Begi Intake Manifold

#541

Aahso, thanks girz. I have not actually seen one. In my view, the "flat" guy looks okay.

Psyber: Das ist nicht was Ich haben .... meant no jab, but tested many manifolds.

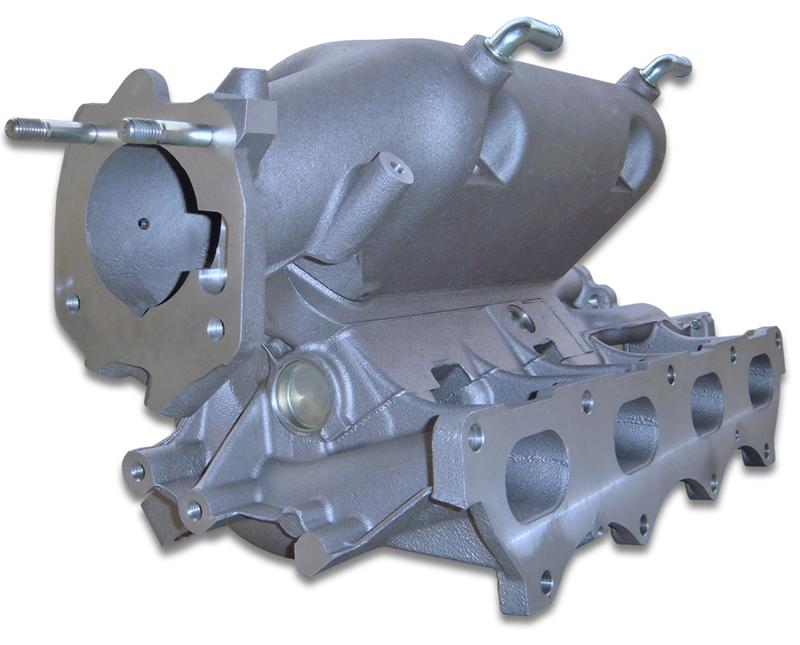

The cast manifold winds up kinda locked in and resists mods. It's also heavy. The fabed manifolds float off into space if not anchored. Castings are the cheapest to make, not counting the pattern work. Patterns are fun to make save an allergy to sawdust.

I like castings, provided one can get inside the things and clean them up. Several other problems exist that I'd like to solve. The throttle position winds up in a clumsey spot and does not inherently contribute to an easy uniform distribution. Better locations all look a bit odd.

Regardless, I'm in the middle of trying to figure it out with thoughts of a new casting. Suggestions are welcome, and I'll consider anything.

corky

Psyber: Das ist nicht was Ich haben .... meant no jab, but tested many manifolds.

The cast manifold winds up kinda locked in and resists mods. It's also heavy. The fabed manifolds float off into space if not anchored. Castings are the cheapest to make, not counting the pattern work. Patterns are fun to make save an allergy to sawdust.

I like castings, provided one can get inside the things and clean them up. Several other problems exist that I'd like to solve. The throttle position winds up in a clumsey spot and does not inherently contribute to an easy uniform distribution. Better locations all look a bit odd.

Regardless, I'm in the middle of trying to figure it out with thoughts of a new casting. Suggestions are welcome, and I'll consider anything.

corky

#542

Glad this thread is fairly recent, I've had a couple of problems with my manifold but no one else has started a thread discussing the same problems as me.

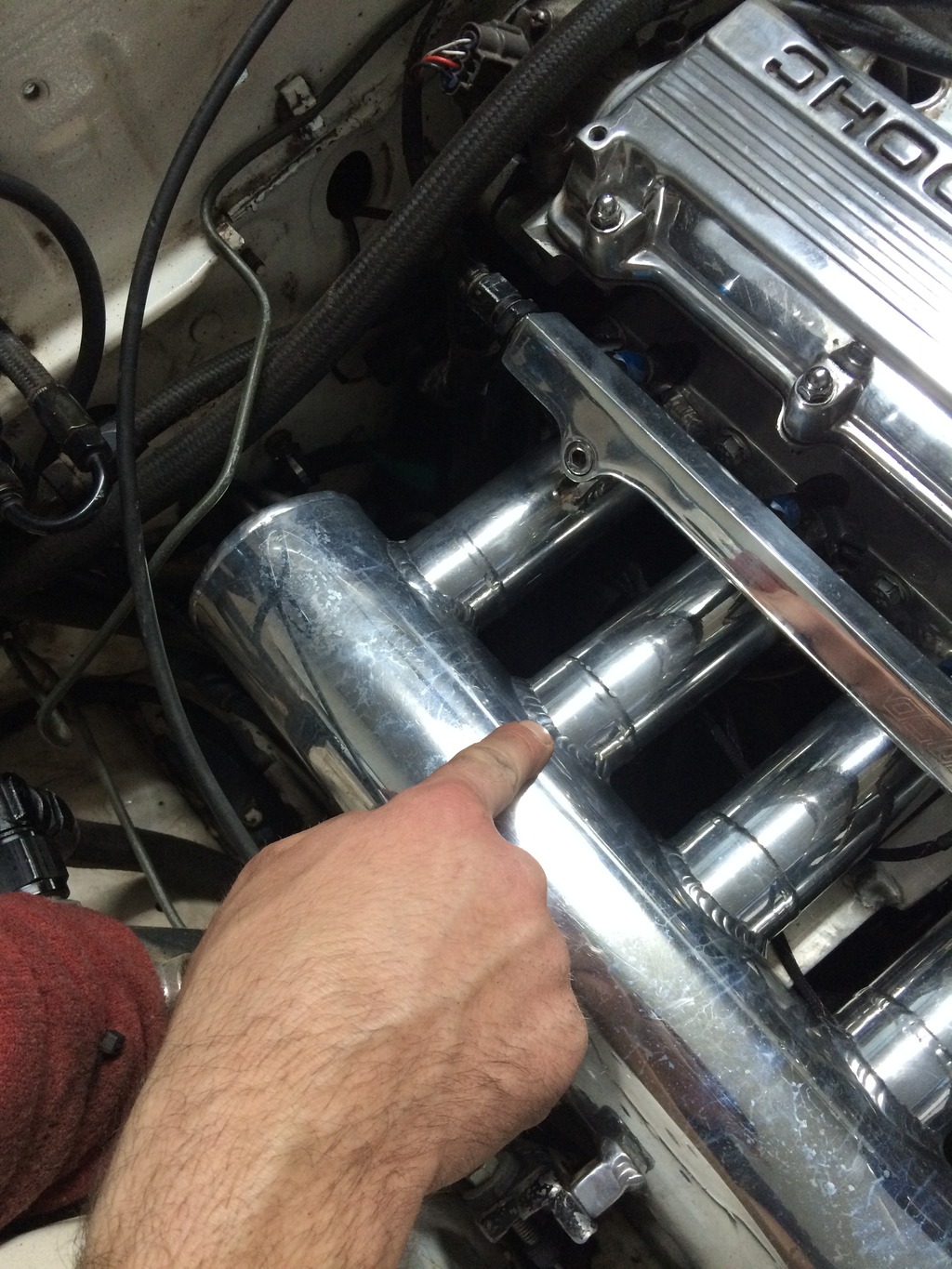

First let me say that I love the manifold, it's seems very well designed and for a race car application is is so much cleaner looking And simple vs oem. This is on a 1.6l car so all the oem upgrades discussed in this thread don't really apply to me.

I have had some problems with the welds on my manifold. The first runner has cracked at the weld twice before, at the manifold, so I built a brace between the first and second runner, but it then cracked again.

I also recently did a boost leak test to troubleshoot some power loss issues and discovered a hairline crack 80% of the way around the #4 runner at the plenum. This isn't a place that supports weight and is very bizarre to me. While diagnosing these issues I found two other pinholes in the welds in my particular manifold. Has anyone else complained of these problems or had similar issues?

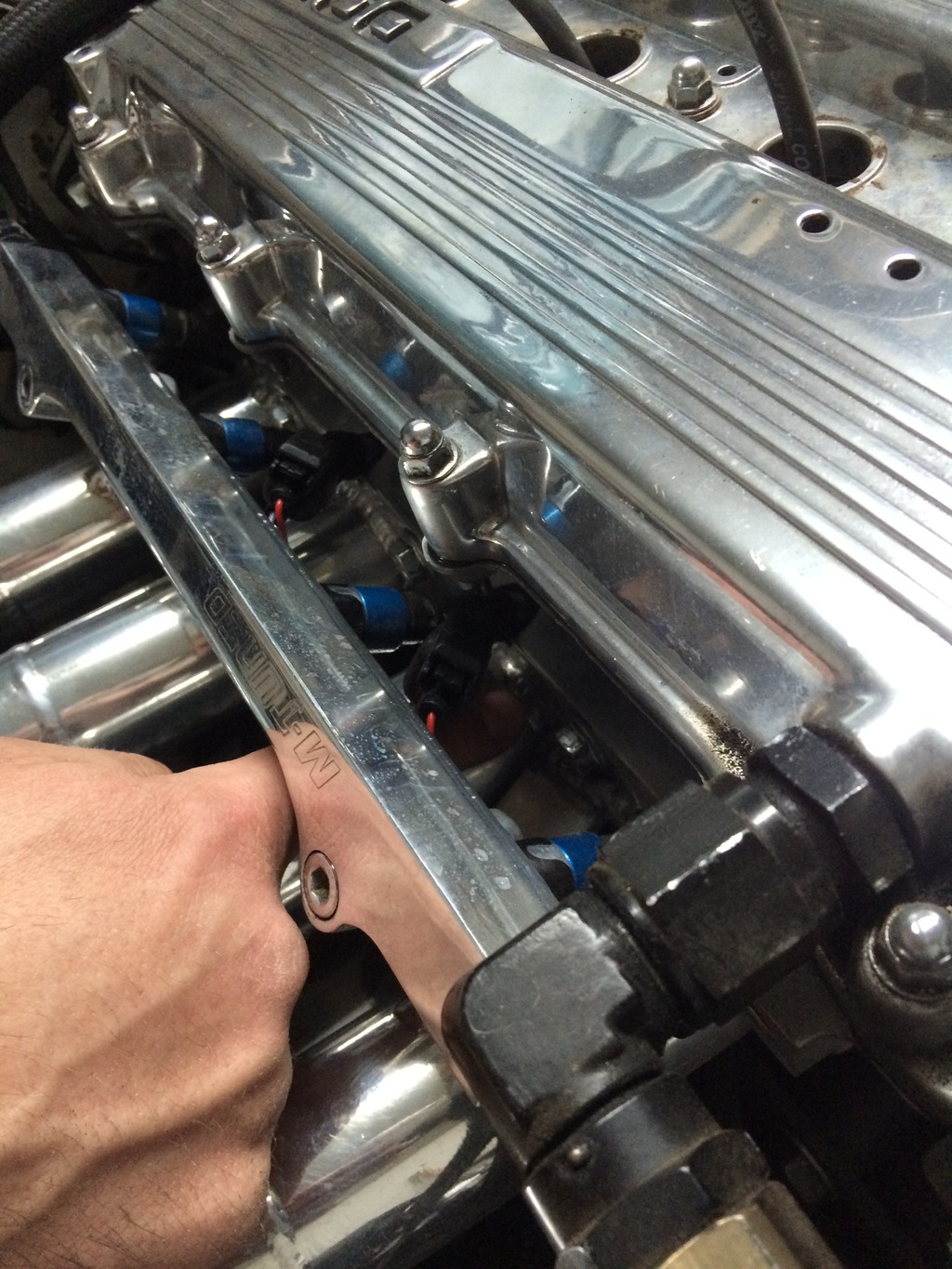

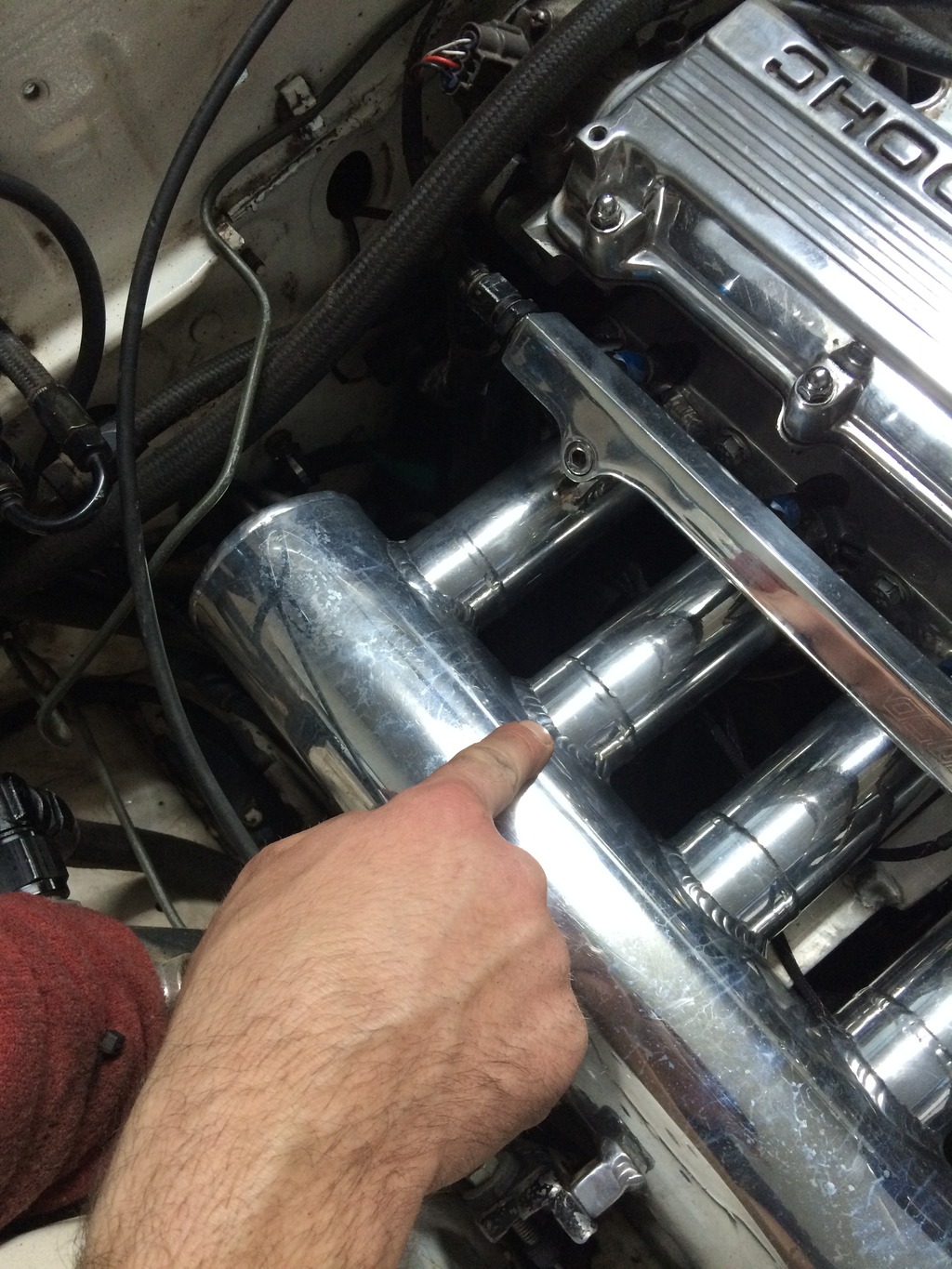

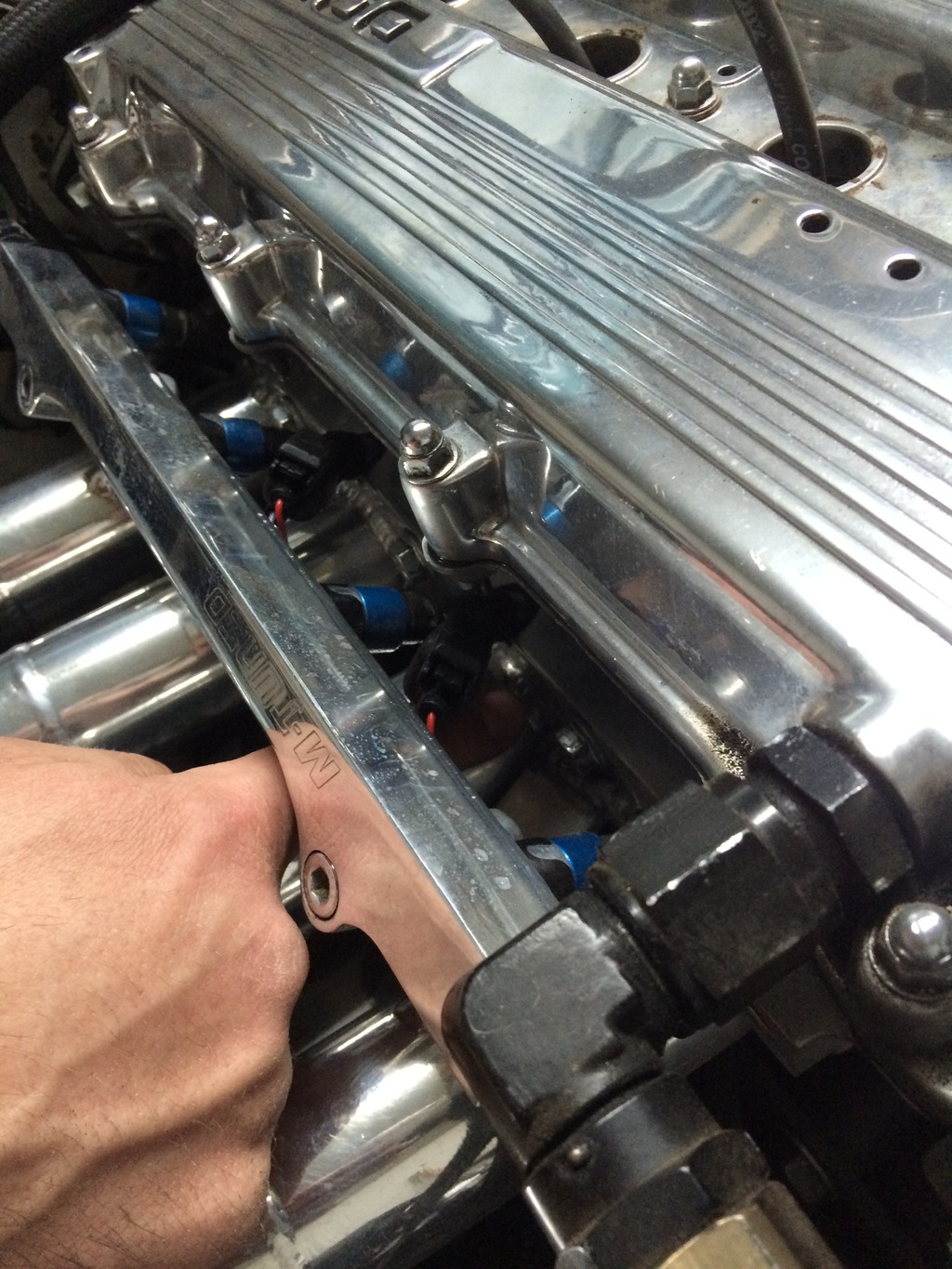

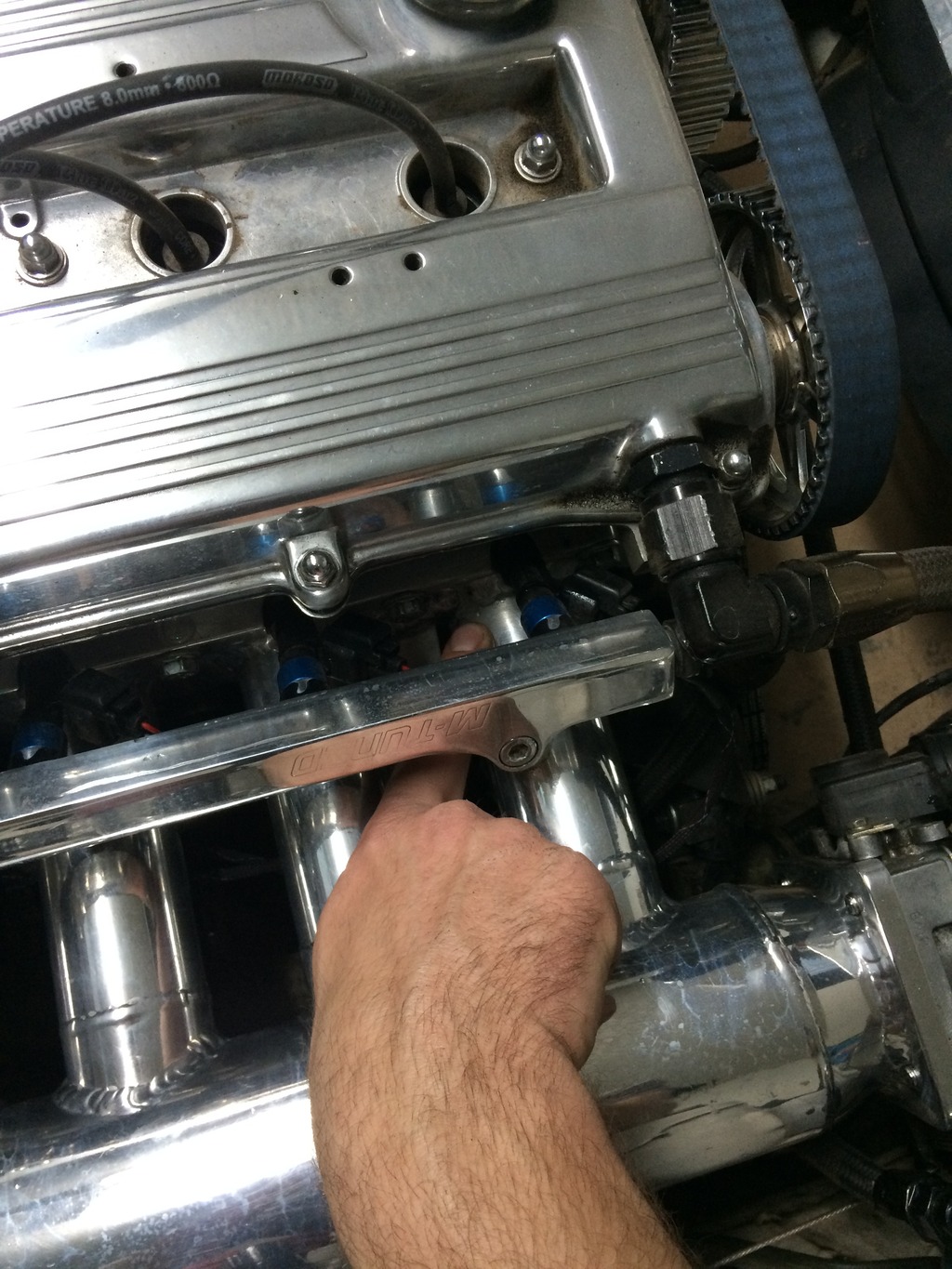

Here are some pics of the locations.

Cracked on the top and the bottom of #4 but not connected in the middle welder said that the crack really opened up once he started welding it to repair it.

Pinhole in #3 in the weld

Pinhole in #2 by the flange in the weld

#1 crack

Again, I'm not trying to pour salt or damage anyone's reputation, just some problems I've encountered and kind of want to hear if anyone else had the same experience or if corky has seen this before. I do really like the manifold a lot but I don't want to keep chasing cracks.

First let me say that I love the manifold, it's seems very well designed and for a race car application is is so much cleaner looking And simple vs oem. This is on a 1.6l car so all the oem upgrades discussed in this thread don't really apply to me.

I have had some problems with the welds on my manifold. The first runner has cracked at the weld twice before, at the manifold, so I built a brace between the first and second runner, but it then cracked again.

I also recently did a boost leak test to troubleshoot some power loss issues and discovered a hairline crack 80% of the way around the #4 runner at the plenum. This isn't a place that supports weight and is very bizarre to me. While diagnosing these issues I found two other pinholes in the welds in my particular manifold. Has anyone else complained of these problems or had similar issues?

Here are some pics of the locations.

Cracked on the top and the bottom of #4 but not connected in the middle welder said that the crack really opened up once he started welding it to repair it.

Pinhole in #3 in the weld

Pinhole in #2 by the flange in the weld

#1 crack

Again, I'm not trying to pour salt or damage anyone's reputation, just some problems I've encountered and kind of want to hear if anyone else had the same experience or if corky has seen this before. I do really like the manifold a lot but I don't want to keep chasing cracks.

#544

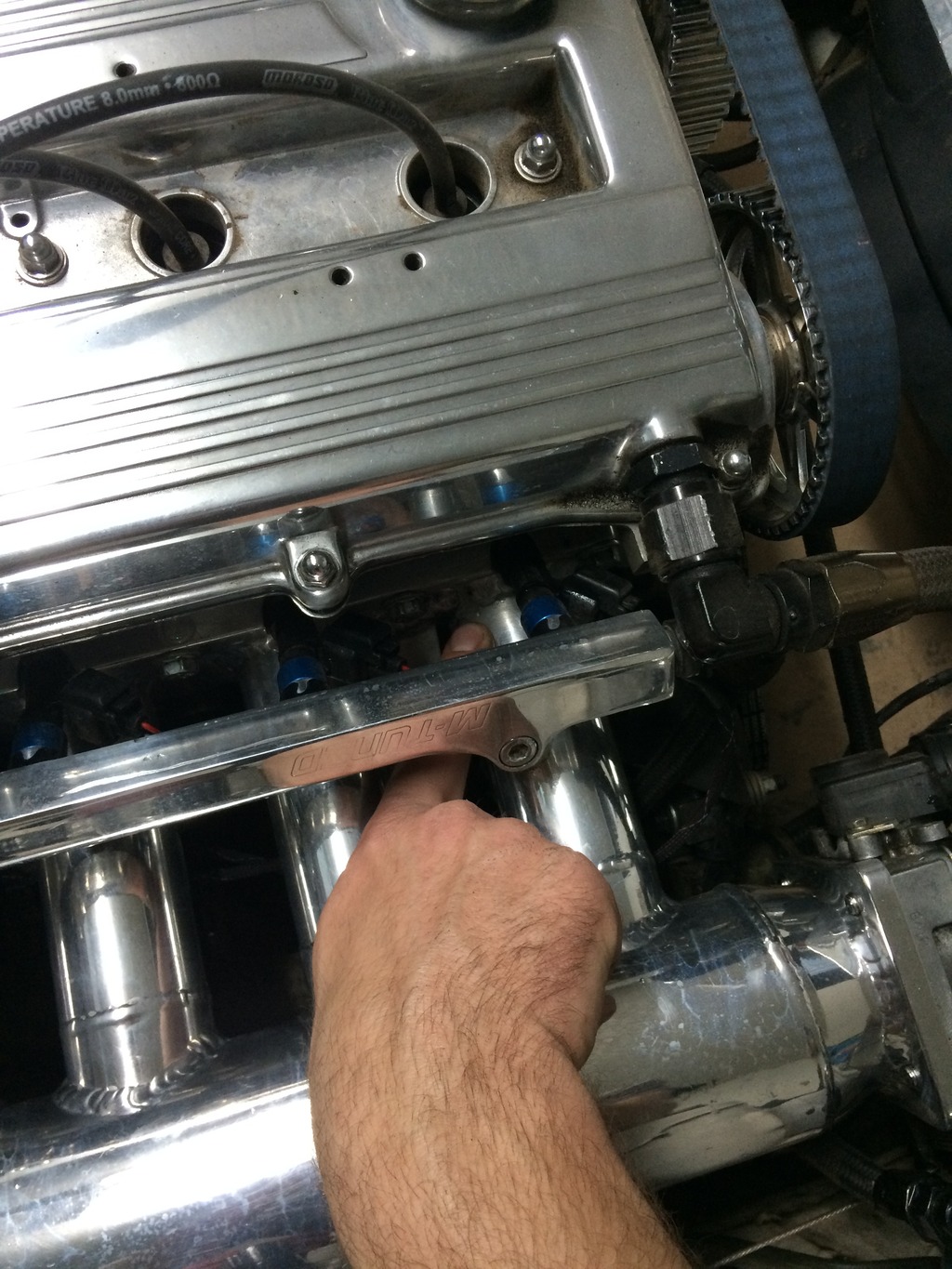

The support brace initially was only 1 piece of flat stock from the flange to the plenum, which cracked once, so I added another piece of flat stock from the middle of the brace to the top of the flange. This time the brace didn't crack but the runner cracked again in the same place

#546

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

The motor mounts are solid metal, the limiter was 7200 spark cut and is now 7500 spark cut.

The support brace initially was only 1 piece of flat stock from the flange to the plenum, which cracked once, so I added another piece of flat stock from the middle of the brace to the top of the flange. This time the brace didn't crack but the runner cracked again in the same place

The support brace initially was only 1 piece of flat stock from the flange to the plenum, which cracked once, so I added another piece of flat stock from the middle of the brace to the top of the flange. This time the brace didn't crack but the runner cracked again in the same place

#550

Pinholes may not even be pinholes but small cracks forming. Though bad welds would cause pinholes

Cracking at the beginning of the runner would support guesses that the vibration caused the cracks.

#552

Regarding the manifold posted, as already said holes are from bad welding. Cracking could be several things. Multiple cracks suggest a fatigue failure. My first guess is the design is the problem. Thin metal hanging unsupported, it vibrates enough to cause a fatigue failure. Solution would be to use thicker materials, reduce the overhang to reduce loading, or brace it to reduce loading. My opinion is that while solid motor mounts aren't ideal, whatever manifold you're running should be strong enough to handle that no problem. I'm sure the OEM cast manifold would run a million miles without cracking on a BP with solid motor mounts, because it's strong enough to no fatigue fail under those conditions.

#554

There is no give to the harsh vibrations or anything (rubber) to dampen the increased nvh.

I guess an example would be upgrading to stiffer motor mounts that increase nvh and shake the entire vehicle. Having a solid mount must rattle everything else like crazy.

Tie in a connected intercooler pipe & plumbing to a mounted intercooler, maybeh it's pulling & pushing on the vibrating manifold

OOoooooor, some weak welds to begin with The increased nvh & vibrations probably don't help the situation.

The increased nvh & vibrations probably don't help the situation.

I guess an example would be upgrading to stiffer motor mounts that increase nvh and shake the entire vehicle. Having a solid mount must rattle everything else like crazy.

Tie in a connected intercooler pipe & plumbing to a mounted intercooler, maybeh it's pulling & pushing on the vibrating manifold

OOoooooor, some weak welds to begin with

The increased nvh & vibrations probably don't help the situation.

The increased nvh & vibrations probably don't help the situation.

#555

The purpose of engine mounts are to reduce vibration by taking energy from the engine moving (the vibration) and dampening it (turning that energy into heat). This reduces the movement of the engine. That's how dampers work, whether it's engine mounts, dampers on your suspension, etc. No dampening will result in more movement.

Regarding the manifold posted, as already said holes are from bad welding. Cracking could be several things. Multiple cracks suggest a fatigue failure. My first guess is the design is the problem. Thin metal hanging unsupported, it vibrates enough to cause a fatigue failure. Solution would be to use thicker materials, reduce the overhang to reduce loading, or brace it to reduce loading. My opinion is that while solid motor mounts aren't ideal, whatever manifold you're running should be strong enough to handle that no problem. I'm sure the OEM cast manifold would run a million miles without cracking on a BP with solid motor mounts, because it's strong enough to no fatigue fail under those conditions.

Regarding the manifold posted, as already said holes are from bad welding. Cracking could be several things. Multiple cracks suggest a fatigue failure. My first guess is the design is the problem. Thin metal hanging unsupported, it vibrates enough to cause a fatigue failure. Solution would be to use thicker materials, reduce the overhang to reduce loading, or brace it to reduce loading. My opinion is that while solid motor mounts aren't ideal, whatever manifold you're running should be strong enough to handle that no problem. I'm sure the OEM cast manifold would run a million miles without cracking on a BP with solid motor mounts, because it's strong enough to no fatigue fail under those conditions.

I think the main issue is a weak design, followed by bad welding.

#556

Yeah. If I designed and sold an intake manifold, it would be designed differently. At a minimum to keep to the design of BEGIs manifold, I'd weld in bracing by the flange and plenum, much like the braces cast on the OEM manifold. But I'd take the same approach the OEM would take, make it strong enough that it never fails, not strong enough that it shouldn't fail.

#559

There is no give to the harsh vibrations or anything (rubber) to dampen the increased nvh.

I guess an example would be upgrading to stiffer motor mounts that increase nvh and shake the entire vehicle. Having a solid mount must rattle everything else like crazy.

Tie in a connected intercooler pipe & plumbing to a mounted intercooler, maybeh it's pulling & pushing on the vibrating manifold

OOoooooor, some weak welds to begin with The increased nvh & vibrations probably don't help the situation.

The increased nvh & vibrations probably don't help the situation.

I guess an example would be upgrading to stiffer motor mounts that increase nvh and shake the entire vehicle. Having a solid mount must rattle everything else like crazy.

Tie in a connected intercooler pipe & plumbing to a mounted intercooler, maybeh it's pulling & pushing on the vibrating manifold

OOoooooor, some weak welds to begin with

The increased nvh & vibrations probably don't help the situation.

The increased nvh & vibrations probably don't help the situation.Again, I'm not out to bash, just trying to see if this is common or just a me thing, I don't know how many people even own these things, they aren't exactly "inexpensive".

#560

Supporting Vendor

iTrader: (1)

Join Date: Sep 2010

Location: Lake Forest, CA

Posts: 7,953

Total Cats: 1,007

I keep laughing at how you guys don't seem to get what Vlad is saying.

Engine vibrates. With rubber mounts, me no feel vibration. With solid mounts, me feel vibration.

it's like you guys think that solid mounts actually make the engine itself vibrate more. that doesn't make any sense. engine vibrates the same, no?

Engine vibrates. With rubber mounts, me no feel vibration. With solid mounts, me feel vibration.

it's like you guys think that solid mounts actually make the engine itself vibrate more. that doesn't make any sense. engine vibrates the same, no?