$2018 GRM challenge turbo miata build. with added insanity.

#61

Challenge budget so far revious challenge budget: 1709.68 recoup total: 820new money: header wrap: 17.10

revious challenge budget: 1709.68 recoup total: 820new money: header wrap: 17.10

misc supplies: 50and fittings: 21.98 (4.99 male coupler, 10x tube nuts for 16.99) race car paint: 14.98 new total: 1813.74

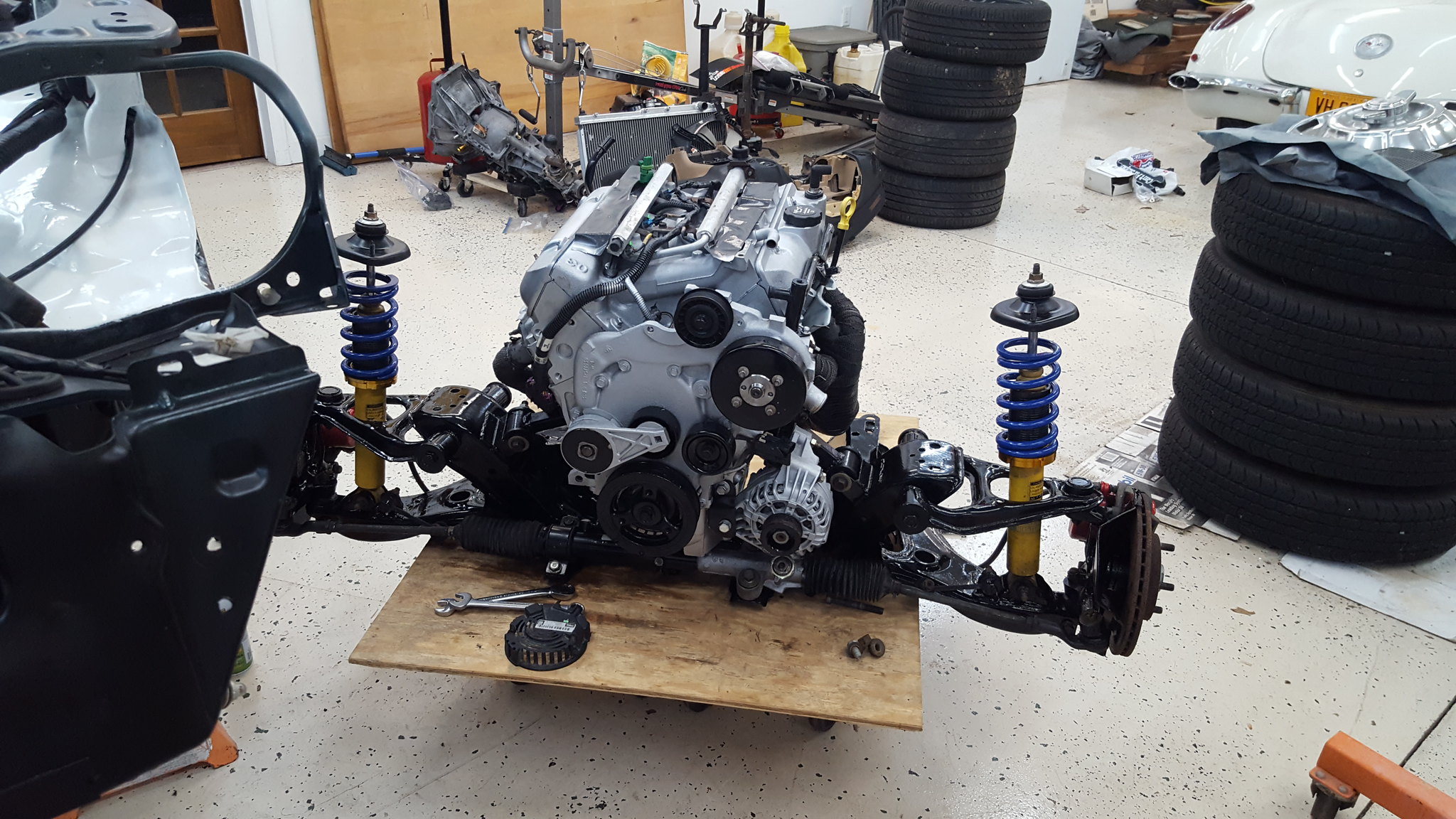

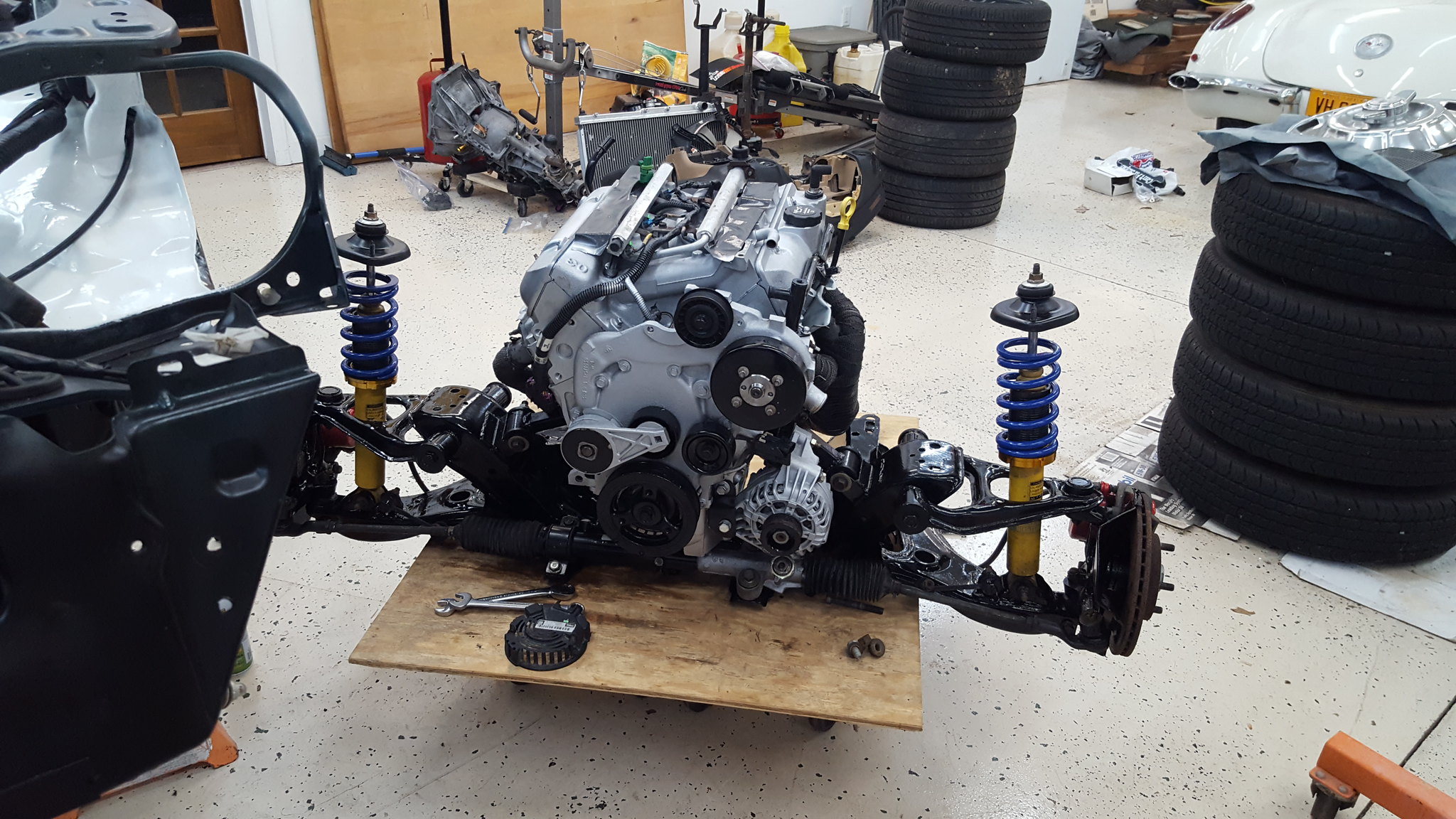

recoup: 820kicking *** and taking names. This weekend was spent helping dad on the 49 ford truck, and getting ready to get the motor back in. the motor started here:

20180630_110948 by Michael Crawford, on Flickrstep one was to make the headers actually fit and flow again. Somehow, when I finished welding them, I screwed up and made all the tubes move. Not sure how I did that, other than stupidity and heat. So I cut them apart a bit, and re-welded them bolted to the engine. They still fit after cooling, so im calling that a win. They really don't look any different in ways that you can tell, other than having all the bolt holes line up. So use your imagination.I then tackled the other bit of stupid I did. When we cut the flanges, we cut them exactly to exhaust gasket size. When I put them together, I shoved the tubes into the holes in the flanges and welded. Obviously, now the headers are smaller than exhaust port size. So I put dykem on the gaskets, dykem on the header, and ran it all together. A bit of creative scribing and jigging, and we had some marks to port to.

20180630_125209 by Michael Crawford, on FlickrI then broke out a new carbide burr on my die grinder.

20180630_131050 by Michael Crawford, on Flickrcouple hours later, and one completely wore out burr

20180630_131049 by Michael Crawford, on Flickr

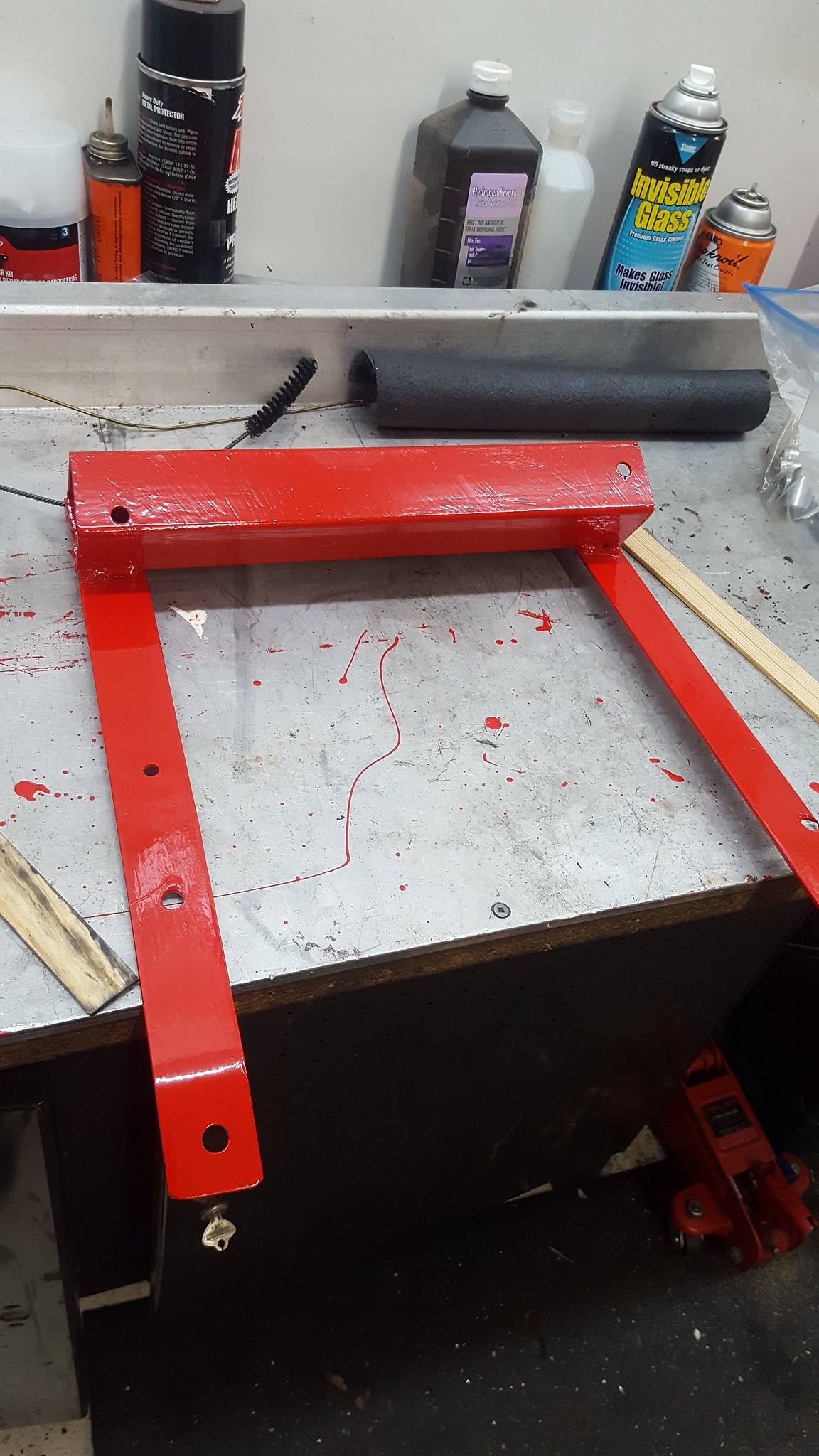

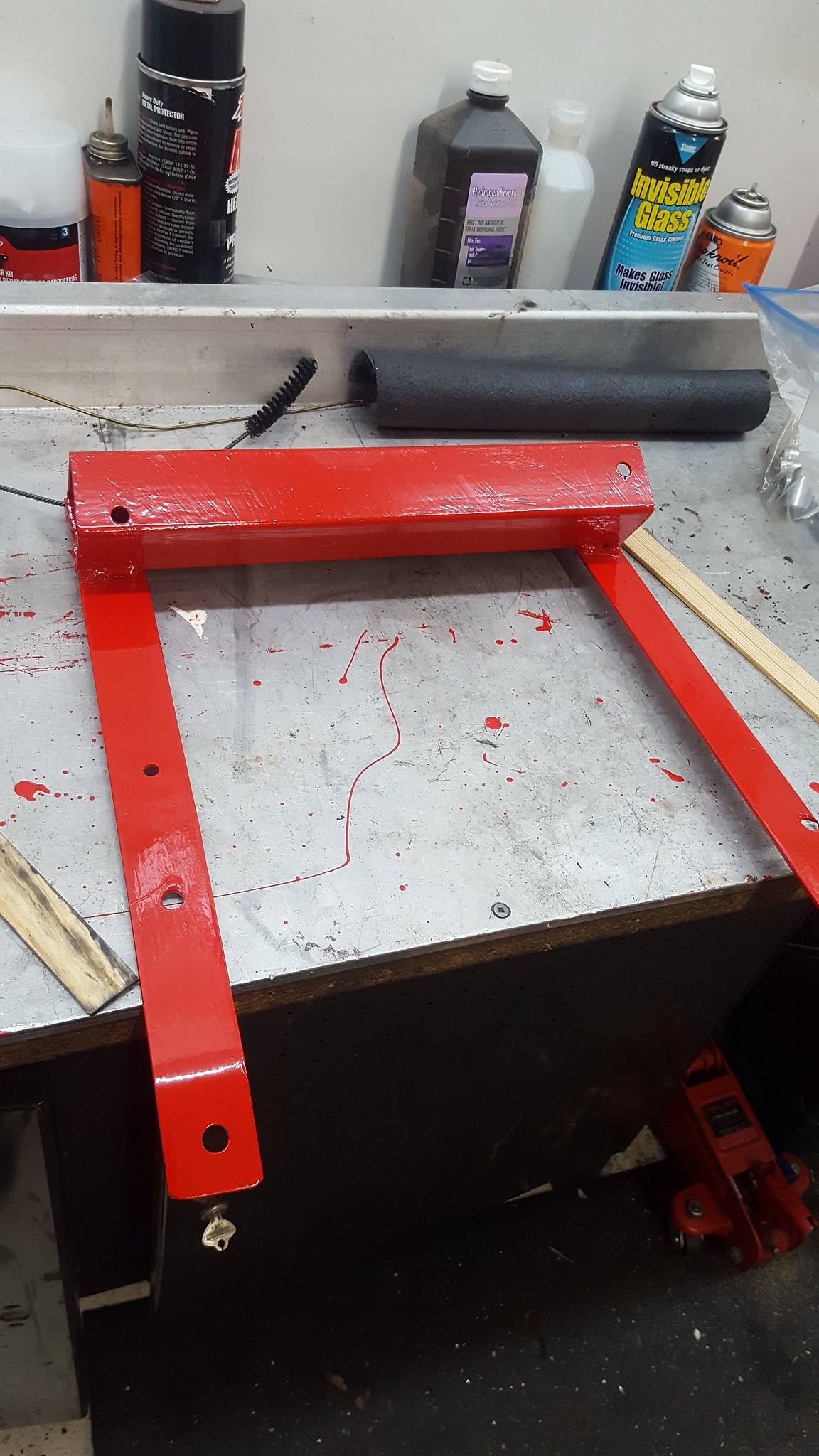

20180630_131044 by Michael Crawford, on Flickrwhen I came back to the shop this morning, dad gave me the headers mostly completed. He took one of the pictures (he used some muffler paste on the flanges. That muffler paste has been on the shelf since he found it under the seat of the tracker when he bought it. Im throwing it in the misc category for budget), and I took the picture of paint. Paint is another of the misc (neither of us remember buying it, and the can is so old that its starting to rust out on the bottom. Dad wanted to use it up.)

20180701_111931 by Michael Crawford, on Flickr

20180701_160440 by Michael Crawford, on Flickr

20180701_160442 by Michael Crawford, on Flickrthey're still uglier than some of the women I woke up next to after a week long bender, but some header wrap and no one will see them. And the header wrap should help underhood temps.

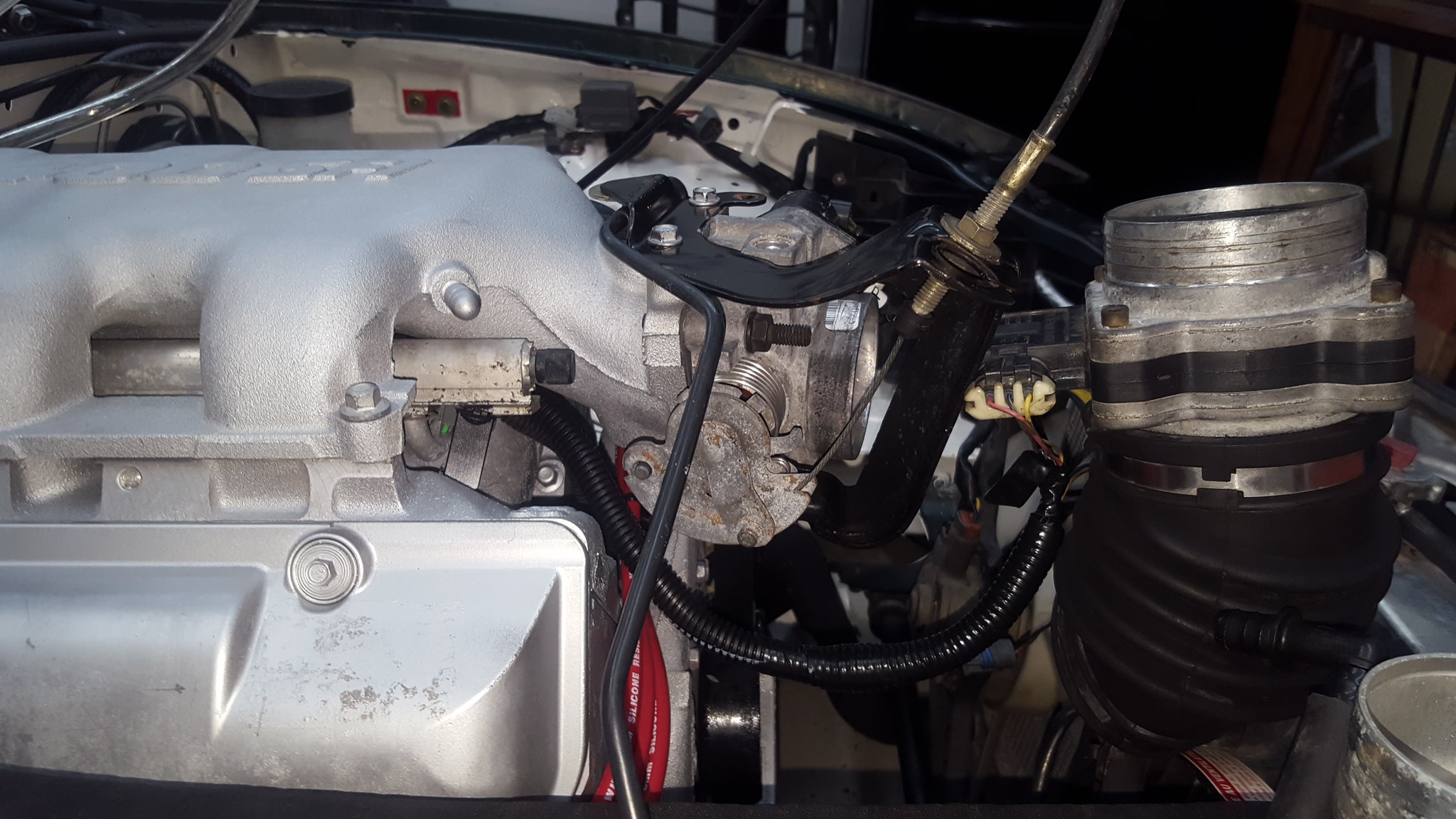

20180701_184256 by Michael Crawford, on Flickrthe next step was getting the engine cleaned, taped, and painted. I finally was convinced to take the easy route of painting the whole engine silver. With black accents. So, super clean, wire brush, brake clean, scrapers, etc. then some painters tape.

20180630_141244 by Michael Crawford, on FlickrI also used some black valspar on the brackets and lines and such. Pulies as well. The hard lines for the cooling system were all modified to work with the new setup, fuel lines modified, and everything bolted back together. (upper intake not bolted on. But sat there to give you the idea. And so I can see it. Turned out GOOD. I was really nervous about it looking like chrome spray paint at first....)

20180701_111934 by Michael Crawford, on Flickr

20180701_153220 by Michael Crawford, on Flickr

20180701_153228 by Michael Crawford, on Flickr

20180701_160407 by Michael Crawford, on Flickr

20180701_160412 by Michael Crawford, on Flickr

20180701_160418 by Michael Crawford, on FlickrI pulled the used clutch and flywheel out of their box to get ready to assemble that when I realized I don't have a pilot bearing. I'm ashamed to say that this clutch will have to do. Its pretty well worn out, but its what I have, and its paid for. These parts are off a 2.2 s10, which is what the 3400 fiero guys use, and wvtumbler recommended for this swap. Hopefully it doesn't slip. I'm going to dress the pressure plate and flywheel with the zizz wheel and a brown pad and hope for the best.

20180701_160234 by Michael Crawford, on Flickr

20180701_111928 by Michael Crawford, on Flickrhopefully the next post will see the engine in the bay, and all but hooked up!Happy 4 th y'all. And remember to thank our servicemen (armed forces, police, and firefighters) for the freedoms we all enjoy in this great country.

revious challenge budget: 1709.68 recoup total: 820new money: header wrap: 17.10

revious challenge budget: 1709.68 recoup total: 820new money: header wrap: 17.10misc supplies: 50and fittings: 21.98 (4.99 male coupler, 10x tube nuts for 16.99) race car paint: 14.98 new total: 1813.74

recoup: 820kicking *** and taking names. This weekend was spent helping dad on the 49 ford truck, and getting ready to get the motor back in. the motor started here:

20180630_110948 by Michael Crawford, on Flickrstep one was to make the headers actually fit and flow again. Somehow, when I finished welding them, I screwed up and made all the tubes move. Not sure how I did that, other than stupidity and heat. So I cut them apart a bit, and re-welded them bolted to the engine. They still fit after cooling, so im calling that a win. They really don't look any different in ways that you can tell, other than having all the bolt holes line up. So use your imagination.I then tackled the other bit of stupid I did. When we cut the flanges, we cut them exactly to exhaust gasket size. When I put them together, I shoved the tubes into the holes in the flanges and welded. Obviously, now the headers are smaller than exhaust port size. So I put dykem on the gaskets, dykem on the header, and ran it all together. A bit of creative scribing and jigging, and we had some marks to port to.

20180630_125209 by Michael Crawford, on FlickrI then broke out a new carbide burr on my die grinder.

20180630_131050 by Michael Crawford, on Flickrcouple hours later, and one completely wore out burr

20180630_131049 by Michael Crawford, on Flickr

20180630_131044 by Michael Crawford, on Flickrwhen I came back to the shop this morning, dad gave me the headers mostly completed. He took one of the pictures (he used some muffler paste on the flanges. That muffler paste has been on the shelf since he found it under the seat of the tracker when he bought it. Im throwing it in the misc category for budget), and I took the picture of paint. Paint is another of the misc (neither of us remember buying it, and the can is so old that its starting to rust out on the bottom. Dad wanted to use it up.)

20180701_111931 by Michael Crawford, on Flickr

20180701_160440 by Michael Crawford, on Flickr

20180701_160442 by Michael Crawford, on Flickrthey're still uglier than some of the women I woke up next to after a week long bender, but some header wrap and no one will see them. And the header wrap should help underhood temps.

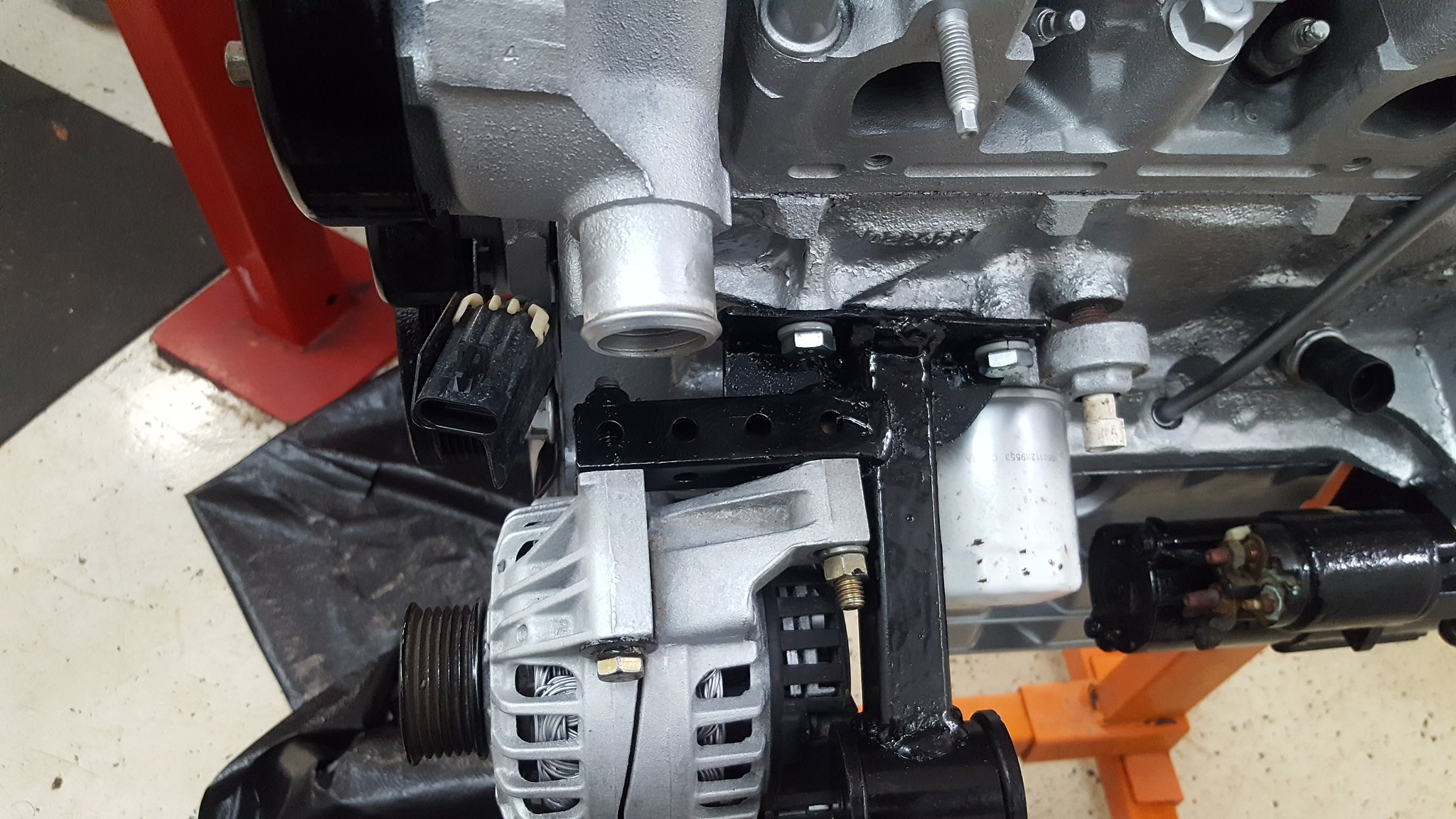

20180701_184256 by Michael Crawford, on Flickrthe next step was getting the engine cleaned, taped, and painted. I finally was convinced to take the easy route of painting the whole engine silver. With black accents. So, super clean, wire brush, brake clean, scrapers, etc. then some painters tape.

20180630_141244 by Michael Crawford, on FlickrI also used some black valspar on the brackets and lines and such. Pulies as well. The hard lines for the cooling system were all modified to work with the new setup, fuel lines modified, and everything bolted back together. (upper intake not bolted on. But sat there to give you the idea. And so I can see it. Turned out GOOD. I was really nervous about it looking like chrome spray paint at first....)

20180701_111934 by Michael Crawford, on Flickr

20180701_153220 by Michael Crawford, on Flickr

20180701_153228 by Michael Crawford, on Flickr

20180701_160407 by Michael Crawford, on Flickr

20180701_160412 by Michael Crawford, on Flickr

20180701_160418 by Michael Crawford, on FlickrI pulled the used clutch and flywheel out of their box to get ready to assemble that when I realized I don't have a pilot bearing. I'm ashamed to say that this clutch will have to do. Its pretty well worn out, but its what I have, and its paid for. These parts are off a 2.2 s10, which is what the 3400 fiero guys use, and wvtumbler recommended for this swap. Hopefully it doesn't slip. I'm going to dress the pressure plate and flywheel with the zizz wheel and a brown pad and hope for the best.

20180701_160234 by Michael Crawford, on Flickr

20180701_111928 by Michael Crawford, on Flickrhopefully the next post will see the engine in the bay, and all but hooked up!Happy 4 th y'all. And remember to thank our servicemen (armed forces, police, and firefighters) for the freedoms we all enjoy in this great country.

#62

I kinda feel like you're not putting enough smoky Yunik into the build. Meaning if another slightly better shape clutch disk was found who's to say it wasn't the one that came with your original purchase? Claiming every little fitting and can of paint? Who's to say they didn't all come from the clearance section?

I'm not suggesting you out right cheat and fudge the true cost of things......but that's exactly what your competition is doing. It's really a race to see who can put together a build sheet that is barely believable.

I'm not suggesting you out right cheat and fudge the true cost of things......but that's exactly what your competition is doing. It's really a race to see who can put together a build sheet that is barely believable.

#63

I'm a man of rigorous honesty. I did pretty well with the amc, and actually got protested. However, because of the build thread and counting EVERYTHING , they wouldn't even accept the protest fee. We also pulled 9th. Being completely honest.

if i fail, I'll fail honestly.

if i win, I'll win honestly.

i do, however, channel my inner yunick, chapman, and frieberger every step of the way that i can. Some parts i just channel them better.

if i fail, I'll fail honestly.

if i win, I'll win honestly.

i do, however, channel my inner yunick, chapman, and frieberger every step of the way that i can. Some parts i just channel them better.

#64

Challenge budget so far revious challenge budget: 1709.68 recoup total: 820new money: plug wires: 10FMV

revious challenge budget: 1709.68 recoup total: 820new money: plug wires: 10FMV

clutch kit: 52.99

plugs: 14.94

fuel injection hose: 2.98

exhaust manifold gaskets: 13.57 FMV new total: 1908.22

recoup: 820so, some ups and downs this week.Got the headers wrapped (first time ever wrapping headers). The stainless zip tie things that came with the header wrap sucked. So dad did safety wire at all the ends. Aint going nowhere now!

20180703_174436 by Michael Crawford, on Flickr

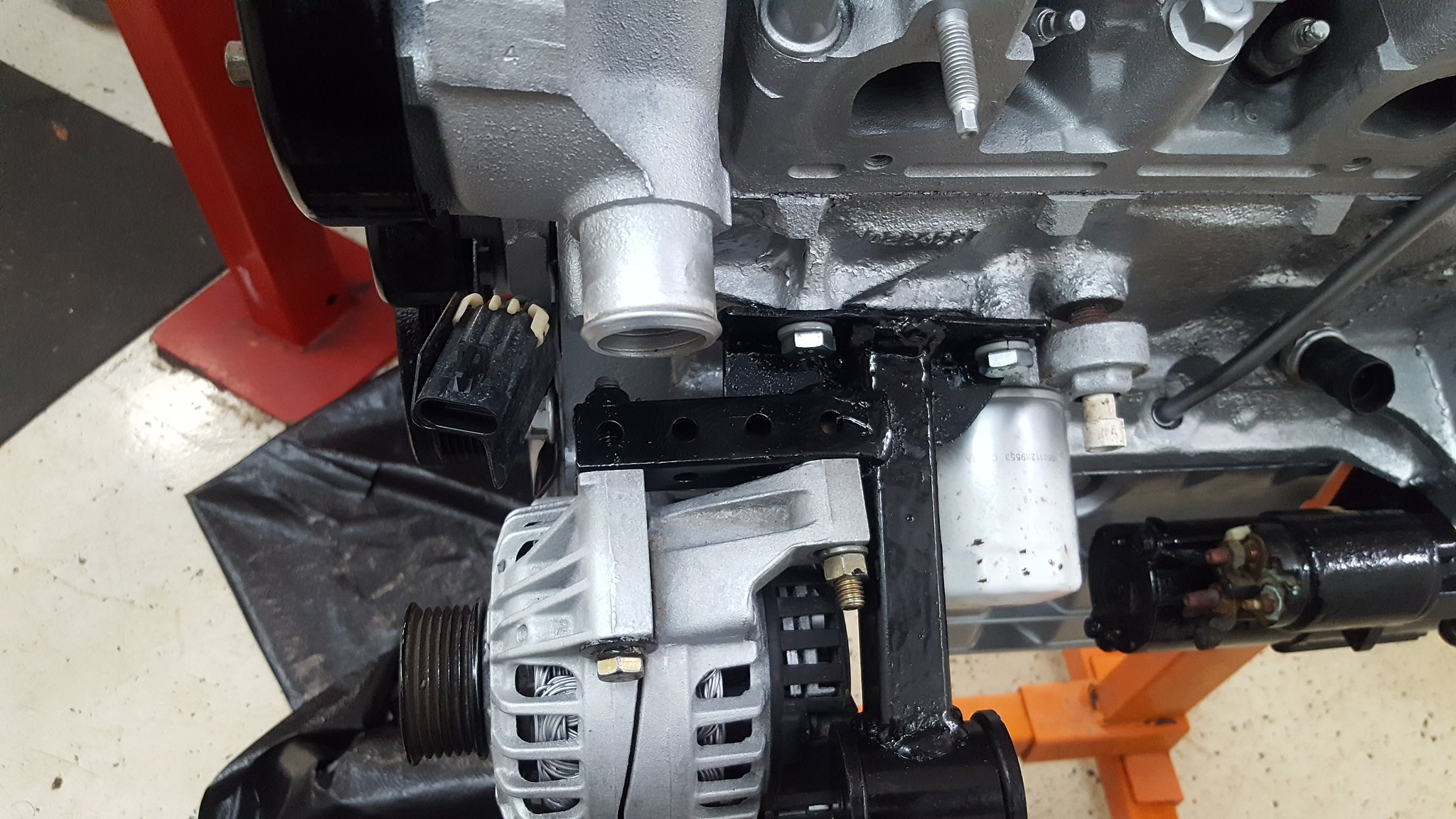

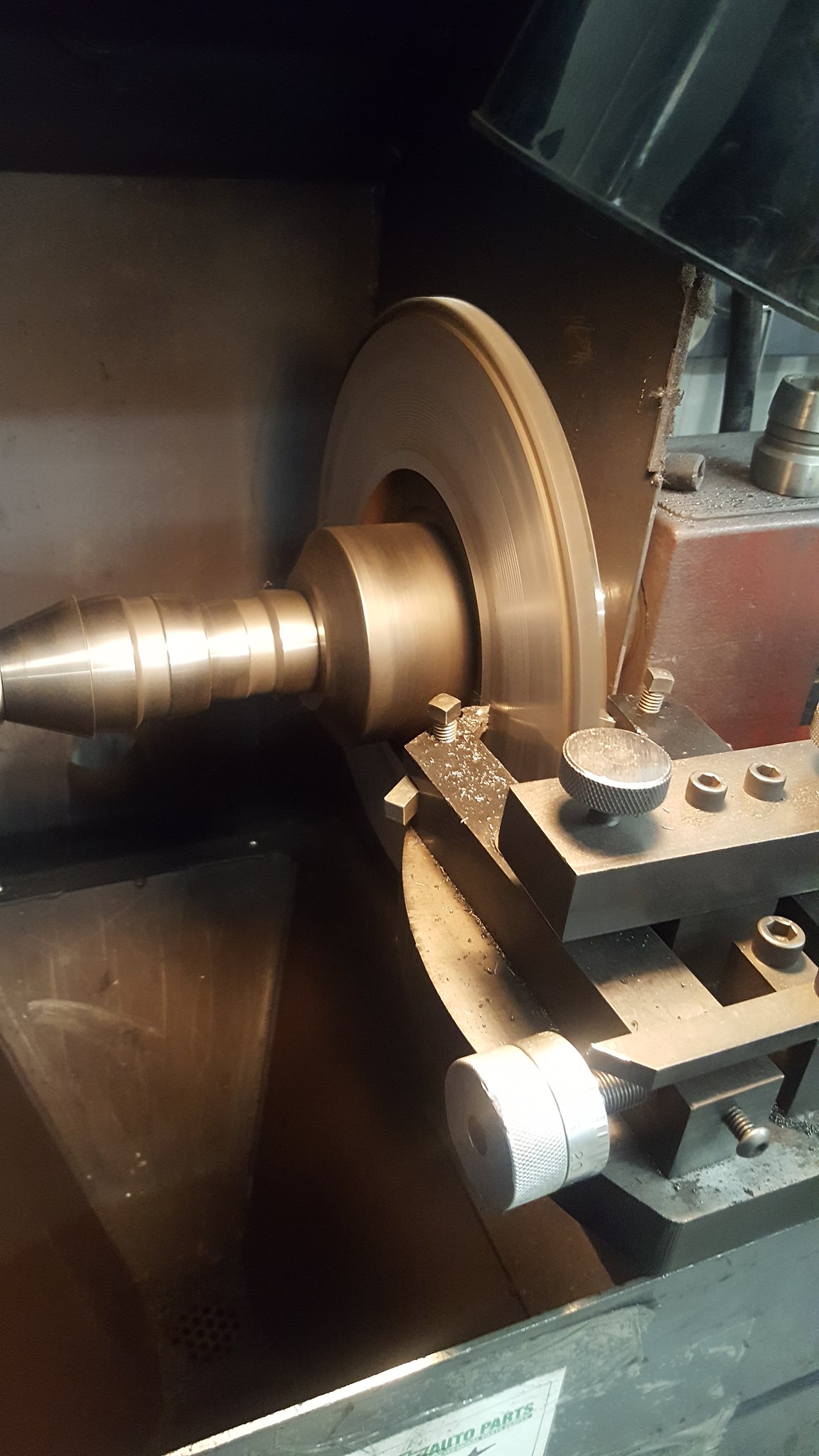

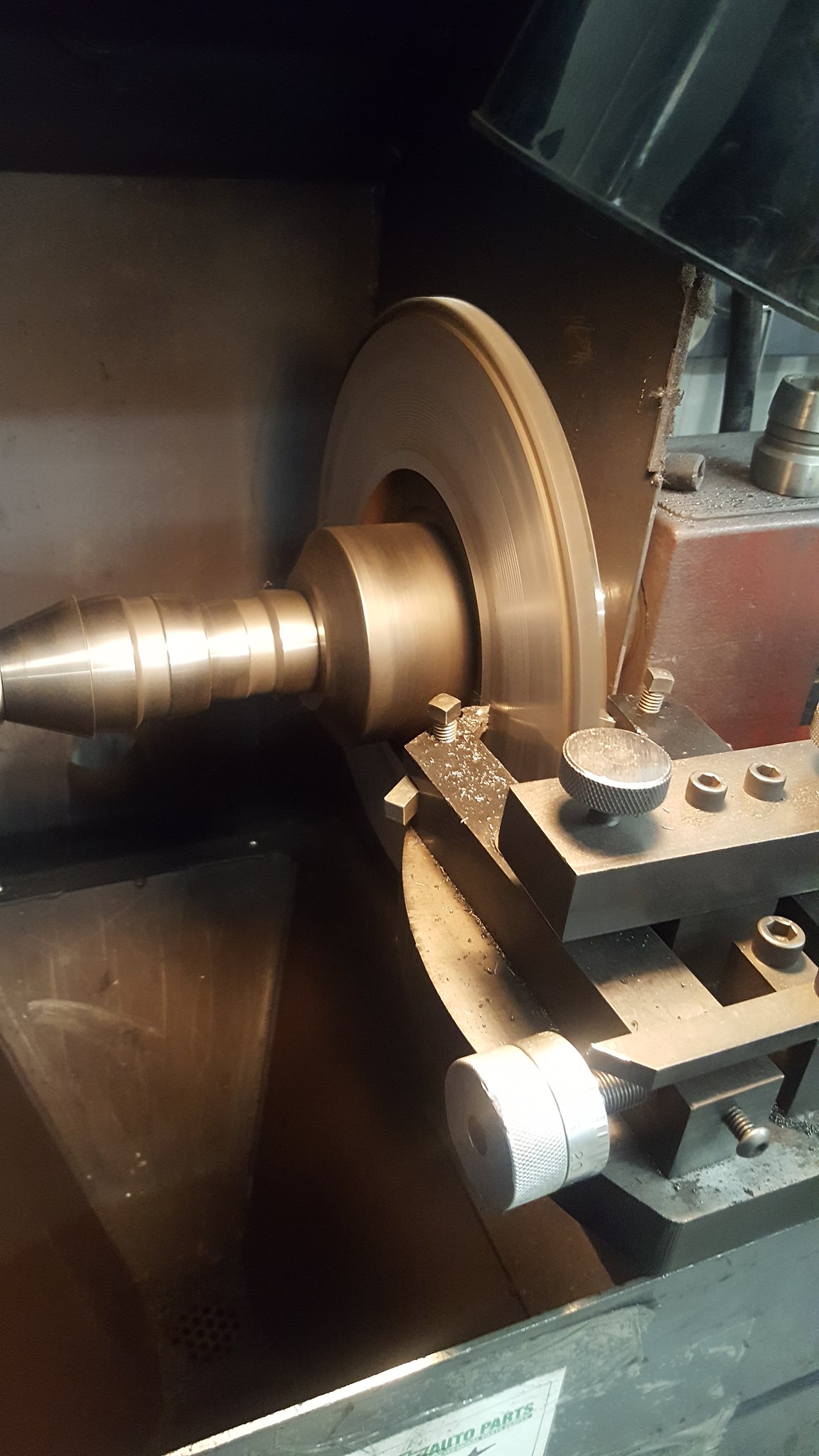

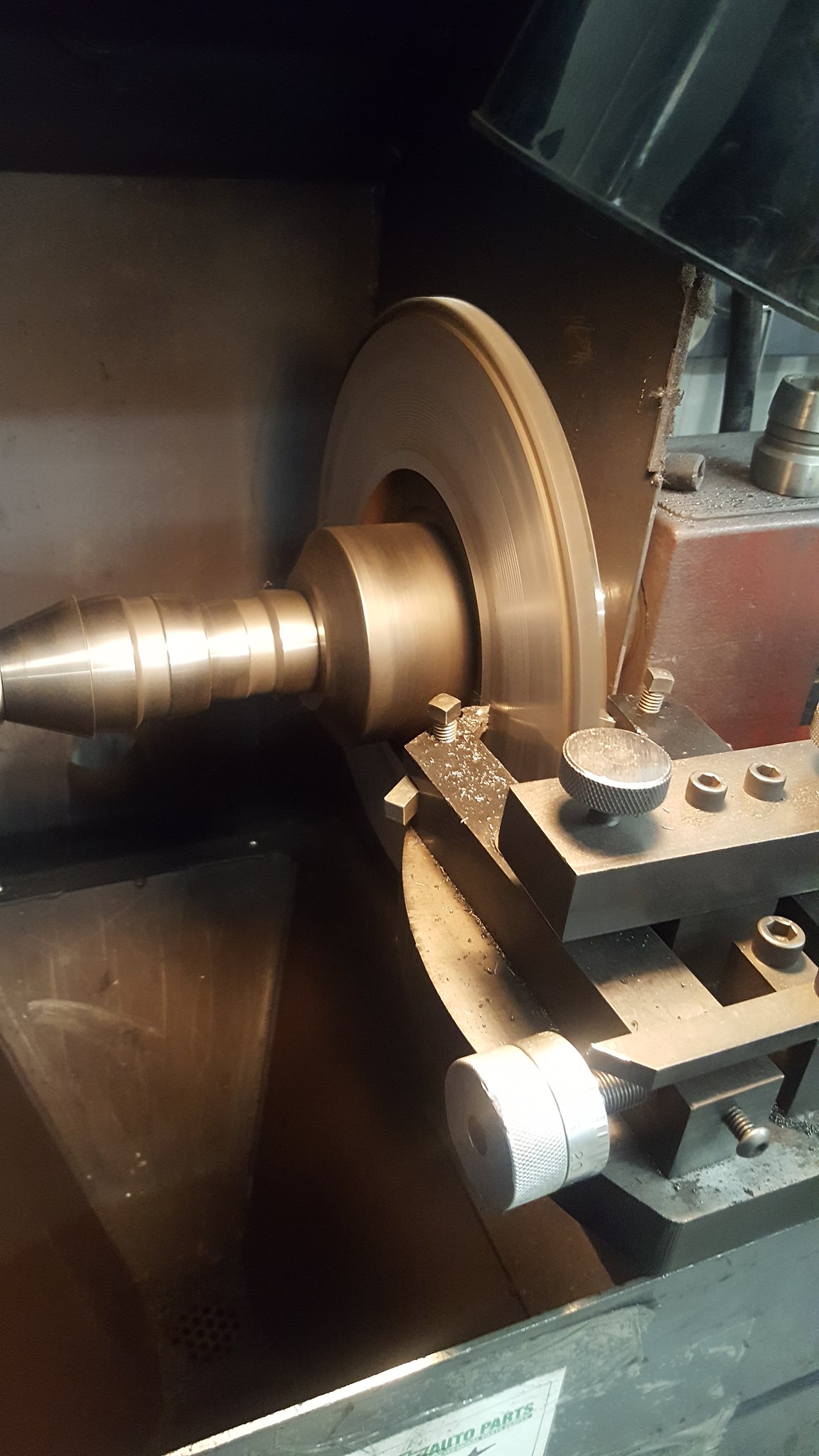

20180703_182229 by Michael Crawford, on FlickrI turned my flywheel on a brake lathe in preparation for putting a new clutch in. it was a hard decision, but I feel the right one. This may mean I forego turbo parts under challenge budget, but I would hate to end my race due to a failed worn out clutch. Much happier twisting an axle or breaking a trans or something.

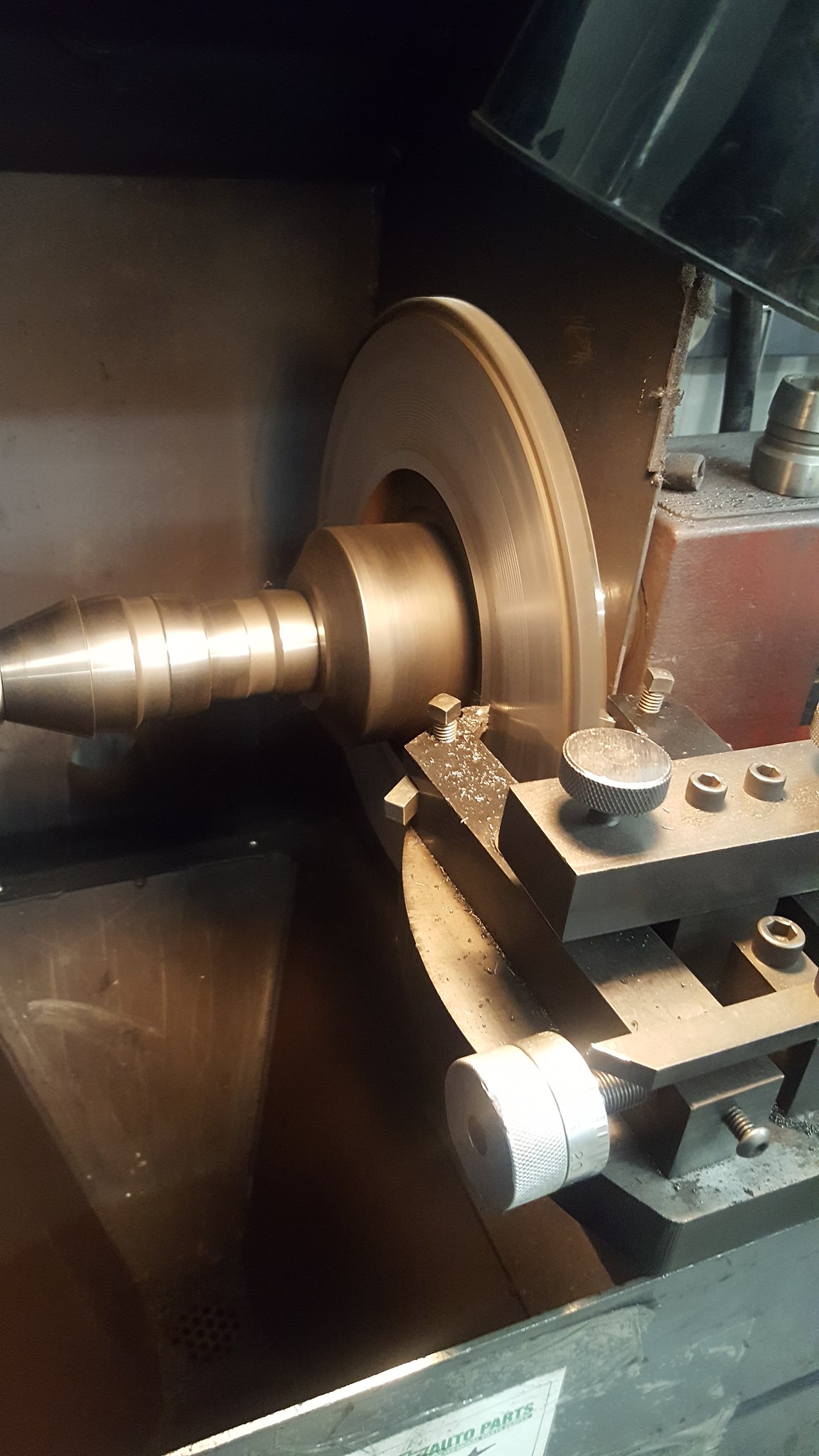

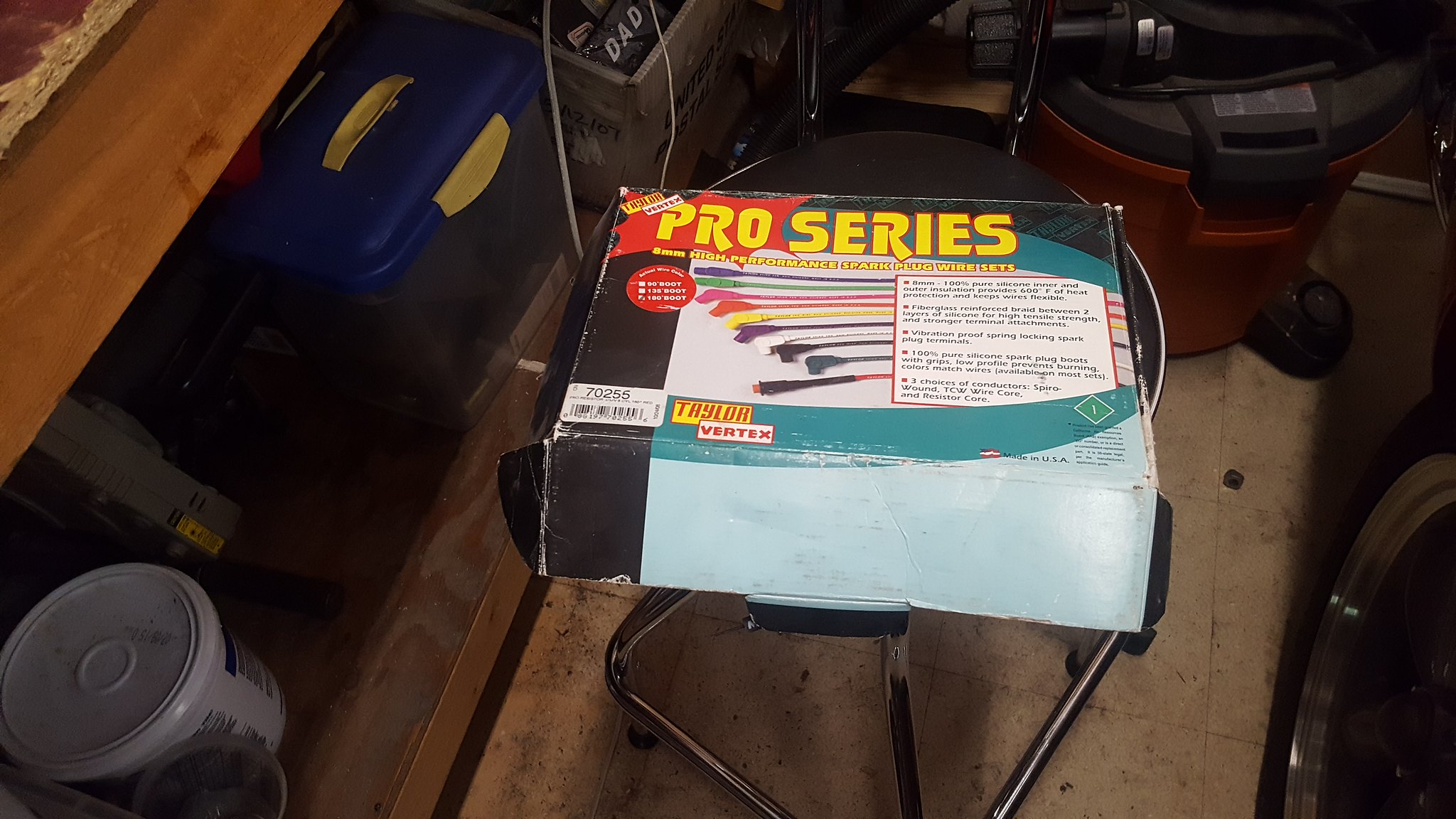

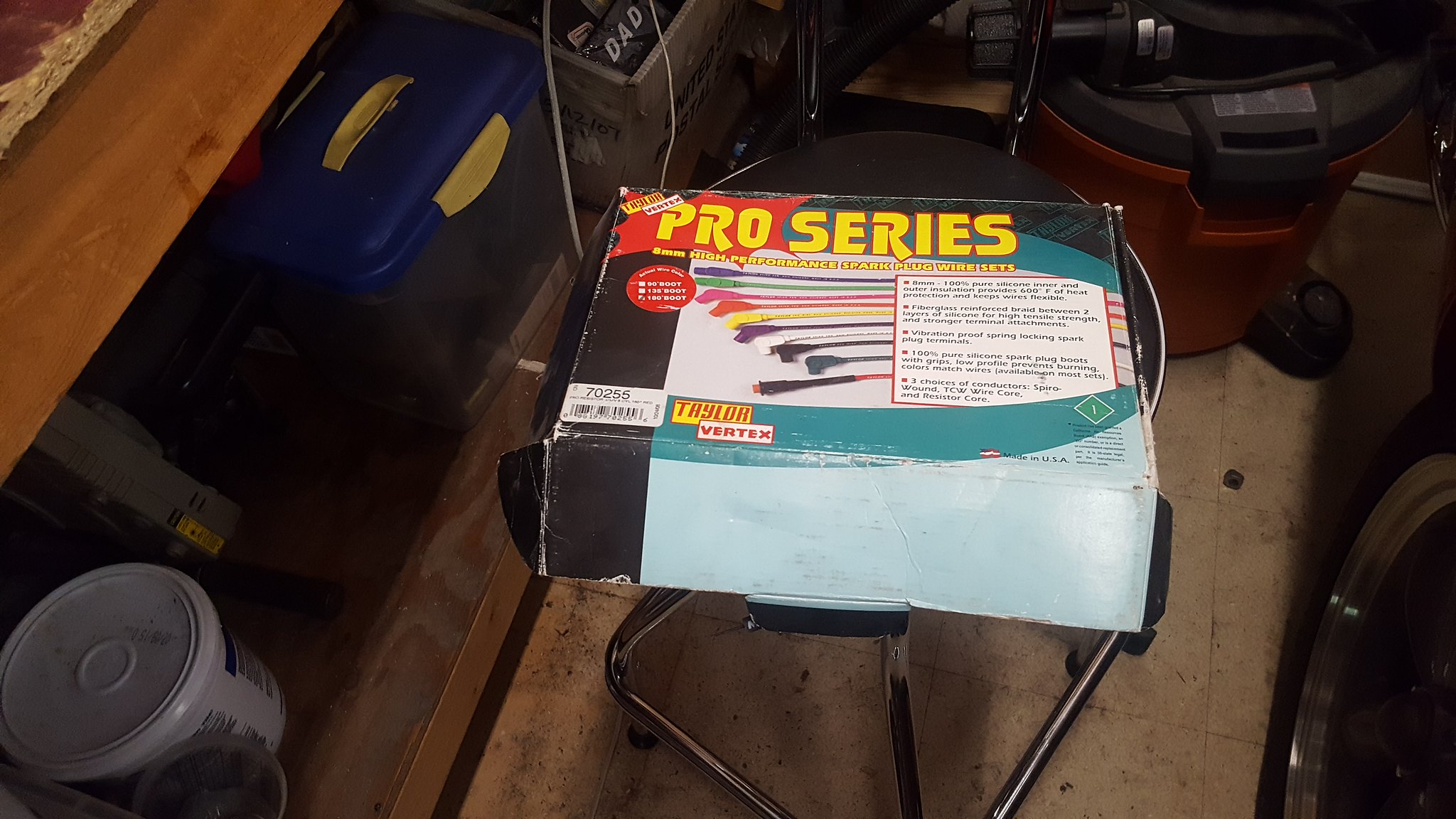

20180702_165318 by Michael Crawford, on Flickrmy free, but put in the budget at FMV plug wires

20180702_131327 by Michael Crawford, on Flickr

20180702_131323 by Michael Crawford, on FlickrI got everything assembled on the stand except the upper intake, and started prepping the engine harness.

20180706_170509 by Michael Crawford, on Flickr

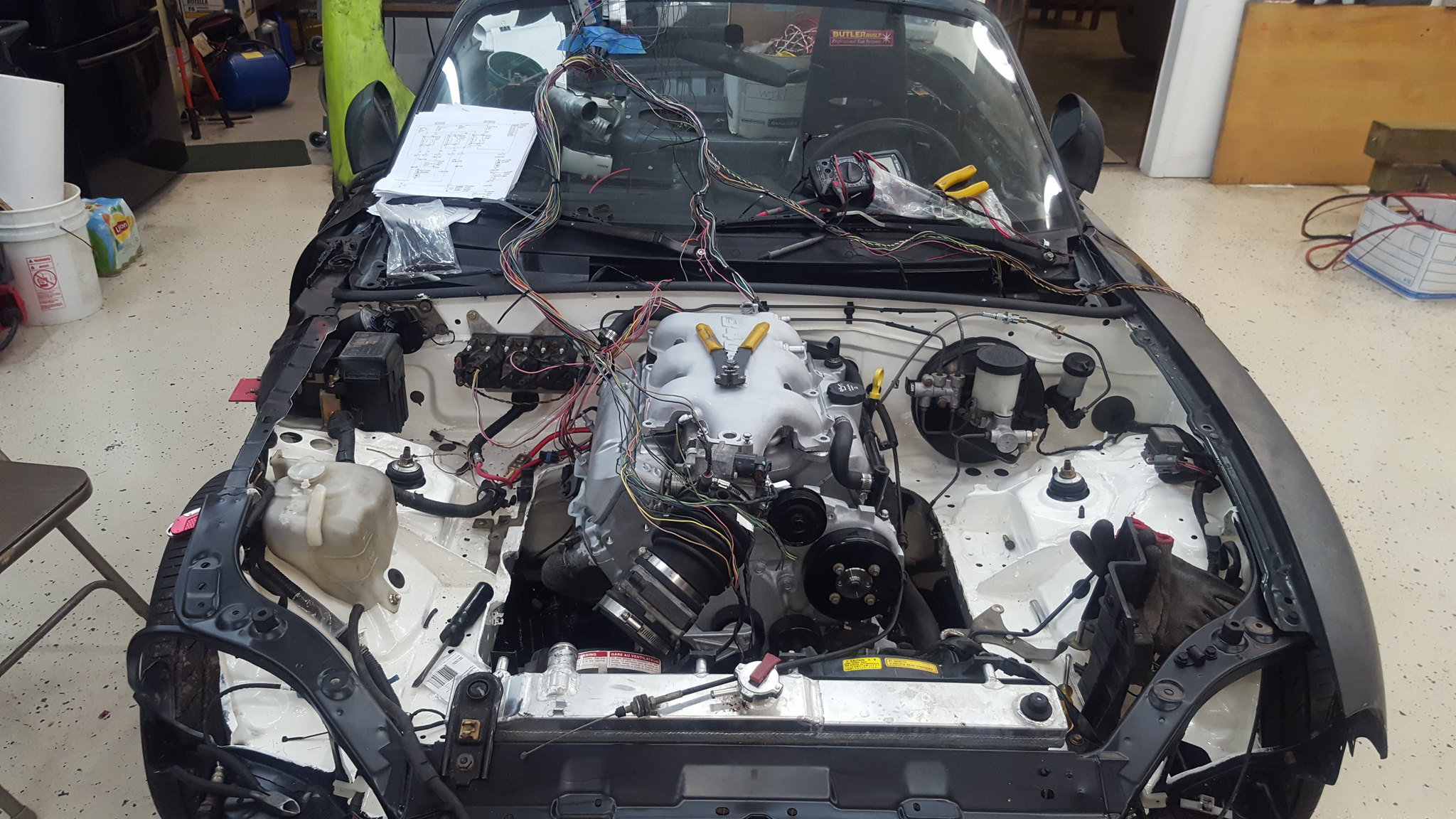

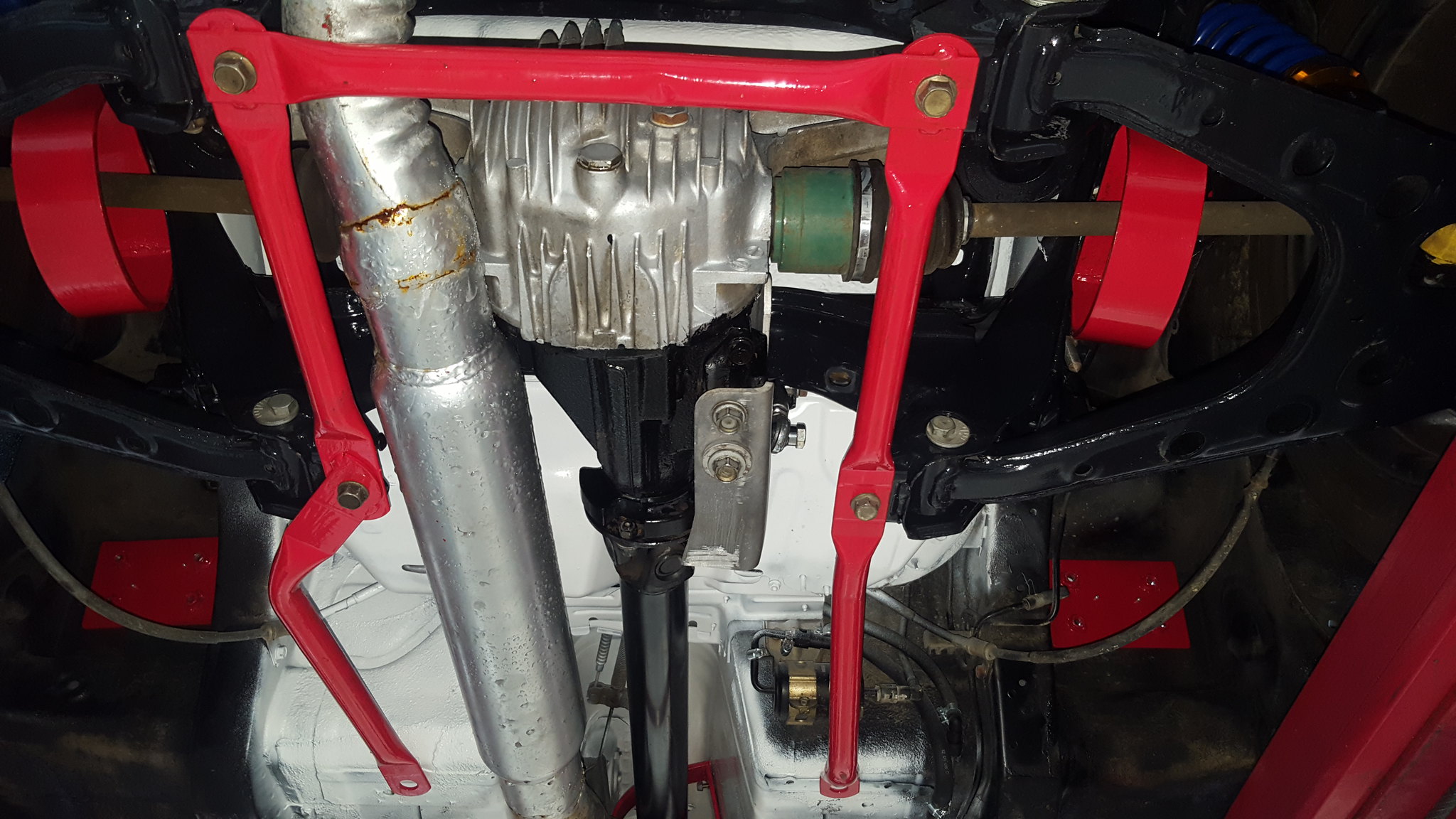

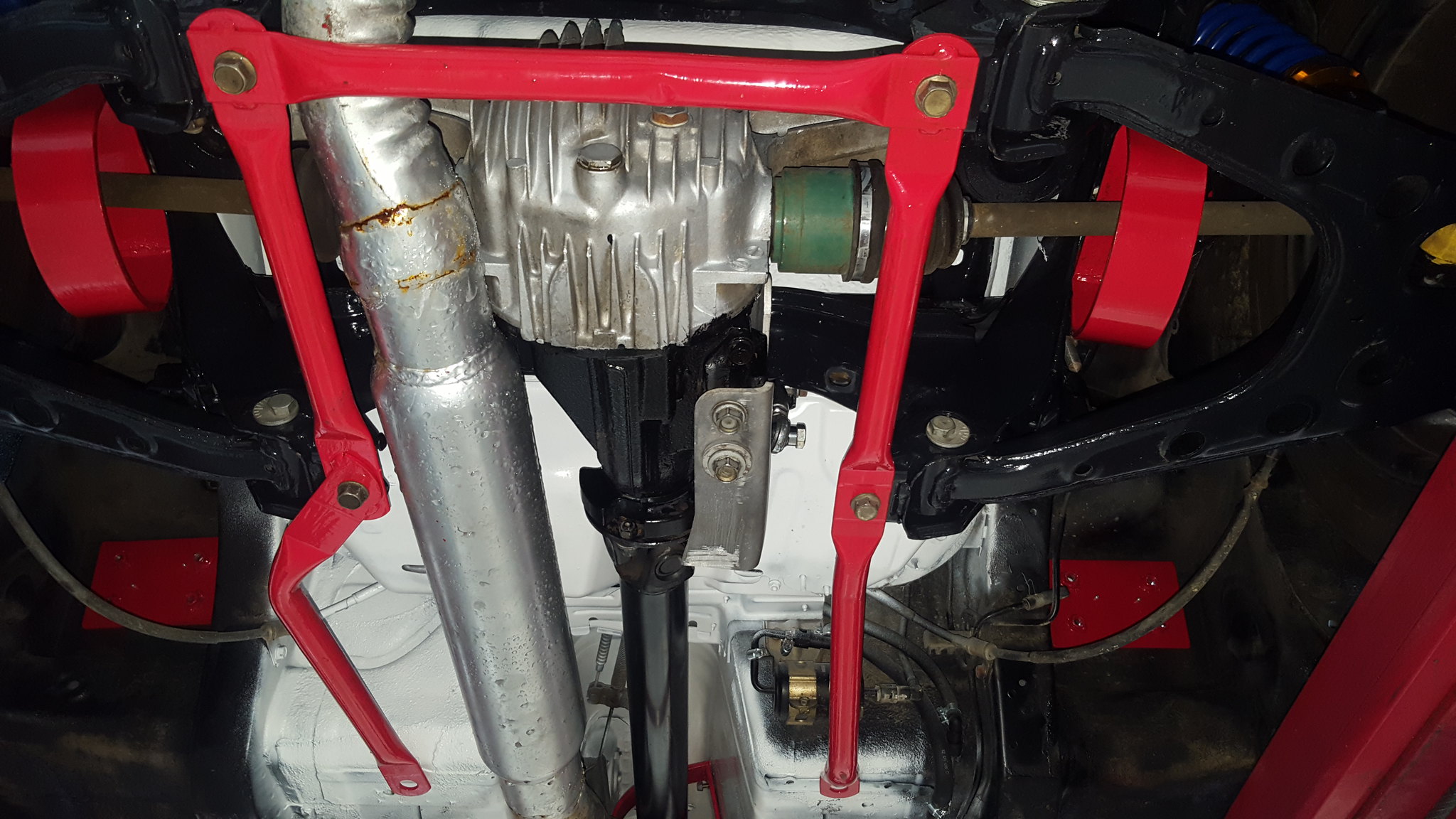

20180706_193250 by Michael Crawford, on Flickr then got it mated to the k frame

20180707_113131 by Michael Crawford, on Flickr and run home

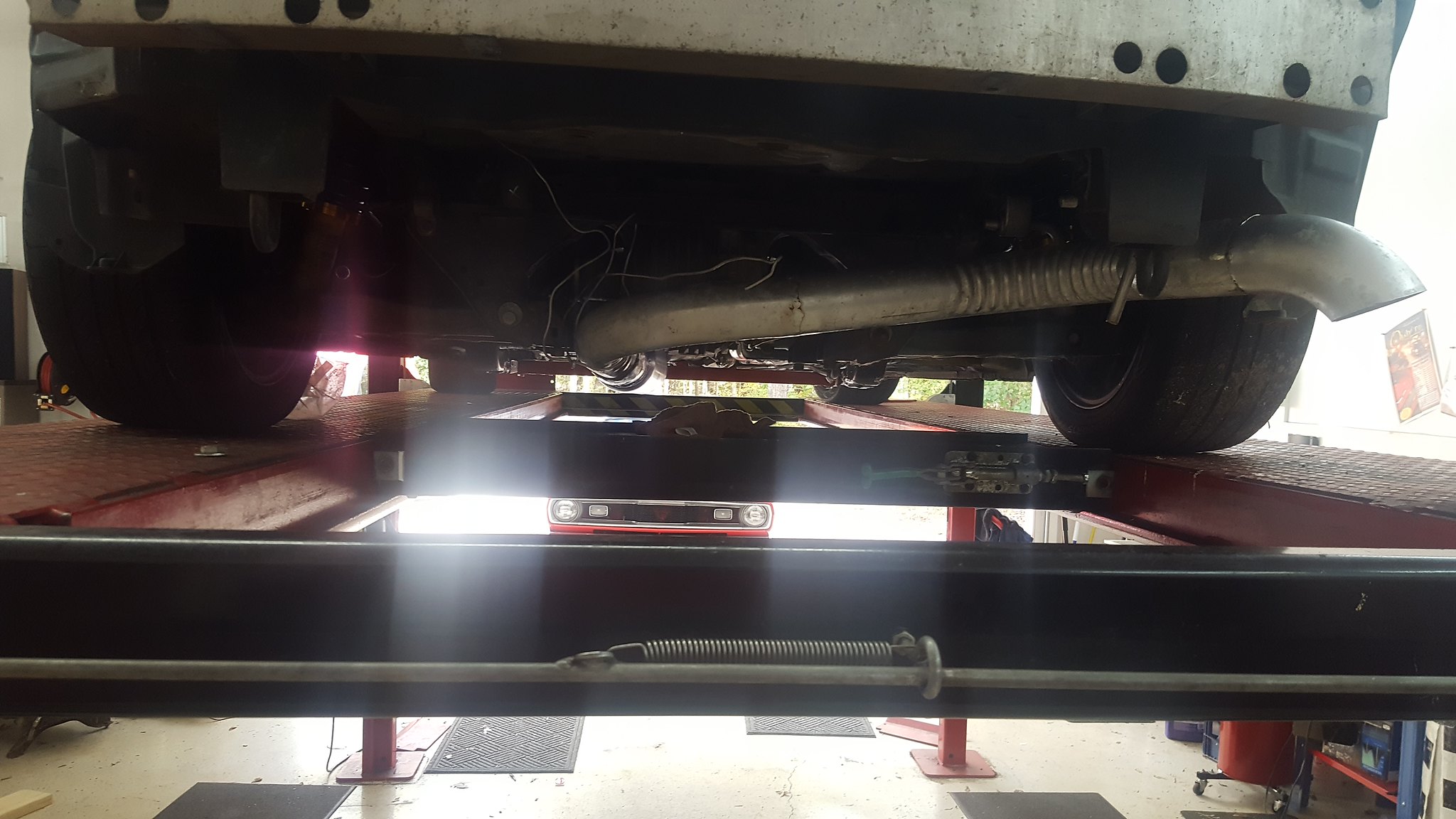

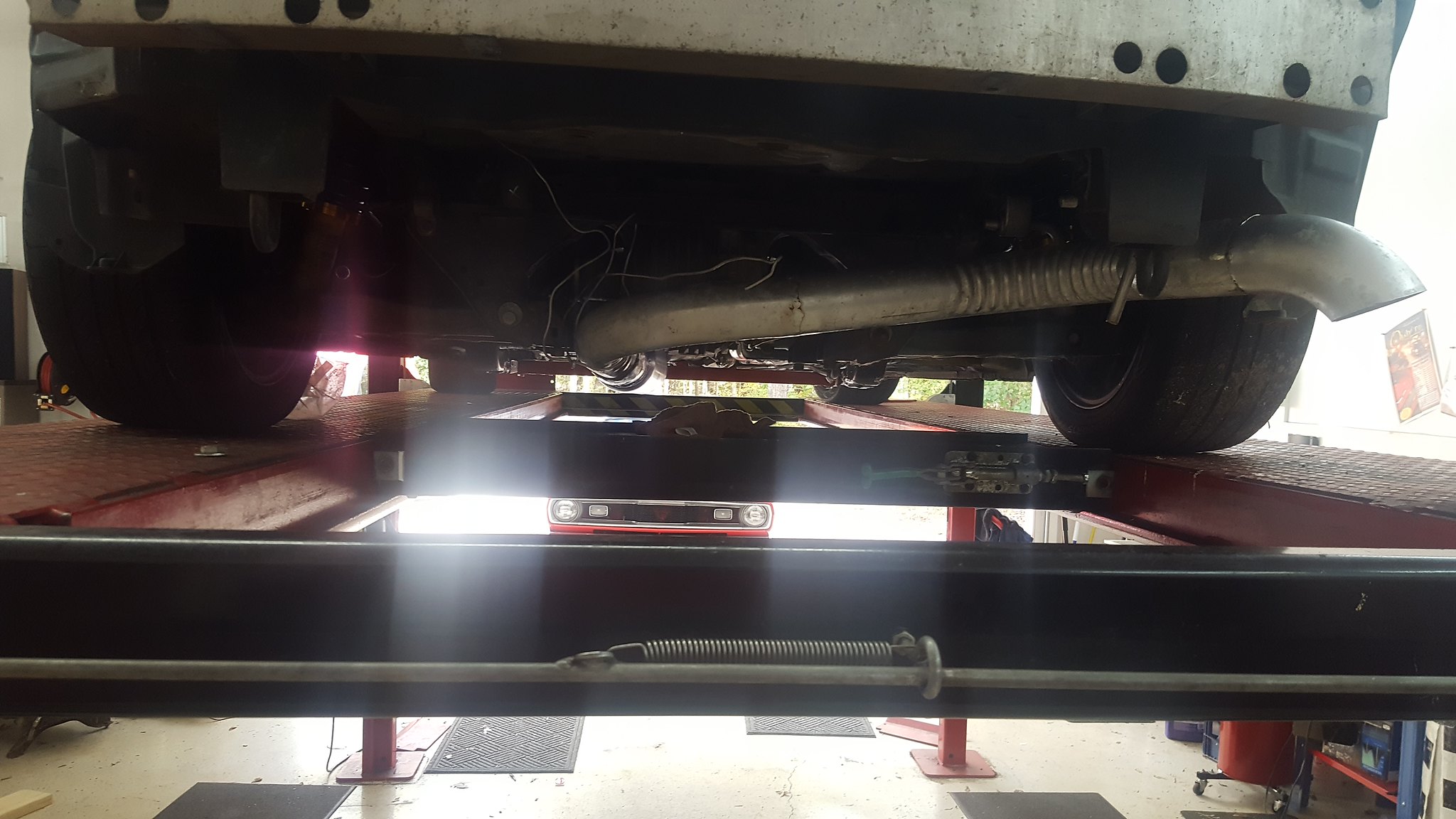

20180707_121624 by Michael Crawford, on Flickrmy joy stopped there. Apparently when welding the k frame, I warped the crap out of it. The rear 4 bolts didn't come close to fitting. So I quit for the night.

20180707_140651 by Michael Crawford, on FlickrToday I tackled it again. Using some creative jack placement, a scissors jack, some ingenuity and leverage, we spread the ears of the k frame that were warped. Its all bolted down. All the coilovers are found to be bottomed out at the moment (on the bumpstops). But by god, its on all 4!!!!

20180707_141856 by Michael Crawford, on Flickr

20180708_082055 by Michael Crawford, on FlickrI went ahead and started laying out the chassis side wiring. Near as I can tell, the chassis is just about standalone ready from the factory in 99. everything will work without the ECU except possibly some gauges and indicators (which I don't have anymore!). I will need to extend the starter and alternator charge wires to reach their new locations, and then find some convenient switched is start and run circuits for the GM engine. Not a whole lot of overlap of GM and Mazda as far as wiring goes, at least as far as I can tell at the moment.The biggest change to the harness is the battery leads and rear wiring. Factory they ran down the trans tunnel on the torque arm. Since that doesn't exist anymore, I ran it through the AC evaporator line hole, under the dash, down the passengers side rocker, and into the trunk.

20180708_090315 by Michael Crawford, on Flickr

20180708_095331 by Michael Crawford, on Flickr

20180708_113712 by Michael Crawford, on Flickr

20180708_113715 by Michael Crawford, on Flickr

20180708_113736 by Michael Crawford, on Flickr

20180708_113730 by Michael Crawford, on Flickr got the frog arms back in

20180708_113722 by Michael Crawford, on Flickrsometimes, you ****** defeat from the jaws of victory. Other times its vice versa!

revious challenge budget: 1709.68 recoup total: 820new money: plug wires: 10FMV

revious challenge budget: 1709.68 recoup total: 820new money: plug wires: 10FMVclutch kit: 52.99

plugs: 14.94

fuel injection hose: 2.98

exhaust manifold gaskets: 13.57 FMV new total: 1908.22

recoup: 820so, some ups and downs this week.Got the headers wrapped (first time ever wrapping headers). The stainless zip tie things that came with the header wrap sucked. So dad did safety wire at all the ends. Aint going nowhere now!

20180703_174436 by Michael Crawford, on Flickr

20180703_182229 by Michael Crawford, on FlickrI turned my flywheel on a brake lathe in preparation for putting a new clutch in. it was a hard decision, but I feel the right one. This may mean I forego turbo parts under challenge budget, but I would hate to end my race due to a failed worn out clutch. Much happier twisting an axle or breaking a trans or something.

20180702_165318 by Michael Crawford, on Flickrmy free, but put in the budget at FMV plug wires

20180702_131327 by Michael Crawford, on Flickr

20180702_131323 by Michael Crawford, on FlickrI got everything assembled on the stand except the upper intake, and started prepping the engine harness.

20180706_170509 by Michael Crawford, on Flickr

20180706_193250 by Michael Crawford, on Flickr then got it mated to the k frame

20180707_113131 by Michael Crawford, on Flickr and run home

20180707_121624 by Michael Crawford, on Flickrmy joy stopped there. Apparently when welding the k frame, I warped the crap out of it. The rear 4 bolts didn't come close to fitting. So I quit for the night.

20180707_140651 by Michael Crawford, on FlickrToday I tackled it again. Using some creative jack placement, a scissors jack, some ingenuity and leverage, we spread the ears of the k frame that were warped. Its all bolted down. All the coilovers are found to be bottomed out at the moment (on the bumpstops). But by god, its on all 4!!!!

20180707_141856 by Michael Crawford, on Flickr

20180708_082055 by Michael Crawford, on FlickrI went ahead and started laying out the chassis side wiring. Near as I can tell, the chassis is just about standalone ready from the factory in 99. everything will work without the ECU except possibly some gauges and indicators (which I don't have anymore!). I will need to extend the starter and alternator charge wires to reach their new locations, and then find some convenient switched is start and run circuits for the GM engine. Not a whole lot of overlap of GM and Mazda as far as wiring goes, at least as far as I can tell at the moment.The biggest change to the harness is the battery leads and rear wiring. Factory they ran down the trans tunnel on the torque arm. Since that doesn't exist anymore, I ran it through the AC evaporator line hole, under the dash, down the passengers side rocker, and into the trunk.

20180708_090315 by Michael Crawford, on Flickr

20180708_095331 by Michael Crawford, on Flickr

20180708_113712 by Michael Crawford, on Flickr

20180708_113715 by Michael Crawford, on Flickr

20180708_113736 by Michael Crawford, on Flickr

20180708_113730 by Michael Crawford, on Flickr got the frog arms back in

20180708_113722 by Michael Crawford, on Flickrsometimes, you ****** defeat from the jaws of victory. Other times its vice versa!

#65

Challenge budget so far revious challenge budget: 1709.68 recoup total: 820new money

revious challenge budget: 1709.68 recoup total: 820new money ulled some fittings I couldn't use from the budget, and added some I scrounged from boxes in the shop.Used 3 of the 5 dorman fittings, so I pulled that as well.So pretty much I just did budget cleanup for this. Recoup: 820

ulled some fittings I couldn't use from the budget, and added some I scrounged from boxes in the shop.Used 3 of the 5 dorman fittings, so I pulled that as well.So pretty much I just did budget cleanup for this. Recoup: 820

new total: 1882.05after the last update, we spent a LOT of time measuring the clutch, hydraulics, etc and doing math. Wanted to make sure wed have enough movement for disengagement. According to the measuring and math, we do! So I put the new clutch in, loctite on the flywheel and pressure plate bolts, etc.

20180702_165318 by Michael Crawford, on Flickr

20180714_105744 by Michael Crawford, on Flickr

20180714_110041 by Michael Crawford, on Flickrthen I put the trans in.nope.First the trans fouled the passengers side header. So I pulled it out.Found out that with the thermostat housing welded to the lower intake, the engine cant pivot far enough down to have the bellhousing clear. So I walked away and did other things for a while. It had stopped being fun.So, were back on it now. The reason? A clutch explosion in the duster. Stopped me cold on that project. And I was going through withdrawals of blank sheet hot rodding.Friday, dad and I dropped the engine and cross member out the bottom, and bolted the trans to the engine on the cradle. Took the opportunity to shorten the bump stops, reinstall the headers, install the fuel lines, etc.

20180810_101203 by Michael Crawford, on Flickrshifter coming through the insulation reminded me of the scene from aliens....

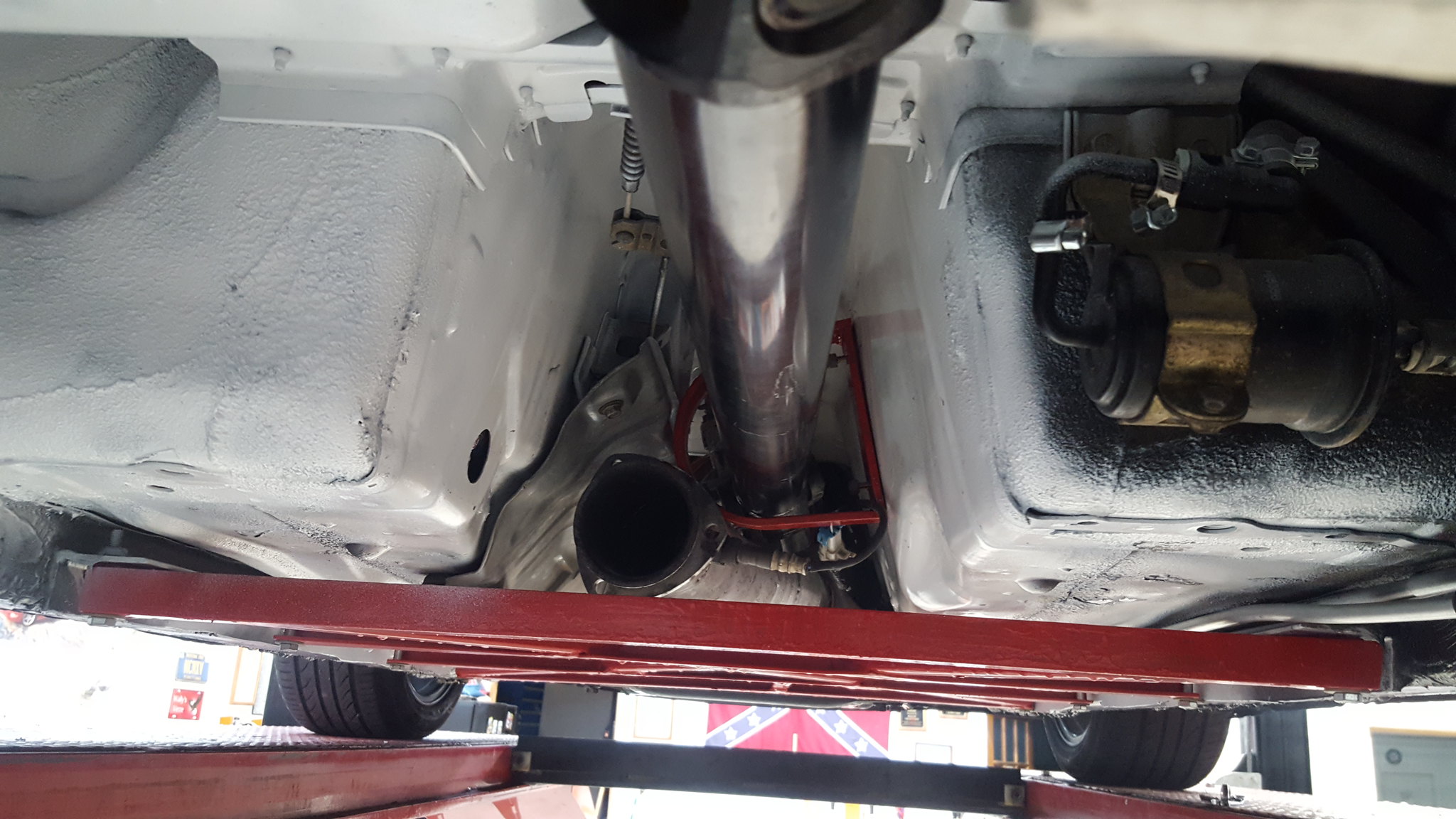

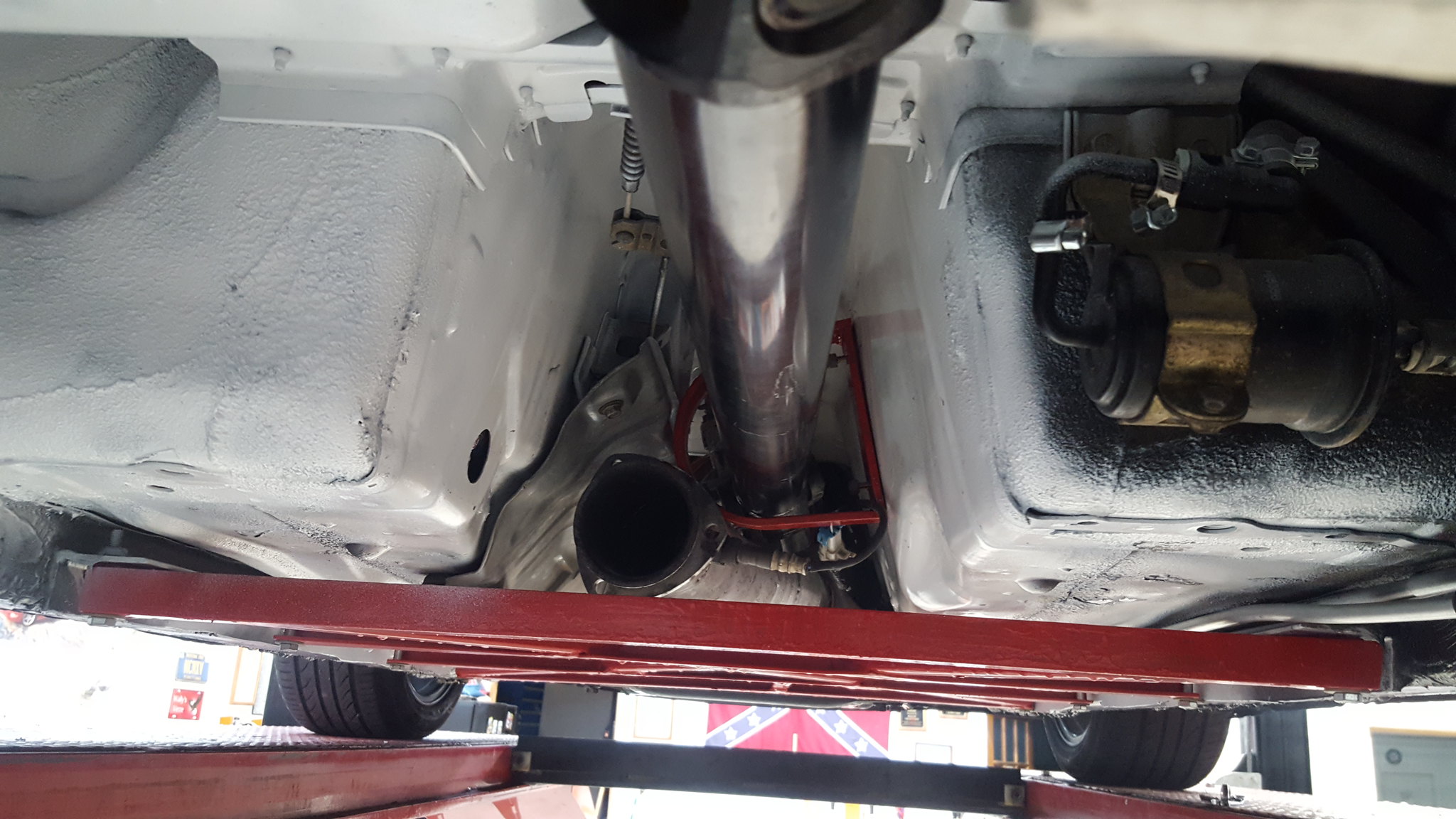

20180810_120931 by Michael Crawford, on Flickrbut, we got it all run home and butterfly brace installed to boot.

20180812_120458 by Michael Crawford, on Flickrtoday I worked on plumbing. Got all the brake lines tightened down, heater hoses and fuel lines run, lower radiator hose, and mocked up the upper hose.

20180812_100908 by Michael Crawford, on Flickrstarting to get excited now. Next stop is wiring, and yanking the rear suspension for bent parts replacement, torsen install, painting, etc.

revious challenge budget: 1709.68 recoup total: 820new money

revious challenge budget: 1709.68 recoup total: 820new money ulled some fittings I couldn't use from the budget, and added some I scrounged from boxes in the shop.Used 3 of the 5 dorman fittings, so I pulled that as well.So pretty much I just did budget cleanup for this. Recoup: 820

ulled some fittings I couldn't use from the budget, and added some I scrounged from boxes in the shop.Used 3 of the 5 dorman fittings, so I pulled that as well.So pretty much I just did budget cleanup for this. Recoup: 820new total: 1882.05after the last update, we spent a LOT of time measuring the clutch, hydraulics, etc and doing math. Wanted to make sure wed have enough movement for disengagement. According to the measuring and math, we do! So I put the new clutch in, loctite on the flywheel and pressure plate bolts, etc.

20180702_165318 by Michael Crawford, on Flickr

20180714_105744 by Michael Crawford, on Flickr

20180714_110041 by Michael Crawford, on Flickrthen I put the trans in.nope.First the trans fouled the passengers side header. So I pulled it out.Found out that with the thermostat housing welded to the lower intake, the engine cant pivot far enough down to have the bellhousing clear. So I walked away and did other things for a while. It had stopped being fun.So, were back on it now. The reason? A clutch explosion in the duster. Stopped me cold on that project. And I was going through withdrawals of blank sheet hot rodding.Friday, dad and I dropped the engine and cross member out the bottom, and bolted the trans to the engine on the cradle. Took the opportunity to shorten the bump stops, reinstall the headers, install the fuel lines, etc.

20180810_101203 by Michael Crawford, on Flickrshifter coming through the insulation reminded me of the scene from aliens....

20180810_120931 by Michael Crawford, on Flickrbut, we got it all run home and butterfly brace installed to boot.

20180812_120458 by Michael Crawford, on Flickrtoday I worked on plumbing. Got all the brake lines tightened down, heater hoses and fuel lines run, lower radiator hose, and mocked up the upper hose.

20180812_100908 by Michael Crawford, on Flickrstarting to get excited now. Next stop is wiring, and yanking the rear suspension for bent parts replacement, torsen install, painting, etc.

#66

Challenge budget so far revious challenge budget: 1882.05 recoup total: 820new money: oil filter sandwich plate: 17.99

revious challenge budget: 1882.05 recoup total: 820new money: oil filter sandwich plate: 17.99

water temp sender block: 4.52

radiator hose: 10.95 advance

shift light: 10.69

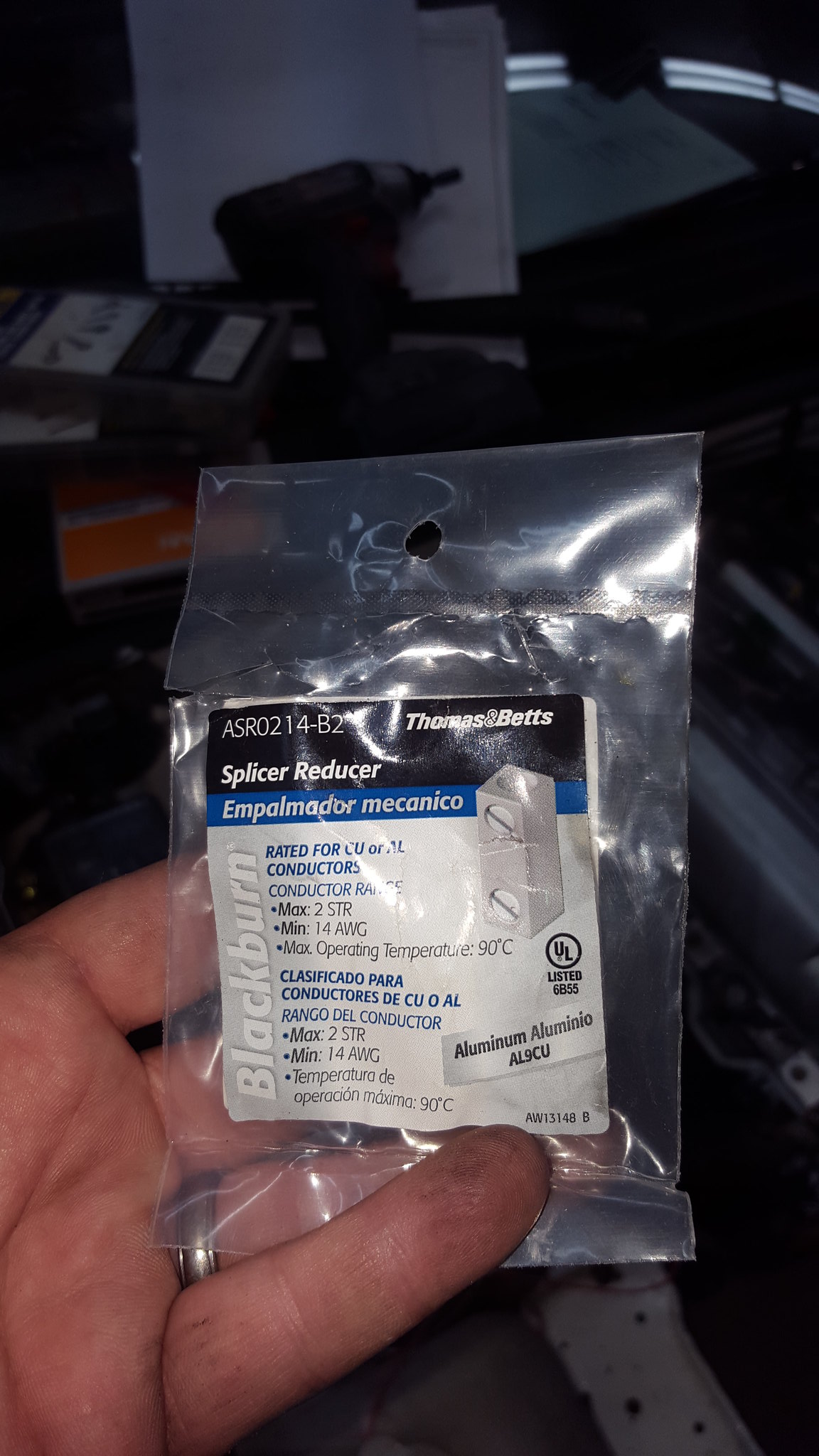

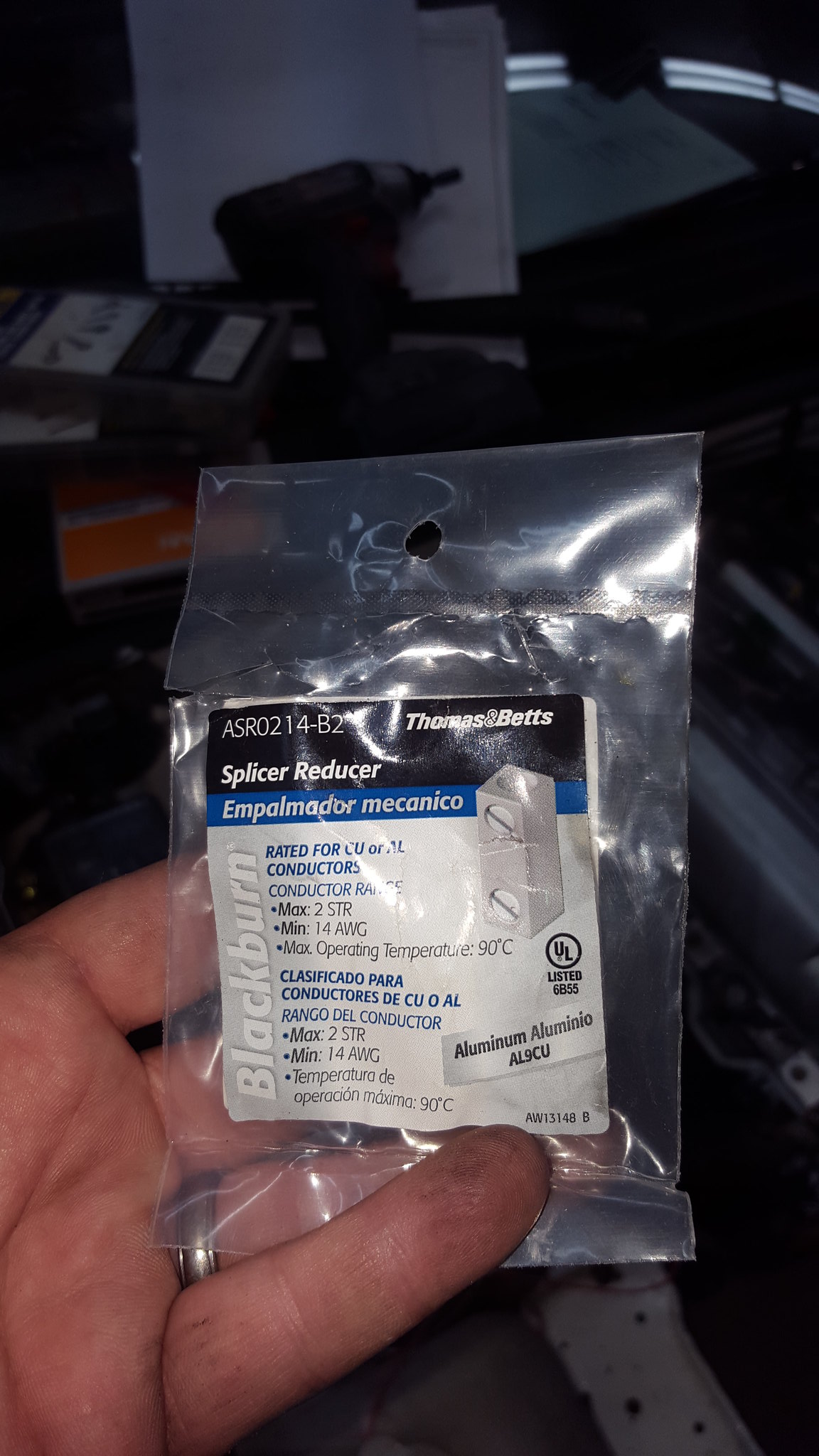

tuned ecm: 120, sinister performancebattery cable splice: lowes. 4.99 pack of 2, needed 1: 2.50removed turbo stuff from the budget. That sucked. Recoup: 820

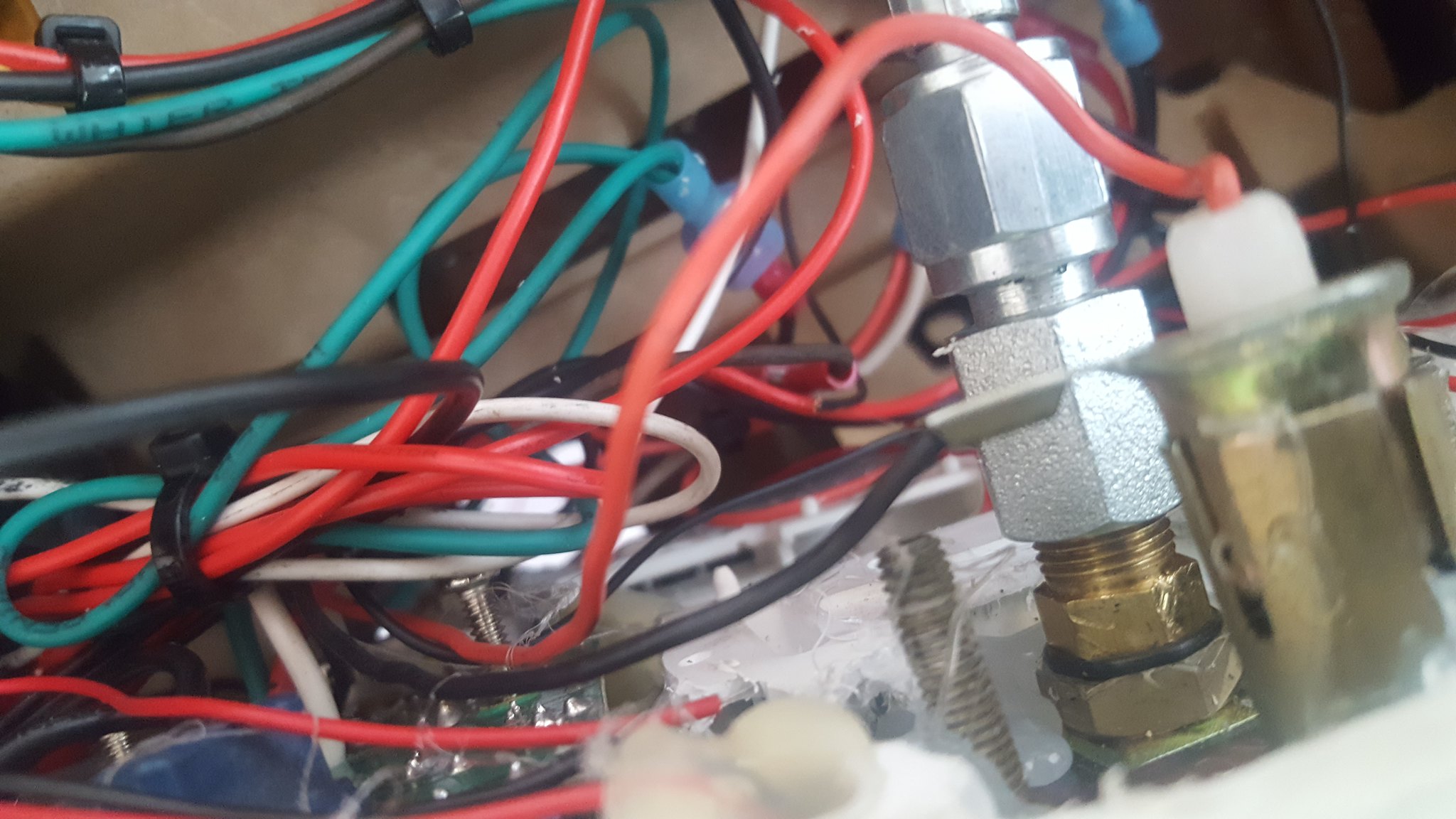

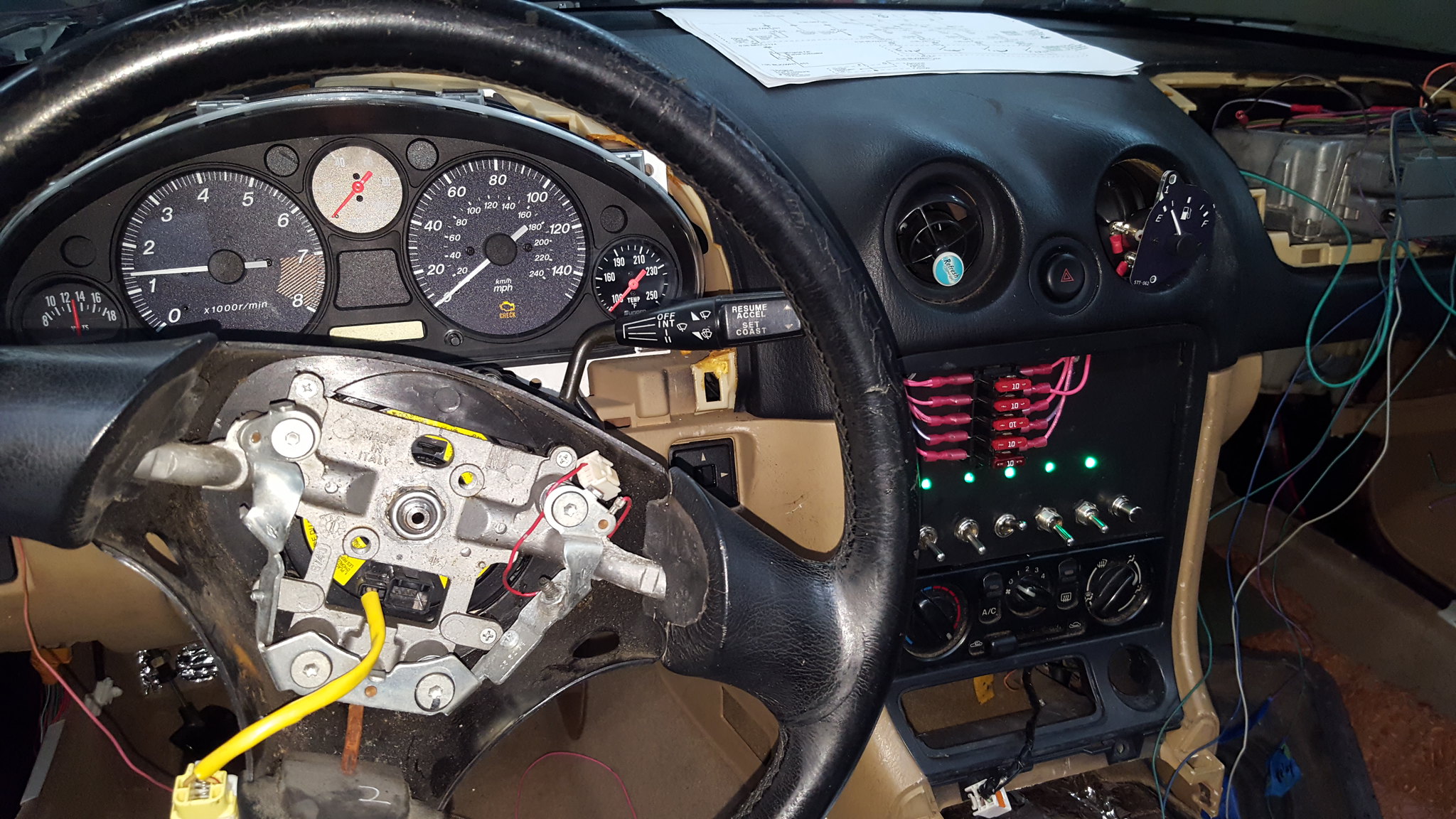

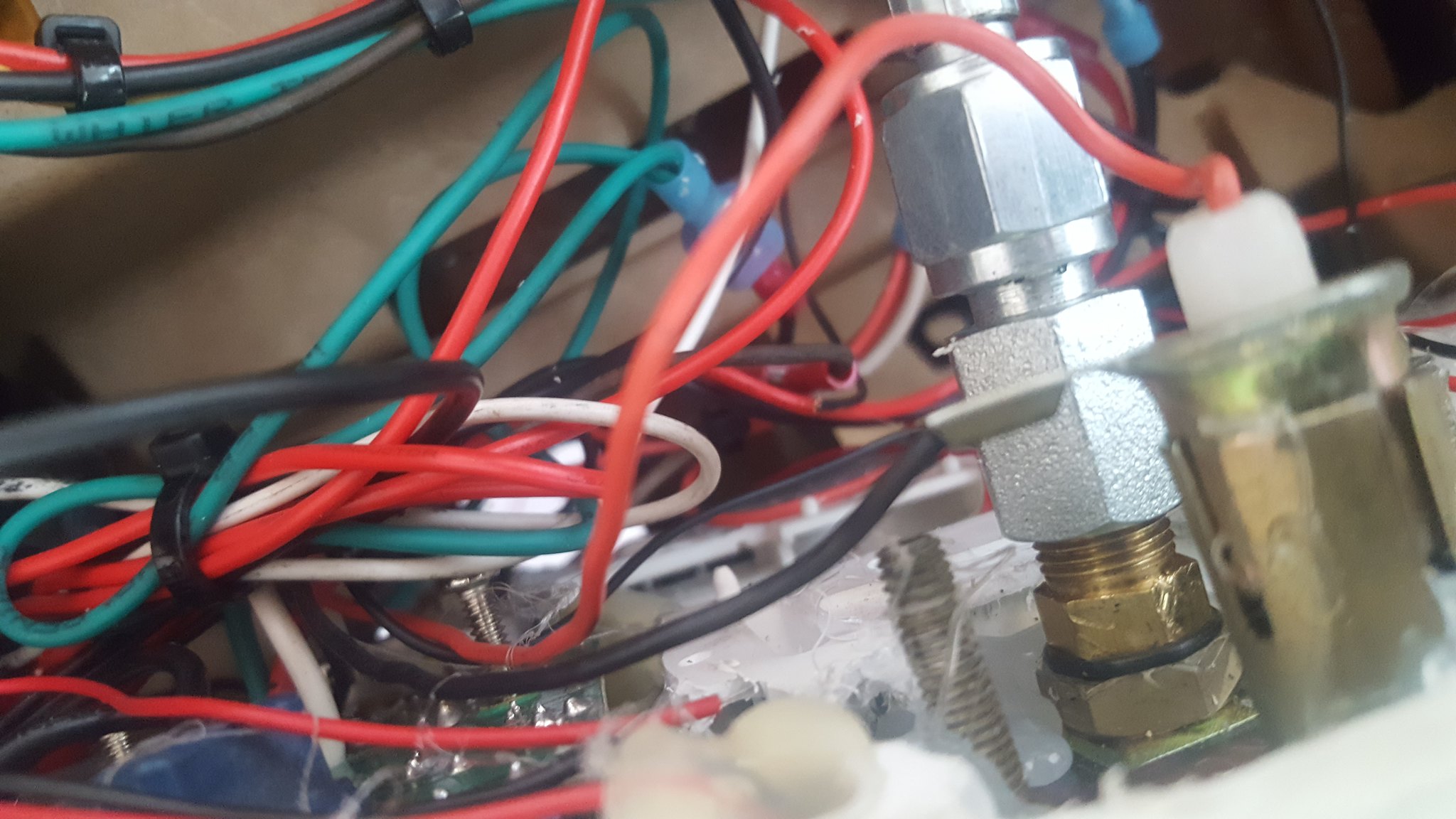

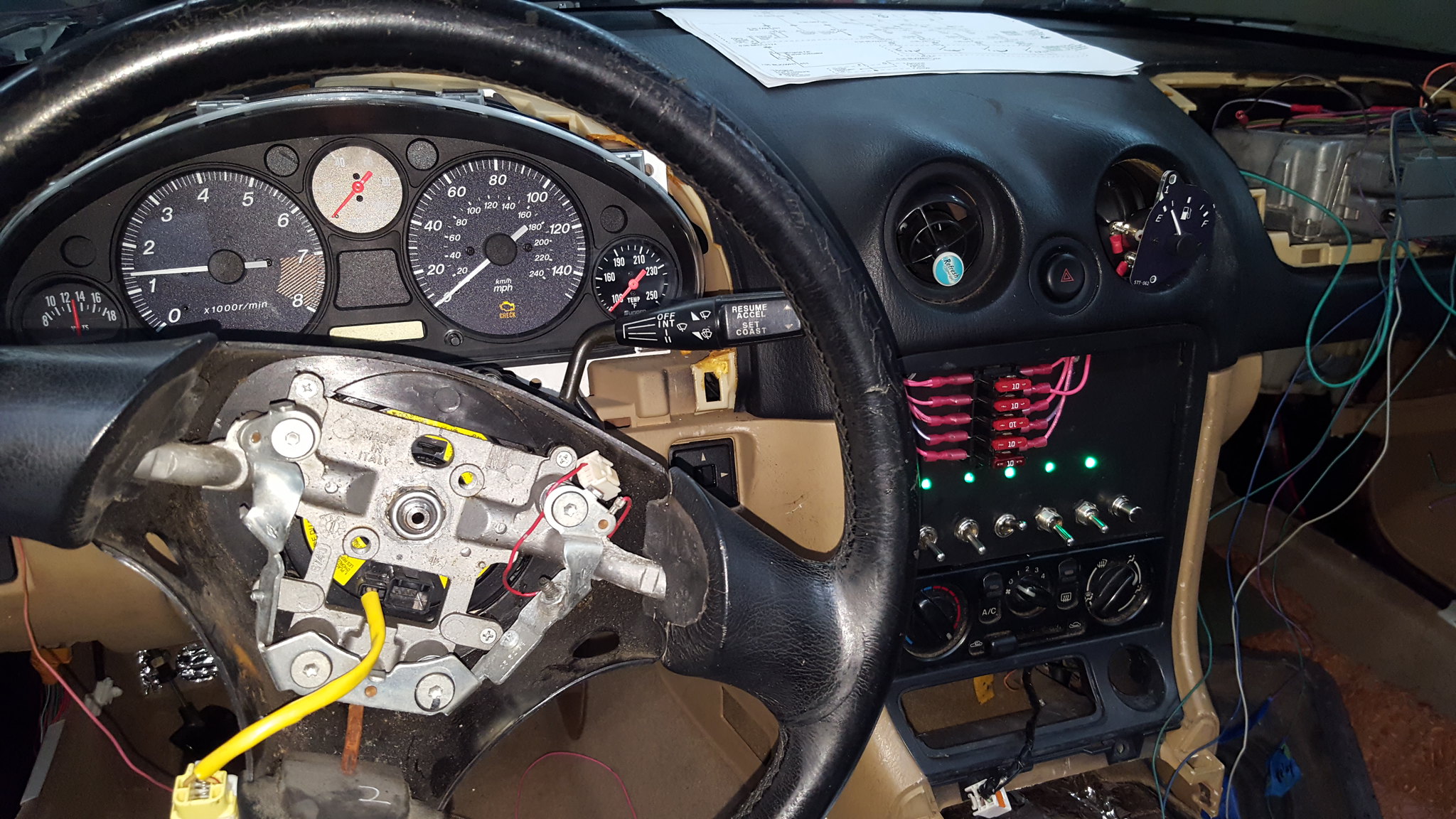

new total: 1932.70well, its been a minute since a legitimate update. Between working, the duster, the bmw, the truck, and family stuff, not a lot of time on this until recently (waiting on parts for the duster). So when we left off.....hell if I remember. Honestly. Its been a wild ride lately. So im just gonna throw it all out there is some way that makes sense to my pea brain.First up in my brain is wiring and such. Its really what ive been spending a lot of time and brain power on, so...I needed an ecm that had all the security measures removed. A friend on the GRM forum has HP tuners, and can do it for me. However, hes in Ohio. I'm not. And at the time, I was in a hurry thinking it was still possible to make $2018 (which is this week). So I spent the money to have it done by sinister performance. Well go back and reflash with HP tuners and fine tune it with a consummate reduction in budget after I actually prove this whole shitshow works.Anyway, we used the 01 impala ecm and harness as GM apparently really upped the security stuff by 04. so, I started de-building and rebuilding the mangled 01 harness. Used large sections of the rondevous harness. I also made the decision to take the easy way out. Almost completely separate harnesses. One for the chassis, one for the engine. The starter is all run off the mazda parts, and the only crossover will be at the battery, fuel pump and fan relays, and gauge cluster. I could have run relays and such, but free toggles, a crappy free fuse block, leftover LED bulbs, and lengths of assorted wires seemed quicker, easier, and cheaper (already had it all, most from pull-a-part and not charged for). The ECU fits beautifully in the cavity where the passengers airbag lived, and the switches/fuses/etc will live on a piece of plastic where the radio went. Anyway, some pictures that don't look like much, as wiring never does in pictures. But I can assure you, its a hell of a lot of work.... battery cable splice 20181007_164659 by Michael Crawford, on Flickrand how the charge cables, starter cables, etc laid out. The gold box came from a car at pull-a-part with a horribly installed amp setup....

20181007_164659 by Michael Crawford, on Flickrand how the charge cables, starter cables, etc laid out. The gold box came from a car at pull-a-part with a horribly installed amp setup.... 20181007_164653 by Michael Crawford, on Flickr then wiring. Lots and lots....

20181007_164653 by Michael Crawford, on Flickr then wiring. Lots and lots.... 20180923_122037 by Michael Crawford, on Flickr

20180923_122037 by Michael Crawford, on Flickr 20180923_154807 by Michael Crawford, on Flickr

20180923_154807 by Michael Crawford, on Flickr 20181003_175712 by Michael Crawford, on Flickr

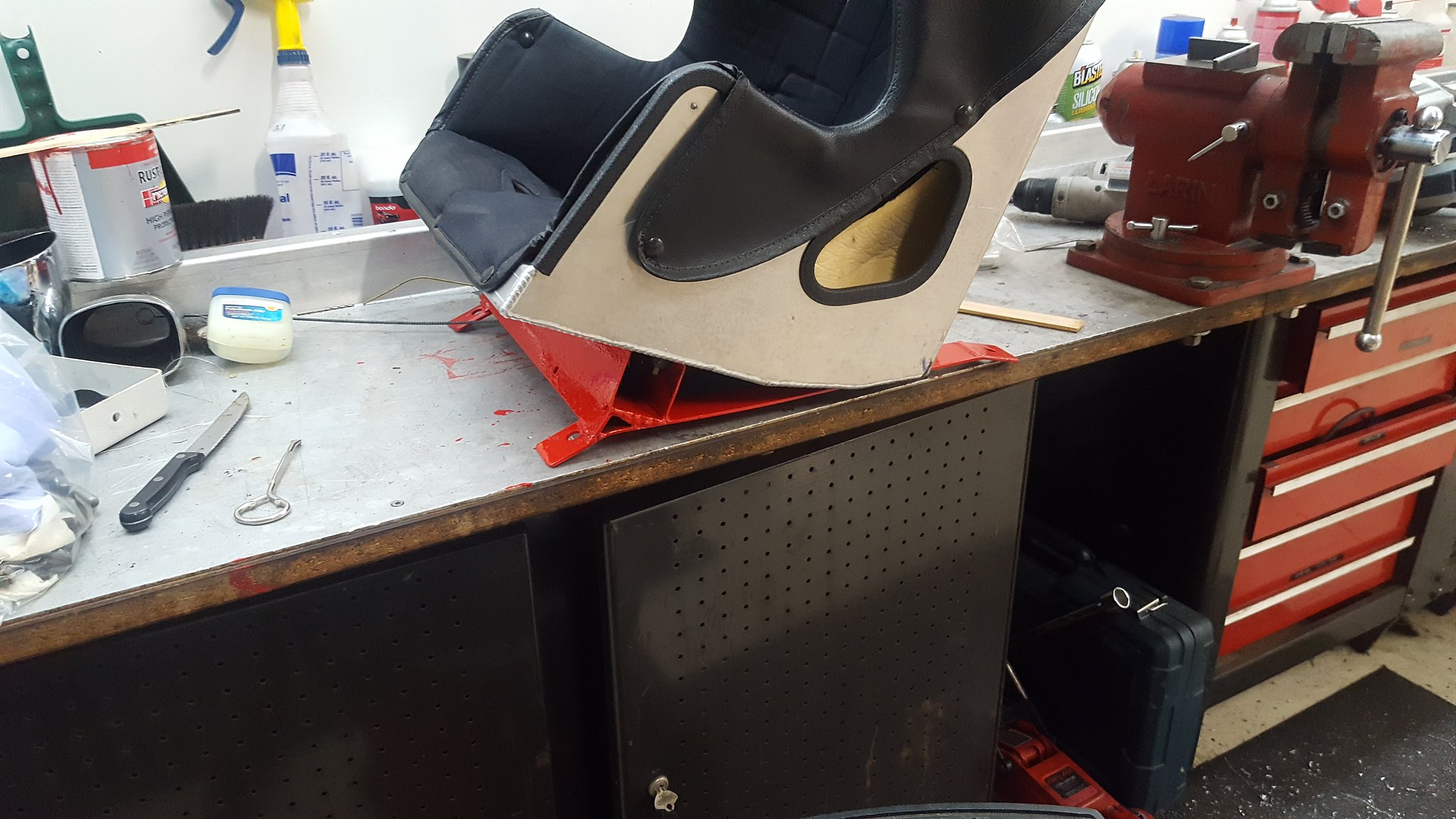

20181003_175712 by Michael Crawford, on Flickr 20181007_163208 by Michael Crawford, on Flickrthe CAD (cardboard aided design) template for the switch panel where the fuel gauge, aux fuse panel, and switches will live. Probably the CEL as well if there's room.

20181007_163208 by Michael Crawford, on Flickrthe CAD (cardboard aided design) template for the switch panel where the fuel gauge, aux fuse panel, and switches will live. Probably the CEL as well if there's room. 20181007_171044 by Michael Crawford, on Flickrdad found the by the road when he was mowing one day. We have no idea what the hell it is, but its plastic and big enough for what I need. Ill trace the template, cut it on the bandsaw, and then drill a ton of holes in it and mount it up like some sort of freak reject from a elementary school science fair.

20181007_171044 by Michael Crawford, on Flickrdad found the by the road when he was mowing one day. We have no idea what the hell it is, but its plastic and big enough for what I need. Ill trace the template, cut it on the bandsaw, and then drill a ton of holes in it and mount it up like some sort of freak reject from a elementary school science fair. 20181007_171107 by Michael Crawford, on Flickrreally, the only other things ive accomplished are plumbing things. The upper radiator hose has been a mother, but after 13 different attempts (no BS) we found a workable solution. The black block in between the two sections is a ryanstar inline water temp sender block. It came with an 1/8 hole in it. My mechanical gauge requires an NPT fitting that's freaking huge. Brother Dallas, being a plumber, has NPT taps. So ill modify it at his house. I don't own any and they're like 20 bucks.

20181007_171107 by Michael Crawford, on Flickrreally, the only other things ive accomplished are plumbing things. The upper radiator hose has been a mother, but after 13 different attempts (no BS) we found a workable solution. The black block in between the two sections is a ryanstar inline water temp sender block. It came with an 1/8 hole in it. My mechanical gauge requires an NPT fitting that's freaking huge. Brother Dallas, being a plumber, has NPT taps. So ill modify it at his house. I don't own any and they're like 20 bucks. 20181006_141426 by Michael Crawford, on Flickrthe other thing was I ordered an oil filter sandwich plate to have a place to hook up my mechanical gauge. I would really rather use a t-fitting and the port that goes to the ECMs oil pressure sender, but its rusted into the block so bad I cant get it out with the engine in place. I ain't pulling the engine again unless I have to. So, budget buggery it is!In other news, we got the fuel system pressure tested. Held full pressure with no leaks first time. No picture, because how the hell do you take a picture of fuel flowing through a hose without leaking?Until next time, y'all. Hug your family and say a prayer of thanks for your health. Never know how long you'll have both.

20181006_141426 by Michael Crawford, on Flickrthe other thing was I ordered an oil filter sandwich plate to have a place to hook up my mechanical gauge. I would really rather use a t-fitting and the port that goes to the ECMs oil pressure sender, but its rusted into the block so bad I cant get it out with the engine in place. I ain't pulling the engine again unless I have to. So, budget buggery it is!In other news, we got the fuel system pressure tested. Held full pressure with no leaks first time. No picture, because how the hell do you take a picture of fuel flowing through a hose without leaking?Until next time, y'all. Hug your family and say a prayer of thanks for your health. Never know how long you'll have both.

revious challenge budget: 1882.05 recoup total: 820new money: oil filter sandwich plate: 17.99

revious challenge budget: 1882.05 recoup total: 820new money: oil filter sandwich plate: 17.99water temp sender block: 4.52

radiator hose: 10.95 advance

shift light: 10.69

tuned ecm: 120, sinister performancebattery cable splice: lowes. 4.99 pack of 2, needed 1: 2.50removed turbo stuff from the budget. That sucked. Recoup: 820

new total: 1932.70well, its been a minute since a legitimate update. Between working, the duster, the bmw, the truck, and family stuff, not a lot of time on this until recently (waiting on parts for the duster). So when we left off.....hell if I remember. Honestly. Its been a wild ride lately. So im just gonna throw it all out there is some way that makes sense to my pea brain.First up in my brain is wiring and such. Its really what ive been spending a lot of time and brain power on, so...I needed an ecm that had all the security measures removed. A friend on the GRM forum has HP tuners, and can do it for me. However, hes in Ohio. I'm not. And at the time, I was in a hurry thinking it was still possible to make $2018 (which is this week). So I spent the money to have it done by sinister performance. Well go back and reflash with HP tuners and fine tune it with a consummate reduction in budget after I actually prove this whole shitshow works.Anyway, we used the 01 impala ecm and harness as GM apparently really upped the security stuff by 04. so, I started de-building and rebuilding the mangled 01 harness. Used large sections of the rondevous harness. I also made the decision to take the easy way out. Almost completely separate harnesses. One for the chassis, one for the engine. The starter is all run off the mazda parts, and the only crossover will be at the battery, fuel pump and fan relays, and gauge cluster. I could have run relays and such, but free toggles, a crappy free fuse block, leftover LED bulbs, and lengths of assorted wires seemed quicker, easier, and cheaper (already had it all, most from pull-a-part and not charged for). The ECU fits beautifully in the cavity where the passengers airbag lived, and the switches/fuses/etc will live on a piece of plastic where the radio went. Anyway, some pictures that don't look like much, as wiring never does in pictures. But I can assure you, its a hell of a lot of work.... battery cable splice

20181007_164659 by Michael Crawford, on Flickrand how the charge cables, starter cables, etc laid out. The gold box came from a car at pull-a-part with a horribly installed amp setup....

20181007_164659 by Michael Crawford, on Flickrand how the charge cables, starter cables, etc laid out. The gold box came from a car at pull-a-part with a horribly installed amp setup.... 20181007_164653 by Michael Crawford, on Flickr then wiring. Lots and lots....

20181007_164653 by Michael Crawford, on Flickr then wiring. Lots and lots.... 20180923_122037 by Michael Crawford, on Flickr

20180923_122037 by Michael Crawford, on Flickr 20180923_154807 by Michael Crawford, on Flickr

20180923_154807 by Michael Crawford, on Flickr 20181003_175712 by Michael Crawford, on Flickr

20181003_175712 by Michael Crawford, on Flickr 20181007_163208 by Michael Crawford, on Flickrthe CAD (cardboard aided design) template for the switch panel where the fuel gauge, aux fuse panel, and switches will live. Probably the CEL as well if there's room.

20181007_163208 by Michael Crawford, on Flickrthe CAD (cardboard aided design) template for the switch panel where the fuel gauge, aux fuse panel, and switches will live. Probably the CEL as well if there's room. 20181007_171044 by Michael Crawford, on Flickrdad found the by the road when he was mowing one day. We have no idea what the hell it is, but its plastic and big enough for what I need. Ill trace the template, cut it on the bandsaw, and then drill a ton of holes in it and mount it up like some sort of freak reject from a elementary school science fair.

20181007_171044 by Michael Crawford, on Flickrdad found the by the road when he was mowing one day. We have no idea what the hell it is, but its plastic and big enough for what I need. Ill trace the template, cut it on the bandsaw, and then drill a ton of holes in it and mount it up like some sort of freak reject from a elementary school science fair. 20181007_171107 by Michael Crawford, on Flickrreally, the only other things ive accomplished are plumbing things. The upper radiator hose has been a mother, but after 13 different attempts (no BS) we found a workable solution. The black block in between the two sections is a ryanstar inline water temp sender block. It came with an 1/8 hole in it. My mechanical gauge requires an NPT fitting that's freaking huge. Brother Dallas, being a plumber, has NPT taps. So ill modify it at his house. I don't own any and they're like 20 bucks.

20181007_171107 by Michael Crawford, on Flickrreally, the only other things ive accomplished are plumbing things. The upper radiator hose has been a mother, but after 13 different attempts (no BS) we found a workable solution. The black block in between the two sections is a ryanstar inline water temp sender block. It came with an 1/8 hole in it. My mechanical gauge requires an NPT fitting that's freaking huge. Brother Dallas, being a plumber, has NPT taps. So ill modify it at his house. I don't own any and they're like 20 bucks. 20181006_141426 by Michael Crawford, on Flickrthe other thing was I ordered an oil filter sandwich plate to have a place to hook up my mechanical gauge. I would really rather use a t-fitting and the port that goes to the ECMs oil pressure sender, but its rusted into the block so bad I cant get it out with the engine in place. I ain't pulling the engine again unless I have to. So, budget buggery it is!In other news, we got the fuel system pressure tested. Held full pressure with no leaks first time. No picture, because how the hell do you take a picture of fuel flowing through a hose without leaking?Until next time, y'all. Hug your family and say a prayer of thanks for your health. Never know how long you'll have both.

20181006_141426 by Michael Crawford, on Flickrthe other thing was I ordered an oil filter sandwich plate to have a place to hook up my mechanical gauge. I would really rather use a t-fitting and the port that goes to the ECMs oil pressure sender, but its rusted into the block so bad I cant get it out with the engine in place. I ain't pulling the engine again unless I have to. So, budget buggery it is!In other news, we got the fuel system pressure tested. Held full pressure with no leaks first time. No picture, because how the hell do you take a picture of fuel flowing through a hose without leaking?Until next time, y'all. Hug your family and say a prayer of thanks for your health. Never know how long you'll have both.

#67

Challenge budget so far revious challenge budget: 1932.70 recoup total: 820new money: oil filter sandwich plate: 5

revious challenge budget: 1932.70 recoup total: 820new money: oil filter sandwich plate: 5

oil pressure gauge fitting: .97

belt: 21.99removed purchased oil filter sandwich plate: -17.99removed quart of holy freaking green: -14.98removed oil pan gasket and plugs per new rules (I deleted them from my spreadsheet and dont feel like looking at the moment. Additionally, I found the other oil pan gasket....) Recoup: 820

new total: 1877.19I've been like a ping pong ball in a blender lately. Doing way too much on way too many things. So this update will be a little scattered. Between going with my family to all sorts of fall events, working WAY too much, fixing the duster, etc, ive been having a hard time keeping track of what im doing with this.So, to start:the plastidip that was done to this car has turned to goo over much of it. Ive been working on peeling/scraping it from the plastics. I tried aircraft stripper, and luckily it didn't damage the plastic. But it wasn't my best idea. Ive found mineral spirits and lacquer thinner with an sos pad, as well as a razor blade to be the most effective means so far. And child labor. (she likes peeling the stuff that will peel) we've got the front bumper done, rear most of the way, and lots more to go everywhere else.

1540468889_15404688612351221519150_mmthumb by Michael Crawford, on Flickr

20181025_141225 by Michael Crawford, on Flickr

20181029_144150 by Michael Crawford, on Flickrnext up is belt routing. I finally figured out what size belt fits. Spent way too much on a belt, but have learned that the original application is a dodge intrepid. Ill snag a used belt next time at the junkyard. That'll cut $19 from the budget. And it'll make me happy to have mopar parts on this.

20181026_185835 by Michael Crawford, on Flickr

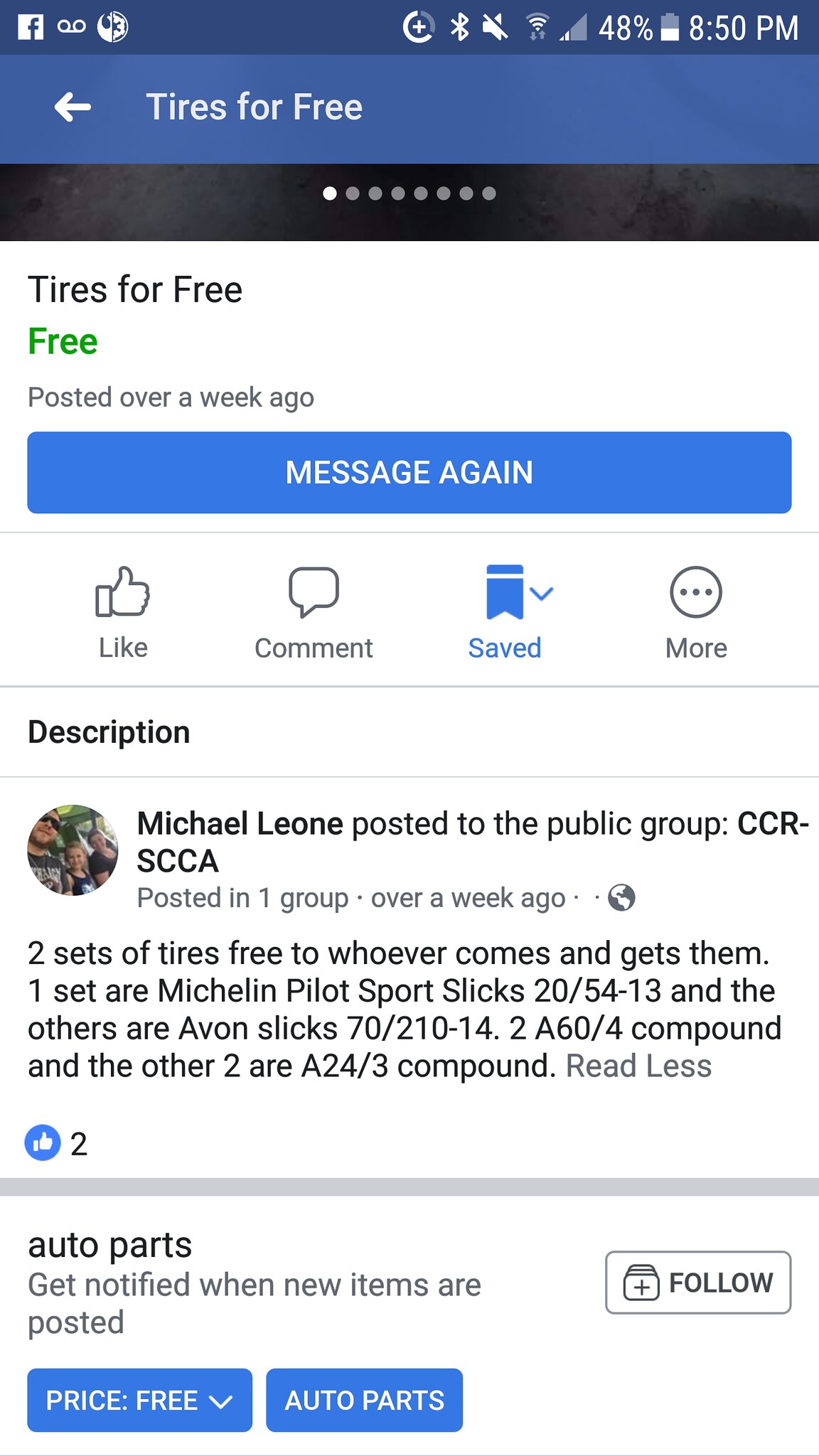

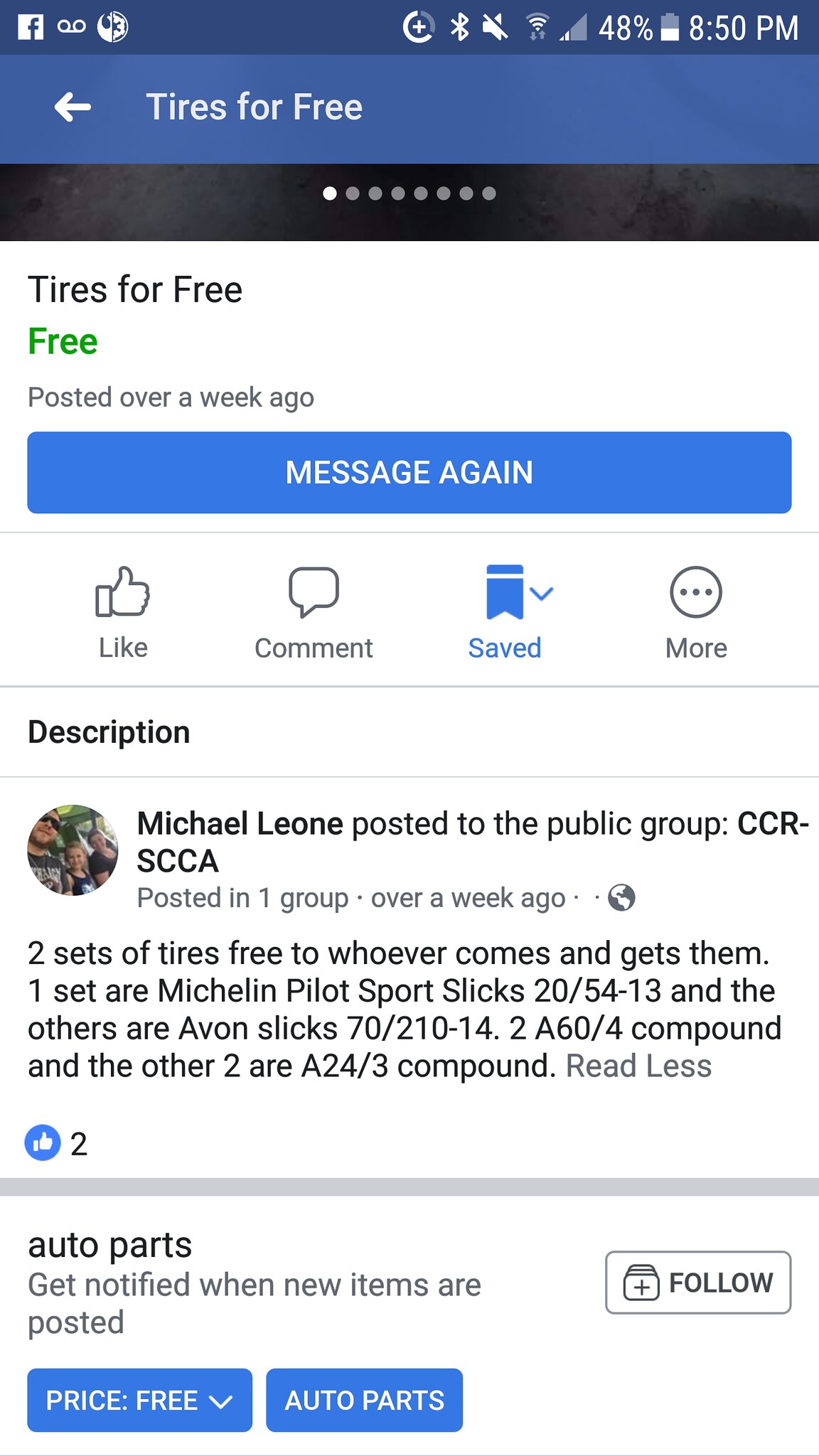

20181026_185904 by Michael Crawford, on FlickrI also picked up some free slicks for the 14s. 21X7x14 avon medium compound. Should cut $140 from the budget if they prove as fast at the SM7 on 15x6 in testing. Im sure as hell going to try! Very nice guy with some awesome garage hardware. And a really nice day and drive with my wife.

Screenshot_20181027-205009 by Michael Crawford, on Flickrthe kinked oil pressure line was really bothering me. The ultra-lites I bought, and then self traded for came with a braided line and a couple of fittings. The engine side fit my oil pressure sandwich plate fine, however the gauge end wouldn't fit. It was 1/8 female NPT, and the sunpro wasn't. So I bought a brass block off plug with a hex head for $.97, drilled, and tapped to make an o-ring sealing bushing (the threads were I think, 5/16 fine. Don't quote me)

20181019_202159 by Michael Crawford, on Flickr

20181026_194239 by Michael Crawford, on Flickr

20181026_194626 by Michael Crawford, on Flickr

20181104_105634 by Michael Crawford, on Flickrhad to make some clearance for it behind the instrument panel.

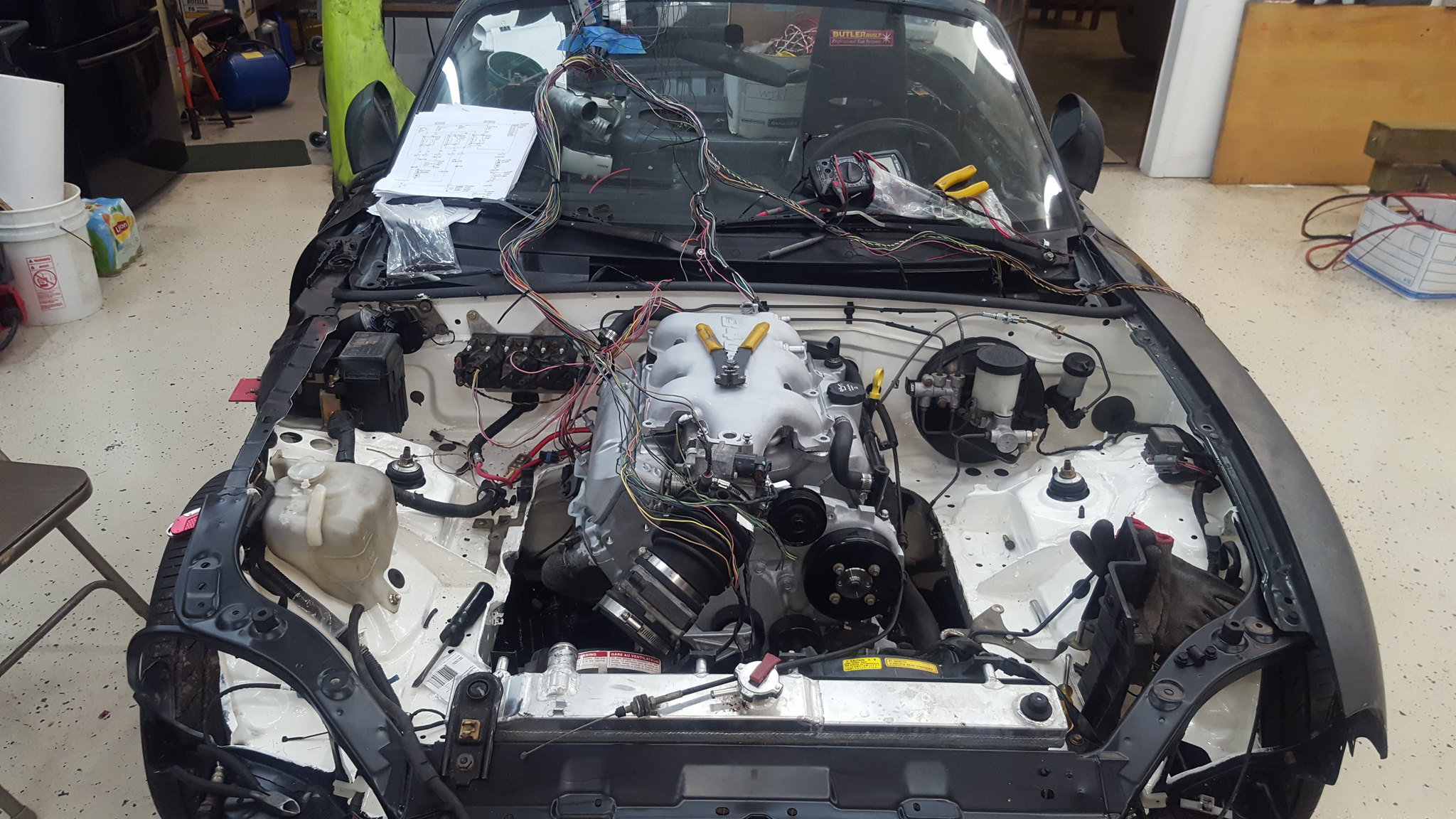

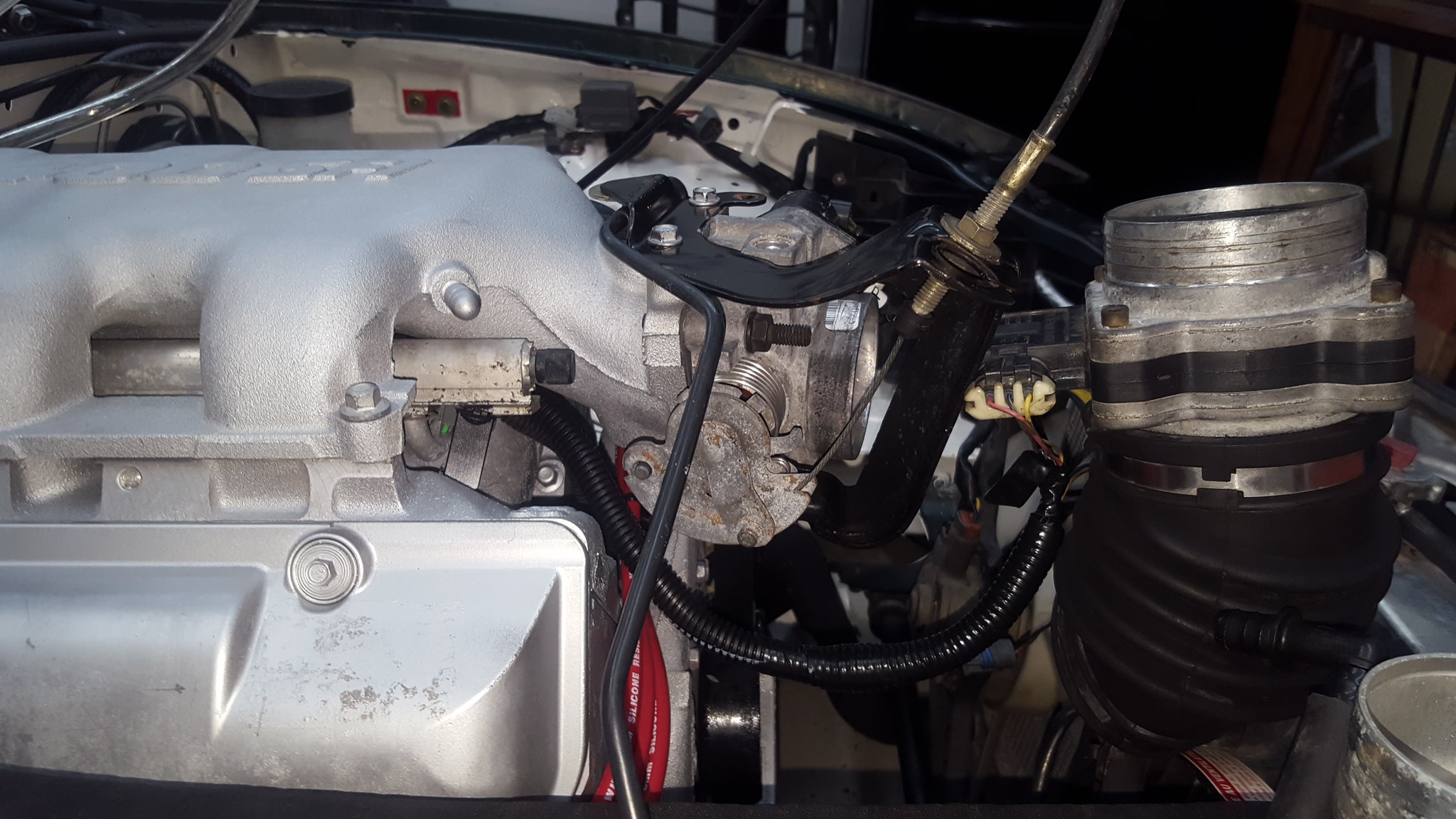

20181104_105627 by Michael Crawford, on Flickrnext, wiring and engine bay stuff.Obviosly, youve seen that the engine is together and wired. But here's some details.The ECM is run almost completely independent from the chassis. Only crossover points are the fan relays, fuel pump relay, OBD2 port, and instrument panel. I built a switch panel from scrap plastic, a free pull-a-part fuse block, some leftover LEDs, and used toggles. It has only now dawned on me that I could have relayed the fuse block, and made life much simpler. Thats revision 2 coming soon. Anyway, I did my best to make the whole engine bay side of things clean, neat, and mostly hidden. Routed the plug wires with zip tie looms, and trying my best to make the hoses neat and tidy (haven't done the fuel pressure regulator/MAP/crankcase vent yet). I'm happy with how its coming out for the most part.

20181019_190432 by Michael Crawford, on Flickr

20181019_190437 by Michael Crawford, on Flickr

20181019_202227 by Michael Crawford, on Flickr

20181021_102253 by Michael Crawford, on Flickr

20181023_170526 by Michael Crawford, on Flickr

20181023_180020 by Michael Crawford, on Flickr

20181025_191007 by Michael Crawford, on Flickrthis brings us up to exhaust. At the end of the post will be a few YouTube links. Needless to say, exhaust on this was NOT optional. We were shooting fireballs from the open headers. But it RUNS now, and actually sounds good. I had to tweak the exhaust upon re-installation for no obvious reason, except the one where I forgot an oxygen sensor bung. But for no good reason the midpipes were now too short, so I had to extend the legs of my merge collector. And I also cut the mushroom heads off the hangars to make install and removal of the rear section easier. I also had to move the collector down towards the butterfly brace so it would stop hitting the driveshaft.But its done now, and sounds GOOD. to me it sounds a lot like an indy car.

20181104_105836 by Michael Crawford, on Flickr

20181104_105844 by Michael Crawford, on Flickr

20181104_105827 by Michael Crawford, on FlickrI backed it out in the driveway to wash the engine bay (it was FILTHY. Pure white looks great when its clean though) and settle the suspension. Its really, really low. The coilovers are and full drop, so it has plenty of room to go up.

20181104_111727 by Michael Crawford, on Flickr

20181104_111747 by Michael Crawford, on Flickr

20181104_111826_001 by Michael Crawford, on Flickr

20181104_112225 by Michael Crawford, on Flickr

20181104_113433 by Michael Crawford, on Flickrso, videos. Because everyone likes video. And these are monumental achievements for me. Near as I can tell, this is the first FWD 60*v6 in a miata that has ever been done. This is also proof that you don't have to spend thousands to do an engine swap. Or be a genius (cause im sure not!). First fire:

legit first run time. It ran long enough to make us sick with the fumes from the header wrap and paint, and the fans to kick on.

shooting fireballs

and with exhaust

next steps are:Figuring out why it has such nasty hesitation.Figuring out how to get the OBD2 port functionalFiguring out how to support the differential without the PPF existing. Sold mount up front maybe?Pulling and painting the rear suspension, as well as brakesmaking a hood fit, and air cleaner assembly.

revious challenge budget: 1932.70 recoup total: 820new money: oil filter sandwich plate: 5

revious challenge budget: 1932.70 recoup total: 820new money: oil filter sandwich plate: 5oil pressure gauge fitting: .97

belt: 21.99removed purchased oil filter sandwich plate: -17.99removed quart of holy freaking green: -14.98removed oil pan gasket and plugs per new rules (I deleted them from my spreadsheet and dont feel like looking at the moment. Additionally, I found the other oil pan gasket....) Recoup: 820

new total: 1877.19I've been like a ping pong ball in a blender lately. Doing way too much on way too many things. So this update will be a little scattered. Between going with my family to all sorts of fall events, working WAY too much, fixing the duster, etc, ive been having a hard time keeping track of what im doing with this.So, to start:the plastidip that was done to this car has turned to goo over much of it. Ive been working on peeling/scraping it from the plastics. I tried aircraft stripper, and luckily it didn't damage the plastic. But it wasn't my best idea. Ive found mineral spirits and lacquer thinner with an sos pad, as well as a razor blade to be the most effective means so far. And child labor. (she likes peeling the stuff that will peel) we've got the front bumper done, rear most of the way, and lots more to go everywhere else.

1540468889_15404688612351221519150_mmthumb by Michael Crawford, on Flickr

20181025_141225 by Michael Crawford, on Flickr

20181029_144150 by Michael Crawford, on Flickrnext up is belt routing. I finally figured out what size belt fits. Spent way too much on a belt, but have learned that the original application is a dodge intrepid. Ill snag a used belt next time at the junkyard. That'll cut $19 from the budget. And it'll make me happy to have mopar parts on this.

20181026_185835 by Michael Crawford, on Flickr

20181026_185904 by Michael Crawford, on FlickrI also picked up some free slicks for the 14s. 21X7x14 avon medium compound. Should cut $140 from the budget if they prove as fast at the SM7 on 15x6 in testing. Im sure as hell going to try! Very nice guy with some awesome garage hardware. And a really nice day and drive with my wife.

Screenshot_20181027-205009 by Michael Crawford, on Flickrthe kinked oil pressure line was really bothering me. The ultra-lites I bought, and then self traded for came with a braided line and a couple of fittings. The engine side fit my oil pressure sandwich plate fine, however the gauge end wouldn't fit. It was 1/8 female NPT, and the sunpro wasn't. So I bought a brass block off plug with a hex head for $.97, drilled, and tapped to make an o-ring sealing bushing (the threads were I think, 5/16 fine. Don't quote me)

20181019_202159 by Michael Crawford, on Flickr

20181026_194239 by Michael Crawford, on Flickr

20181026_194626 by Michael Crawford, on Flickr

20181104_105634 by Michael Crawford, on Flickrhad to make some clearance for it behind the instrument panel.

20181104_105627 by Michael Crawford, on Flickrnext, wiring and engine bay stuff.Obviosly, youve seen that the engine is together and wired. But here's some details.The ECM is run almost completely independent from the chassis. Only crossover points are the fan relays, fuel pump relay, OBD2 port, and instrument panel. I built a switch panel from scrap plastic, a free pull-a-part fuse block, some leftover LEDs, and used toggles. It has only now dawned on me that I could have relayed the fuse block, and made life much simpler. Thats revision 2 coming soon. Anyway, I did my best to make the whole engine bay side of things clean, neat, and mostly hidden. Routed the plug wires with zip tie looms, and trying my best to make the hoses neat and tidy (haven't done the fuel pressure regulator/MAP/crankcase vent yet). I'm happy with how its coming out for the most part.

20181019_190432 by Michael Crawford, on Flickr

20181019_190437 by Michael Crawford, on Flickr

20181019_202227 by Michael Crawford, on Flickr

20181021_102253 by Michael Crawford, on Flickr

20181023_170526 by Michael Crawford, on Flickr

20181023_180020 by Michael Crawford, on Flickr

20181025_191007 by Michael Crawford, on Flickrthis brings us up to exhaust. At the end of the post will be a few YouTube links. Needless to say, exhaust on this was NOT optional. We were shooting fireballs from the open headers. But it RUNS now, and actually sounds good. I had to tweak the exhaust upon re-installation for no obvious reason, except the one where I forgot an oxygen sensor bung. But for no good reason the midpipes were now too short, so I had to extend the legs of my merge collector. And I also cut the mushroom heads off the hangars to make install and removal of the rear section easier. I also had to move the collector down towards the butterfly brace so it would stop hitting the driveshaft.But its done now, and sounds GOOD. to me it sounds a lot like an indy car.

20181104_105836 by Michael Crawford, on Flickr

20181104_105844 by Michael Crawford, on Flickr

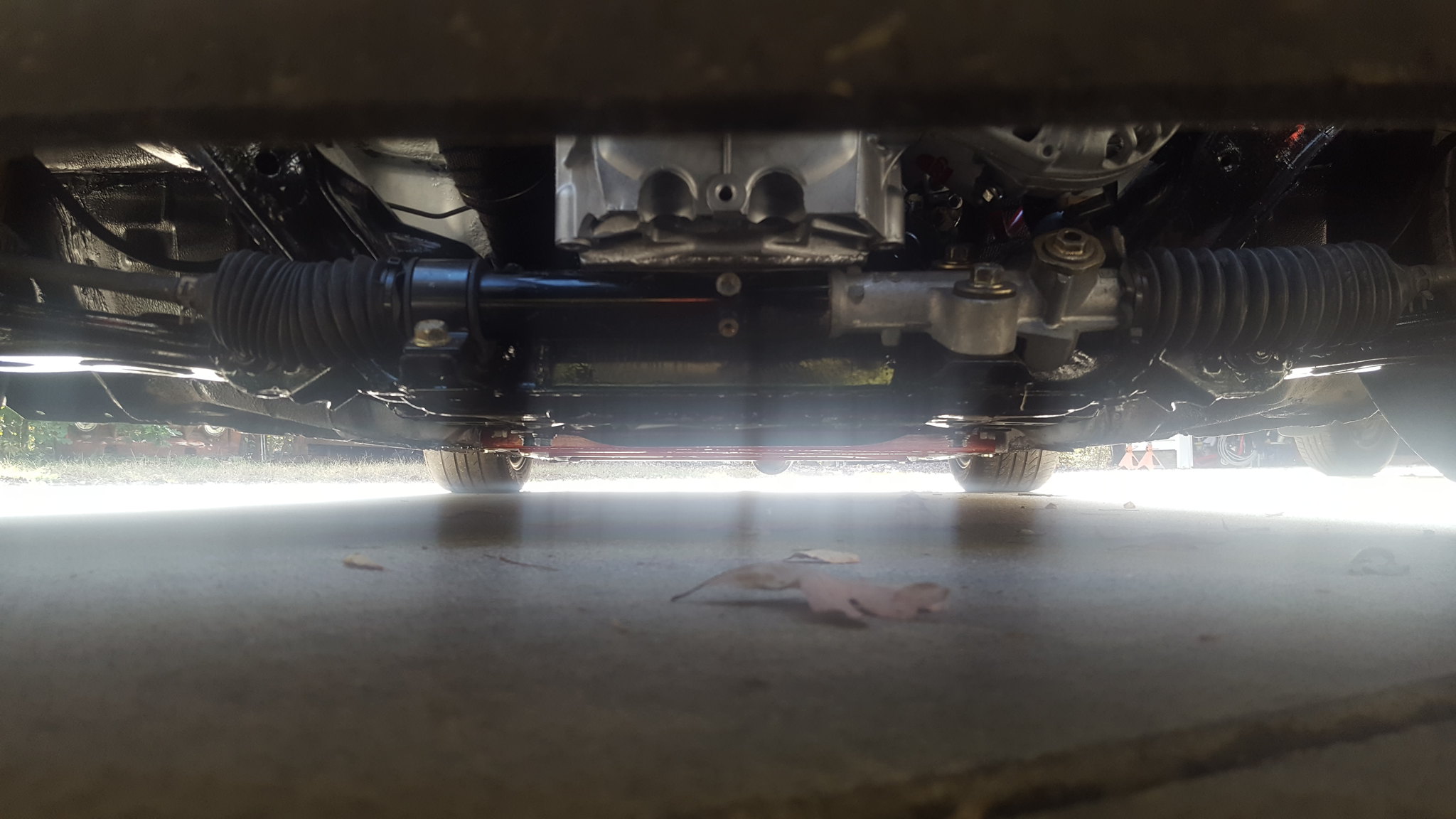

20181104_105827 by Michael Crawford, on FlickrI backed it out in the driveway to wash the engine bay (it was FILTHY. Pure white looks great when its clean though) and settle the suspension. Its really, really low. The coilovers are and full drop, so it has plenty of room to go up.

20181104_111727 by Michael Crawford, on Flickr

20181104_111747 by Michael Crawford, on Flickr

20181104_111826_001 by Michael Crawford, on Flickr

20181104_112225 by Michael Crawford, on Flickr

20181104_113433 by Michael Crawford, on Flickrso, videos. Because everyone likes video. And these are monumental achievements for me. Near as I can tell, this is the first FWD 60*v6 in a miata that has ever been done. This is also proof that you don't have to spend thousands to do an engine swap. Or be a genius (cause im sure not!). First fire:

#68

this update brings no financial changes at this time. Really, the only part that I used was in my magic bits bucket (lives right next to my fab metal bucket full of odd pieces of metal) and I have yet to determine fair market value of the heim. Its pictured below, but came off a set of addco sway bars on a c5 corvette after they became horribly noisy. I had 4, but am down to just this one that I know of. Met be one more in the bucket at the bottom, but.....anyway, here it is. Whats it worth?

20181116_165748 by Michael Crawford, on Flickrregardless, its being used as part of my PPF delete. Ive been waffling back and forth for a month about how I want to do it, and finally, due to analysis paralysis, just made something simple and adjustable.

20181116_201858 by Michael Crawford, on Flickrthis gets welded to the rear crossmember on the passengers side directly to the outboard side of the original PPF that I cut down to make the lower mount. It will be fully boxed into the subframe, and should be welded in this week sometime when I remove the subframe. Then paint it, swap in the 4:11 torsen, and put it back under. Probably going to paint the underside of the car around the rear cradle white like I did the engine bay and tunnel.I've been chipping away at the dash a bit more. I re-clocked the tach needle to actually read properly, bolted the dash in, tided up all the gauge cluster wiring, mounted the ECU, etc. ECU is mounted behind the cover for the passengers air bag, and fit like GM and mazda planned this swap. I also went ahead and bolted in the gutted AC evaporator box to finish that as well.

20181109_172101 by Michael Crawford, on Flickrin the process of this, I figured out why the OBD2 port wasn't working. Mazda and gm send the data on a different pin using a different protocol. The scanner is smart enough that it cant/wont use the wrong protocol on the wrong pin. Once I swapped the pin to the GM location, worked plain and easy. I also relayed the auxiliary switch panel and fused the line from the battery with a 50 amp maxifuse, but apparently didn't take any pictures of either, so you'll have to take my word for it.I needed to see another visual progress after all the wiring, so I went after some interior work. Pulled the kick panels, windshield trim, glove box, and knee panel out of storage. Became shocked at how much it all weighed. The pile from storage:

20181116_153644 by Michael Crawford, on FlickrI pulled the steel plate from the knee panel, and the inner structure from the glove box while keeping the hinges and latch. I also stripped all the jute and foam from the backs of the other panels. My highly calibrated left arm says that I reduced the weight by roughly 50% from stock, with no outward indication.

20181116_154757 by Michael Crawford, on Flickr

20181116_165646 by Michael Crawford, on Flickrand all put together looking like a car again. Still have to figure out how to gut the airbag assembly from the steering wheel while retaining the horn function and cover for appearance sake. And install the kick panels, steering column trim, dead pedal, etc. lots of interior to go back in.....

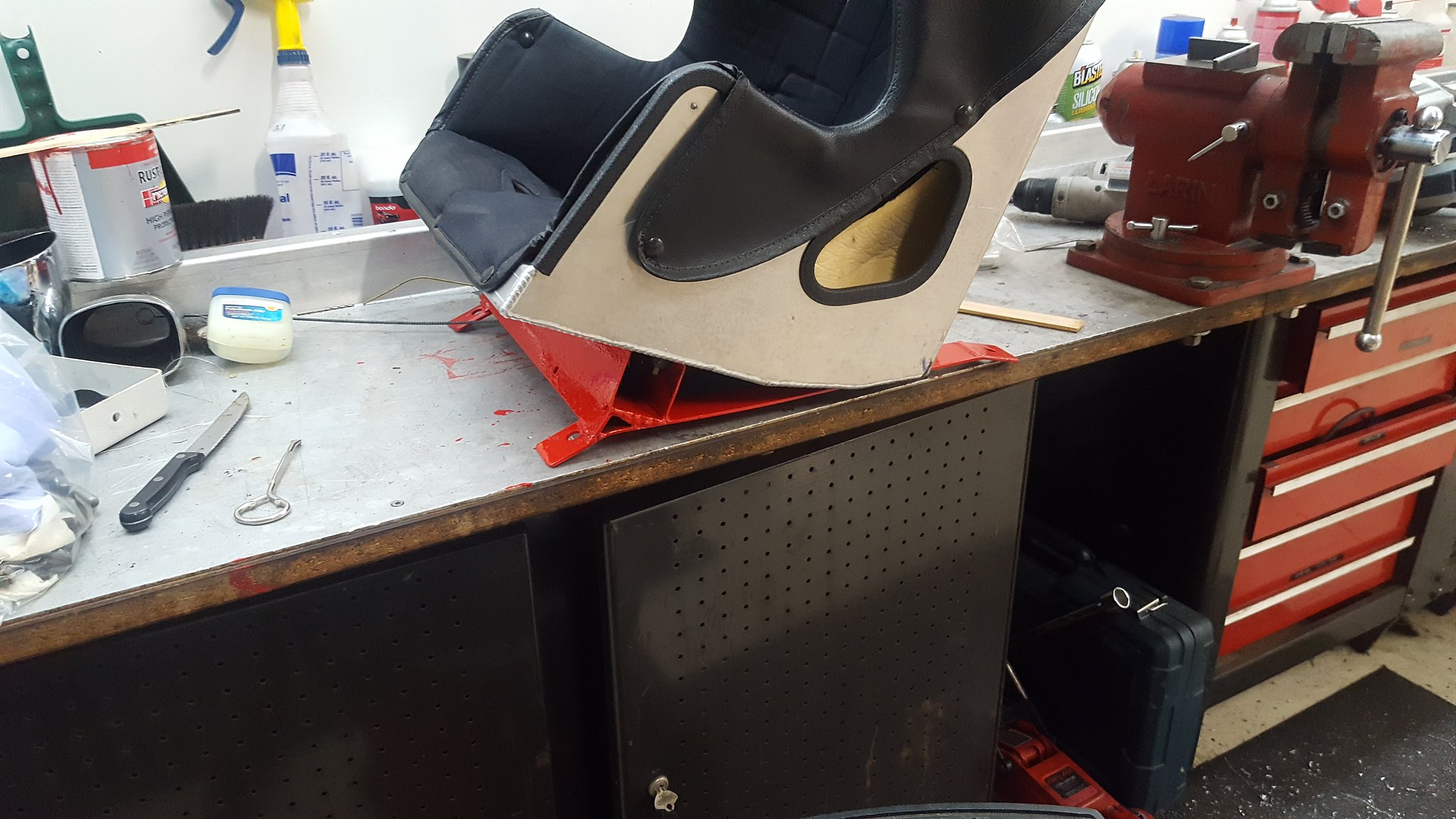

20181118_110952 by Michael Crawford, on Flickrthe shift light is going to be mounted where the dome light was above the rearview if I can make it fit in a way im happy with, may require cutting. You know, since NOTHING has been left untouched in this build. Except the gauge hood. I didn't mess with that at all. Yet.While ive been chipping away at electrical, dads been cleaning, painting, and prepping sub assemblies. Seat mounts were ground, cleaned, and painted, seat cover cleaned, hardware torqued, etc. ready to be bolted in after the roll bar.

20181116_165754 by Michael Crawford, on Flickr

20181116_201749 by Michael Crawford, on FlickrI refit the roll bar to remind myself of what needed done. Two tabs to tack on, some finish welding on the floor backing plates, finish welding the roll bar (Stave of AMC fame volunteered to do that), clean and paint. Clean up the hackery on the body shell form where I cut for clearance, bolt it in, and make some close out panels.

20181118_160602 by Michael Crawford, on FlickrI mounted up the rear bumper. Need to eradicate the structure from underneath it yet that should lighten the car a few more pounds as well.

20181109_172637 by Michael Crawford, on Flickrlastly for this update is my puzzler. You see, I have to redo the throttle cable setup for ANY hope of a hood fitting. However, there's an issue there. I had thought it would be just as simple as moving the mount point towards the intake bu 90 degrees.Except it binds at anything over about 45 degrees from where it is now. Which really doesn't get me anything for hood clearance or cosmetics. Im open to ideas on how to lower the sleeved and fixed end without binding issues though. There has to be a way, and the only option I can come up with is to use a smooth stud to pivot the cable down like a pulley. That way the housing can come at a 90 to the angle of pull.Heres pictures. Help me brainstorm. Please.

20181109_172707 by Michael Crawford, on Flickr

20181109_172703 by Michael Crawford, on Flickr

20181116_165748 by Michael Crawford, on Flickrregardless, its being used as part of my PPF delete. Ive been waffling back and forth for a month about how I want to do it, and finally, due to analysis paralysis, just made something simple and adjustable.

20181116_201858 by Michael Crawford, on Flickrthis gets welded to the rear crossmember on the passengers side directly to the outboard side of the original PPF that I cut down to make the lower mount. It will be fully boxed into the subframe, and should be welded in this week sometime when I remove the subframe. Then paint it, swap in the 4:11 torsen, and put it back under. Probably going to paint the underside of the car around the rear cradle white like I did the engine bay and tunnel.I've been chipping away at the dash a bit more. I re-clocked the tach needle to actually read properly, bolted the dash in, tided up all the gauge cluster wiring, mounted the ECU, etc. ECU is mounted behind the cover for the passengers air bag, and fit like GM and mazda planned this swap. I also went ahead and bolted in the gutted AC evaporator box to finish that as well.

20181109_172101 by Michael Crawford, on Flickrin the process of this, I figured out why the OBD2 port wasn't working. Mazda and gm send the data on a different pin using a different protocol. The scanner is smart enough that it cant/wont use the wrong protocol on the wrong pin. Once I swapped the pin to the GM location, worked plain and easy. I also relayed the auxiliary switch panel and fused the line from the battery with a 50 amp maxifuse, but apparently didn't take any pictures of either, so you'll have to take my word for it.I needed to see another visual progress after all the wiring, so I went after some interior work. Pulled the kick panels, windshield trim, glove box, and knee panel out of storage. Became shocked at how much it all weighed. The pile from storage:

20181116_153644 by Michael Crawford, on FlickrI pulled the steel plate from the knee panel, and the inner structure from the glove box while keeping the hinges and latch. I also stripped all the jute and foam from the backs of the other panels. My highly calibrated left arm says that I reduced the weight by roughly 50% from stock, with no outward indication.

20181116_154757 by Michael Crawford, on Flickr

20181116_165646 by Michael Crawford, on Flickrand all put together looking like a car again. Still have to figure out how to gut the airbag assembly from the steering wheel while retaining the horn function and cover for appearance sake. And install the kick panels, steering column trim, dead pedal, etc. lots of interior to go back in.....

20181118_110952 by Michael Crawford, on Flickrthe shift light is going to be mounted where the dome light was above the rearview if I can make it fit in a way im happy with, may require cutting. You know, since NOTHING has been left untouched in this build. Except the gauge hood. I didn't mess with that at all. Yet.While ive been chipping away at electrical, dads been cleaning, painting, and prepping sub assemblies. Seat mounts were ground, cleaned, and painted, seat cover cleaned, hardware torqued, etc. ready to be bolted in after the roll bar.

20181116_165754 by Michael Crawford, on Flickr

20181116_201749 by Michael Crawford, on FlickrI refit the roll bar to remind myself of what needed done. Two tabs to tack on, some finish welding on the floor backing plates, finish welding the roll bar (Stave of AMC fame volunteered to do that), clean and paint. Clean up the hackery on the body shell form where I cut for clearance, bolt it in, and make some close out panels.

20181118_160602 by Michael Crawford, on FlickrI mounted up the rear bumper. Need to eradicate the structure from underneath it yet that should lighten the car a few more pounds as well.

20181109_172637 by Michael Crawford, on Flickrlastly for this update is my puzzler. You see, I have to redo the throttle cable setup for ANY hope of a hood fitting. However, there's an issue there. I had thought it would be just as simple as moving the mount point towards the intake bu 90 degrees.Except it binds at anything over about 45 degrees from where it is now. Which really doesn't get me anything for hood clearance or cosmetics. Im open to ideas on how to lower the sleeved and fixed end without binding issues though. There has to be a way, and the only option I can come up with is to use a smooth stud to pivot the cable down like a pulley. That way the housing can come at a 90 to the angle of pull.Heres pictures. Help me brainstorm. Please.

20181109_172707 by Michael Crawford, on Flickr

20181109_172703 by Michael Crawford, on Flickr

#69

Challenge budget so far revious challenge budget: 1877.19 recoup total: 820new money: another can of white from lowes 3.98

revious challenge budget: 1877.19 recoup total: 820new money: another can of white from lowes 3.98

heim: 1 from my magic bucketdriveshaft safety loops: 40 from J&t weldinggiant K&N air filter: 2.06 pull-a-part Recoup: 820

new total: 1902.29so, ive been chipping away over the holiday weekend. Tuesday on my lunch break, o swung by J&T welding I alblemarle to get the 2x1/4 plate I needed for the driveshaft and CV axle safetly loops, and have it bent. $40 later, and 30 minutes, I had this in the back of the car. We needed roughly 6 inches between the verticals on the legs. So thats what I asked for, and pretty much what we wound up with.

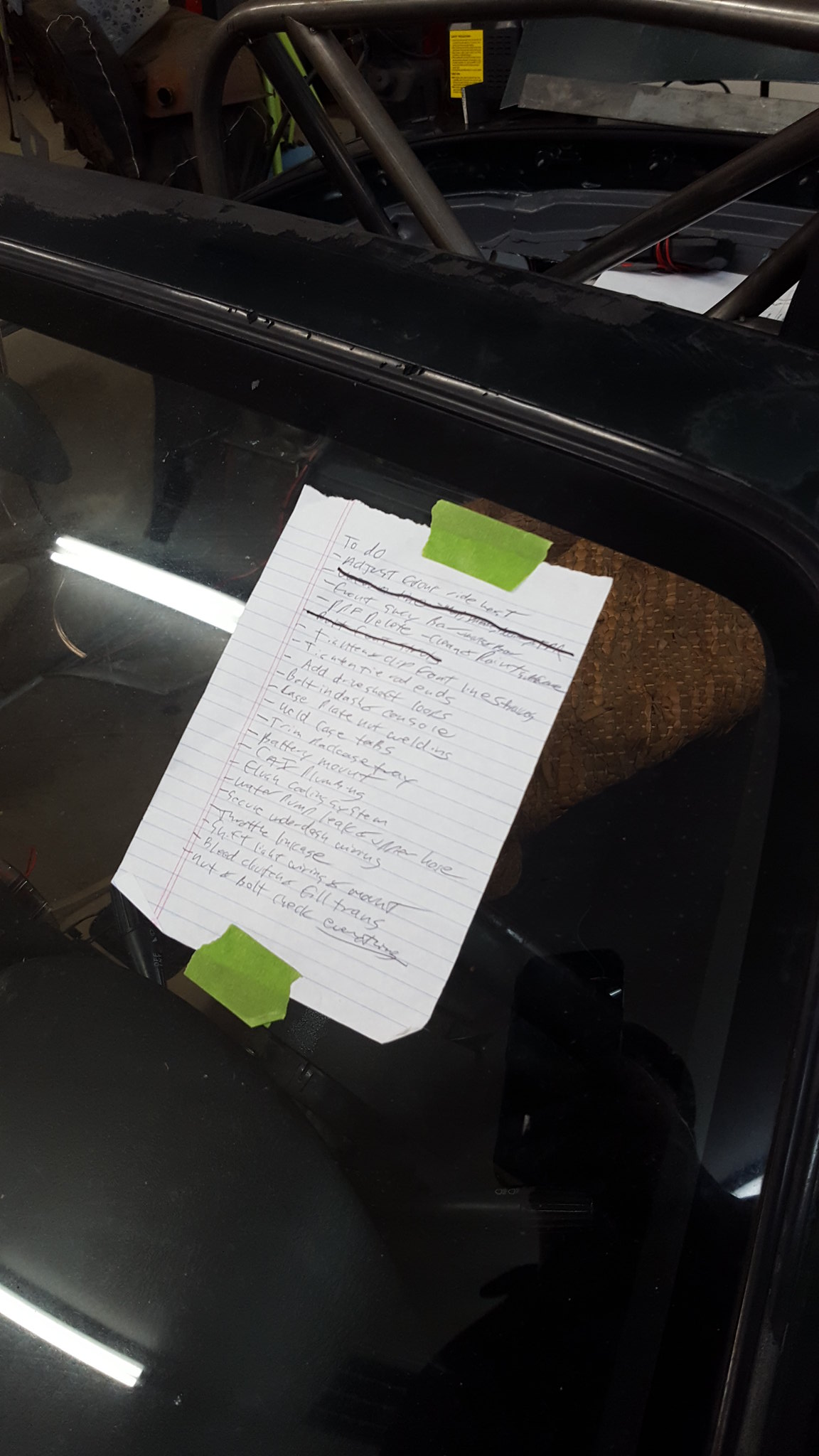

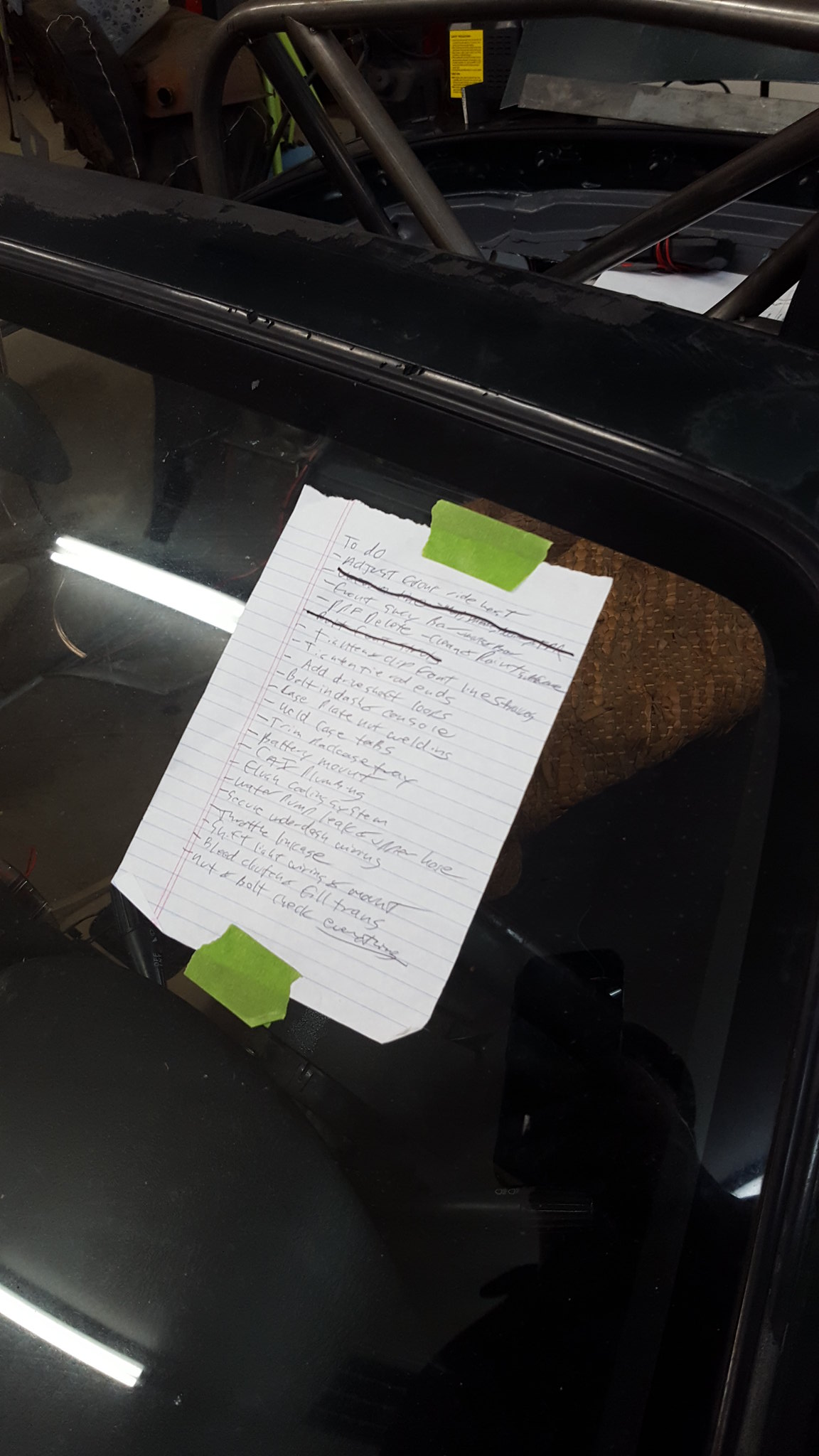

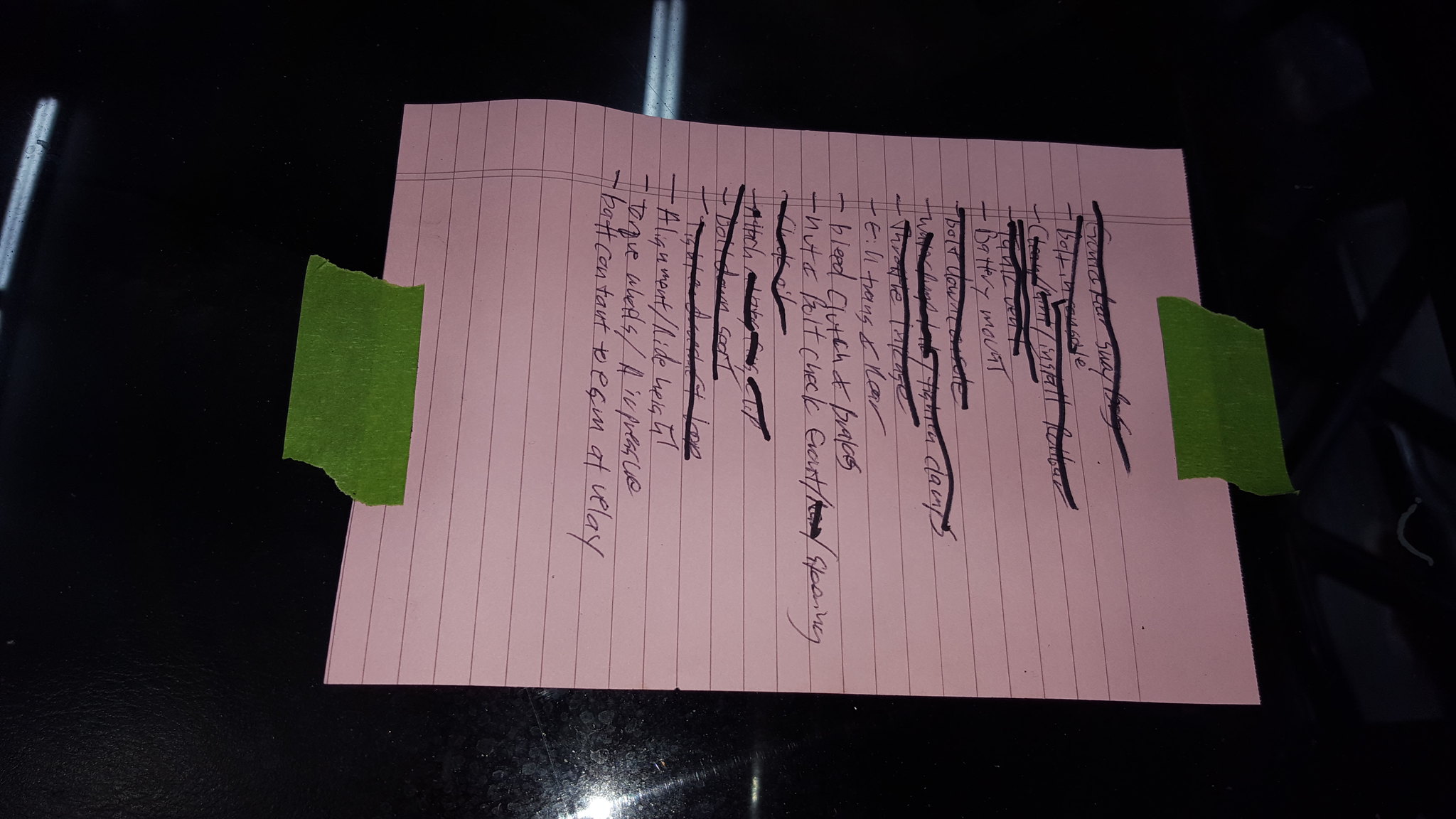

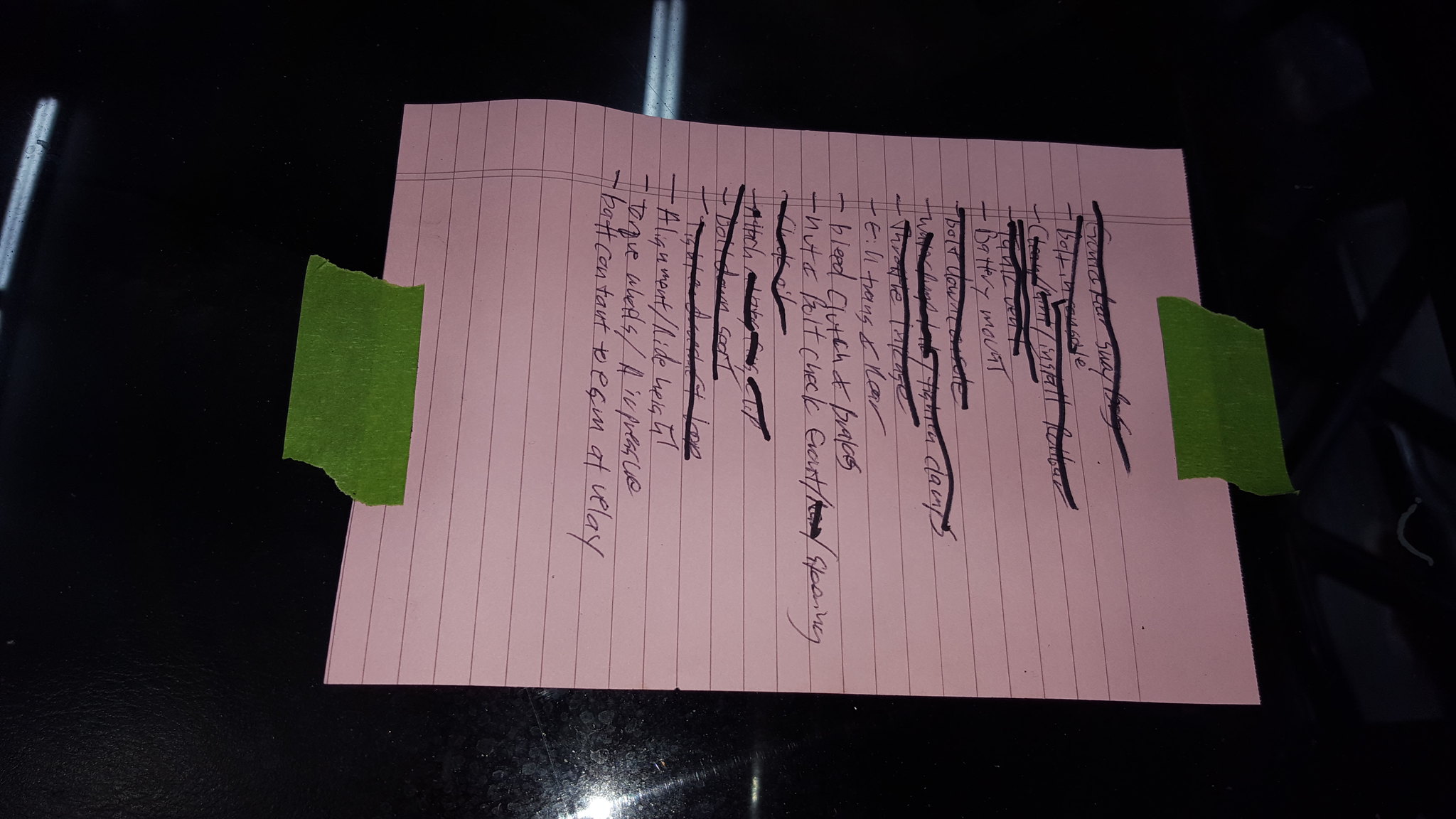

20181119_124615 by Michael Crawford, on FlickrTuesday, while waiting for an appointment, I made a to-do list.

20181120_183625 by Michael Crawford, on Flickrstep one was Tuesday night, which was getting the CAI built, vacuum lines finished, and the throttle linkage sorted out. By the middle of the evening, I thought I had it all sorted out. I used one of my multiple aftermarket air filters, and the biggest I could fit. It happened to be a K&N. See, I buy them any time I see one at pull-a-part. For 2.06, I figure I cant lose. I have AEM, K&N, Spectre, ebay, and a greddy. Seriously, I have like 9 different aftermarket cone filters in storage. This one, If I remember right, was on a 3800 Buick. But don't quote me on that, its been in storage for probably 5 years. Maybe longer. I mounted the giant filter directly to the end of the MAF, tucked low behind the radiator. I dug it. Also, I cut and bent the stock throttle linkage bracket until it looked like it would clear, pretty much mimicking the car version of the GM bracket. (I bought a car version Wednesday morning, but it didn't wind up being the solution).I also finally did all the vacuum hoses and lines. Used scraps of hose ive scavenged from various cars over the years, as well as scraps of the factory nylon vacuum lines. Still need to get a factory style MAP sensor mount (didn't take the right tools with me to the yard for that) or make one, but its otherwise done!

20181120_193804 by Michael Crawford, on Flickrhowever, I wasn't feeling like the hood was going to fit without a giant hole being cut.

20181120_193809 by Michael Crawford, on FlickrWednesday I ran by the junkyard real quick, had an eye-doctors appointment, and then spent the day helping my wife around the house.Thursday (thanksgiving), we had dinner at my folks place (where im building the car). I was specifically told I could NOT get dirty or stinky before dinner and family portraits. So I looked at the list, and decided to bolt the dash in (not picture worthy), secure under dash wiring (not picture worthy), and see how big a hole we would have to cut. Initially, it was looking REALLY BIG.But then, I pulled the entire CAI (hood was hitting breather hose fitting and IAT) and then the throttle bracket (again, hood hitting it). Without ANY cutting, we get here:

20181122_113126 by Michael Crawford, on Flickrvia horrible cell phone pictures and some guesstimation, we see that we only have to notch a 6 inch wide underhood brace to clear the intake manifold. Ill then need to build an underslung throttle cable bracket assembly, and a completely different CAI setup. But having an externally stock appearing hood was worth it!

20181122_095559 by Michael Crawford, on FlickrThursday night after portraits, I finally made our fuel gauge. Used an old mudflap, some hole saws, my drill press, and a glue gun to turn the passengers side eyeball vent into a fuel gauge. I found that the gauge will read accurately when entirely divorced from the cluster, just like a GM gauge. That was a very nice thing to find out.

20181122_175346 by Michael Crawford, on Flickr

20181122_175711 by Michael Crawford, on Flickr

20181123_092810 by Michael Crawford, on Flickr

20181123_093202 by Michael Crawford, on Flickryesterday, I decided to finish tackling the PPF delete, as well as get the car ready to finish cleaning and painting parts, as well as replace the bent driver side rear suspension arms.To attach the upper joint, I had previously made this:

20181116_201858 by Michael Crawford, on Flickrto actually attach these brackets to the subframe, I pulled the subframe out, cut the spot welded flange down, welded the L brackets, then added a reinforcement/boxing strap up the subframe. Should be stronger than the metal its attached to, which is all I can ask for.

20181123_134620 by Michael Crawford, on Flickrwhile I had the subframe out, I figured it was a great time to make the CV axle loops. After all, I had the fab tools out already, right?My plan was to use the UCA mounting bolts to hold it in, thereby supporting the midpoint of the shaft in the event of failure. So, measure, mark, drill, weld, cut, repeat...

20181123_134518 by Michael Crawford, on Flickr

20181123_143618 by Michael Crawford, on Flickr

20181123_151618 by Michael Crawford, on Flickrthere was a little more trimming and profile work done after these pictures, but you get the idea. The D shaped one will bolt through the passengers side of the trans tunnel just above the merge for the exhaust. You know, in all the spare room I have here.

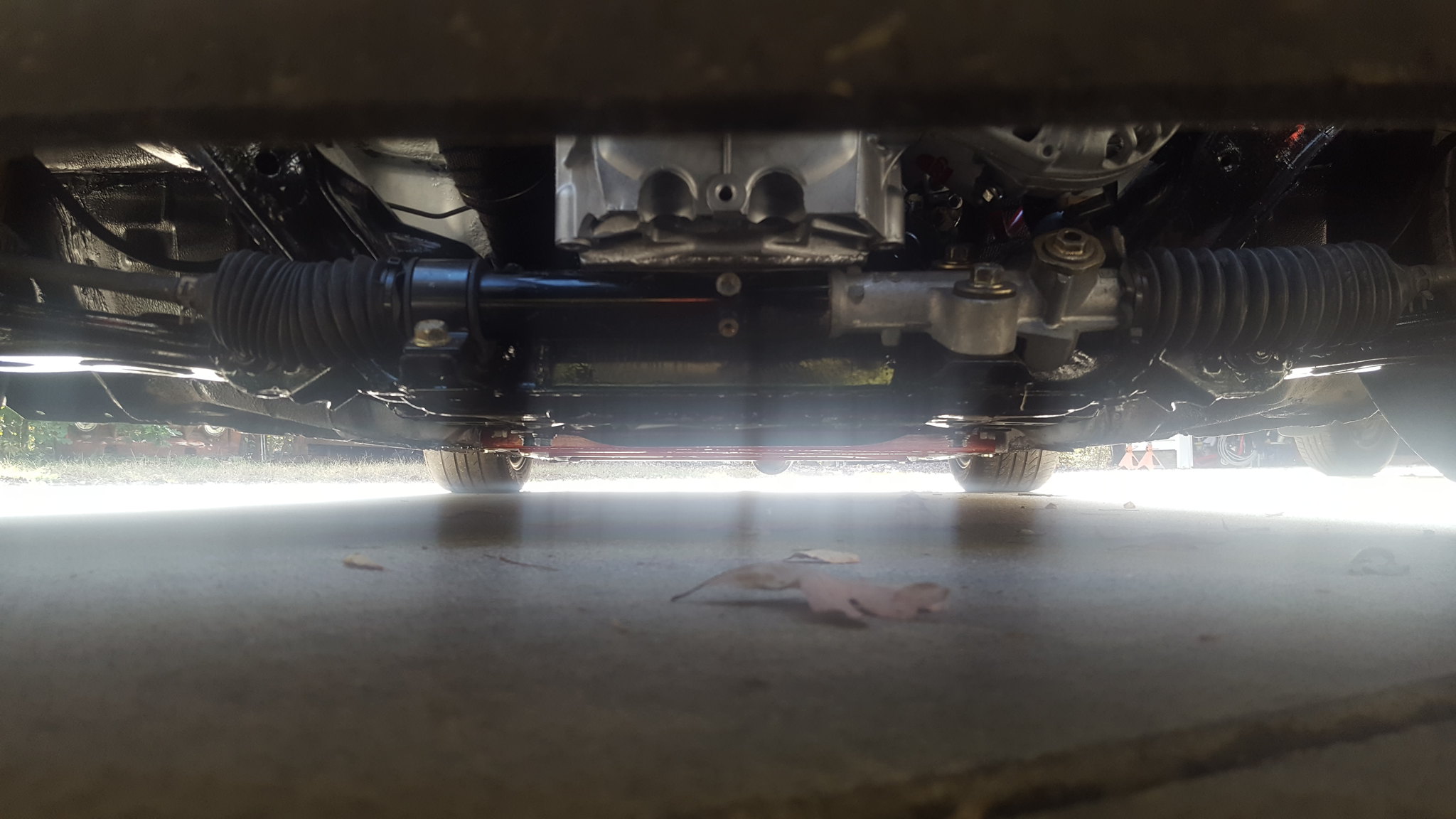

20181123_134653 by Michael Crawford, on FlickrI then switched gears for the last part of the day to cleaning and painting the underside of the car.I have to say that since I quit smoking, I have become much more susceptible to fumes. Spray paint never used to bother me. The following pictures gave me a hell of a headache. But the AMC proved to me just how nice working on a car with white engine bay and undercarriage can be. So I HAD to do it.

20181123_134645 by Michael Crawford, on Flickr

20181124_130927 by Michael Crawford, on FlickrToday, I finished cleaning all the suspension parts and loops and cage plates and such for painting. No pictures. I also spent the morning over at Steve's place, where he used his welding talent, 220 welder, and surface plate to finish weld my roll bar. Now I need to clean it, and paint it. Im debating between satin black, or color matched tan to match the interior. Both have their advantages and disadvantages. But cosmetically, with no top at all, dark green paint and tan interior, I don't know which would look better. I also didn't take a picture of the finished welded product, and for that I apologize. But heres one of Steve welding!

20181124_102538 by Michael Crawford, on Flickrtomorrow is thanksgiving with my in-laws (fried turkey and homemade collards. I ain't missing that!) so I don't know if I will be able to swing by the shop to lay some paint down or not. Hopefully I can, but no promises. Im really pushing to have test drive by Christmas. If I can do that, ill be really happy. And were awfully close!

revious challenge budget: 1877.19 recoup total: 820new money: another can of white from lowes 3.98

revious challenge budget: 1877.19 recoup total: 820new money: another can of white from lowes 3.98heim: 1 from my magic bucketdriveshaft safety loops: 40 from J&t weldinggiant K&N air filter: 2.06 pull-a-part Recoup: 820

new total: 1902.29so, ive been chipping away over the holiday weekend. Tuesday on my lunch break, o swung by J&T welding I alblemarle to get the 2x1/4 plate I needed for the driveshaft and CV axle safetly loops, and have it bent. $40 later, and 30 minutes, I had this in the back of the car. We needed roughly 6 inches between the verticals on the legs. So thats what I asked for, and pretty much what we wound up with.

20181119_124615 by Michael Crawford, on FlickrTuesday, while waiting for an appointment, I made a to-do list.

20181120_183625 by Michael Crawford, on Flickrstep one was Tuesday night, which was getting the CAI built, vacuum lines finished, and the throttle linkage sorted out. By the middle of the evening, I thought I had it all sorted out. I used one of my multiple aftermarket air filters, and the biggest I could fit. It happened to be a K&N. See, I buy them any time I see one at pull-a-part. For 2.06, I figure I cant lose. I have AEM, K&N, Spectre, ebay, and a greddy. Seriously, I have like 9 different aftermarket cone filters in storage. This one, If I remember right, was on a 3800 Buick. But don't quote me on that, its been in storage for probably 5 years. Maybe longer. I mounted the giant filter directly to the end of the MAF, tucked low behind the radiator. I dug it. Also, I cut and bent the stock throttle linkage bracket until it looked like it would clear, pretty much mimicking the car version of the GM bracket. (I bought a car version Wednesday morning, but it didn't wind up being the solution).I also finally did all the vacuum hoses and lines. Used scraps of hose ive scavenged from various cars over the years, as well as scraps of the factory nylon vacuum lines. Still need to get a factory style MAP sensor mount (didn't take the right tools with me to the yard for that) or make one, but its otherwise done!

20181120_193804 by Michael Crawford, on Flickrhowever, I wasn't feeling like the hood was going to fit without a giant hole being cut.

20181120_193809 by Michael Crawford, on FlickrWednesday I ran by the junkyard real quick, had an eye-doctors appointment, and then spent the day helping my wife around the house.Thursday (thanksgiving), we had dinner at my folks place (where im building the car). I was specifically told I could NOT get dirty or stinky before dinner and family portraits. So I looked at the list, and decided to bolt the dash in (not picture worthy), secure under dash wiring (not picture worthy), and see how big a hole we would have to cut. Initially, it was looking REALLY BIG.But then, I pulled the entire CAI (hood was hitting breather hose fitting and IAT) and then the throttle bracket (again, hood hitting it). Without ANY cutting, we get here:

20181122_113126 by Michael Crawford, on Flickrvia horrible cell phone pictures and some guesstimation, we see that we only have to notch a 6 inch wide underhood brace to clear the intake manifold. Ill then need to build an underslung throttle cable bracket assembly, and a completely different CAI setup. But having an externally stock appearing hood was worth it!

20181122_095559 by Michael Crawford, on FlickrThursday night after portraits, I finally made our fuel gauge. Used an old mudflap, some hole saws, my drill press, and a glue gun to turn the passengers side eyeball vent into a fuel gauge. I found that the gauge will read accurately when entirely divorced from the cluster, just like a GM gauge. That was a very nice thing to find out.

20181122_175346 by Michael Crawford, on Flickr

20181122_175711 by Michael Crawford, on Flickr

20181123_092810 by Michael Crawford, on Flickr

20181123_093202 by Michael Crawford, on Flickryesterday, I decided to finish tackling the PPF delete, as well as get the car ready to finish cleaning and painting parts, as well as replace the bent driver side rear suspension arms.To attach the upper joint, I had previously made this:

20181116_201858 by Michael Crawford, on Flickrto actually attach these brackets to the subframe, I pulled the subframe out, cut the spot welded flange down, welded the L brackets, then added a reinforcement/boxing strap up the subframe. Should be stronger than the metal its attached to, which is all I can ask for.

20181123_134620 by Michael Crawford, on Flickrwhile I had the subframe out, I figured it was a great time to make the CV axle loops. After all, I had the fab tools out already, right?My plan was to use the UCA mounting bolts to hold it in, thereby supporting the midpoint of the shaft in the event of failure. So, measure, mark, drill, weld, cut, repeat...

20181123_134518 by Michael Crawford, on Flickr

20181123_143618 by Michael Crawford, on Flickr

20181123_151618 by Michael Crawford, on Flickrthere was a little more trimming and profile work done after these pictures, but you get the idea. The D shaped one will bolt through the passengers side of the trans tunnel just above the merge for the exhaust. You know, in all the spare room I have here.

20181123_134653 by Michael Crawford, on FlickrI then switched gears for the last part of the day to cleaning and painting the underside of the car.I have to say that since I quit smoking, I have become much more susceptible to fumes. Spray paint never used to bother me. The following pictures gave me a hell of a headache. But the AMC proved to me just how nice working on a car with white engine bay and undercarriage can be. So I HAD to do it.

20181123_134645 by Michael Crawford, on Flickr

20181124_130927 by Michael Crawford, on FlickrToday, I finished cleaning all the suspension parts and loops and cage plates and such for painting. No pictures. I also spent the morning over at Steve's place, where he used his welding talent, 220 welder, and surface plate to finish weld my roll bar. Now I need to clean it, and paint it. Im debating between satin black, or color matched tan to match the interior. Both have their advantages and disadvantages. But cosmetically, with no top at all, dark green paint and tan interior, I don't know which would look better. I also didn't take a picture of the finished welded product, and for that I apologize. But heres one of Steve welding!

20181124_102538 by Michael Crawford, on Flickrtomorrow is thanksgiving with my in-laws (fried turkey and homemade collards. I ain't missing that!) so I don't know if I will be able to swing by the shop to lay some paint down or not. Hopefully I can, but no promises. Im really pushing to have test drive by Christmas. If I can do that, ill be really happy. And were awfully close!

#70

Challenge budget so far revious challenge budget: 1902.29 recoup total: 820new money:used serpentine belt from pull-a-part: 4.95roll bar paint: 3.99 (was 8.99 at oriellys, but used the $5 coupon I got in the mail) Recoup: 820

revious challenge budget: 1902.29 recoup total: 820new money:used serpentine belt from pull-a-part: 4.95roll bar paint: 3.99 (was 8.99 at oriellys, but used the $5 coupon I got in the mail) Recoup: 820

new total: 1911.23so, ive been in thrash mode. Lots of caffeine and heavy metal music. I NEED to see this thing moving under its own power soon. Ive been working on it for well over a year now.....Thursday night I started with a pile of parts and hardware that dad had cleaned and painted for me (he did all the really nice final coats on this stuff, as im not that great a brush painter). The only issues I ran into was that the upper control arm bolts were too short for proper engagement when the CV shaft safety loops were added. So a couple grade 8 bolts and nylock nuts from the bins were used. And, since I redesigned the upper PPF delete mount on the fly, I had to change the mounting hole in the chunk of the stock PPF. 20181125_091438 by Michael Crawford, on Flickr

20181125_091438 by Michael Crawford, on Flickr 20181128_174550 by Michael Crawford, on Flickr

20181128_174550 by Michael Crawford, on Flickr 20181128_174557 by Michael Crawford, on FlickrBut got it all assembled with the “new” 4.11 torsen, and slid under the car.

20181128_174557 by Michael Crawford, on FlickrBut got it all assembled with the “new” 4.11 torsen, and slid under the car. 20181130_181025 by Michael Crawford, on FlickrFriday I raised it all up, drilled another hole, torqued everything, and went to install the factory rear brace.

20181130_181025 by Michael Crawford, on FlickrFriday I raised it all up, drilled another hole, torqued everything, and went to install the factory rear brace. 20181130_195146 by Michael Crawford, on FlickrIt wouldn't fit. Hit the exhaust. I got to looking, and realized there was a piece of the differential aluminum casting hanging the exhaust up from going up further. So I got out the sawzall.

20181130_195146 by Michael Crawford, on FlickrIt wouldn't fit. Hit the exhaust. I got to looking, and realized there was a piece of the differential aluminum casting hanging the exhaust up from going up further. So I got out the sawzall. 20181130_201001 by Michael Crawford, on FlickrGot it all bolted up, tightened down, drilled the holes for the driveshaft safety loop with a freaking DREMEL and carbide burr because I couldn't fit the drill in there, and called it a night. Well, after getting the drivers rear quarter beat somewhat into shape to fit the rear bumper cover, and mounted the shift light above the rear-view with a bit of tripled up plumbers hanging strap (scrap from a job site)

20181130_201001 by Michael Crawford, on FlickrGot it all bolted up, tightened down, drilled the holes for the driveshaft safety loop with a freaking DREMEL and carbide burr because I couldn't fit the drill in there, and called it a night. Well, after getting the drivers rear quarter beat somewhat into shape to fit the rear bumper cover, and mounted the shift light above the rear-view with a bit of tripled up plumbers hanging strap (scrap from a job site) 20181130_195136 by Michael Crawford, on Flickr

20181130_195136 by Michael Crawford, on Flickr 20181130_201444 by Michael Crawford, on Flickr

20181130_201444 by Michael Crawford, on Flickr 20181130_201429 by Michael Crawford, on Flickr

20181130_201429 by Michael Crawford, on Flickr 20181130_190233 by Michael Crawford, on Flickr

20181130_190233 by Michael Crawford, on Flickr 20181130_190223 by Michael Crawford, on Flickr

20181130_190223 by Michael Crawford, on Flickr 20181130_202912 by Michael Crawford, on FlickrSaturday morning started with flushing the cooling system of my vinegar and water flush. I didn't take pictures, but y'all should've seen the crap we knocked out. To facilitate this, and fixing the water pump leak, I pulled the few bolts and zipties holding the front clip and fans in, and cleaned everything else out of the car from stem to stern. While it was outside, I cut the package tray shelf to the scribe d lines, dressed the edges, vacuumed everything out, etc. generally made it a much nicer work environment. I also went ahead and put in the kick panels, dead pedal, sill plates, etc. got tired of cutting myself and laying on the sharp edges of the pinch around the door frame. Why I didn't do this a month ago, I don't know. Guess im a slow learner or something. I also reinstalled the windshield plastics and weatherstripping somewhere in the last week as well.

20181130_202912 by Michael Crawford, on FlickrSaturday morning started with flushing the cooling system of my vinegar and water flush. I didn't take pictures, but y'all should've seen the crap we knocked out. To facilitate this, and fixing the water pump leak, I pulled the few bolts and zipties holding the front clip and fans in, and cleaned everything else out of the car from stem to stern. While it was outside, I cut the package tray shelf to the scribe d lines, dressed the edges, vacuumed everything out, etc. generally made it a much nicer work environment. I also went ahead and put in the kick panels, dead pedal, sill plates, etc. got tired of cutting myself and laying on the sharp edges of the pinch around the door frame. Why I didn't do this a month ago, I don't know. Guess im a slow learner or something. I also reinstalled the windshield plastics and weatherstripping somewhere in the last week as well. 20181125_101709 by Michael Crawford, on Flickr

20181125_101709 by Michael Crawford, on Flickr 20181130_181039 by Michael Crawford, on FlickrI pushed the car inside, spread out a tarp, and dad cleaned/painted the rollbar with VHT rollbar and chassis paint. While it was drying, dad and I pop riveted the nut plates to the body, got the hardware lined up, loctite out, etc. when the rollbar was dry enough, we sat it in place and bolted it down with lock washers and blue loctite gel. Thankfully it didn't move too much when Steve welded it, so only the drivers rear leg needed a prybar to line the holes back up. But its got every fastener I designed it to have, and damn sure ain't going anywhere.

20181130_181039 by Michael Crawford, on FlickrI pushed the car inside, spread out a tarp, and dad cleaned/painted the rollbar with VHT rollbar and chassis paint. While it was drying, dad and I pop riveted the nut plates to the body, got the hardware lined up, loctite out, etc. when the rollbar was dry enough, we sat it in place and bolted it down with lock washers and blue loctite gel. Thankfully it didn't move too much when Steve welded it, so only the drivers rear leg needed a prybar to line the holes back up. But its got every fastener I designed it to have, and damn sure ain't going anywhere. 20181201_140155 by Michael Crawford, on Flickr