EPIC nuts/studs loosening thread (reposting stupid stuff without reading = warning)

#221

The new BEGI manifolds are 10mm x 1.5, on the inlet side that is. The DP flange is 8mm, but that is determined by the threads on the turbine housing.

I am still going to use Stage-8 fasteners on the DP side, though I am using bolts, not studs/nuts. It should make it a lot easier to install. One of the reasons installation is such a PIA is having to separate the assembly past the end of the stud.

I am still going to use Stage-8 fasteners on the DP side, though I am using bolts, not studs/nuts. It should make it a lot easier to install. One of the reasons installation is such a PIA is having to separate the assembly past the end of the stud.

#222

If you guys will post exactly what is needed, I have a very good friend in the specialty nut & bolt business who may be able to locate what you want.

A286 is the grade type?

Keith said 3/8-24 & 5/16-24 (what length?)

Also what nut?

Not sure he can find anything different, but he has always come through before.

Since I am just getting in to this you sort of need to be specific.

Mac

A286 is the grade type?

Keith said 3/8-24 & 5/16-24 (what length?)

Also what nut?

Not sure he can find anything different, but he has always come through before.

Since I am just getting in to this you sort of need to be specific.

Mac

#223

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

The standard thread A-286 hardware should not be hard to find. The metric is the tough one.

I am looking for the following:

- A-286 is the material (high-strength stainless steel, 150 ksi or so), or whatever the ISO/DIN equivalent material is.

- Socket head cap screws, 10mm x 1.5 pitch, 35mm grip length. Only need 4, but always a good idea to have a couple of extras.

- Washers to go with that too, minimum outer diameter, just slightly larger than the head. The washers preferably need to be A-286 as well, or another high-strength stainless steel, so they do not compress under the load. Only need 4, but always a good idea to have a couple of extras.

If he can find them, great

I am looking for the following:

- A-286 is the material (high-strength stainless steel, 150 ksi or so), or whatever the ISO/DIN equivalent material is.

- Socket head cap screws, 10mm x 1.5 pitch, 35mm grip length. Only need 4, but always a good idea to have a couple of extras.

- Washers to go with that too, minimum outer diameter, just slightly larger than the head. The washers preferably need to be A-286 as well, or another high-strength stainless steel, so they do not compress under the load. Only need 4, but always a good idea to have a couple of extras.

If he can find them, great

#225

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

The other way to go here since I have the S4 manifold, would be to drill out the existing metric threads and through-bolt it to the T2 flange on the exhaust manifold. I think someone raised this idea earlier. This way, standard thread fasteners are available from McMaster.com

But, they are not cheap. For a set of 4 A-286 'super alloy' bolts (3/8"-16), nuts, and washers, it is $143 without shipping.

But, they are not cheap. For a set of 4 A-286 'super alloy' bolts (3/8"-16), nuts, and washers, it is $143 without shipping.

#231

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,189

Total Cats: 1,135

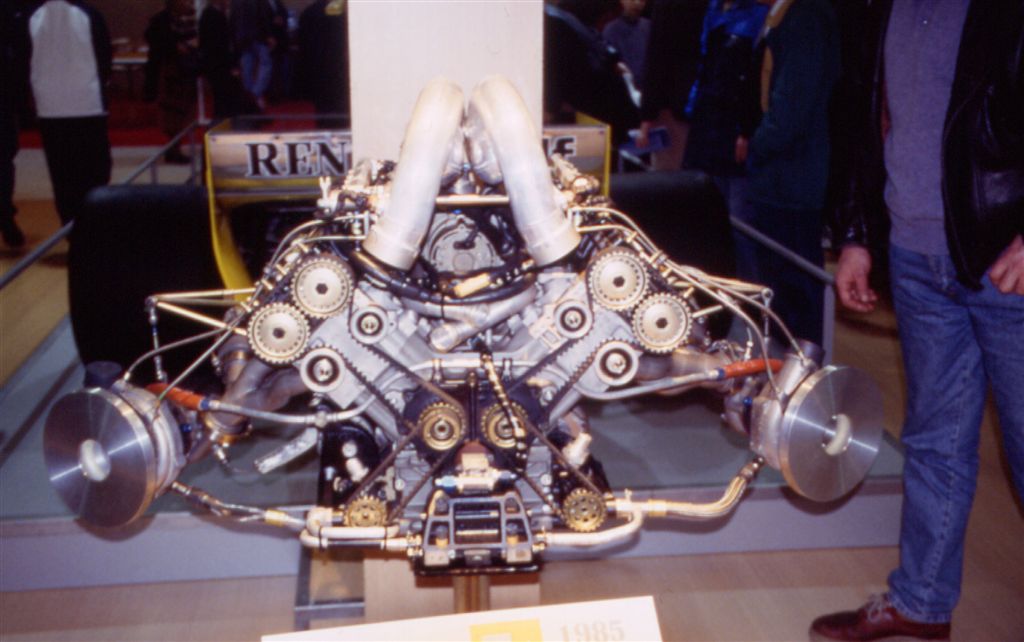

Yeah but those are only like 1500hp....that's nothing really.

One thing I notice with all of these pictures is they double the manifold-head studs/bolts that we have. Otherwise they have seemingly minimal bracing and magical bolts and nuts. So jealous. WHY DOESN'T MY $1250 GREDDY KIT WORK AS GOOD AT A FORMULA ONE CAR?!?!?!!!!!11?!!!!

#235

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

^ LOL maybe. I remember seeing some footage of a modern F1 engine header under test; I think it was on Speed's tech brief during F1 coverage. Bright glowing orange, constantly. It is amazing they hold together. I think they use titanium these days.

Here we go:

Those manifolds on the 1.5L 1300+ HP qualifying engines in the F1 turbo era must have been super hot, unless they ran them richer to compensate.

Here is a shot of a Ferrari turbo F1 motor. 1.5L V6, stupid power. Amazing. It would be nice if we could get 1000+ HP per liter out of the BP. Anyone care to try

Here we go:

Those manifolds on the 1.5L 1300+ HP qualifying engines in the F1 turbo era must have been super hot, unless they ran them richer to compensate.

Here is a shot of a Ferrari turbo F1 motor. 1.5L V6, stupid power. Amazing. It would be nice if we could get 1000+ HP per liter out of the BP. Anyone care to try

Last edited by ZX-Tex; 07-01-2009 at 10:42 AM.

#237

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

^ LOL maybe. I remember seeing some footage of a modern F1 engine header under test; I think it was on Speed's tech brief during F1 coverage. Bright glowing orange, constantly. It is amazing they hold together. I think they use titanium these days.

Here we go:

Those manifolds on the 1.5L 1300+ HP qualifying engines in the F1 turbo era must have been super hot, unless they ran them richer to compensate.

Here is a shot of a Ferrari turbo F1 motor. 1.5L V6, stupid power. Amazing. It would be nice if we could get 1000+ HP per liter out of the BP. Anyone care to try

Here we go:

Those manifolds on the 1.5L 1300+ HP qualifying engines in the F1 turbo era must have been super hot, unless they ran them richer to compensate.

Here is a shot of a Ferrari turbo F1 motor. 1.5L V6, stupid power. Amazing. It would be nice if we could get 1000+ HP per liter out of the BP. Anyone care to try

#239

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

^On that note... I got the 10mm Class 12.9 fasteners from Mcmaster today. Minimum buy was 25 so I have a lot of them. I can ship some out if y'all are interested, but they are pretty cheap if you just want to get them from Mcmaster or somewhere else. Not sure how soon I'll be installing them, still waiting on word for when my rejuvenated turbo will be ready. I have a small tube of resbond ready to go thanks to the group buy. I think I'll risk not using the safety wire and go with resbond for the sake of experimentation.

I also got the Stage-8 bolts I am going to use on the DP flange. It is nice looking hardware, just like in the pictures. They have socket heads so it should make installation a lot easier.

The plan is to mate the manifold and turbo outside of the car, mate that assy to the head, then install the DP. That should now be possible with bolts on the DP (instead of studs). I'll probably use anti-seize on the DP bolts. I may or may not use resbond on the cyl head manifold studs/nuts, have not decided yet.

Still no luck finding the metric A-286 hardware. I found some at the NASA-Goddard site, but the thread pitch was wrong, and I think you can only get those anyway if you are using them to build something for NASA. It is part of a supply of hard-to-find fasteners that Goddard maintains for NASA and their contractors. Good idea really. I suppose we could always have a redux of that Top Gear episode when they tried to launch that POS 3-wheeled Renault into the sky, but replace it with a Miata... Did I mention I have done a little spacecraft development work?

I also got the Stage-8 bolts I am going to use on the DP flange. It is nice looking hardware, just like in the pictures. They have socket heads so it should make installation a lot easier.

The plan is to mate the manifold and turbo outside of the car, mate that assy to the head, then install the DP. That should now be possible with bolts on the DP (instead of studs). I'll probably use anti-seize on the DP bolts. I may or may not use resbond on the cyl head manifold studs/nuts, have not decided yet.

Still no luck finding the metric A-286 hardware. I found some at the NASA-Goddard site, but the thread pitch was wrong, and I think you can only get those anyway if you are using them to build something for NASA. It is part of a supply of hard-to-find fasteners that Goddard maintains for NASA and their contractors. Good idea really. I suppose we could always have a redux of that Top Gear episode when they tried to launch that POS 3-wheeled Renault into the sky, but replace it with a Miata... Did I mention I have done a little spacecraft development work?

#240

2 Props,3 Dildos,& 1 Cat

iTrader: (8)

Join Date: Jun 2005

Location: Fake Virginia

Posts: 19,338

Total Cats: 573

ZX, I'm curious to see how the 12.9 hardware works. In a high-stretch application, they may be more prone to breakage than a lower grade option because of the higher material hardness.

Remember, bolts are springs. Your bolt has to be more springy than what it clamps together or it will break or permanently deform.

Remember, bolts are springs. Your bolt has to be more springy than what it clamps together or it will break or permanently deform.