Pictures of my rod for Hustler

#63

Dann

#64

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

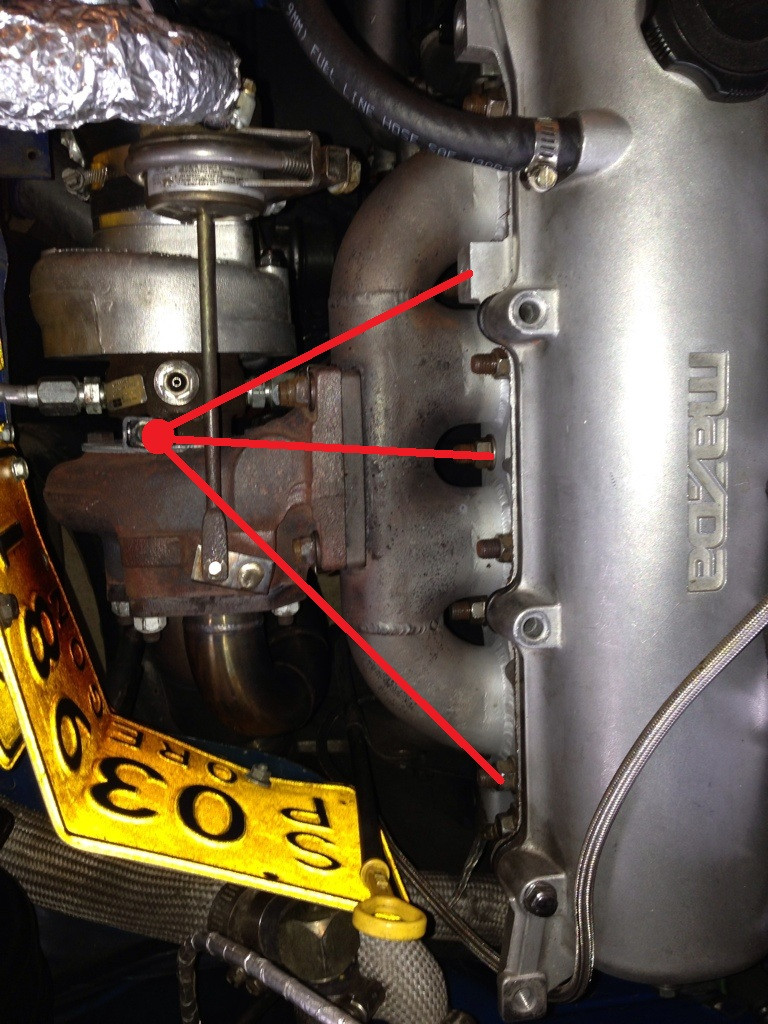

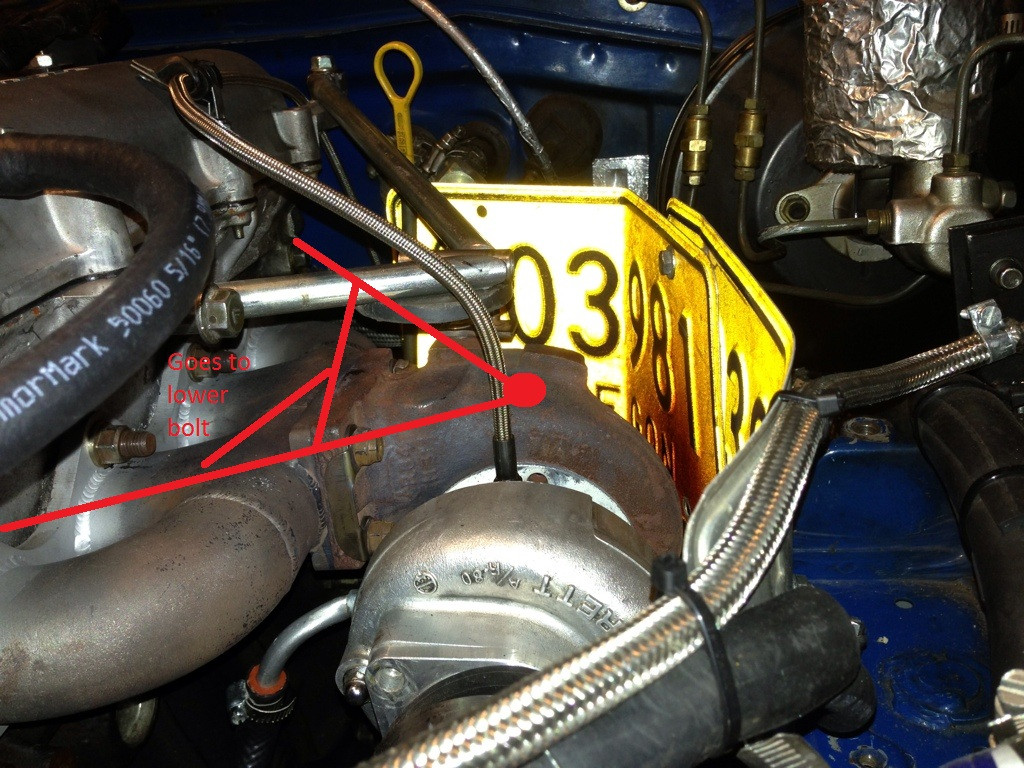

You may or may not be right, whats nice about it being a turnbuckle is that while its on the dyno I can and will turn the turnbuckle and find out just how far the manifold moves, if its more than a few millimetres I will do a very strong turnbuckle from under the turbo to the engine mount.

Dann

Dann

#73

The green would be the force applied to the bracket.

Sure the bracket supports it self however remember you're talking about an M6 bolt there and a 10" long bar to put force on it. The 1/16-1/8" wall around it increases the tension until the opposite corners hit the bolt and at that point you're putting every bit of bending force on the bolt.

Say u're putting upwards force on it. The opposite corners that will contact the bolt will be the one where your arrow is pointing and the top on the right where the bolt head is at.

You can easily snap a m6 bolt just by over torquing it.. imagine how easy it is to snap it with a 10" bar .

To make things worse, theres a gasket those bolts hold. Every bit of upwards or downwards motion increases and loosens the force on that gasket.

#80

Cpt. Slow

Thread Starter

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,197

Total Cats: 1,136

Lots to think about. I also thought of a much better way to fabricate the 2nd design, so I'll be making a 3rd prototype going to the VC bolts, 1/4" rod, 3rd member, etc. Gimmie some time though, I'm about to start a week of work and quizes in class.

Keep in mind they're only 5" long, not 10. We're really talking about tiny motions, I'm not too worried about it.

Keep in mind they're only 5" long, not 10. We're really talking about tiny motions, I'm not too worried about it.