Any ideas to fix a manifold-to-turbo leak that already has 10mm inconel studs?

#21

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

//edit// After giving it some thought, I decided not to worry over this for the moment. My secondary intentions were to quickly familiarize myself with this car anyway. I will take care of this and other forced upgrades + maintenance when the 180k+milestone is reached [this was all done at 159,xxx]. My mains are just beginning to show signs of leakage too lol, so it must be a sign to postpone the actual boost. Thanks again to those who chimed in! I am definitely not done here - far from it.

Loosen the other 3 nuts, then tighten them all evenly. It looks like you're just pinching the nut against the turbine housing because everything else is tightened down already.

If the stud is too long, then that's BEGi's problem - our kit fits perfectly.

#22

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

Hornetball, read this thread:

https://www.miataturbo.net/prefabbed-turbo-kits-3/epic-nuts-studs-loosening-thread-reposting-stupid-stuff-without-reading-%3D-warning-35874/

The entire thing, every single post, front to back.

#23

Newb

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Chula Vista SD

Posts: 44

Total Cats: 0

ANYWAY, my turbo's bearings just sh*t the bed thanks to excessively held load when needed to get over inclines and the like. I am trying to source another Garrett T25/T28 and have inquired about an S15 GT28R locally. There is also a Godspeed T28 available on CL, but I am trying to steer clear of that for now if possible even though people have had their successes with ChinaChargers - was simply never a fan really. I am just trying to plan out how to approach the flange/stud/manifold situation this time since I can only afford to do this one more time; everyone's advice thus far is being taken into consideration. Luckily, the SR20 turbos should allow me to re-use my -3IF oil feed and the rest of the fittings; I believe anything else requires ordering a different one.

hornetball - I knew that your SN looked familiar. I enjoyed reading your build thread a month or two ago.

#24

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

The only other way would be if the flange of the nut were being caught by the turbo, but there's a washer in there that has a larger OD so that's clearly not the case.

Either that or you've galled the threads and the nut is locked up tight, which makes it seem like the turbine housing is still hitting it.

#25

100% wrong.

Hornetball, read this thread:

https://www.miataturbo.net/showthread.php?t=35874

The entire thing, every single post, front to back.

Hornetball, read this thread:

https://www.miataturbo.net/showthread.php?t=35874

The entire thing, every single post, front to back.

Don't dispute that I'm wrong. Just ask my wife.

#26

Newb

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Chula Vista SD

Posts: 44

Total Cats: 0

You might be correct, but the verdict will have to wait for when I remove it and play around again. Depending on how soon I can source a replacement locally, I will have time either tonight or Thursday night after classes.

#27

100% wrong.

Hornetball, read this thread:

https://www.miataturbo.net/showthread.php?t=35874

The entire thing, every single post, front to back.

Hornetball, read this thread:

https://www.miataturbo.net/showthread.php?t=35874

The entire thing, every single post, front to back.

Perhaps your objection is the recommendation of 8.8 or 10.9 bolts rather than Inconel studs. Rest assured, I would not run nor recommend 8.8/10.9 for the track. I'm with you there. However, my 8.8's are holding up well for street and some auto-x. I've put a ton of miles on with no issues. I should have asked whether OP was intending to track the car. My bad.

#29

Newb

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Chula Vista SD

Posts: 44

Total Cats: 0

...and your one post calling a nut a bolt

Yes, anyone would be correct in presuming that I have no intentions on tracking this car. The manifold came with these studs already in place, so that was not my unnecessary decision.

Yes, anyone would be correct in presuming that I have no intentions on tracking this car. The manifold came with these studs already in place, so that was not my unnecessary decision.

#31

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

I honestly would not try to remove the studs. I resbonded them in around this time last year. I would say to take the manifold with you if you are picking up a turbo locally. This way you can try and make sure it fits before you buy it.

#33

Former Vendor

iTrader: (9)

Join Date: Jan 2008

Location: Bay Area, California

Posts: 929

Total Cats: 9

I just realized bboyalan has my old manifold and downpipe. So it is a Begi manifold with the TSE studs. I had them working fine with a China 2871. Although I do think I had to get them all started with the turbo apart from the manifold and then slowly tighten them all down one at a time.

I honestly would not try to remove the studs. I resbonded them in around this time last year. I would say to take the manifold with you if you are picking up a turbo locally. This way you can try and make sure it fits before you buy it.

I honestly would not try to remove the studs. I resbonded them in around this time last year. I would say to take the manifold with you if you are picking up a turbo locally. This way you can try and make sure it fits before you buy it.

#34

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

Perhaps your objection is the recommendation of 8.8 or 10.9 bolts rather than Inconel studs. Rest assured, I would not run nor recommend 8.8/10.9 for the track. I'm with you there. However, my 8.8's are holding up well for street and some auto-x. I've put a ton of miles on with no issues. I should have asked whether OP was intending to track the car. My bad.

The wire doesn't keep it all together - it may stop the fasteners from turning, but that doesn't mean they won't elongate and cause a leak anyway.

The basic synopsis of the stud thread is that it's a metallurgy issue and not a fastener issue, so regardless of what solution you use to keep the fasteners from rotating, you have to address the weakness in the fastener itself.

#35

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

After looking at the picture he posted again of the close up I have to agree that he is not using the nuts you originally sent me. I sent him all the parts I originally got, except for new c-clips, the old ones were destroyed when I removed them so I bought new ones to send out.

#36

Newb

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Chula Vista SD

Posts: 44

Total Cats: 0

Ah, are these the "correct" nuts supplied by TSE accordingly? I honestly thought that they were just miscellaneous used bits with the others. They also measure 15mm but have a slightly smaller head. The unused BEGi standard 10mm studs accepted them easily as expected.

I left the car at home today and will do the same tomorrow because of the current turbo's condition in addition to [what I believe to be] the mains pissing themselves as mentioned earlier. I am planning on tearing into the car tomorrow night and temporarily reverting to "stock"/naturally aspirated. Hopefully my -10 AN plug arrives by Friday too. A reassessment just sounds like a good idea before investing in another turbo so soon; a select few are in sight though!

I left the car at home today and will do the same tomorrow because of the current turbo's condition in addition to [what I believe to be] the mains pissing themselves as mentioned earlier. I am planning on tearing into the car tomorrow night and temporarily reverting to "stock"/naturally aspirated. Hopefully my -10 AN plug arrives by Friday too. A reassessment just sounds like a good idea before investing in another turbo so soon; a select few are in sight though!

#38

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Ah, are these the "correct" nuts supplied by TSE accordingly? I honestly thought that they were just miscellaneous used bits with the others. They also measure 15mm but have a slightly smaller head. The unused BEGi standard 10mm studs accepted them easily as expected.

I left the car at home today and will do the same tomorrow because of the current turbo's condition in addition to [what I believe to be] the mains pissing themselves as mentioned earlier. I am planning on tearing into the car tomorrow night and temporarily reverting to "stock"/naturally aspirated. Hopefully my -10 AN plug arrives by Friday too. A reassessment just sounds like a good idea before investing in another turbo so soon; a select few are in sight though!

I left the car at home today and will do the same tomorrow because of the current turbo's condition in addition to [what I believe to be] the mains pissing themselves as mentioned earlier. I am planning on tearing into the car tomorrow night and temporarily reverting to "stock"/naturally aspirated. Hopefully my -10 AN plug arrives by Friday too. A reassessment just sounds like a good idea before investing in another turbo so soon; a select few are in sight though!

#39

Newb

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Chula Vista SD

Posts: 44

Total Cats: 0

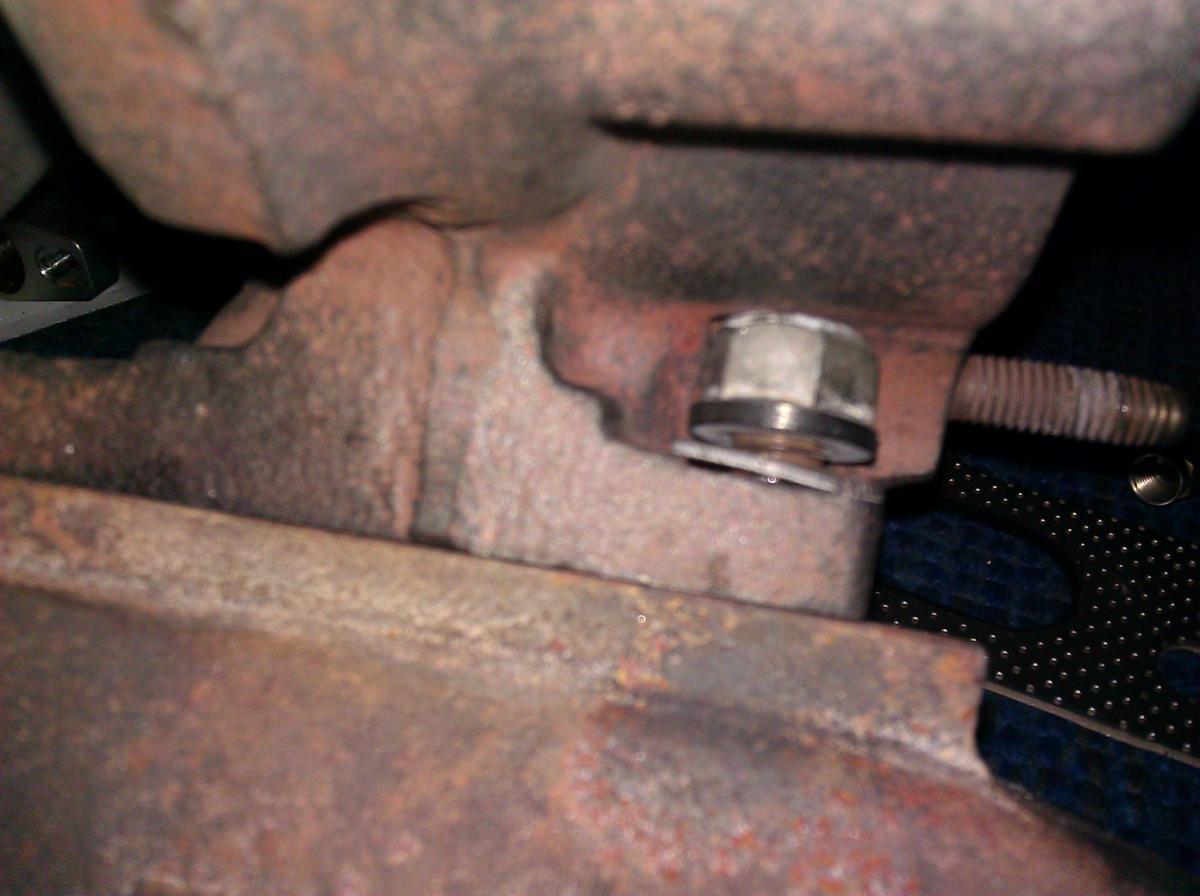

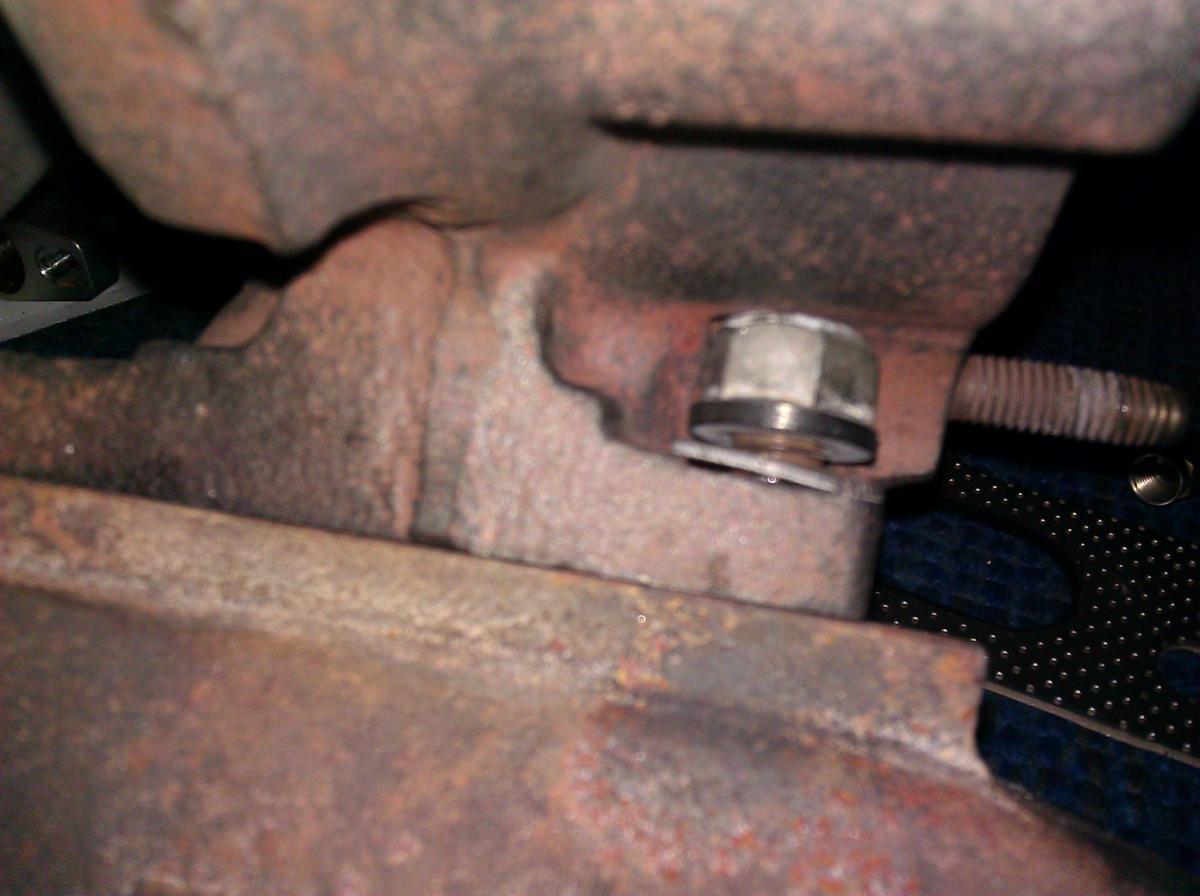

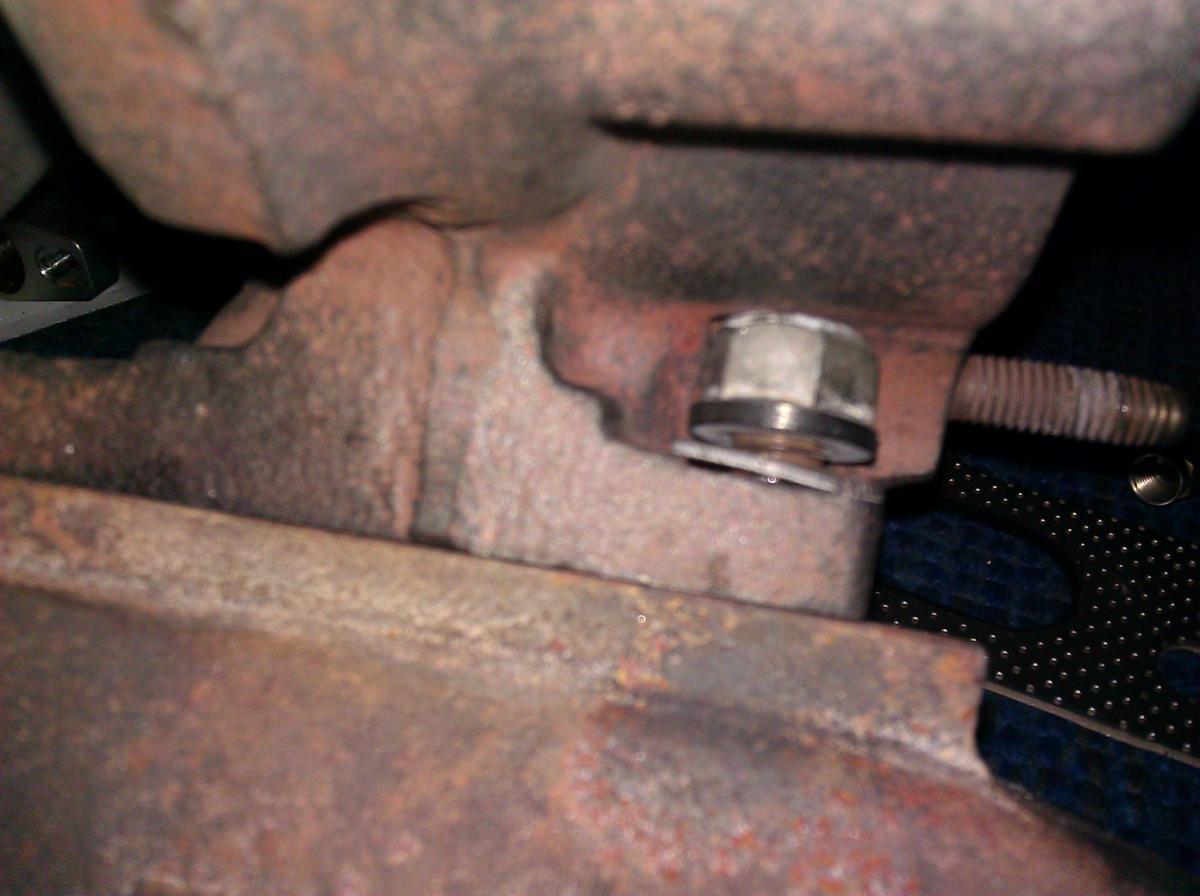

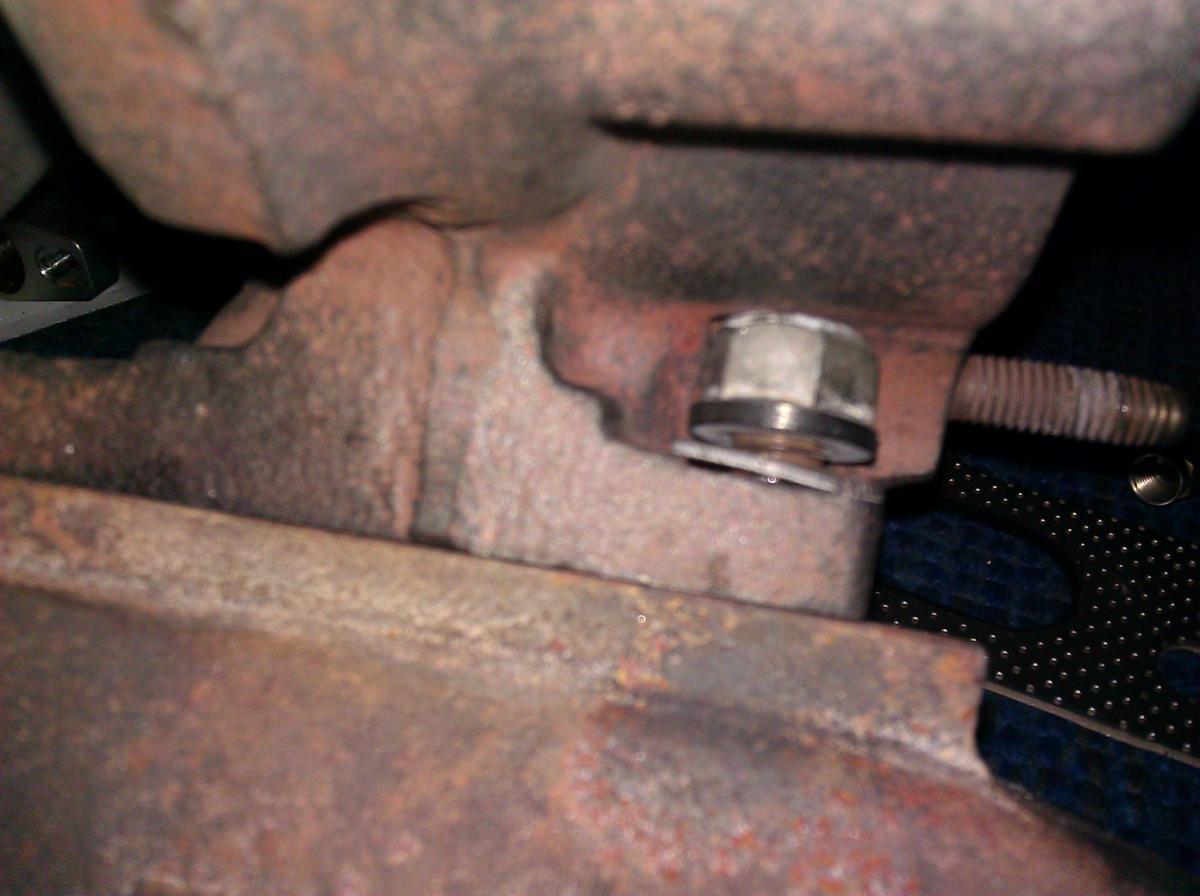

Just to bring a little closure to this thread, here is how it looked when I tried threading it again with the parts removed from the car:

This is the flange sitting on top of the manifold slightly tilted.

This is as far as it will go with the turbo pulled back, wiggled, whatever.

If you look closely, you can somewhat see the section of the housing above and behind the washer that causes the fitment issue. That is what it looks like to me anyway.

I will be posting in the classifieds now and later again today to help recoup my costs, so hopefully there is some interest.

This is the flange sitting on top of the manifold slightly tilted.

This is as far as it will go with the turbo pulled back, wiggled, whatever.

If you look closely, you can somewhat see the section of the housing above and behind the washer that causes the fitment issue. That is what it looks like to me anyway.

I will be posting in the classifieds now and later again today to help recoup my costs, so hopefully there is some interest.

#40

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Just to bring a little closure to this thread, here is how it looked when I tried threading it again with the parts removed from the car:

This is the flange sitting on top of the manifold slightly tilted.

This is as far as it will go with the turbo pulled back, wiggled, whatever.

If you look closely, you can somewhat see the section of the housing above and behind the washer that causes the fitment issue. That is what it looks like to me anyway.

I will be posting in the classifieds now and later again today to help recoup my costs, so hopefully there is some interest.

This is the flange sitting on top of the manifold slightly tilted.

This is as far as it will go with the turbo pulled back, wiggled, whatever.

If you look closely, you can somewhat see the section of the housing above and behind the washer that causes the fitment issue. That is what it looks like to me anyway.

I will be posting in the classifieds now and later again today to help recoup my costs, so hopefully there is some interest.

This is going to be a street car correct and not a track car you should be fine running normal studs and nuts on the car. I ran like that for 3 years without an issue of stretching. This way you could just sale the Inconel studs and not be out as much money.

I am also very sorry that the studs are not working for you. I honestly did not have my old SR20 T25 when I installed the Inconel studs so I had no way to test them. Had I known one would be to long I would have been up front about it.