Nothing to see here, just project Sisyphus, move along

#771

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

No EDM that I'm aware of, but I'm going to make some calls tomorrow. This is way beyond my ability to unfuck.

I ended up spending 20 minutes with a set of jewelers files removing the weld nubs as well as i could and then retapped the remaining holes. Studs feel super loose now, not sure if that's good or not

I ended up spending 20 minutes with a set of jewelers files removing the weld nubs as well as i could and then retapped the remaining holes. Studs feel super loose now, not sure if that's good or not

#773

Oof. G, you just can't catch a break man. Broken studs suck.

How loose is loose? They should thread in pretty easy from my memory of installing the TSE studs. Besides once threaded all the way with resbond I don't think you'll have issues.

Resbond that ****, fix the broken stud, and put your nuts on and call it could.

How loose is loose? They should thread in pretty easy from my memory of installing the TSE studs. Besides once threaded all the way with resbond I don't think you'll have issues.

Resbond that ****, fix the broken stud, and put your nuts on and call it could.

#774

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

Yes, the Resbond should bridge it.

So sorry to see this. Plunge EDM would work but it will take a big tank.

Can you get to the offending **** on the back side and file them away? Or are they internal?

Also, is there some way to pre-dissolve the Resbond chemically before attempting the extraction?

10mm stud in that one location?

Worst case, new flange.

End of solitary brain storming session.

So sorry to see this. Plunge EDM would work but it will take a big tank.

Can you get to the offending **** on the back side and file them away? Or are they internal?

Also, is there some way to pre-dissolve the Resbond chemically before attempting the extraction?

10mm stud in that one location?

Worst case, new flange.

End of solitary brain storming session.

#777

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Oof. G, you just can't catch a break man. Broken studs suck.

How loose is loose? They should thread in pretty easy from my memory of installing the TSE studs. Besides once threaded all the way with resbond I don't think you'll have issues.

Resbond that ****, fix the broken stud, and put your nuts on and call it could.

How loose is loose? They should thread in pretty easy from my memory of installing the TSE studs. Besides once threaded all the way with resbond I don't think you'll have issues.

Resbond that ****, fix the broken stud, and put your nuts on and call it could.

Not really an option I want to pursue. The 10mm stud won't fit without A LOT of modification on the housing. Clearances are TIGHT as it is. Having said that, maybe I'll buy a TSE 10mm nut and see what kind of modifications I need to make. I know Soviet made it work, but he didn't exactly post a lot of pics of the process.

The point of using the 8mm inconel was finding an off the shelf solution so I didn't have to sit there all night like a chinese monk with a dremel and a file making things fit.

Manifold was coated by Swain. Just throwing a new flange on there may not be as easy as you might expect.

It's cool, I appreciate it.

If the threads can't be salvaged I can always try a helicoil or time-sert. Or drill a big bastard hole and weld in a new piece of material with a fresh tapped hole in it.

I have options but none of them are attractive.

#780

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

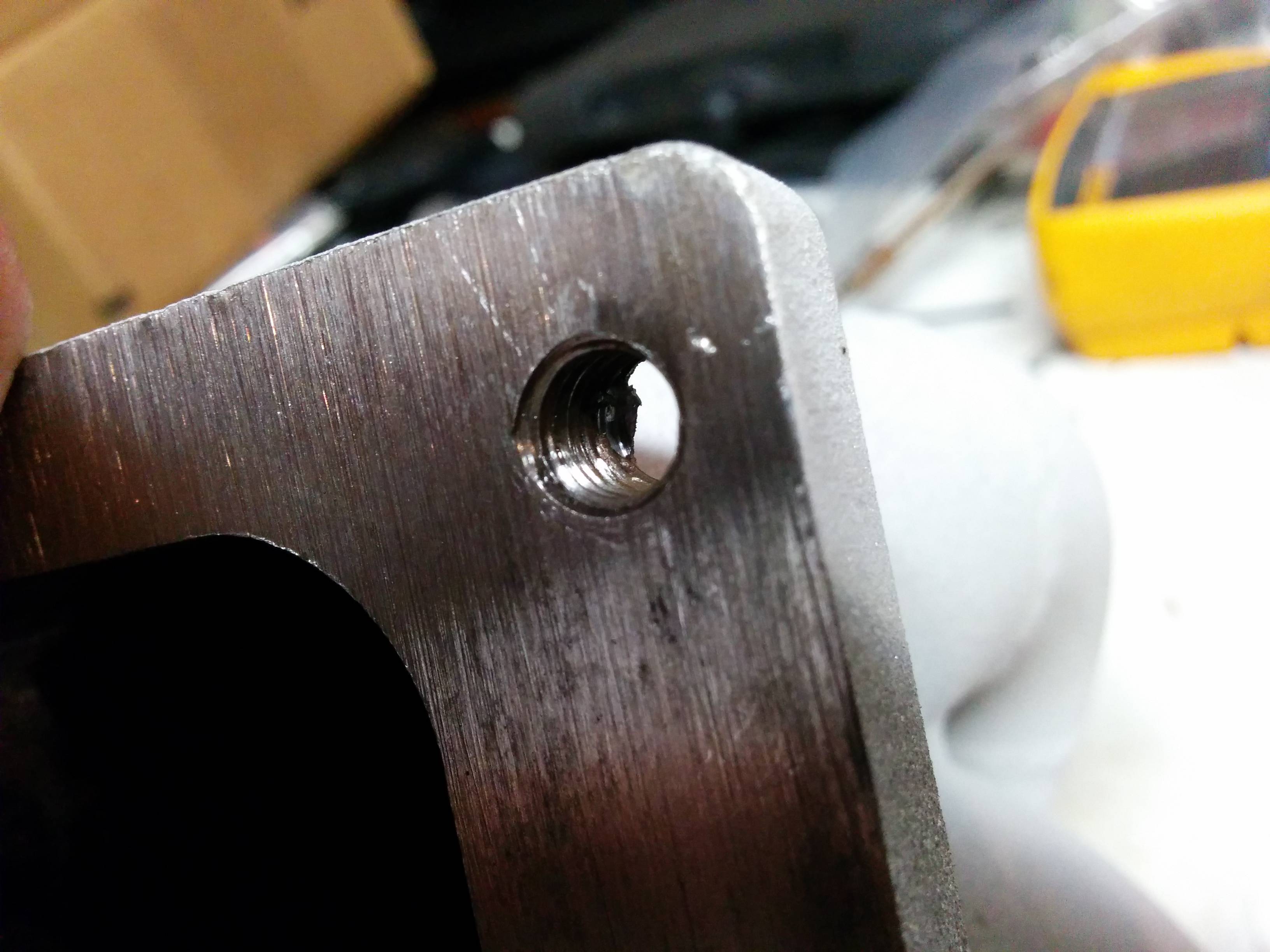

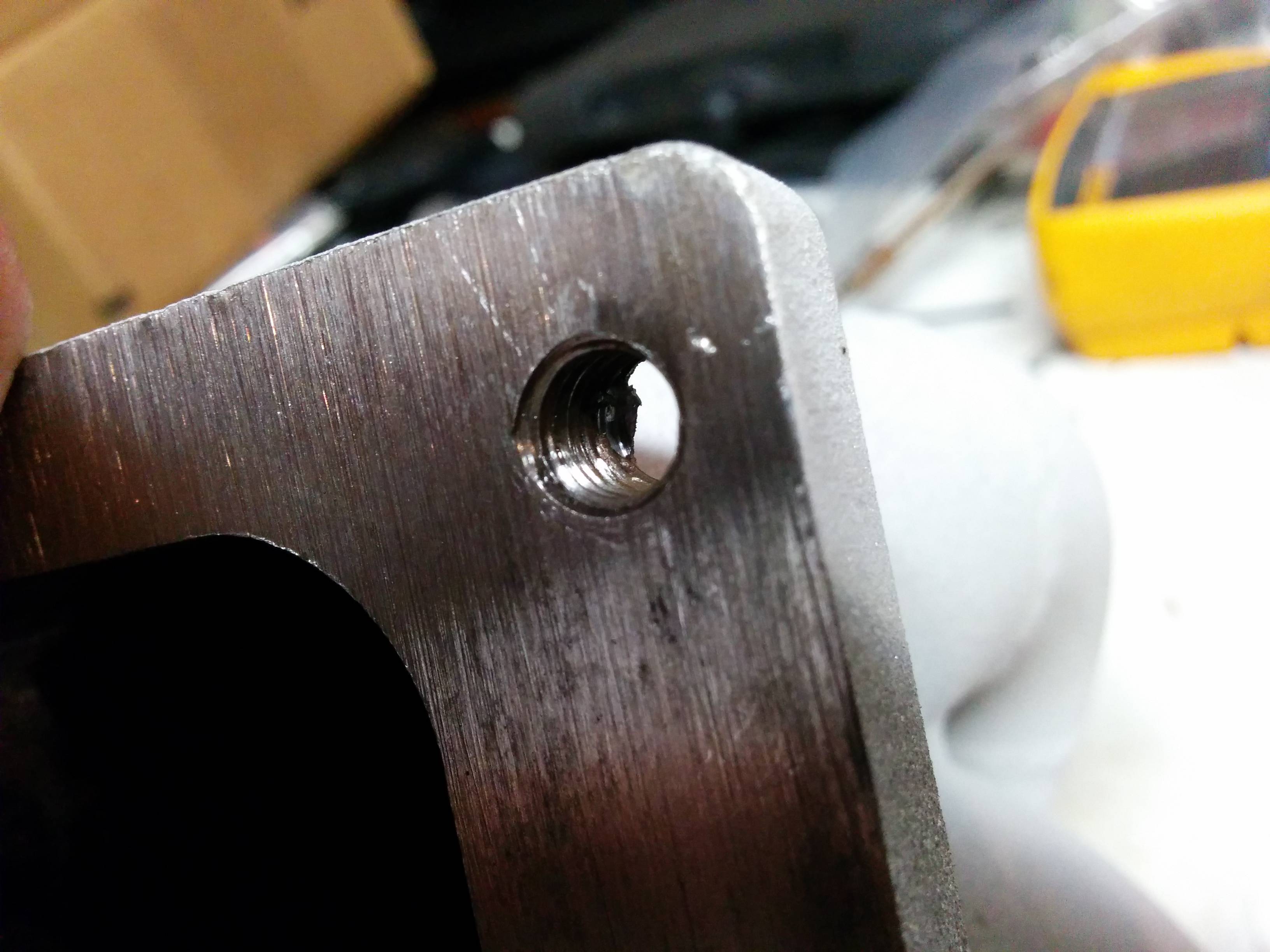

Just to give you an idea of exactly how badly I fucked this up, here is a pic of one of the "****" in one of the other threaded holes:

That's after I decided the force on the tap seemed a bit ...excessive. I removed the rest of that blob with the aforementioned files and finished retaping. It was not fun. The bluing in the blob should give you an idea of how hardened that material was after welding. At this point, I'm not convinced the Swain coating had anything to do with it.

That's after I decided the force on the tap seemed a bit ...excessive. I removed the rest of that blob with the aforementioned files and finished retaping. It was not fun. The bluing in the blob should give you an idea of how hardened that material was after welding. At this point, I'm not convinced the Swain coating had anything to do with it.