Fastest spooling 6PSI ish turbo

#21

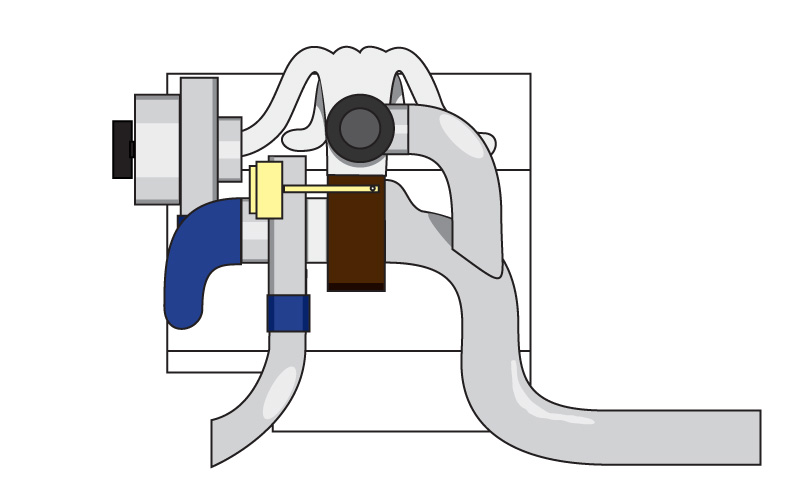

The only thing I'm trying to figure out is the logistics of fitting a turbo. I would need a log style manifold with a bottom mount turbo on the 3/4 runners. Clock the turbo towards the shock tower and run the turbo directly into the supercharger inlet. Brain, your picture is pretty much exactly what I was thinking. I'm quite impressed with your paint skillz BTW... lol

#22

How to compound turbo set ups work? Would the smaller turbo not choke the larger compressor? I think if I can figure out how that works, then I should be able to make it work since they are both compressor based and similar.

The way I look at it, it will be like a compound turbo set up but without the added heat that a turbo gives off VS. a rotrex. That, and fitting an actual compound turbo set up on a 4 cyl Miata with it able to create enough pressure would be difficult.

The way I look at it, it will be like a compound turbo set up but without the added heat that a turbo gives off VS. a rotrex. That, and fitting an actual compound turbo set up on a 4 cyl Miata with it able to create enough pressure would be difficult.

#25

ON compound turbo setups the smaller turbo is after the larger one, so it never sees atmospheric pressure after the larger turbo spools. Since the smaller turbo is force fed the boost from the larger, and never chokes. It just chugs along at a relatively low PR and doesn't know that it's actually moving a significantly larger VOLUME of air.

#27

Looks interesting... Baby turbo gets it's exhaust gases from the big turbo, but feeds it's charge air into the big turbo which then feeds it to the motor. Or is it the other way around? Hard to tell on this set up because the turbos look very close in size.

This on the other hand is a bit more clear...

#29

Centrifugal compressors are better than roots blowers at drawing air in, but your flow issue is going to be an area choke flow limitation at the small compressor inlet, as only so much air will flow through the area of the compressor inlet before reaching near mach/ choke flow.

Now, if you wanted to put a 3076 or larger on it and blow from the turbo into the Rotrex, you could make a really horrible peaky pain in the butt that would make astronomical pressure ratios between 7000 and 8000 rpm, and pretty much suck to drive, lol.

Now, if you wanted to put a 3076 or larger on it and blow from the turbo into the Rotrex, you could make a really horrible peaky pain in the butt that would make astronomical pressure ratios between 7000 and 8000 rpm, and pretty much suck to drive, lol.

#30

Ok, so theoredically you spool a small GT25 to whatever it has to go to to see your target boost as fast as possible through the Rotrex. When the intake manifold sees 20 PSI (due to the multiplication PR of the Rotrex) the wastegate opens however much it needs to to keep the boost at 20PSI.

If I go off my current Boost/PR plot... if I boost 12PSI as a base on the turbo I should see 19PSI at the manifold by 3300-3400RPM. Since it would work on a ramp up type rate it's hard to get the exact measurement. I based it off a static measurement of 4PSI the rotrex gives out at about 3600RPM right now. Most turbos these days can hit 12PSI by 3600RPM I would think.

And if I want to see, say 13-14PSI, boost the turbo to 10PSI and I should hit 13.35PSI by approx 3000RPM. That's going off 10PSI (1.68PR)x 2PSI (1.136PR) at 2963RPM. And again, since it would be working on a ramp I would likely see it sooner since as the turbo is spooling 6-8-10PSI it would be multiplying as it spooled.

So I guess what you would do is feed the small turbo into the Rotrex, and run the boost controller off the intake manifold with whatever you want your peak boost to be.

If I go off my current Boost/PR plot... if I boost 12PSI as a base on the turbo I should see 19PSI at the manifold by 3300-3400RPM. Since it would work on a ramp up type rate it's hard to get the exact measurement. I based it off a static measurement of 4PSI the rotrex gives out at about 3600RPM right now. Most turbos these days can hit 12PSI by 3600RPM I would think.

And if I want to see, say 13-14PSI, boost the turbo to 10PSI and I should hit 13.35PSI by approx 3000RPM. That's going off 10PSI (1.68PR)x 2PSI (1.136PR) at 2963RPM. And again, since it would be working on a ramp I would likely see it sooner since as the turbo is spooling 6-8-10PSI it would be multiplying as it spooled.

So I guess what you would do is feed the small turbo into the Rotrex, and run the boost controller off the intake manifold with whatever you want your peak boost to be.

Last edited by falcon; 07-29-2011 at 02:19 PM.

#31

This is a pretty standard compound setup. Here, the exhaust goes small turbine --> large turbine, but compressor flow goes large compressor --> small compressor. The small compressor will still pull air through the large compressor at low boost, and stuff will get most real as the larger compressor spools.

#33

haha. you show off.

I could make it even more interesting by using RPM based boost control. :P

I think I found my winter project.

So since were talking 10-12PSI now... I'd think a GT2554R should be enough? OR step it up to a 2560R? What exhaust housing would be ideal for spool without choking too much up high?

I could make it even more interesting by using RPM based boost control. :P

I think I found my winter project.

So since were talking 10-12PSI now... I'd think a GT2554R should be enough? OR step it up to a 2560R? What exhaust housing would be ideal for spool without choking too much up high?

#34

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,656

Total Cats: 3,011

This is a pretty standard compound setup. Here, the exhaust goes small turbine --> large turbine, but compressor flow goes large compressor --> small compressor. The small compressor will still pull air through the large compressor at low boost, and stuff will get most real as the larger compressor spools.

#38

This idea literally came out of the blue and you know it may not happen. But where would we be as a group if no one ever tried new things to help progress the way we build our cars?

#40

Lol,... well I like the Rotrex and I like how it makes good power up top without much heat. It's just lacking a bit down low which can sometimes be frustrating. On the track I don't really notice it since I have a 4.3 and run 13's but on the street an extra punch down low would be great.

And we all know how fun it is to troll S/C folk.

And we all know how fun it is to troll S/C folk.