Oil cooler tech

#481

I mounted my cooler in the same location with the hoses off the bottom. The topic of the inlet location came up in my build thread and it was pointed out that the oil is thick enough to push the air out. I verified this with an IR heat gun, temps were even across the core.

#483

I want to move my oil cooler from immediately behind the front bumper to somewhere safer.

Behind the radiator looks like the best place for me.

One potential further issue with this setup.... As discussed earlier in this thread, an inverted oil cooler is much nicer from an oil line routing aspect in this location, but I'm worried about time to get oil pressure on startup. From Megasquirt datalogs, it takes 1.9 seconds from first firing with my current setup (albeit the oil lines need to be fairly long for that). Does anyone have the time it takes to get oil pressure both before and after an inverted cooler setup?

Behind the radiator looks like the best place for me.

- No need to cut inlet holes - bonnet vents already draw too much attention.

- Nice routing of oil lines not having to pass through any areas that might rub or get caught in a minor incident.

- The oil cooler will get fed warm air

- An extra heat exchanger will impact flow through radiator (and so coolant temps in a marginal system)

One potential further issue with this setup.... As discussed earlier in this thread, an inverted oil cooler is much nicer from an oil line routing aspect in this location, but I'm worried about time to get oil pressure on startup. From Megasquirt datalogs, it takes 1.9 seconds from first firing with my current setup (albeit the oil lines need to be fairly long for that). Does anyone have the time it takes to get oil pressure both before and after an inverted cooler setup?

#484

This might be a basic question but I'd like some input from others here.

I have a 1.6l in a '91 running a Rotrex at around 200 whp (let's not talk about tq here). I have the FM oil cooler kit bolted up to the steering rack with a small duct in front capturing and pushing air through it. I just hooked up my oil temp gauge using an adapter on the oil drain plug. After driving around all day I didn't see temps above 175 degrees. I spent a good 30 mins on the highway in 4th at high rpms just to see if I could get oil temps up and really not much happened above 170. From what I understand this is "bad".

With the setup I have, is this bad? Am I over thinking this? I expected temps to be higher after a couple hours of driving. Am I just not creating enough heat driving on the highway?

I have a 1.6l in a '91 running a Rotrex at around 200 whp (let's not talk about tq here). I have the FM oil cooler kit bolted up to the steering rack with a small duct in front capturing and pushing air through it. I just hooked up my oil temp gauge using an adapter on the oil drain plug. After driving around all day I didn't see temps above 175 degrees. I spent a good 30 mins on the highway in 4th at high rpms just to see if I could get oil temps up and really not much happened above 170. From what I understand this is "bad".

With the setup I have, is this bad? Am I over thinking this? I expected temps to be higher after a couple hours of driving. Am I just not creating enough heat driving on the highway?

#487

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

The sump is the correct place to measure from. There should be very little difference in temp from the sump to the oil cooler inlet, since that oil is just passing through the pickup tube and pump. (e: that is wrong)

The oil in the sump is the stuff that's just fallen off the engine, and that's the temp you're trying to measure.

The oil in the sump is the stuff that's just fallen off the engine, and that's the temp you're trying to measure.

Last edited by Savington; 07-03-2019 at 09:25 PM.

#488

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

This might be a basic question but I'd like some input from others here.

I have a 1.6l in a '91 running a Rotrex at around 200 whp (let's not talk about tq here). I have the FM oil cooler kit bolted up to the steering rack with a small duct in front capturing and pushing air through it. I just hooked up my oil temp gauge using an adapter on the oil drain plug. After driving around all day I didn't see temps above 175 degrees. I spent a good 30 mins on the highway in 4th at high rpms just to see if I could get oil temps up and really not much happened above 170. From what I understand this is "bad".

With the setup I have, is this bad? Am I over thinking this? I expected temps to be higher after a couple hours of driving. Am I just not creating enough heat driving on the highway?

I have a 1.6l in a '91 running a Rotrex at around 200 whp (let's not talk about tq here). I have the FM oil cooler kit bolted up to the steering rack with a small duct in front capturing and pushing air through it. I just hooked up my oil temp gauge using an adapter on the oil drain plug. After driving around all day I didn't see temps above 175 degrees. I spent a good 30 mins on the highway in 4th at high rpms just to see if I could get oil temps up and really not much happened above 170. From what I understand this is "bad".

With the setup I have, is this bad? Am I over thinking this? I expected temps to be higher after a couple hours of driving. Am I just not creating enough heat driving on the highway?

#489

The sump is the correct place to measure from. There should be very little difference in temp from the sump to the oil cooler inlet, since that oil is just passing through the pickup tube and pump. The oil in the sump is the stuff that's just fallen off the engine, and that's the temp you're trying to measure.

(I do have a band-aid sender-in-the-drain-plug, rather than having a well position oil temp bung, however, so perhaps that accounts for at least some of it)

--Ian

#492

No, I meant what I typed.

So either the oil pump and cooler are heating the oil up by 20-ish degrees (which seems unlikely), or the sender in the oil pan drain plug is not accurately reflecting the temperature of the oil that the pickup is pulling out. Swapping the senders doesn't change it, either, so it's a mechanical thing not an electronic one.

--Ian

So either the oil pump and cooler are heating the oil up by 20-ish degrees (which seems unlikely), or the sender in the oil pan drain plug is not accurately reflecting the temperature of the oil that the pickup is pulling out. Swapping the senders doesn't change it, either, so it's a mechanical thing not an electronic one.

--Ian

#494

This disparity only manifests on track, though, and I've only tried it in ~ 20 minute sessions. It's possible that might reverse given enough time to heat soak the pan/etc.

--Ian

#496

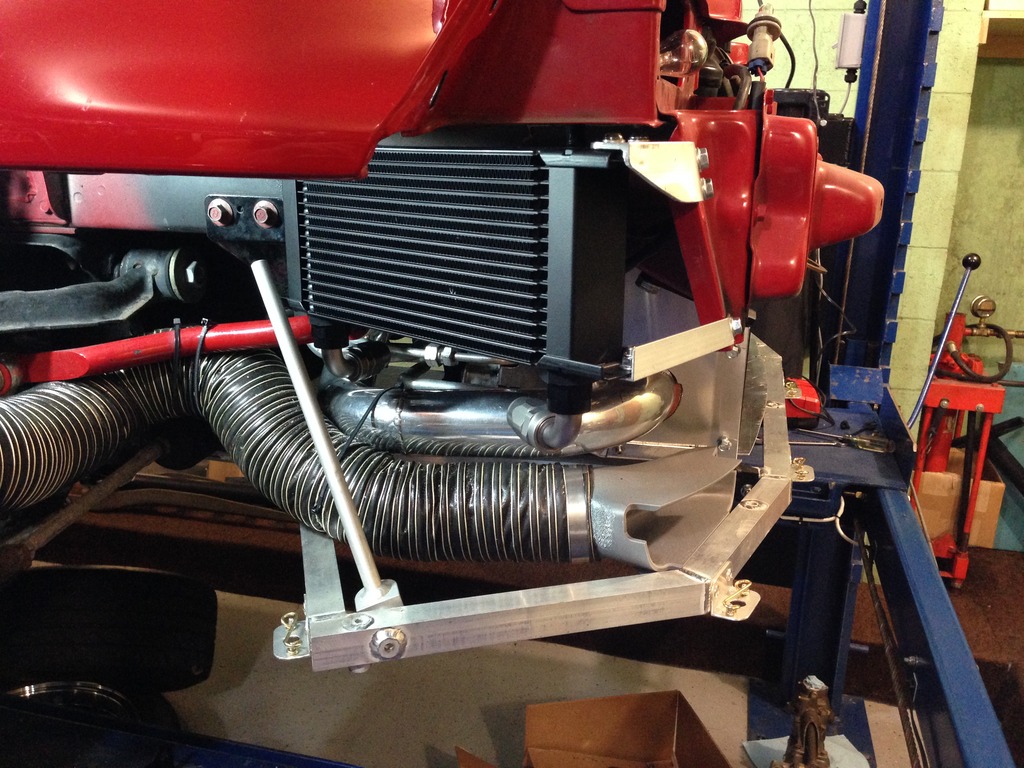

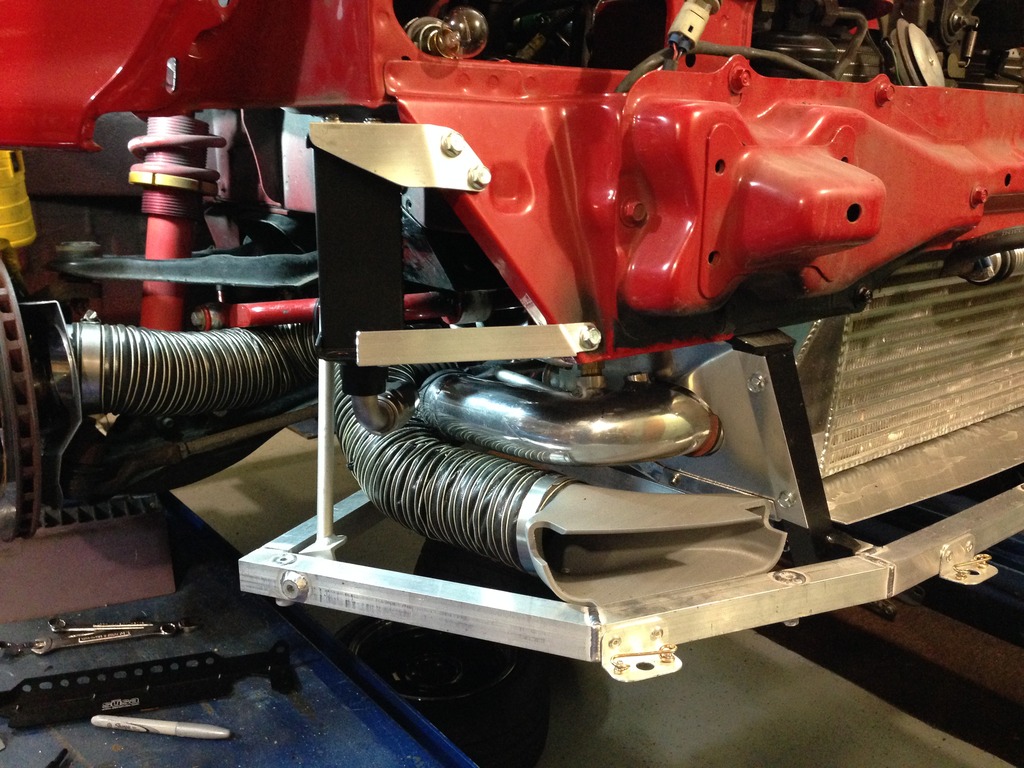

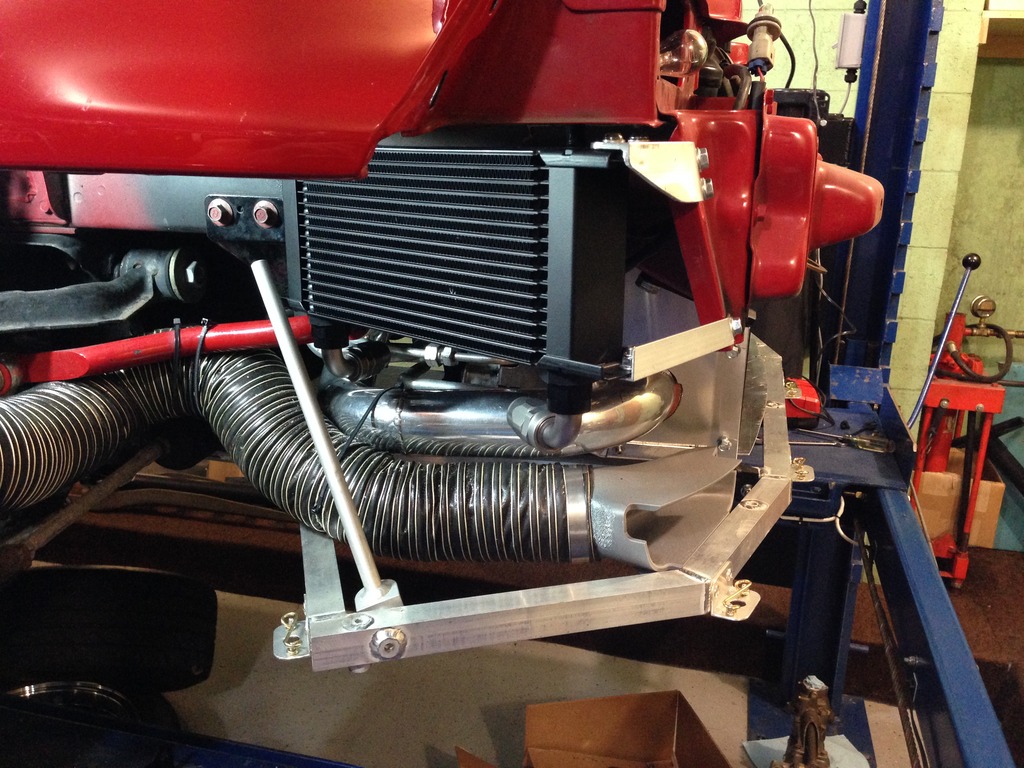

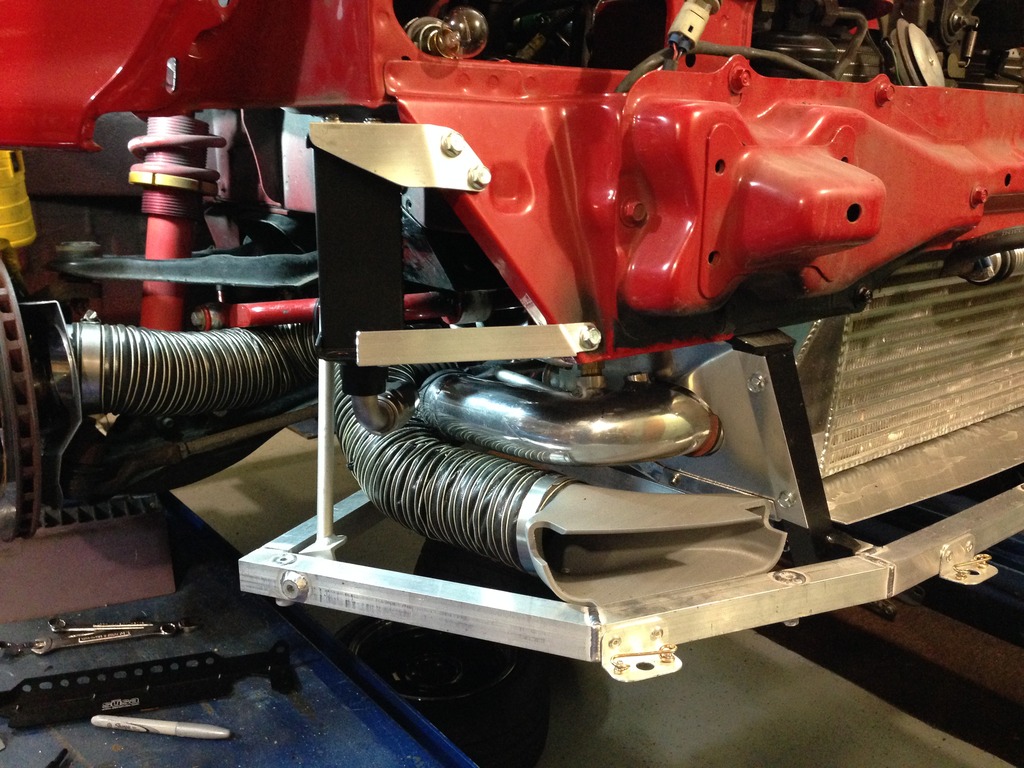

I recently finished installing my oil cooler kit from Trackspeed (19 row) and I thought I would share.

First off, I have an intercooler and A/C already in front of my Koyo 38mm rad. They are fairly well ducted but i was already seeing water temps creeping upward throughout each 20 minute track session without ever leveling off, so i didn't think stacking the oil cooler with the other heat exchangers was a good idea. I decided to put it as high as possible in the front right corner of the car.

Being that the wheel well is a high pressure area with rocks and debris flying around constantly, I decided that ducting the exit air out the front bumper just in front of the wheel would be…better. In other words I stole the idea from Ryan Passey.

I started out by fabricating the mounting brackets and adding rivet nuts to the chassis to bolt it in. Part of the bracketry was for attaching the duct work.

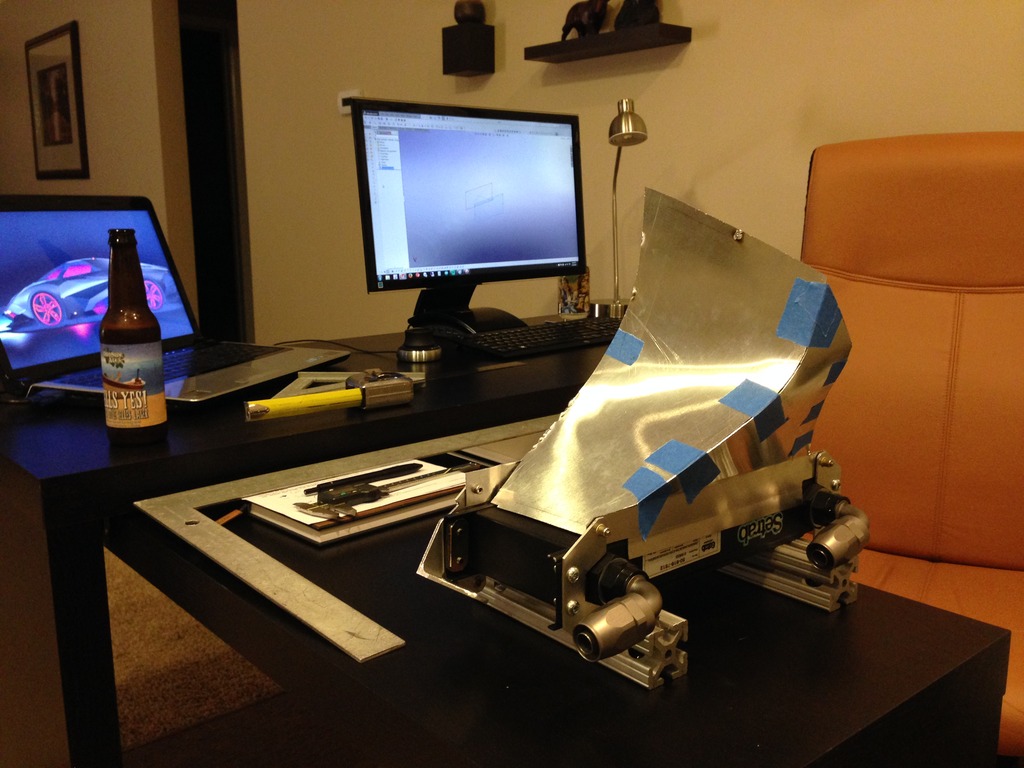

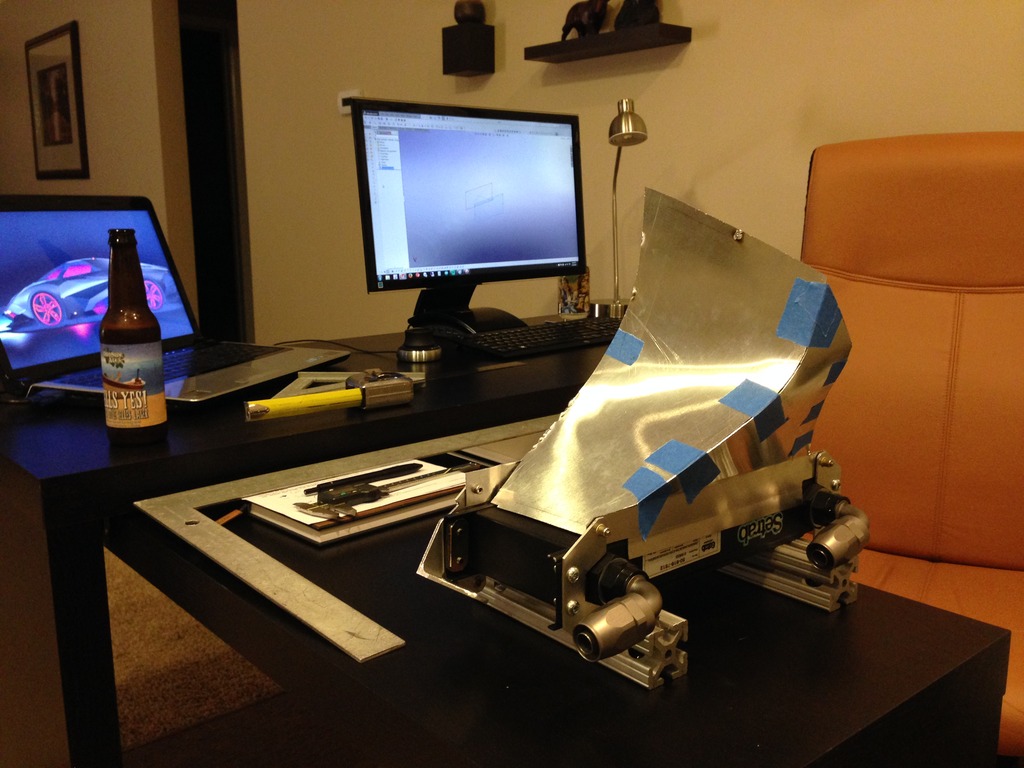

First I attempted to fabricate the ducting from aluminum. I had a feeling I was using too thin of a gauge and it would be hard to weld. I was right - I just don't have the chops to weld .035" alum, so I gave up on welding and took a more "fun" approach

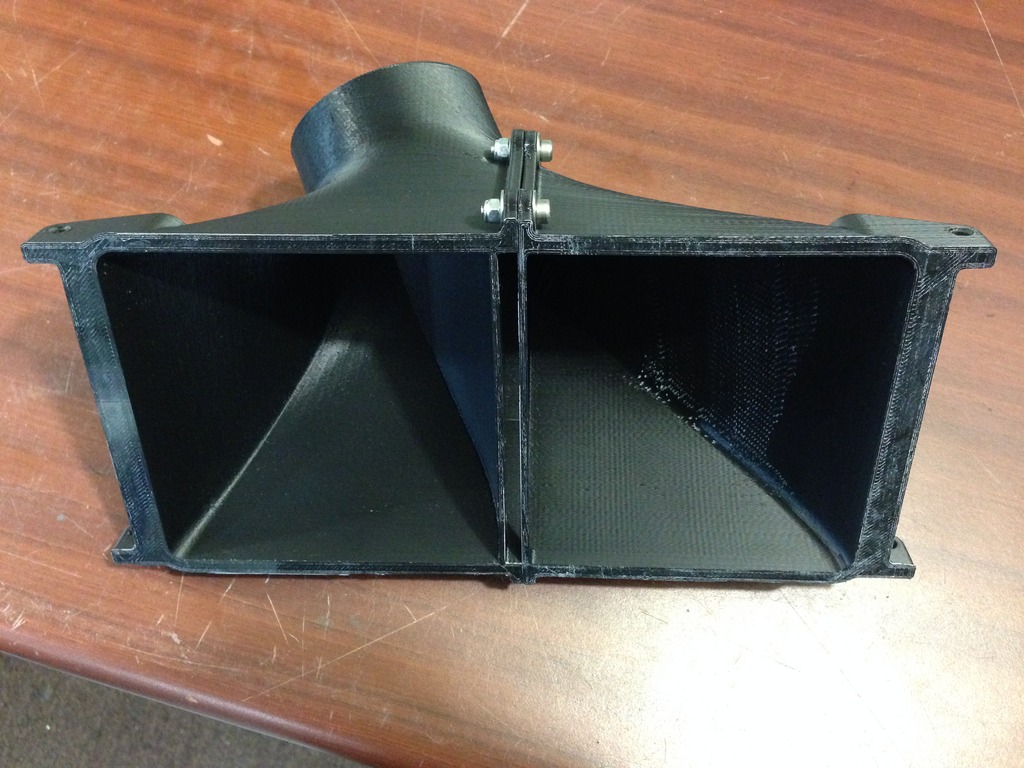

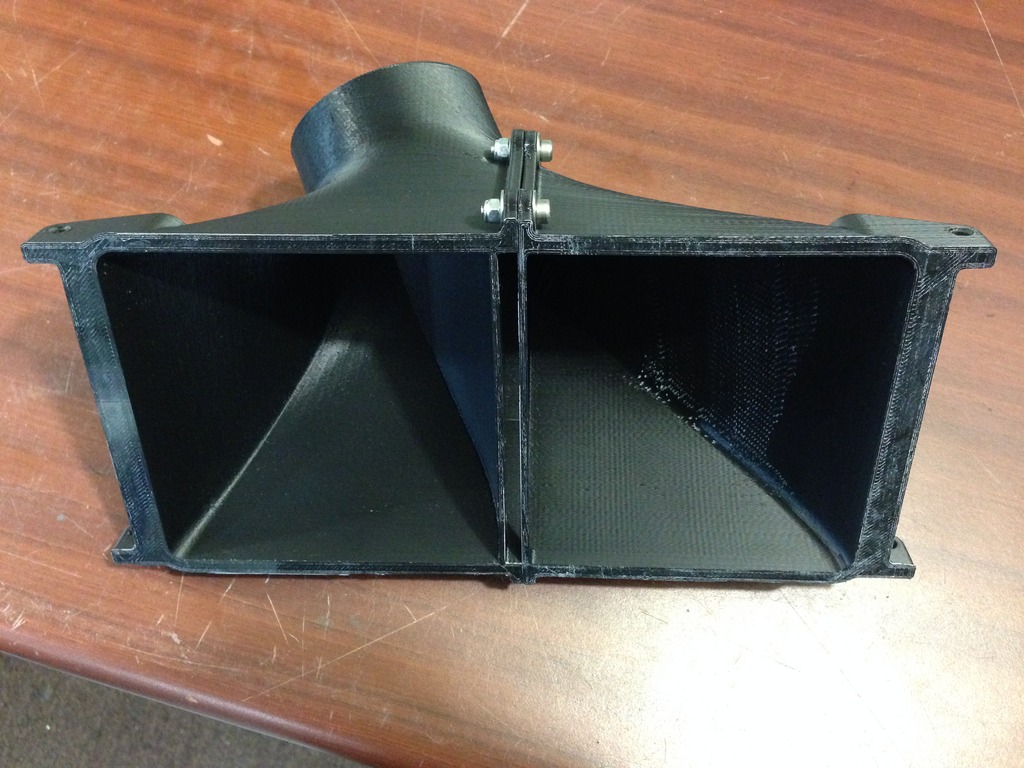

Being that I have a home made 3-D printer in my kitchen, it was the natural choice for plan B. I started out by transferring the measurements off the aluminum prototype into a SolidWorks model. I had to print both the inlet side and the outlet side in two halves, since my build platform is only 8x8x11. It took a few iterations and a couple failed prints but I finally got some decent parts! They are printed from ABS so hopefully it will be able to take the temperature. We will see what happens at the next track day.

The inlet starts out as a 3" aluminum tube that I mounted to the frame. I cut a hole in the bumper and poked it out. The printed inlet duct is connected to the aluminum tube via a short piece of brake duct hose, which keeps some flexibility in the system in case the front gets bumped (the printed parts really aren't that strong).

First off, I have an intercooler and A/C already in front of my Koyo 38mm rad. They are fairly well ducted but i was already seeing water temps creeping upward throughout each 20 minute track session without ever leveling off, so i didn't think stacking the oil cooler with the other heat exchangers was a good idea. I decided to put it as high as possible in the front right corner of the car.

Being that the wheel well is a high pressure area with rocks and debris flying around constantly, I decided that ducting the exit air out the front bumper just in front of the wheel would be…better. In other words I stole the idea from Ryan Passey.

I started out by fabricating the mounting brackets and adding rivet nuts to the chassis to bolt it in. Part of the bracketry was for attaching the duct work.

First I attempted to fabricate the ducting from aluminum. I had a feeling I was using too thin of a gauge and it would be hard to weld. I was right - I just don't have the chops to weld .035" alum, so I gave up on welding and took a more "fun" approach

Being that I have a home made 3-D printer in my kitchen, it was the natural choice for plan B. I started out by transferring the measurements off the aluminum prototype into a SolidWorks model. I had to print both the inlet side and the outlet side in two halves, since my build platform is only 8x8x11. It took a few iterations and a couple failed prints but I finally got some decent parts! They are printed from ABS so hopefully it will be able to take the temperature. We will see what happens at the next track day.

The inlet starts out as a 3" aluminum tube that I mounted to the frame. I cut a hole in the bumper and poked it out. The printed inlet duct is connected to the aluminum tube via a short piece of brake duct hose, which keeps some flexibility in the system in case the front gets bumped (the printed parts really aren't that strong).

I have been using FM Oil Cooler kit for sometime now. But over the weekend it was one of the hotter days and the oil temp gets too high after 5 or so hot laps, so I guess I need to do something about the ducting work or fit one like yours. Would you sell your 3d printed duct and brackets?

#497

Wow amazing job!

I have been using FM Oil Cooler kit for sometime now. But over the weekend it was one of the hotter days and the oil temp gets too high after 5 or so hot laps, so I guess I need to do something about the ducting work or fit one like yours. Would you sell your 3d printed duct and brackets?

I have been using FM Oil Cooler kit for sometime now. But over the weekend it was one of the hotter days and the oil temp gets too high after 5 or so hot laps, so I guess I need to do something about the ducting work or fit one like yours. Would you sell your 3d printed duct and brackets?

FM cooler uses -8 lines. Too small for a BP.

That is all

__________________

#499

I want to move my oil cooler from immediately behind the front bumper to somewhere safer.

Behind the radiator looks like the best place for me.

One potential further issue with this setup.... As discussed earlier in this thread, an inverted oil cooler is much nicer from an oil line routing aspect in this location, but I'm worried about time to get oil pressure on startup. From Megasquirt datalogs, it takes 1.9 seconds from first firing with my current setup (albeit the oil lines need to be fairly long for that). Does anyone have the time it takes to get oil pressure both before and after an inverted cooler setup?

Behind the radiator looks like the best place for me.

- No need to cut inlet holes - bonnet vents already draw too much attention.

- Nice routing of oil lines not having to pass through any areas that might rub or get caught in a minor incident.

- The oil cooler will get fed warm air

- An extra heat exchanger will impact flow through radiator (and so coolant temps in a marginal system)

One potential further issue with this setup.... As discussed earlier in this thread, an inverted oil cooler is much nicer from an oil line routing aspect in this location, but I'm worried about time to get oil pressure on startup. From Megasquirt datalogs, it takes 1.9 seconds from first firing with my current setup (albeit the oil lines need to be fairly long for that). Does anyone have the time it takes to get oil pressure both before and after an inverted cooler setup?

However from an oil cooling aspect, it's not as effective as I'd like on track, and maybe too effective on the road.

Compared to the 13 row cooler in free air in front of rad, this runs 10C cooler, but as I found out on my last trackday during a bit of an unseasonably warm spell, it reached 123C peak in 23C ambient. I had made some shrouding between the rad and the oil cooler to force air into it, this looks like its fallen off. Does anyone have any recommendations for tape that would stick to an oil cooler at 120C+? I'll also make some shrouding improvements in front of the rad, 123C is a bit hot for my liking.

On the road, in 5C ambient (with 93C Mocal thermostat and still the OEM oil warmer), it can only maintain 80C above 70mph. Drop to a 50mph zone and it falls to low 70s.

#500

I installed a 25 row Setrab behind the radiator. I was able to remove 1.5 metres of oil line compared to my routing at the front of the car. This has reduced my oil pressure lag on startup to 1.4s which is a nice improvement. (I kept the cooler upright)

However from an oil cooling aspect, it's not as effective as I'd like on track, and maybe too effective on the road.

Compared to the 13 row cooler in free air in front of rad, this runs 10C cooler, but as I found out on my last trackday during a bit of an unseasonably warm spell, it reached 123C peak in 23C ambient. I had made some shrouding between the rad and the oil cooler to force air into it, this looks like its fallen off. Does anyone have any recommendations for tape that would stick to an oil cooler at 120C+? I'll also make some shrouding improvements in front of the rad, 123C is a bit hot for my liking.

On the road, in 5C ambient (with 93C Mocal thermostat and still the OEM oil warmer), it can only maintain 80C above 70mph. Drop to a 50mph zone and it falls to low 70s.

However from an oil cooling aspect, it's not as effective as I'd like on track, and maybe too effective on the road.

Compared to the 13 row cooler in free air in front of rad, this runs 10C cooler, but as I found out on my last trackday during a bit of an unseasonably warm spell, it reached 123C peak in 23C ambient. I had made some shrouding between the rad and the oil cooler to force air into it, this looks like its fallen off. Does anyone have any recommendations for tape that would stick to an oil cooler at 120C+? I'll also make some shrouding improvements in front of the rad, 123C is a bit hot for my liking.

On the road, in 5C ambient (with 93C Mocal thermostat and still the OEM oil warmer), it can only maintain 80C above 70mph. Drop to a 50mph zone and it falls to low 70s.

Initially I mounted my huge 310mm x 19 row vertically behind the radiator (where the AC fan would go), with some brackets supporting it a few cm away from the core face. This is obviously bad as you are not getting forced air, so I added some cut aluminium sheet to the passenger side, and sealed top and bottom with Al tape.

This proved not efficient enough for the track, so I re-did this plate and added another one on the other side, this time only a few mm between the edge of the plates and the core.

This was suficient for track use with ITBs and then at 230hp with the rotrex, even in a decently warm day (24-25C) I reached a peak oil temperature of 110, but at that point water temperature was 103C.

I did not have perfect ducting during that last trackday and my radiator was mounted in the AC condenser slots, with my large IC I had a small-ish gap between the IC and front crossmember which meant low airflow to the top of the rad.

Since this positioning means Oil temperature is a bit more influenced by Water Temp, if you have good stable water temperatures and you duct them together it should be enough.

I have since moved the rad back to the original position, but now my oil cooler is flat against the Rad, since there is no space due to the large RB sway:

This means I shouldnt need to add side plates to duct it, but I will if needed. Combined with my better ducting, greatly increasing the gap for air to go around the IC and adding reroute my water temps should be much reduced, as well as my oil temps.

Of note, I have the rotrex oil cooler at the front on the side and directly in front of where the oil cooler is, so that was an extra impediment to cooling.

Before I had the rotrex, with ITBs at 170hp, on a track where I spent more time at higher RPM and a hotter day, I saw 95C oil temperatures.

TD;DR: If you FULLY duct the Oil cooler to the Rad, and its decently big, it should be enough even for Portugal Summer temperatures