Splitter material--what do you use?

#81

I'd like to see someone give bamboo a try. It's light, extremely hard but also bends and has long strands that would seem to me to act a lot like carbon...cheap carbon. It would need to be weatherized just like any other wood product.

I know that there are laminated floor panels for sale, but I'm not sure if any sheets are available in the right thickness.

I know that there are laminated floor panels for sale, but I'm not sure if any sheets are available in the right thickness.

thats ******* expensive.

#83

Project Panels Mahogany Plywood (Price Varies by Size)-1840 at The Home Depot

$24.80 in a 4X8 sheet

One sheet gets divided up into 3 pieces and laminated double layer thick in the parts that pick up my mounting and that stick forward of the air dam.

Last edited by bbundy; 10-08-2014 at 02:25 PM.

#89

US Composites is cheaper, seems to generate the same results as west systems.

Epoxy : Epoxy Resins and Hardeners

Epoxy : Epoxy Resins and Hardeners

#91

not sure if its already been mentioned, but I used 1/2" fiberglass reinforced plywood for one on my integra. Its the stuff that trailer walls are often made of.

Wasn't the lightest thing in the world, but super strong and I could stand on it.

How do you guys typically attach them under the car? Any consideration to a design that can shear off easily in on off-track excursion or impact?

Wasn't the lightest thing in the world, but super strong and I could stand on it.

How do you guys typically attach them under the car? Any consideration to a design that can shear off easily in on off-track excursion or impact?

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

#93

Supporting Vendor

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

The 949 Racing method uses cables in front, and the rear is not hard mounted, just set on top of a lip of the subframe. The advantage to this is the front of the splitter can lift if you scrape over a curb, but it is sturdy under downward pressure.

-Ryan

#94

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

+1 to hardmounted. I use a steel/aluminum frame mounted to the front crash support. Rear is bolted to the subframe with two M6 bolts, nothing structural. In a mega-big frontal impact, the bolts will pull through the aluminum tube and the splitter will break free, but otherwise it will stay in place. No bumper attachments.

#95

+1 to hardmounted. I use a steel/aluminum frame mounted to the front crash support. Rear is bolted to the subframe with two M6 bolts, nothing structural. In a mega-big frontal impact, the bolts will pull through the aluminum tube and the splitter will break free, but otherwise it will stay in place. No bumper attachments.

When I eventually build one for this car, the plan will be to make it just strong enough to be functional, but the first thing to break in an impact.

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

#96

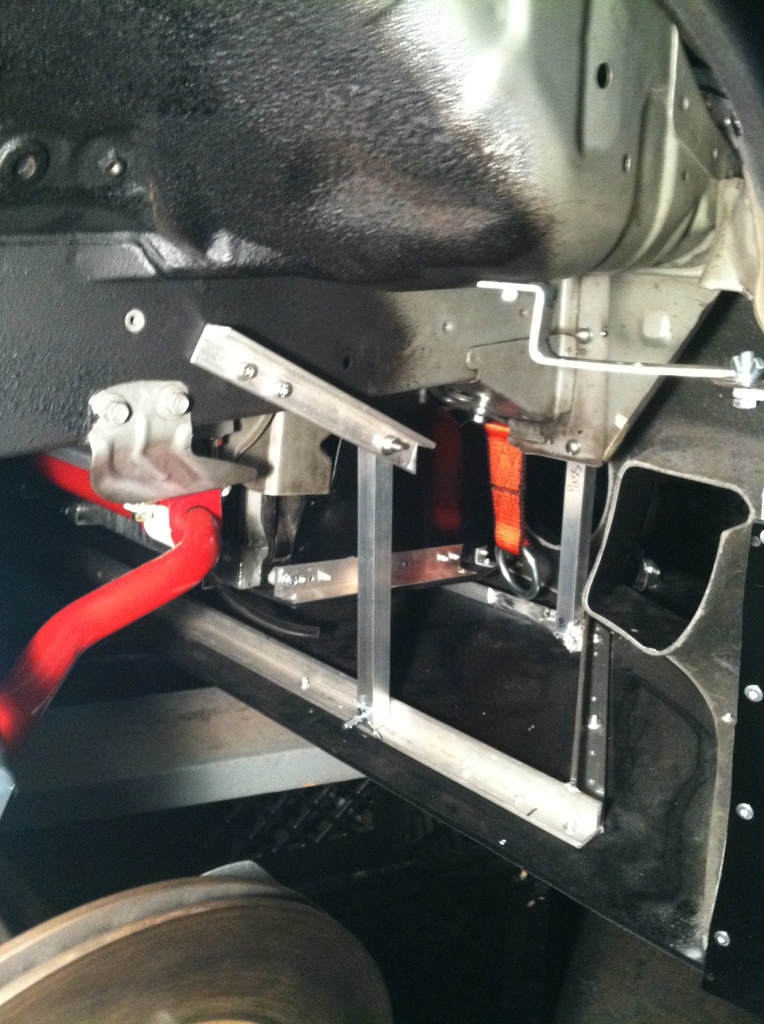

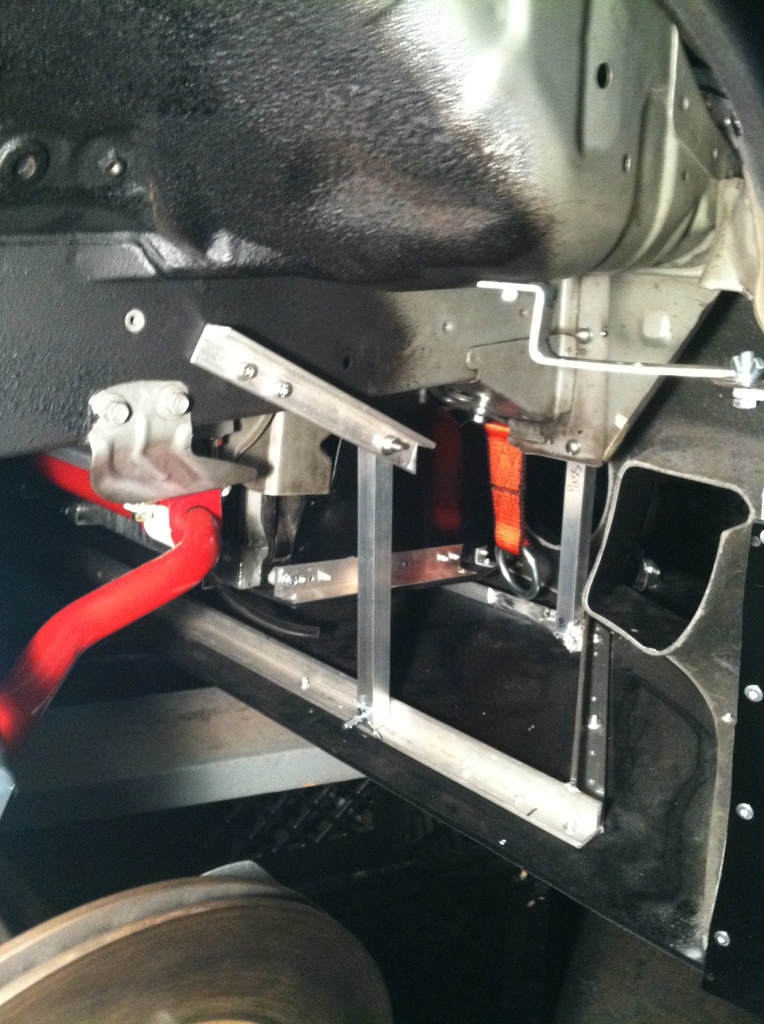

Here's how I made my frame and mounted it. The forward uprights mount via two bolts, and rear use stock bolt holes, the two pieces of aluminum would hopefully act as a hinge and pivot after the front upright tears/pulls off the bolts sandwiching it to the crash support area. Those bolt heads are just slightly bigger than the holes so it should be able to rip off without bending that structure it's bolted too. Trapezoid frame is riveted to the splitter.

#97

3/8 birch. 4 simple mounting points are 10x stronger than I ever expected. Used to use aluminum until an off at a very expensive, low track time event. The aluminum folded down on one side and back at the hot pit lane I couldn't kick, stomp, or jump my fat *** on it hard enough to rip it off. This is my old small alum. splitter. just 2 L shaped aluminum brackets with all thread on front, and oem bumper support rod at rear.