Trackspeed's '02SE "Acamas" - EFR6758, TSE motor, 500whp or bust

#104

Elite Member

iTrader: (1)

Join Date: Apr 2014

Location: SF Bay Area, CA

Posts: 3,073

Total Cats: 550

My point is that I think we should start with pid values at whatever the simple algorithm sets them at for the firmware we are using.

I left my slider at 0 or 1 I think, and my solenoid at 19hz. I know people will disagree but I also had better luck with 30ms interval than 50ms and now I am actually running 15ms interval.

I am very happy with my closed loop ebc now, it reaches my target as early as possible and holds it to 6500. Granted I am on a completely different setup.

#108

Elite Member

iTrader: (1)

Join Date: Apr 2014

Location: SF Bay Area, CA

Posts: 3,073

Total Cats: 550

I realize the valve can only react at 51ms or so, but the way I see it the algorithm can run 3 times per valve cycle at 15ms. I could be wrong but it seems to oscillate less at a shorter interval.

My main point is that I think you are correct about starting from the basic pid settings.

My main point is that I think you are correct about starting from the basic pid settings.

#110

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

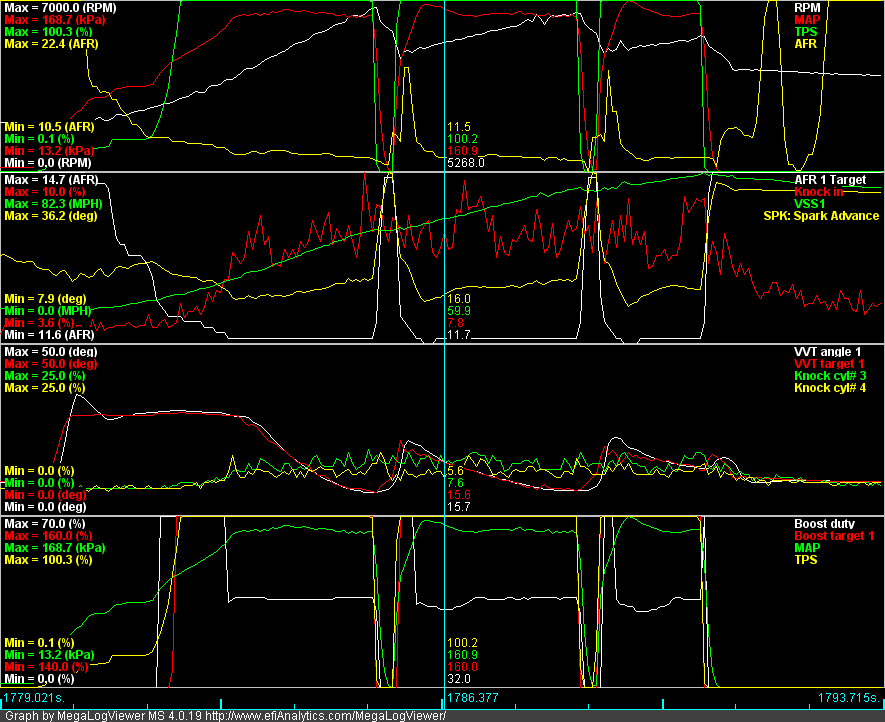

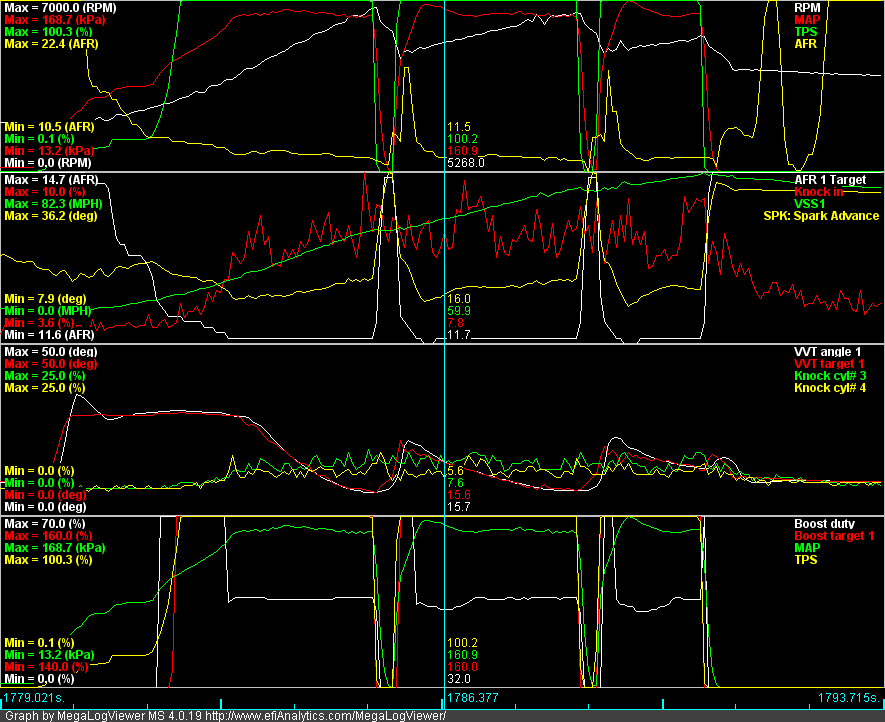

1.4.0 is much better. The plunging DC% issue is gone. This is Basic mode, slider at 360. Bias duty is 33% across the board. I almost want to go higher with the slider or add more P with advanced mode.

#112

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Make sure you test different conditions. Heat soak. Cold. Etc. 1.4 is so easy to setup because the bias table is always in use. So PID doesn't have to do much in the conditions you tuned for. If conditions change that's when you actually need to tune PID.

Something I did was set the bias table off by a few percent in different directions along the rev range. Forcing PID to do some work. Then you can fine tune it.

With your baller wastegate you won't see the improvements in 1.4 as much. My hanky wastegate needs a lot more duty (10% more) randomly at 5200rpm. Then needs to go back down. So in 1.3.4 I had a nasty dip. With 1.4 I can tune it out with the bias table.

As sonofthehill stated. I'm not sure if the code changed. But starting at 100,100,100 for PID made a world of difference.

Something I did was set the bias table off by a few percent in different directions along the rev range. Forcing PID to do some work. Then you can fine tune it.

With your baller wastegate you won't see the improvements in 1.4 as much. My hanky wastegate needs a lot more duty (10% more) randomly at 5200rpm. Then needs to go back down. So in 1.3.4 I had a nasty dip. With 1.4 I can tune it out with the bias table.

As sonofthehill stated. I'm not sure if the code changed. But starting at 100,100,100 for PID made a world of difference.

#113

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

A quick change of direction, and a peek into the future. One of the many things we'll use this chassis to develop is a T5 swap kit, and this is the beginning of that development. The box is a -238 code from a 1996 3.8L Mustang, which is desirable for a few reasons:

I snagged this after confirming with G-Force that it's a suitable candidate to build later on. They actually said it's more desirable than an older V8 box as the basis for a built gearbox, since the newer V6 boxes are typically in much better shape.

For people who want a 100% bolt-in solution, you'll have to shell out $1100 for a new T5z box, but converting the V6 box to V8 spec is easy. You need the input shaft, bearing, bearing cover plate, and a shim kit, all of which can be had for ~$140 or so, which means you can put the gearbox itself together for well under $300 without any special one-time deals or hard to find parts.

The clutch disc was $110 and it's a performance organic disc with a 10-spline T5 center. It will get swapped for a 26-spline piece when I do a G-Force gearset next year. All the G-Force boxes are set up around 7.18" input shafts (V8), not the ~7.8" shafts that came in the V6s, so in order to accomodate built gearboxes, we'll build around the 7.18" length.

The bellhousing is cut off a blown 5-speed (everyone considering this swap probably has a blown 5-speed in their garage) and it will be milled down to the correct length and welded to an adapter plate which will be done in a few weeks. Using a chopped-up OEM bellhousing means I can retain the stock TOB, stock clutch fork, and stock hydraulics, so from the front, it will look like a Miata transmission with a 10-spline input shaft sticking through, and there are no issues with reliability or fitment on any of those critical items.

So that's the trans>engine attachment all sorted out. Next big puzzle is the shifter extension. The PPF bracket should be a little easier.

- It's a World-Class box

- It has a 3.35 1st gear which means that you can swap the input shaft from a 3.35 V8 box into it with ease.

- The 0.75 overdrive is a big step down from the .843 in the car now, but not as deep as the .63 ODs in all the V8 boxes

- It has an electronic speedo sender, and with a Dakota box and a little work, it should talk nicely to the NB speedometer and MS3

- It was $130 at the junkyard, not $800 like all the V8 boxes are

I snagged this after confirming with G-Force that it's a suitable candidate to build later on. They actually said it's more desirable than an older V8 box as the basis for a built gearbox, since the newer V6 boxes are typically in much better shape.

For people who want a 100% bolt-in solution, you'll have to shell out $1100 for a new T5z box, but converting the V6 box to V8 spec is easy. You need the input shaft, bearing, bearing cover plate, and a shim kit, all of which can be had for ~$140 or so, which means you can put the gearbox itself together for well under $300 without any special one-time deals or hard to find parts.

The clutch disc was $110 and it's a performance organic disc with a 10-spline T5 center. It will get swapped for a 26-spline piece when I do a G-Force gearset next year. All the G-Force boxes are set up around 7.18" input shafts (V8), not the ~7.8" shafts that came in the V6s, so in order to accomodate built gearboxes, we'll build around the 7.18" length.

The bellhousing is cut off a blown 5-speed (everyone considering this swap probably has a blown 5-speed in their garage) and it will be milled down to the correct length and welded to an adapter plate which will be done in a few weeks. Using a chopped-up OEM bellhousing means I can retain the stock TOB, stock clutch fork, and stock hydraulics, so from the front, it will look like a Miata transmission with a 10-spline input shaft sticking through, and there are no issues with reliability or fitment on any of those critical items.

So that's the trans>engine attachment all sorted out. Next big puzzle is the shifter extension. The PPF bracket should be a little easier.

#114

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,891

Total Cats: 398

Excellent Andrew. Much happier to see you doing this than BEGI which won't ever really do it.

also interested in seeing what you come up with on the shifter extension...my biggest issue. But if you're requiring/expecting customers to get into the guts of their boxes then supplying a longer shift rod would be a simple supported solution.

And yeah, stay away from the .63 5th. I dislike mine a lot.

also interested in seeing what you come up with on the shifter extension...my biggest issue. But if you're requiring/expecting customers to get into the guts of their boxes then supplying a longer shift rod would be a simple supported solution.

And yeah, stay away from the .63 5th. I dislike mine a lot.

#115

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

This is fukin awesome. Are you getting the adapter plate made? Or is there a t5 input plate readily available?

Do you see this as a future TSE project (should I go buy a t5 right now? )?

)?

What are those t5's rated to stock? Are you doing a G-force gearset because of ratios or strength reason.

Will you be able to run the v6 gearbox even though it is the 7.8" shaft?

Do you see this as a future TSE project (should I go buy a t5 right now?

)?

)?What are those t5's rated to stock? Are you doing a G-force gearset because of ratios or strength reason.

Will you be able to run the v6 gearbox even though it is the 7.8" shaft?

#117

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I know you opted to do a shifter adapter and cut the tunnel to make it fit. What do you think about removing that freeze plug? I don't think it can be left open, but I think it could be sealed back up fairly easily.

#118

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

This is fukin awesome. Are you getting the adapter plate made? Or is there a t5 input plate readily available?

Do you see this as a future TSE project (should I go buy a t5 right now? )?

)?

What are those t5's rated to stock? Are you doing a G-force gearset because of ratios or strength reason.

Will you be able to run the v6 gearbox even though it is the 7.8" shaft?

Do you see this as a future TSE project (should I go buy a t5 right now?

)?

)?What are those t5's rated to stock? Are you doing a G-force gearset because of ratios or strength reason.

Will you be able to run the v6 gearbox even though it is the 7.8" shaft?

It is something we will offer. It's clearly a needed product, and I will clearly need one for this car, so it will definitely see production. Whether we decide to do hybrid 5-speed bellhousings or cast our own remains to be seen.

My -238 box is rated to 265ft.lbs, same as the WC V8 boxes. I'll do a G-Force gearset for the ratios.

I am swapping a 7.18" shaft into my V6 box. See last post for details/cost

#119

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Saw that, the first post confused me about the input shaft lengths.

Excited to see this progress. Makes me want to go get my blown 5 speed and cut the bellhousing off. I did just get a TIG...hmmm. I need to find twin disc clutch discs for the t5 too I guess.

Either way this is going to be cool. I like that price. And maybe its time to take a stab at rebuilding a transmission.

Custom driveshaft? Or chop and weld the mustang and miata.

Excited to see this progress. Makes me want to go get my blown 5 speed and cut the bellhousing off. I did just get a TIG...hmmm. I need to find twin disc clutch discs for the t5 too I guess.

Either way this is going to be cool. I like that price. And maybe its time to take a stab at rebuilding a transmission.

Custom driveshaft? Or chop and weld the mustang and miata.