Honda intake manifold

#221

He may be addressing the fact that the runners almost exactly match the BP flange, but not the B6.

Still, we've been over it several times in this thread...cut the 1.6L mani 3" back from flange, and cut the Honda mani where the runners converge.

I'll let you know exactly how far back that is when I get it done. Gotta swap shocks again before I can get to it though.

Still, we've been over it several times in this thread...cut the 1.6L mani 3" back from flange, and cut the Honda mani where the runners converge.

I'll let you know exactly how far back that is when I get it done. Gotta swap shocks again before I can get to it though.

Thanks, I saw this, but was'nt sure about it,

#227

I do everything in SolidWorks and MATLAB here at A&M, which stinks now since the place I picked up my Associates taught us Maple, C++ and AutoCAD. It's like learning new languages -literally- sometimes.

At least I use AutoCAD daily for work.

240, will send you a PM, but I'm basically trying to model the power curve of a car and relate that to vehicle speeds through a transmission model for a project due at the end of the month. I understand all this mechanically, but am having trouble telling the computer what to do with it.

At least I use AutoCAD daily for work.

240, will send you a PM, but I'm basically trying to model the power curve of a car and relate that to vehicle speeds through a transmission model for a project due at the end of the month. I understand all this mechanically, but am having trouble telling the computer what to do with it.

#228

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

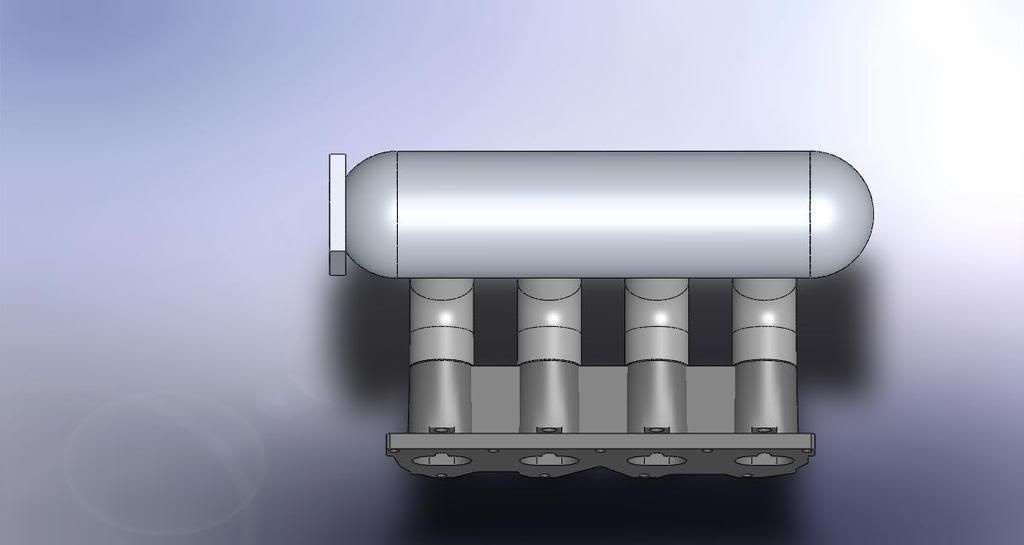

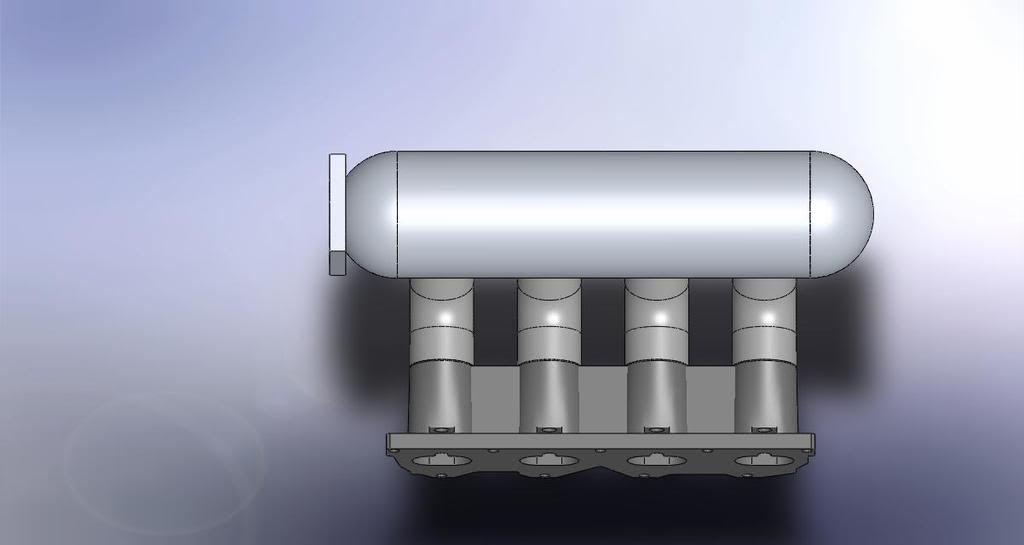

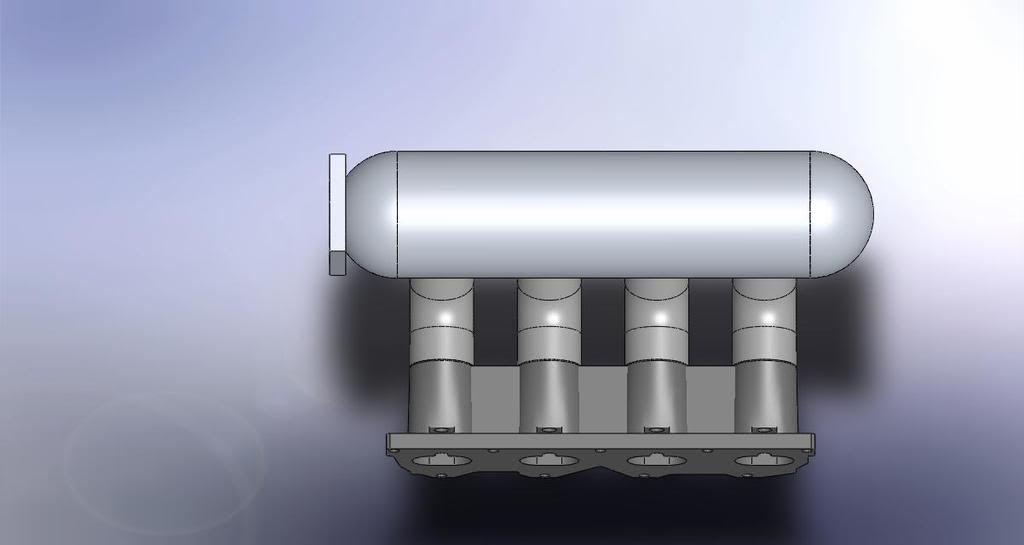

I used Solidworks to come up with mine, just didn't know how to setup the boundry layer crap up correctly in Floworks.

Here you can clearly see that extra 1" of runner length I was talking about.

Here you can clearly see that extra 1" of runner length I was talking about.

#233

The theory goes that shorter runners are good for higher RPM flow relative to longer runners which tend to help with velocity into the combustion chamber and that means great low-end flow.

More air flow at low RPMs tend to make a nice early, fat band of TQ at low RPM where lots of flow up top tends to make for TQ at high RPM. High RPM TQ = HP.

But its a lot more complex than that and I really dont know much beyond that basic idea.

More air flow at low RPMs tend to make a nice early, fat band of TQ at low RPM where lots of flow up top tends to make for TQ at high RPM. High RPM TQ = HP.

But its a lot more complex than that and I really dont know much beyond that basic idea.

#236

Large diameter runner= lower flow velocity and higher CFM flow capacity

Longer intake runner = lower RPM torque peak

Shorter intake runner = higher RPM torque peak

Combine long/short with small/large to match cylinder head airflow and engine RPM range

Long runners are not always limited to low RPM stump pullers; a well designed long runner tunnel ram manifold makes more midrange torque and high end power than a state of the art single plane short runner hi-rise manifold.

#237

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

That is a gross oversimplification.

Shorter runners resonate over a larger range giving a flat torque band (both high and low)

Longer runners resonate in a shorter range giving a 'lump' of torque in a specific spot.

#238

I thought runner length had more to do with Helmholtz frequencies causing pulses which help to stack air into the intake valve. Same thing is commonly done with exhaust headers. You can time the returning pressure wave from the last valve opening to return at the same time the valve will open again with proper length runners.

This of course only works for a certain rpm, or small range, and you can't make runners that are the full wavelength, so they usually divide the wavelength by four, much like a sonotube application.

I'm pulling this all from memory and don't have time to back it up with research so I may be off, and I've yet actually ran the calc for our motors and desired powerband. I just did a simple interpolation between stock runner length and Honda B series aftermarket runners (tuned for 8200rpm!) to get an idea of how long our runners should be to keep torque up from the usual drop-off after 5K rpm to redline.

This of course only works for a certain rpm, or small range, and you can't make runners that are the full wavelength, so they usually divide the wavelength by four, much like a sonotube application.

I'm pulling this all from memory and don't have time to back it up with research so I may be off, and I've yet actually ran the calc for our motors and desired powerband. I just did a simple interpolation between stock runner length and Honda B series aftermarket runners (tuned for 8200rpm!) to get an idea of how long our runners should be to keep torque up from the usual drop-off after 5K rpm to redline.

#239

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

The air in your IM travels like sound waves. When the intake valve closes, more and more waves of air pile up within the runner. It then bounces around within the runner until the intake valve opens again. The plenum acts as a resonance chamber.

When my IM was fitted I had a nasty resonance at exactly 4000RPM.

view it yourself here:

I held my foot as steady as I could to bring the revs up to 4000RPM, as soon as you hit it it's like the starting gun at the Kentucky Derby, the revs just take off.

I found that the throttle cable was oscillating so violently and so rapidly it was actually pulling the throttle cable tight thus opening the throttle further. When driving you could feel the throttle pedal literally drop to the floor. I had to dampen this resonance on the throttle cable by fitting some vacuum line around it.

With that said, I elaborate on my simplification:

Longer runners will increase torque in lower RPMs because they have a lower resonant frequency. Coupled with the fact that the length and combination of typically smaller OEM diameters help increase the air velocity.

Shorter runners will increase torque in higher RPMs because they have a higher resonant frequency. Further exaggerated by the shorter length and combination of typically larger diameters promote higher air flow rates, however hinder low-end performance due to this same fact.

It's all a compromise.

When my IM was fitted I had a nasty resonance at exactly 4000RPM.

view it yourself here:

I held my foot as steady as I could to bring the revs up to 4000RPM, as soon as you hit it it's like the starting gun at the Kentucky Derby, the revs just take off.

I found that the throttle cable was oscillating so violently and so rapidly it was actually pulling the throttle cable tight thus opening the throttle further. When driving you could feel the throttle pedal literally drop to the floor. I had to dampen this resonance on the throttle cable by fitting some vacuum line around it.

With that said, I elaborate on my simplification:

Longer runners will increase torque in lower RPMs because they have a lower resonant frequency. Coupled with the fact that the length and combination of typically smaller OEM diameters help increase the air velocity.

Shorter runners will increase torque in higher RPMs because they have a higher resonant frequency. Further exaggerated by the shorter length and combination of typically larger diameters promote higher air flow rates, however hinder low-end performance due to this same fact.

It's all a compromise.

#240

The lump of torque in a specific spot is probably only achievable if you simultaneously tuned intake runner, cam and exhaust header length to that spot. compare the torque curves of a production TPI 350 Chevy V8 (long runner, small diameter) and a modern LS6 (medium runner, large diameter) and tell me where the "lump of torque" is on the TPI engine.