate at random? No weird trigger errors, where the engine somehow syncs on the wrong half the cycle?

I don't really know much of anything but I downloaded the software and looked at the configs and I see it seems to be a hold duty type, with a PID set that can be modified off coolant temp plus a long term trim? That looks to be a million times better than MS3, which I can't get to control 100% worth a ******* ****.

Like I said, I don't know anything about haltek, but I got the software and picked a ECU and made a new tune and enabled cam control I/O without reading a manual, enough so I can see how it is tuned. The only thing I don't see is a way to disable the VVT below a set RPM, is that a thing?

My complaints with MS3 are pretty simple. If I enable VVT at all coolant temps it's impossible to tune because you have one set of PID values, so I only run it when it's goood and hot which for my street car is a ******* waste. Haltek has PID off coolant temp, I believe this will fix that 100%

Next, MS3 won't let me kill VVT at idle. 95% of the time it's fine, but sometimes I can't get the valve to not chatter at 100% duty to the valve. I've tried heavier oil, a different actuator/head, and a bunch of crazy lying to the controller to make it stop without much luck. I'd really, really like to completely stop oil to the valve at idle, or even purposefully run it negative duty (per the hold duty programmed) so that I am really, really sure it's fully retarded and locked up. I also think this could help the ******* horrible chatter some VVT cars seem to have on startup. Don't see how you can stop the engine with oil still potentially in the actuator and have it lock out like it's supposed to for startup. OEM has to do something different. I don't get the startup slap if I don't run VVT for a drive or two.

Does Haltek do anything like that, or could it be made to without help from the higher ups?

Also, if you're running Haltek and VVT on a miata, do you like? Follows pretty close to target, doesn't wildly oscillate at random? No weird trigger errors, where the engine somehow syncs on the wrong half the cycle?

#2

I run an Elite 1500 on a VVT. I don't think it has any start up chatter but I don't have the most sensitive mechanical ears. These is a VCT base map where you can see Haltech's base map setup for the 1.8VVT. Its in Basemaps, Mazda, MX5, HT-140921 - Mazda MX5 VCT. Think I was also given another which was HT-140921 E1500 Mazda MX5 NB VCT.e1500-235

Looking at my map - I run different base duties at different coolant temps as well as PIDs at Vs coolant temps. It also has a long term trim applied to the base duty Vs coolant temp. You could change these to oil temp if you have the sensor.

The base map settings result in an actual angle slightly lower than my target - I currently run quite thin oil as NA so possibly part of it. I've not put time into correcting it but the trim pushes up the base duties a bit. I upped my targets to get the actuals I wanted as a quick fix.

I wouldn't call the control instantaneously perfect but its not miles out.

At idle my target is zero and the actual also zeros. Idles like a pig if you have material cam advance at very low revs.

Looking at my map - I run different base duties at different coolant temps as well as PIDs at Vs coolant temps. It also has a long term trim applied to the base duty Vs coolant temp. You could change these to oil temp if you have the sensor.

The base map settings result in an actual angle slightly lower than my target - I currently run quite thin oil as NA so possibly part of it. I've not put time into correcting it but the trim pushes up the base duties a bit. I upped my targets to get the actuals I wanted as a quick fix.

I wouldn't call the control instantaneously perfect but its not miles out.

At idle my target is zero and the actual also zeros. Idles like a pig if you have material cam advance at very low revs.

#6

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Thank you for the info Mr Plow, the 1500 is what I was looking at!

When you are idling does the Elite send out any duty cycle to the valve at all? Or, if you are targeting zero will it actually pause control?

Rev, I've had a couple different people tell me they get the chatter too, on startup or idling. If you would be so kind as to share your PID settings I would appreciate it. I am running P50 I25 D180 at ~500Hz and I get decent control over 3K RPM and oscillating garbage below ~3,000RPM. So, I can't cruise at 45 mph and use VVT. If I tune the PID to fix the oscillations it completely nerfs it, undershoots for days above 3K then overshoots and oscillates before it maybe eventually settles. I've been trying various things for at least a year now, different oil, different targets, different PID settings, frequencies, etc. Closest I've got leaves me not using VVT 95% of the time and so I guess MS3 VVT works, 5% of the time.

TheBeerBaron, Yep I've got a flyback diode. It's in my ECU and not at the solenoid but that should be good enough according to what I know.

When you are idling does the Elite send out any duty cycle to the valve at all? Or, if you are targeting zero will it actually pause control?

Rev, I've had a couple different people tell me they get the chatter too, on startup or idling. If you would be so kind as to share your PID settings I would appreciate it. I am running P50 I25 D180 at ~500Hz and I get decent control over 3K RPM and oscillating garbage below ~3,000RPM. So, I can't cruise at 45 mph and use VVT. If I tune the PID to fix the oscillations it completely nerfs it, undershoots for days above 3K then overshoots and oscillates before it maybe eventually settles. I've been trying various things for at least a year now, different oil, different targets, different PID settings, frequencies, etc. Closest I've got leaves me not using VVT 95% of the time and so I guess MS3 VVT works, 5% of the time.

TheBeerBaron, Yep I've got a flyback diode. It's in my ECU and not at the solenoid but that should be good enough according to what I know.

#7

Elite Member

iTrader: (10)

Join Date: Jun 2006

Location: Athens, Greece

Posts: 5,979

Total Cats: 356

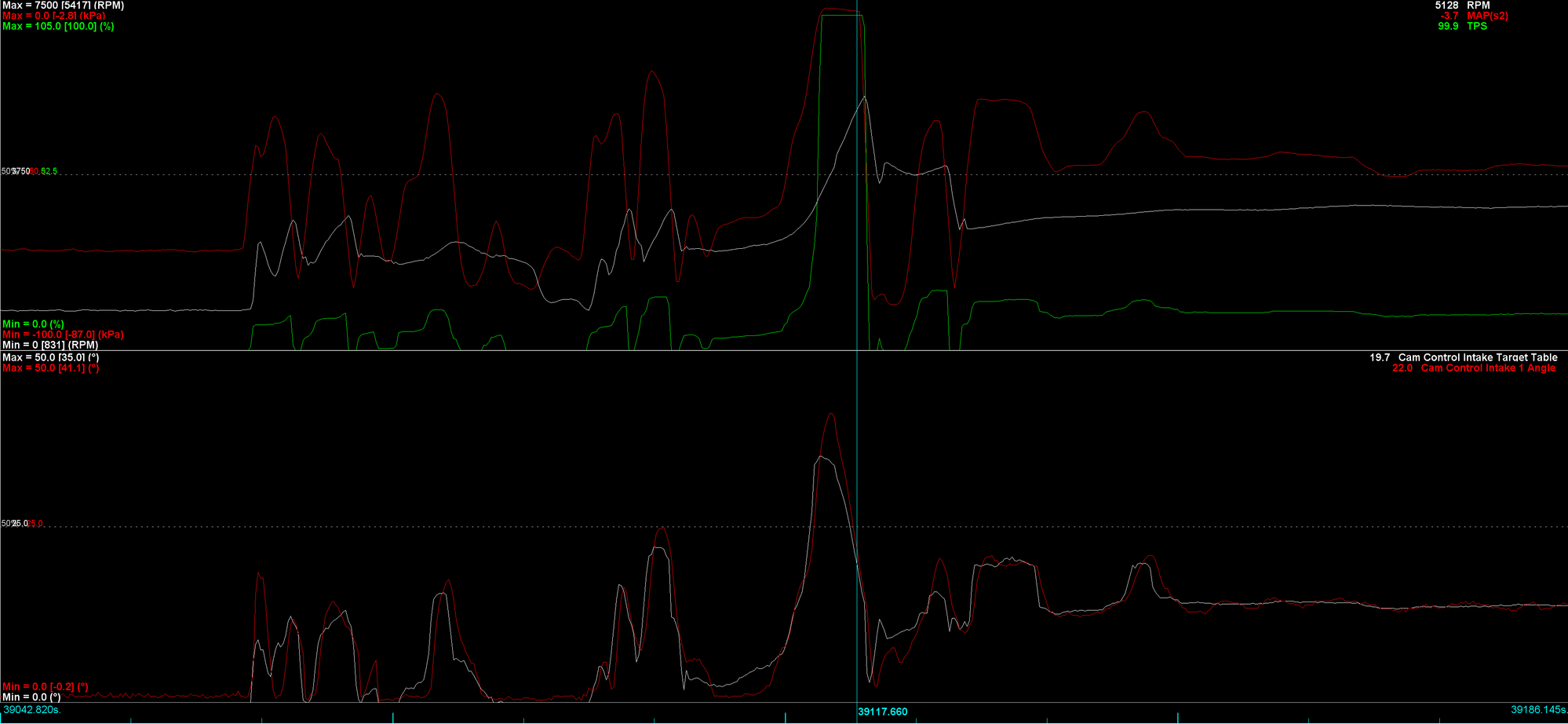

Here's a typical log from my car. It's about 1.5 years ago because I've literally not touched the tune since then.

PID = 50/17/130

I=25 will add more duty over time compared to I=17 when the error is not instantly reduced by P. This will cause laggy over/undershoots.

I=180 will cause more instability while the target is changing and the controller is trying to match the actual angle with the target.

In general, it's best if for example you can run P=50 (or any number that gets you to 99% of the target) and zero I or D. Too little P and you won't reach close to your target. Too much and it will overshoot and oscillate.

Integration (the I) will try to correct that last 1% or 2% at the cost of causing the laggy response.

D will try to stop oscillation from too much P or I but it in itself will cause oscillations if you add too much.

I also tend to calibrate so my 0% duty (valve disconnected) gets me 1-2% degrees of timing at idle, and I target -0.5 or something like that at idle.

Hope that helps.

PID = 50/17/130

I=25 will add more duty over time compared to I=17 when the error is not instantly reduced by P. This will cause laggy over/undershoots.

I=180 will cause more instability while the target is changing and the controller is trying to match the actual angle with the target.

In general, it's best if for example you can run P=50 (or any number that gets you to 99% of the target) and zero I or D. Too little P and you won't reach close to your target. Too much and it will overshoot and oscillate.

Integration (the I) will try to correct that last 1% or 2% at the cost of causing the laggy response.

D will try to stop oscillation from too much P or I but it in itself will cause oscillations if you add too much.

I also tend to calibrate so my 0% duty (valve disconnected) gets me 1-2% degrees of timing at idle, and I target -0.5 or something like that at idle.

Hope that helps.

#8

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Thank you, but to be honest this just shows how megasquirt sucks at VVT.

You probably don't get chatter because you let duty slowly taper to zero by lying about cam angles. You look to target "zero" below about 2K, but you have it set so that reads as 3 degrees so megasquirt keeps pulling duty. So, you also get a lot of lag leaving "zero" target. I guess I could do that, I have done that, but I use the minimum duty settings megasquirt provides to stop that and to get it responding faster without massive overshoot at low RPMs because I don't get nice slow smooth response like that using those PIDs.

And I've tried a whole heap of VVT PID settings. I've read up on how it works from a million different sources. I trolled through the 1.4 source and figured out exactly how it calculates, or how it did, might, still calculate. I don't think the integral works that way, more makes it ramp to target faster from accumulated error. If "P" is correct, "I" should never accumulate and allow oscillations in the first place. Besides, kind of irrelevant, VVT isn't hardly ever steady target in the first place. 50/17/130 posted everywhere and I can't even pull off stable VVT at 65MPH in 6th gear at 50-75kpa, I will get low frequency oscillations that swing intake pressures and knock around turbo RPM by a few thousand RPMs. More integral will more quickly damp these slow speed oscillations, and then more derivative will settle the crazy integral from "winding up." It works for me above 3KRPM, besides the fact that it beats the ever living daylights out of my actuator because whoever coded the VVT control didn't put one ******* ounce of effort into making something useful for it's intended purpose...

You probably don't get chatter because you let duty slowly taper to zero by lying about cam angles. You look to target "zero" below about 2K, but you have it set so that reads as 3 degrees so megasquirt keeps pulling duty. So, you also get a lot of lag leaving "zero" target. I guess I could do that, I have done that, but I use the minimum duty settings megasquirt provides to stop that and to get it responding faster without massive overshoot at low RPMs because I don't get nice slow smooth response like that using those PIDs.

And I've tried a whole heap of VVT PID settings. I've read up on how it works from a million different sources. I trolled through the 1.4 source and figured out exactly how it calculates, or how it did, might, still calculate. I don't think the integral works that way, more makes it ramp to target faster from accumulated error. If "P" is correct, "I" should never accumulate and allow oscillations in the first place. Besides, kind of irrelevant, VVT isn't hardly ever steady target in the first place. 50/17/130 posted everywhere and I can't even pull off stable VVT at 65MPH in 6th gear at 50-75kpa, I will get low frequency oscillations that swing intake pressures and knock around turbo RPM by a few thousand RPMs. More integral will more quickly damp these slow speed oscillations, and then more derivative will settle the crazy integral from "winding up." It works for me above 3KRPM, besides the fact that it beats the ever living daylights out of my actuator because whoever coded the VVT control didn't put one ******* ounce of effort into making something useful for it's intended purpose...

#10

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

"Well" is a matter of opinion. If I run my car exactly as you have yours set it lags behind because it obviously would trying to hit an impossible target then overshoots right at about 3K RPM every single gear change, falls on it's face.

Glad it works for you, still don't make it right in the slightest.

Glad it works for you, still don't make it right in the slightest.

#12

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Are we even looking at the same log? Because you lag behind by more than a second every single time you leave no advance before lazily reaching target, sometimes. Leaving full retard less than ~40% DC, you get no advance. You don't use minimum DC, so you get overshoots after target retarding. Every. Single. Time. I could probably fix the delay and the retard overshoot but I'd introduce some slapping of course.

Haltek will let me map a base duty cycle off a 3d table, be it oil or coolant temp and RPMs or whatever I want really. Pretty sure that would fix the slap and nerf the delay. Such a simple thing, why is getting even the most basic **** added to megasquirt impossible?

Don't get me wrong, that's impressive for what it's done with, but it's ******* bullshit. And as I said earlier, my car is worse than yours using the same exact settings. I can't let megasquirt roll into duty cycle like that leaving idle. It will not lazily climb to target, it will lag, lag, lag, violent overshoot and fall on it's face.

And it looks like haltech is ******* garbage for canbus inputs, gereat...

Thought of something. I can use MS3 to calculate cam angles and targets over canbus, then do whatever the **** I want with the valve with my own code. Hard part is done. Still have to deal with MS3 shitting the bed on detecting sync rarely, but what are you gonna do...

Haltek will let me map a base duty cycle off a 3d table, be it oil or coolant temp and RPMs or whatever I want really. Pretty sure that would fix the slap and nerf the delay. Such a simple thing, why is getting even the most basic **** added to megasquirt impossible?

Don't get me wrong, that's impressive for what it's done with, but it's ******* bullshit. And as I said earlier, my car is worse than yours using the same exact settings. I can't let megasquirt roll into duty cycle like that leaving idle. It will not lazily climb to target, it will lag, lag, lag, violent overshoot and fall on it's face.

And it looks like haltech is ******* garbage for canbus inputs, gereat...

Thought of something. I can use MS3 to calculate cam angles and targets over canbus, then do whatever the **** I want with the valve with my own code. Hard part is done. Still have to deal with MS3 shitting the bed on detecting sync rarely, but what are you gonna do...

Last edited by deezums; 11-11-2020 at 02:37 AM.

#13

Yes - Haltech CAN is locked up which is a PITA. I think of it as an Iphone - expensive (compared to MS), nice to look at, easy to use but locked up.

A number of items are also outboard on Elite - Wideband controller, EGT amplifier, additional I/O adapter etc. This is additional cost and space requirements if you wish to use them.

I should probably re-visit my VVT control settings now I've done a ton on the rest of the map. Something to play with while I develop turbo manifold parts in the background.

A number of items are also outboard on Elite - Wideband controller, EGT amplifier, additional I/O adapter etc. This is additional cost and space requirements if you wish to use them.

I should probably re-visit my VVT control settings now I've done a ton on the rest of the map. Something to play with while I develop turbo manifold parts in the background.

#14

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Scratch that, then. No way in hell I'm spending that much to not be able to read data off canbus, but a elite 1500 is ~$1300 and a MS3 pro is ~$1300, so it's not even any more expensive. I've already got a ton of hardware that broadcasts data, I'm not replacing it all. I can't replace it all with their IO boxes if money were no concern, analog sucks and most of my external hardware is never analog. I would have to make a bunch of DACs, too. It's friggen 2020...

Plus it doesn't do miata 36-2, or anything other than a single tooth cam while running a missing tooth crank trigger. Not anywhere near as big a deal to me, but it's there.

Plus it doesn't do miata 36-2, or anything other than a single tooth cam while running a missing tooth crank trigger. Not anywhere near as big a deal to me, but it's there.

#16

By CAN locked I'm refering to what I have read: The Haltech uses proprietary CAN messaging, so you are limited to using only Haltech CAN devices for inputs to the ECU unless the external device manufacturer has specifically made it on their protocol.

You can read CAN messaging out of the ECU and Haltech will provide the CAN protocol - again this may be a faff to setup and depends on the flexibility of your other devices.

Too many horrible stories of voltage/ground offsets on analogue wideband inputs for me to try it.

You can read CAN messaging out of the ECU and Haltech will provide the CAN protocol - again this may be a faff to setup and depends on the flexibility of your other devices.

Too many horrible stories of voltage/ground offsets on analogue wideband inputs for me to try it.

#17

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Yes, it's locked 100%. Edit : Few days later (weekend) and Haltech has sent me the entire canbus protocol they currently have implemented. From 100% locked to as open as the current code allows. PM me if you want copies.

For example, my wideband broadcasts 2 unsigned data bits at offset zero on CAN ID 1000 or 0x3E8. In megasquirt I can go into can receiving and tell it this info. Then, every time it sees a canbus packet with address 0x3E8 it will copy the data into the running parameters. I do this for EGT, baro, accelerometers, yaw, pitch, and roll, and a bunch of other things that are never, ever analog signals in the first place. Haltech has decided this is too complicated for most people (data type, size, offset and address) so they don't implement it.

I could buy an IO box and decode the protocol and implement it myself, but that's ******* bullshit I shouldn't have to do.

As far as reading live data, that is supported. A similar comparison would be MS3's dash broadcasting.

For example, my wideband broadcasts 2 unsigned data bits at offset zero on CAN ID 1000 or 0x3E8. In megasquirt I can go into can receiving and tell it this info. Then, every time it sees a canbus packet with address 0x3E8 it will copy the data into the running parameters. I do this for EGT, baro, accelerometers, yaw, pitch, and roll, and a bunch of other things that are never, ever analog signals in the first place. Haltech has decided this is too complicated for most people (data type, size, offset and address) so they don't implement it.

I could buy an IO box and decode the protocol and implement it myself, but that's ******* bullshit I shouldn't have to do.

As far as reading live data, that is supported. A similar comparison would be MS3's dash broadcasting.

Last edited by deezums; 11-16-2020 at 06:02 PM.

#18

So Haltech is probably not for you.

One trick you can do to open up the ECU market to MX5 owners - and I'm surprised a lot have not cottoned onto this: The Haltech Plug and Play harness is available separately. The main ECU connectors use 1.0 superseal connectors. Same as Motec, same as Emtron, Link g4 extreme and a number of others. It would be very simple to use a pre-made Haltech plug and play adapter and loom with other options of ECU. It is very easy to de-pin and repin superseal 1.0 without any specialist tools as pin allocations will be different.

You can also get all OEM ecu settings from the Haltech basemap. An Emtron SL4 with a Haltech plug and play harness would be a pretty strong combo IMO.

One trick you can do to open up the ECU market to MX5 owners - and I'm surprised a lot have not cottoned onto this: The Haltech Plug and Play harness is available separately. The main ECU connectors use 1.0 superseal connectors. Same as Motec, same as Emtron, Link g4 extreme and a number of others. It would be very simple to use a pre-made Haltech plug and play adapter and loom with other options of ECU. It is very easy to de-pin and repin superseal 1.0 without any specialist tools as pin allocations will be different.

You can also get all OEM ecu settings from the Haltech basemap. An Emtron SL4 with a Haltech plug and play harness would be a pretty strong combo IMO.

#19

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,178

Total Cats: 1,681

So Haltech is probably not for you.

One trick you can do to open up the ECU market to MX5 owners - and I'm surprised a lot have not cottoned onto this: The Haltech Plug and Play harness is available separately. The main ECU connectors use 1.0 superseal connectors. Same as Motec, same as Emtron, Link g4 extreme and a number of others. It would be very simple to use a pre-made Haltech plug and play adapter and loom with other options of ECU. It is very easy to de-pin and repin superseal 1.0 without any specialist tools as pin allocations will be different.

You can also get all OEM ecu settings from the Haltech basemap. An Emtron SL4 with a Haltech plug and play harness would be a pretty strong combo IMO.

One trick you can do to open up the ECU market to MX5 owners - and I'm surprised a lot have not cottoned onto this: The Haltech Plug and Play harness is available separately. The main ECU connectors use 1.0 superseal connectors. Same as Motec, same as Emtron, Link g4 extreme and a number of others. It would be very simple to use a pre-made Haltech plug and play adapter and loom with other options of ECU. It is very easy to de-pin and repin superseal 1.0 without any specialist tools as pin allocations will be different.

You can also get all OEM ecu settings from the Haltech basemap. An Emtron SL4 with a Haltech plug and play harness would be a pretty strong combo IMO.

I like my Haltech a good bit. But or 95% percent of NA/NB miata owners the MSPNP-Pro is a better choice.

#20

I've not had an issue with my adapter harness other than adding additional items which I've done pretty quickly as an additional sub loom. The adapter harness could be a very fast way to get a Motec, Emtron, Link G4 Fury etc installed into a miata if you didn't want to take on building a loom to start off (which I did not).

I have nothing against any ecu and I'm not on the sell based on my own purchases. I've not used anything else so cannot comment objectively.

I have nothing against any ecu and I'm not on the sell based on my own purchases. I've not used anything else so cannot comment objectively.