Fastest spooling 6PSI ish turbo

#41

I bought a turbo one time that the guy told me was from an SR20. It wasn't. It actually was from a 80's Sunbird turbo coupe, I think. It was a garrett with a .48 turbine/ .49 compressor. It spooled stupid fast and made decent power and torque, but anything over 8 psi and it would fall on it's face after 6,000 RPM. Might be what you're looking for.

#42

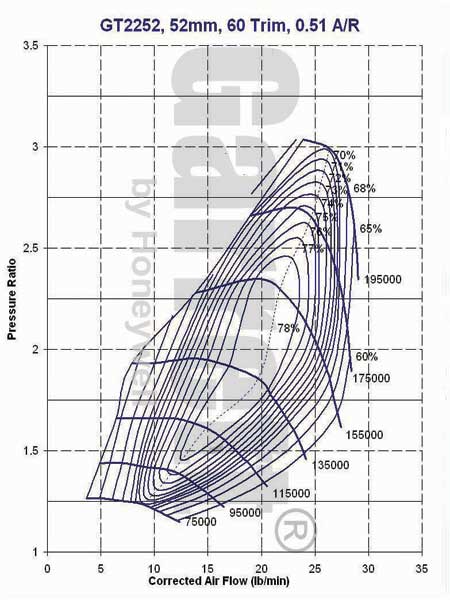

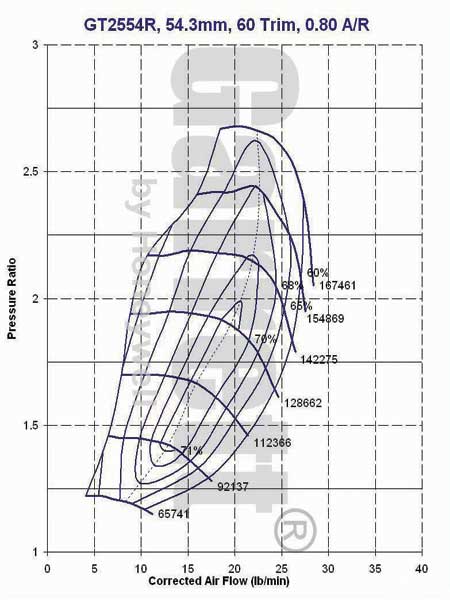

The GT22 looks like it would actually do the job fairly well VS. the GT2554R.

I basically need a turbo that will make 10PSI as fast as possible without choking on the compressor side at 300+whp. I'm thinking a hybrid small turbine/large compressor is really the only answer. Since most of the exhaust gasses would be bypassing the turbine in the upper RPMs through a giant wastegate... a small turbine may not be a bad idea.

Any ideas?

Then there is the smaller GT2560R which seems to have a decent efficiency towards the right of the map.

I don't think I would be going over a 2.5PR ratio anyhow. The PR on the turbo will lower significantly at higher RPM with the blower pulling air through the compressor.

#45

http://www.mr2forum.org/forum/index....-rotrex-power/

http://www.youtube.com/watch?v=96QbY...mbedded#t=106s

http://www.youtube.com/watch?v=96QbY...mbedded#t=106s

Toyota Celica beats F1 cars at Goodwood

The 800bhp (597kW) Toyota Celica driven by former British Rally Champion, Johnny Milner needed just 48.07 seconds to claim the title of the fastest car at Goodwood 2011.

The car is a super-lightweight Celica GT4 (1050kg) with a 2.0 Corolla WRC four-cylinder engine fitted with a Rotrex supercharger and Garrett GT35/42 turbocharger. Thereís also a nitrous oxide injection system to reduce the turbo lag off the line.

Itís actually a sixth generation Celica, but the driverís seat has been shifted further back (12 inches) for better weight distribution. Raising the wheel arches and suspension mounts has also lowered the carís centre of gravity for more precise handling.

All in all this is a purpose built weapons grade hill climb machine that is capable of quicker times that recent F1 cars and anything else that wants to challenge for the fastest car at Goodwood title.

SPRINT SERIES TOYOTA CELICA GT4 TECHNICAL SPECIFICATION

Engine type Corolla WRC four-cylinder, 16-valve

Displacement (cc) 1,998

Turbocharger Garrett GT35/42

Supercharger Rotrex, belt-driven

Engine management Motec

Compression ratio 9.7:1

Max. power (DIN hp @ rpm) 700 @ 5,700 at 2bar boost

>800 with nitrous oxide boost

Fuel tank capacity (l) 15

Weight (kg) 1,050

Transmission Mactrack 5-speed manual with Fensport triple-plate clutch

Suspension (front & rear) Reiger Corolla WRC 3-way adjustable dampers,

Brakes Front 343mm and rear 295mm Corolla WRC ventilated discs with Alcon callipers

Wheels 18in

The 800bhp (597kW) Toyota Celica driven by former British Rally Champion, Johnny Milner needed just 48.07 seconds to claim the title of the fastest car at Goodwood 2011.

The car is a super-lightweight Celica GT4 (1050kg) with a 2.0 Corolla WRC four-cylinder engine fitted with a Rotrex supercharger and Garrett GT35/42 turbocharger. Thereís also a nitrous oxide injection system to reduce the turbo lag off the line.

Itís actually a sixth generation Celica, but the driverís seat has been shifted further back (12 inches) for better weight distribution. Raising the wheel arches and suspension mounts has also lowered the carís centre of gravity for more precise handling.

All in all this is a purpose built weapons grade hill climb machine that is capable of quicker times that recent F1 cars and anything else that wants to challenge for the fastest car at Goodwood title.

SPRINT SERIES TOYOTA CELICA GT4 TECHNICAL SPECIFICATION

Engine type Corolla WRC four-cylinder, 16-valve

Displacement (cc) 1,998

Turbocharger Garrett GT35/42

Supercharger Rotrex, belt-driven

Engine management Motec

Compression ratio 9.7:1

Max. power (DIN hp @ rpm) 700 @ 5,700 at 2bar boost

>800 with nitrous oxide boost

Fuel tank capacity (l) 15

Weight (kg) 1,050

Transmission Mactrack 5-speed manual with Fensport triple-plate clutch

Suspension (front & rear) Reiger Corolla WRC 3-way adjustable dampers,

Brakes Front 343mm and rear 295mm Corolla WRC ventilated discs with Alcon callipers

Wheels 18in

#46

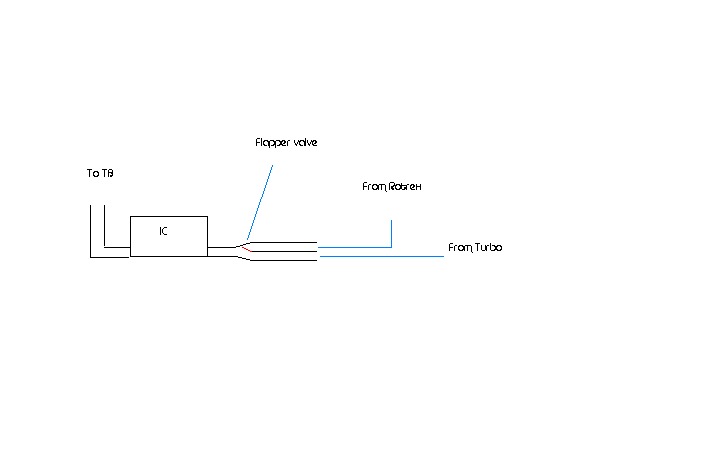

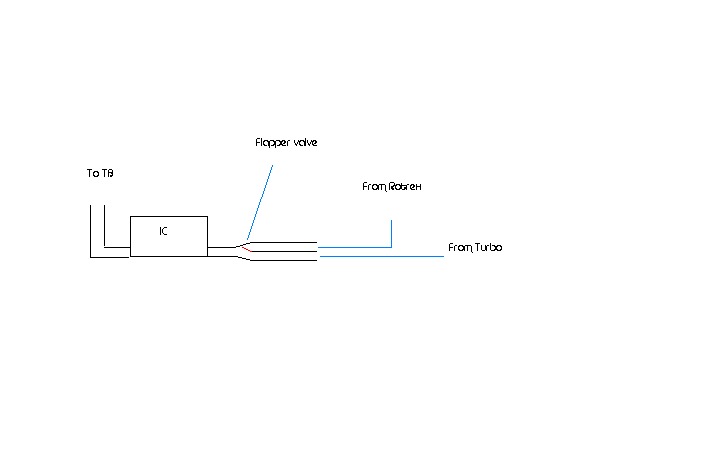

I know this may be missing the whole point, of compounding the two. But would this work?

Normal Rotrex setup and mount. A turbo tim bottom mount type set up. Both flowing into a collector with a flapper valve. At lower rpm the little turbo is spooled up and pushing more air than the rotrex, as the rotrex comes into it's prime it pushes the flapper valve down closing or mostly closing the turbo side of the collector. This then flows into the IC with the map sensor post IC.

Would this work?

Crappy paint drawing

If this is hyperish, flame away.

Normal Rotrex setup and mount. A turbo tim bottom mount type set up. Both flowing into a collector with a flapper valve. At lower rpm the little turbo is spooled up and pushing more air than the rotrex, as the rotrex comes into it's prime it pushes the flapper valve down closing or mostly closing the turbo side of the collector. This then flows into the IC with the map sensor post IC.

Would this work?

Crappy paint drawing

If this is hyperish, flame away.

#48

falcon,

unfortunately, the way you're considering this has a bunch of practical roadblocks to making it work well. The most significant probably is you will have to bypass the turbo compressor at some point, as the amount of flow will completely choke it once you have the rotrex really going. At that point you will lose a lot of boost anyway because of the effective restriction through the turbo compressor and likely the excessive temp rise because you'll fall off the cliff on comp efficiency. Not to mention a good chance you'll be overspeeding the compressor wheel causing damage to it and probably the bearing.

Which aspect is likely to be worse would depend mostly on how you try to calibrate it. If you don't wastegate enough flow, overspeed and temp will be the main issues, along with high turbine inlet pressures, and if you do wastegate the flow enough so you don't overspeed the compressor, you will just choke the rotrex.

The only way it will function reasonably well sticking with the plan you describe, is to completely bypass the turbo on both ends once the rotrex is making good boost. Depending on the comp map for it, you might be able to re-pulley the rotrex for the higher boost and use the turbo to compensate for the soggy bottom end. Something very small would be best I think, in the GT15 range. One of the OEM turbos off the Ford 3.5L would probably be a good choice if you can find one cheap, they are GT1549.

unfortunately, the way you're considering this has a bunch of practical roadblocks to making it work well. The most significant probably is you will have to bypass the turbo compressor at some point, as the amount of flow will completely choke it once you have the rotrex really going. At that point you will lose a lot of boost anyway because of the effective restriction through the turbo compressor and likely the excessive temp rise because you'll fall off the cliff on comp efficiency. Not to mention a good chance you'll be overspeeding the compressor wheel causing damage to it and probably the bearing.

Which aspect is likely to be worse would depend mostly on how you try to calibrate it. If you don't wastegate enough flow, overspeed and temp will be the main issues, along with high turbine inlet pressures, and if you do wastegate the flow enough so you don't overspeed the compressor, you will just choke the rotrex.

The only way it will function reasonably well sticking with the plan you describe, is to completely bypass the turbo on both ends once the rotrex is making good boost. Depending on the comp map for it, you might be able to re-pulley the rotrex for the higher boost and use the turbo to compensate for the soggy bottom end. Something very small would be best I think, in the GT15 range. One of the OEM turbos off the Ford 3.5L would probably be a good choice if you can find one cheap, they are GT1549.

#49

Senior Member

iTrader: (4)

Join Date: Aug 2010

Location: Farmington Hills, MI

Posts: 460

Total Cats: 15

#56

joking about what? twin charging? It's been done before with a Rotrex.

I think the best way to do it is like a compound turbo set up where the big turbo (in this case the rotrex) feeds the small turbo's inlet. Then when the big turbo (rotrex) takes over it blows through the little turbo. That's how must compound turbo set ups are made.

I think the best way to do it is like a compound turbo set up where the big turbo (in this case the rotrex) feeds the small turbo's inlet. Then when the big turbo (rotrex) takes over it blows through the little turbo. That's how must compound turbo set ups are made.

#57

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,656

Total Cats: 3,011

I see two misconceptions in the arguments against this setup. The first is that the small turbo will be out of its efficiency range due to high pressure after the Rotrex starts moving air. The thing to remember about the compressor maps is that it is a pressure ratio and not an absolute pressure being portrayed on the maps. If you add, say, one BAR of pressure to the inlet of the turbo compressor, that will be 1 PR on your compressor map and not 2 PR as a starting point.

The second is that some of you are confusing mass of air on the compressor map with volume. When the Rotrex is making positive pressure the mass of pre-compressed air entering the turbo will be far greater than the mass if it was simply atmospheric air entering the turbo. I'm no engineer, but I believe this will effect the mass calculations when reading the compressor map as well. You are essentially moving the base calculations for atmospheric conditions of pressure and mass of air by changing the pressure and mass of the air by volume that enters the compressor inlet. The compressor "sees" different atmospheric conditions than ambient.

Have you ever seen a shop air compressor with a multi-cylinder compound design that uses a very large piston feeding a smaller one and then going to the tank? The smaller one is not choking the larger one's ability to feed the tank. The large volume entering the big cylinder is a much smaller volume when leaving it and can easily fit into the smaller cylinder to be compressed even further. This idea is nothing new.

The second is that some of you are confusing mass of air on the compressor map with volume. When the Rotrex is making positive pressure the mass of pre-compressed air entering the turbo will be far greater than the mass if it was simply atmospheric air entering the turbo. I'm no engineer, but I believe this will effect the mass calculations when reading the compressor map as well. You are essentially moving the base calculations for atmospheric conditions of pressure and mass of air by changing the pressure and mass of the air by volume that enters the compressor inlet. The compressor "sees" different atmospheric conditions than ambient.

Have you ever seen a shop air compressor with a multi-cylinder compound design that uses a very large piston feeding a smaller one and then going to the tank? The smaller one is not choking the larger one's ability to feed the tank. The large volume entering the big cylinder is a much smaller volume when leaving it and can easily fit into the smaller cylinder to be compressed even further. This idea is nothing new.

#59

I see two misconceptions in the arguments against this setup. The first is that the small turbo will be out of its efficiency range due to high pressure after the Rotrex starts moving air. The thing to remember about the compressor maps is that it is a pressure ratio and not an absolute pressure being portrayed on the maps. If you add, say, one BAR of pressure to the inlet of the turbo compressor, that will be 1 PR on your compressor map and not 2 PR as a starting point.

The second is that some of you are confusing mass of air on the compressor map with volume. When the Rotrex is making positive pressure the mass of pre-compressed air entering the turbo will be far greater than the mass if it was simply atmospheric air entering the turbo. I'm no engineer, but I believe this will effect the mass calculations when reading the compressor map as well. You are essentially moving the base calculations for atmospheric conditions of pressure and mass of air by changing the pressure and mass of the air by volume that enters the compressor inlet. The compressor "sees" different atmospheric conditions than ambient.

Have you ever seen a shop air compressor with a multi-cylinder compound design that uses a very large piston feeding a smaller one and then going to the tank? The smaller one is not choking the larger one's ability to feed the tank. The large volume entering the big cylinder is a much smaller volume when leaving it and can easily fit into the smaller cylinder to be compressed even further. This idea is nothing new.

The second is that some of you are confusing mass of air on the compressor map with volume. When the Rotrex is making positive pressure the mass of pre-compressed air entering the turbo will be far greater than the mass if it was simply atmospheric air entering the turbo. I'm no engineer, but I believe this will effect the mass calculations when reading the compressor map as well. You are essentially moving the base calculations for atmospheric conditions of pressure and mass of air by changing the pressure and mass of the air by volume that enters the compressor inlet. The compressor "sees" different atmospheric conditions than ambient.

Have you ever seen a shop air compressor with a multi-cylinder compound design that uses a very large piston feeding a smaller one and then going to the tank? The smaller one is not choking the larger one's ability to feed the tank. The large volume entering the big cylinder is a much smaller volume when leaving it and can easily fit into the smaller cylinder to be compressed even further. This idea is nothing new.