Further Thread on Oil Supply

#61

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,660

Total Cats: 3,011

I already lost a turbo to crap getting caught in the little oil feed line when the dipstick melted. But when the engine is cold it is common for the internal bypass in the filter to open and let garbage through anyway.

#65

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

I was not able to find it. However, I believe you will find that my head pressure, when hot, when flowing oil out of the hose with restrictor and no Turbo (more than it will in actual turbo use), was greater than the minimums for the bottom end. To me, that clenches it.

Block factory minimum is 7 psi at 1000 RPM and I got 10 at the head while flowing oil.

I have contemplated putting the tee in at the head and moving the factory idiot gauge sender to the head along with my turbo feed. Then if the head got below the factory level for the block, it would show.

Block factory minimum is 7 psi at 1000 RPM and I got 10 at the head while flowing oil.

I have contemplated putting the tee in at the head and moving the factory idiot gauge sender to the head along with my turbo feed. Then if the head got below the factory level for the block, it would show.

#67

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,499

Total Cats: 4,080

Your test was flawed.

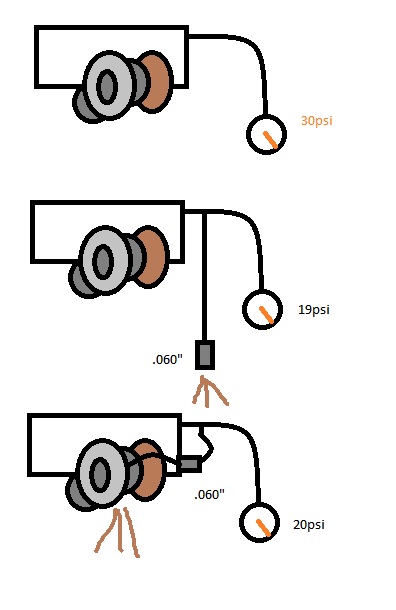

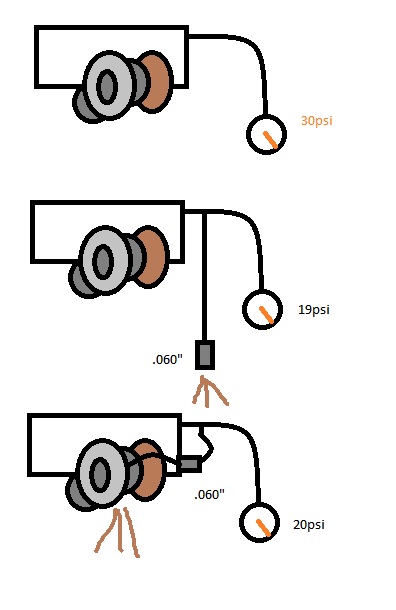

When I first read this it seemed like you added a restriction and saw a pressure drop?

But we all know that couldn't be the case, but then I reread how you did the test and I see the issue.

This does NOT illustrate a ~10psi pressure drop.

Notice how when you added the turbo the pressure increased again? it's because a restriction will add pressure. You needed to do the same test as the middle drawing WITHOUT the restrictor to actually do any sort of reliable test.

But even then it wasn't setup to test the pressure drop as you're only testing the effects of the restrictor/turbo on the flow at THAT particular hole.

You to put the gauge BEFORE the head (oil pressure sender) to see if there's a pressure drop to the entire flow of oil to the head, NOT just the one outlet itself. Or if you used a two gauge setup on the outlet, much like a leakdown tester.

When I first read this it seemed like you added a restriction and saw a pressure drop?

But we all know that couldn't be the case, but then I reread how you did the test and I see the issue.

This does NOT illustrate a ~10psi pressure drop.

Notice how when you added the turbo the pressure increased again? it's because a restriction will add pressure. You needed to do the same test as the middle drawing WITHOUT the restrictor to actually do any sort of reliable test.

But even then it wasn't setup to test the pressure drop as you're only testing the effects of the restrictor/turbo on the flow at THAT particular hole.

You to put the gauge BEFORE the head (oil pressure sender) to see if there's a pressure drop to the entire flow of oil to the head, NOT just the one outlet itself. Or if you used a two gauge setup on the outlet, much like a leakdown tester.

#69

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

Guys, sorry that I did not see these last two posts until today.

Brain. I disagree that I should test as you propose. It would be pretty unconceivable that the pressure at the sending unit would go down. That pressure is controlled by the pressure relief valve of the oil pump. I would be quite surprised to see that drop even in the typical scenario of when the turbo feed is taken there.

Note that I am not measuring pressure drop, but rather pressure change.

I am assuming that the pressure in the head is somewhat uniform after the restrictor that is between the block and the head. That restrictor is what causes: 1) The bottom end oil pressure to remain the same; 2) the pressure in the head to drop, when there is flow.

The pressure goes back up 1psi when adding the turbo because the flow out of the head decreases, meaning the flow into the head also decreases, lowering the pressure drop (now used correctly by me) across the block / head orifice to be less.

If I run a test where I open the port completely, then I hemorage at the head and for sure will get a very low pressure.

The purpose of the test is to determine if drawing oil from that back port would cause the head oil pressure to fall to unsafe (admitedly not defined, but a judgement call) level.

Agreed, that having the gauge in a secondary port would be a little bit better, but it would still need to be a head port, not a block port. That is, after the block / head restrictor.

18: See also posts 54 and 55.

I have not opened the Turbo or the valve cover, but there have been no detectable, negative effects from this oil feed. However, I am not suggesting anyone else do it as I know it is a risk.

Brain. I disagree that I should test as you propose. It would be pretty unconceivable that the pressure at the sending unit would go down. That pressure is controlled by the pressure relief valve of the oil pump. I would be quite surprised to see that drop even in the typical scenario of when the turbo feed is taken there.

Note that I am not measuring pressure drop, but rather pressure change.

I am assuming that the pressure in the head is somewhat uniform after the restrictor that is between the block and the head. That restrictor is what causes: 1) The bottom end oil pressure to remain the same; 2) the pressure in the head to drop, when there is flow.

The pressure goes back up 1psi when adding the turbo because the flow out of the head decreases, meaning the flow into the head also decreases, lowering the pressure drop (now used correctly by me) across the block / head orifice to be less.

If I run a test where I open the port completely, then I hemorage at the head and for sure will get a very low pressure.

The purpose of the test is to determine if drawing oil from that back port would cause the head oil pressure to fall to unsafe (admitedly not defined, but a judgement call) level.

Agreed, that having the gauge in a secondary port would be a little bit better, but it would still need to be a head port, not a block port. That is, after the block / head restrictor.

18: See also posts 54 and 55.

I have not opened the Turbo or the valve cover, but there have been no detectable, negative effects from this oil feed. However, I am not suggesting anyone else do it as I know it is a risk.

#70

Running a 94 bottom end with a VVT head, oil sourced from the OEM location, with the factory oil pressure gauge attached.

Cold start shows ~35psi, which slowly drops to about 18psi as the engine & oil warm up. It holds steady there, it'll jump over 20psi if you wind it out all the way. My initial concern was the relatively small delta between idle and redline...I expected to see at least a 10psi difference. I would assume adding a restriction downstream would bump those numbers slightly.

I honestly had no idea what the minimum requirement was to keep the head happy (consensus seems to be 7psi), but I've never had any indication that the head was starving.

This is all with 10w-30 dino oil, and it's predicated on the assumption that the OEM gauge is somewhat accurate.

#72

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

I wouldn't be concerned with starving just the head. Sixshooter suggested somewhere that the VVT engines had a larger oil pump to supply the solenoid. What you are measuring is the bottom end oil pressure and that is scary low (though it would not cause my NB1 oil pressure gauge to indicate low pressure).

Maybe others that have put VVT's on older blocks will jump in.

Or see this: VVT with thin oil pump

Maybe others that have put VVT's on older blocks will jump in.

Or see this: VVT with thin oil pump

#73

@DNMakinson...yeah, I'm not thrilled with the oil pressure readings I'm seeing. Part of that is what I spoke to above, and part of that is the fact that I'm still using the 94 oil pump. I think the bottom end oil pressure is fine, my concern is whether I can properly feed the VVT solenoid AND a turbo on the setup I currently have.

Stupid question time: The typical route is to tap the oil pan to feed your turbo. The oil pump supplies pressure if you go this route too, correct?

I made a rookie mistake and started a build around a cheap part (local VVT head). Boo.

#74

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

You drill and tap the oil pan for the oil drain line only.

Last edited by shuiend; 02-19-2015 at 09:43 AM.

#75

Retired Mech Design Engr

Thread Starter

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

No, the normal way to feed oil to the turbo is on 90-95.5 blocks to use the oil feed port of the driver side of the block. On the 96+-05 blocks you put a tee in at the oil pressure sender and run the line around from the drivers passenger's side.

You drill and tap the oil pan for the oil drain line only.

You drill and tap the oil pan for the oil drain line only.

#77

This thread inspired me to take the miata out for the first time in a few months.

My oil pressure nearly mirrored what JasonC SBB noted in the "VVT with thin oil pump" thread:

"With 82*C oil (180*F), I only get

16-17 psi at idle,

28 psi at 3000 RPM, and

38 psi at 6000 RPM."

except mine would barely crack 30psi at 6000rpm.

Can anyone confirm that the NB2 oil pump retrofits?

My oil pressure nearly mirrored what JasonC SBB noted in the "VVT with thin oil pump" thread:

"With 82*C oil (180*F), I only get

16-17 psi at idle,

28 psi at 3000 RPM, and

38 psi at 6000 RPM."

except mine would barely crack 30psi at 6000rpm.

Can anyone confirm that the NB2 oil pump retrofits?

#80

This thread inspired me to take the miata out for the first time in a few months.

My oil pressure nearly mirrored what JasonC SBB noted in the "VVT with thin oil pump" thread:

"With 82*C oil (180*F), I only get

16-17 psi at idle,

28 psi at 3000 RPM, and

38 psi at 6000 RPM."

except mine would barely crack 30psi at 6000rpm.

Can anyone confirm that the NB2 oil pump retrofits?

My oil pressure nearly mirrored what JasonC SBB noted in the "VVT with thin oil pump" thread:

"With 82*C oil (180*F), I only get

16-17 psi at idle,

28 psi at 3000 RPM, and

38 psi at 6000 RPM."

except mine would barely crack 30psi at 6000rpm.

Can anyone confirm that the NB2 oil pump retrofits?

35 psi idle

45 psi cruising constant load on freeway

75 psi WOT

This is based off a second oil pressure gauge I installed and not the factory 1.6 gauge. The factor gauge was even higher than that.

How much oil pressure is too much pressure?

edit: stock 1.6 running rotella t6 synthetic