Further Thread on Oil Supply

#84

Great thread, big help! Hope somebody can advise if my oil pressure is normal and OK please.

96 na8, with AVO turbo kit(GT25xx, oil and water cooled), peaks at near 8psi. While prepping for turbo we saw some very high pressures (real gauge tapped off T at normal sender point), ~80psi, then one day nothing. On removing the pan found relief valve stuck open. Removed the slug, cleaned up roughness, refitted. Saw ~60psi on cold start. After turbo , fed with oil from T at sender fitting, fully hot through we see at 1000rpm 16-18psi, 32psi at 2k, 40psi at 4k. We used to get some HLA noise at cold start until recently replacing the oil filter - now pressure comes up quicker, and there is no HLA noise, but there is a not change between start and pressure registering on gauge. Under 2k mi on the oil, 10-50 synthetic.

Sound normal? Has under 60k miles on it, tons of power.

thanks

jp

96 na8, with AVO turbo kit(GT25xx, oil and water cooled), peaks at near 8psi. While prepping for turbo we saw some very high pressures (real gauge tapped off T at normal sender point), ~80psi, then one day nothing. On removing the pan found relief valve stuck open. Removed the slug, cleaned up roughness, refitted. Saw ~60psi on cold start. After turbo , fed with oil from T at sender fitting, fully hot through we see at 1000rpm 16-18psi, 32psi at 2k, 40psi at 4k. We used to get some HLA noise at cold start until recently replacing the oil filter - now pressure comes up quicker, and there is no HLA noise, but there is a not change between start and pressure registering on gauge. Under 2k mi on the oil, 10-50 synthetic.

Sound normal? Has under 60k miles on it, tons of power.

thanks

jp

#85

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,038

Total Cats: 6,604

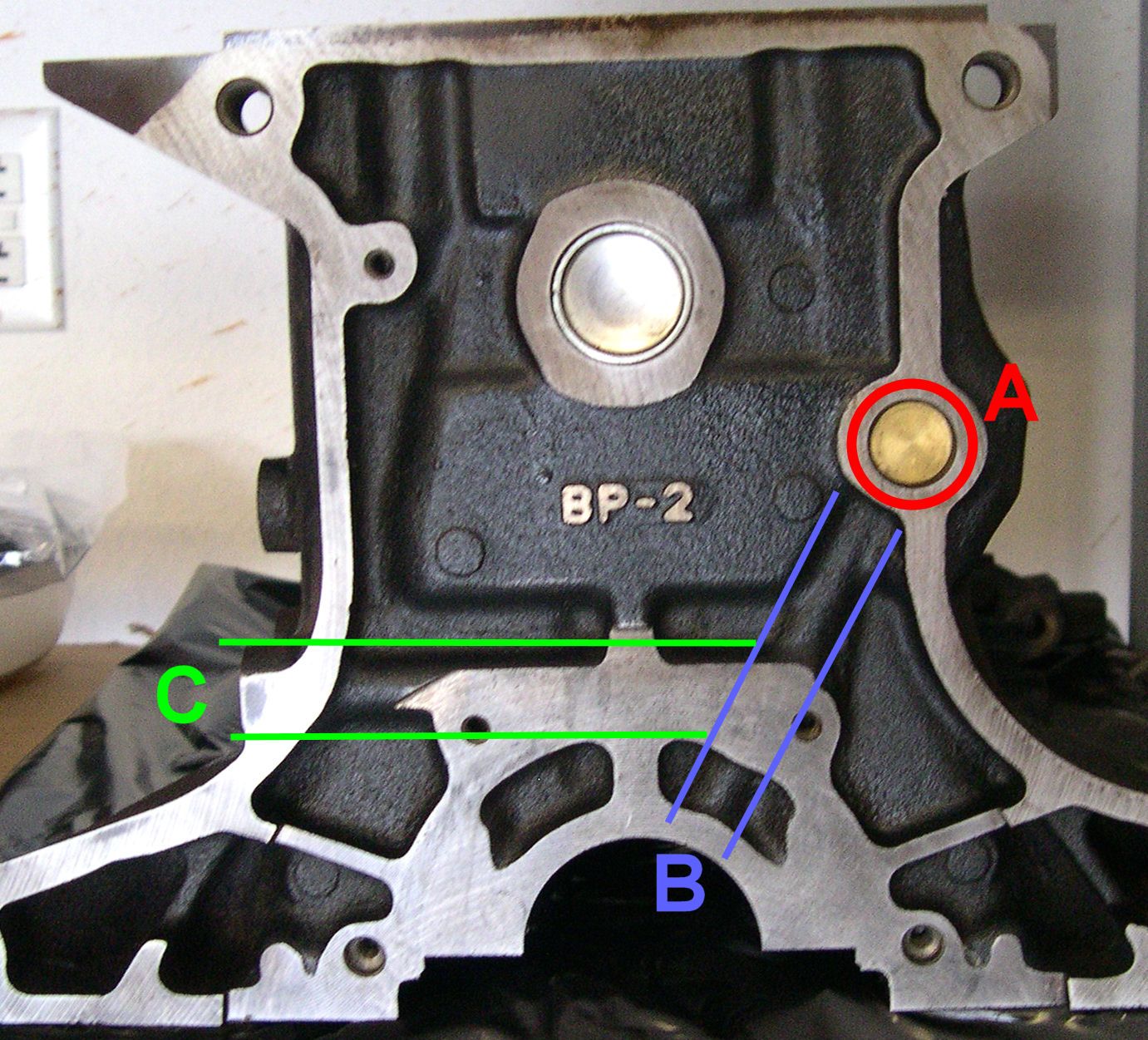

Around 2009, I made precisely this observation and posted the results in another thread. I can't find the exact images which I used there, but here's a recreation based upon a photo I took of the back of a '99 block:

The red circle marked "A" is the main oil galley, which runs from the front of the block all the way to the back, and is supplied directly by the output of the oil filter. The feed up to the head (through the restrictor) taps off of this line midway, as do all of the feeds which run down to the main crankshaft bearings. The oil pressure sensor hole is also drilled transversely into this line, and in VVT engines, the oil supply to the intake cam is also sourced from the same location.

The blue lines marked "B" outline the casting feature which surrounds the drilled passage running down to the rear main crankshaft bearing.

The green lines marked "C" outline the casting feature which, in the GTX, '90-'93 Miata and MSM blocks is drilled out to supply oil to the turbo. The casting hump is present on all BP blocks, it's simply not drilled out on most of them. If you possess the ability to make a perfectly straight and level hole a few mm wide through five inches of cast iron without deviating by more than 1°, then you can convert any '94-'05 BP block into an MSM block simply by drilling inwards from the outer surface of this casting feature until you reach the diagonal passage (B) which runs from the main galley down to the rear main bearing. This is how Mazda did it in every single factory-turbo variant of the B-series engine.

Here is the spot where you would drill from:

Note that the commend I made on that image about "early NA block" should read "1.6 or MSM block." That was a very old image from before I'd started thinking about the MSM.

TL;DR: The block casting is identical across all 1.8L B engines, and is conceptually identical (in terms of the oil passages) to all 1.6L blocks, be they 323GTX or stock Miata. Only the machining differs, to expose the oil (and coolant) through casting features which are present regardless of whether the machining operation is performed or not.

#86

If you possess the ability to make a perfectly straight and level hole a few mm wide through five inches of cast iron without deviating by more than 1°, then you can convert any '94-'05 BP block into an MSM block simply by drilling inwards from the outer surface of this casting feature until you reach the diagonal passage (B) which runs from the main galley down to the rear main bearing.

--Ian

#88

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,038

Total Cats: 6,604

The level of precision you have specified (a few thou) is more precise than one the I specified (1° of arc over 5", which comes to an error or .0873", much more than "a few thou.")

#91

With a really really rigid drill press, a couple thousand dollars worth of fixture (miata crank mandrel, 18" sin table, etc), a couple days worth of setup, and a few blocks you're willing to scrap till you get it setup right? Sure.

And joe, you're right. I should have done the math out.

And joe, you're right. I should have done the math out.

#92

From what I remember of older threads theres a coolant passage you have to miss along with having a small range to do it. If the boss on the block is faced accurately at the factory then maybe you could setup off that and get away with making a smaller jig with a drill bushing based off the boss and maybe be ok. But I dont believe it is.

#94

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,038

Total Cats: 6,604

Go buy a 1" x 6" plank of hard wood. Measure the diameter of a crank main oil passage, and drill a hole that size through the plank the short way, 5" from the edge.

Now, try to perfectly intersect that hole from the perpendicular face 5" away.

Then, imagine doing the same in cast iron.

#95

It seems like you could fixture it by welding up a couple of U-shaped brackets out of square tubing, then bolting them to the head bolt holes on one side and the main cap holes on the other. Set it on its side, put some kind of adjustment screws on it so you can level it, then clamp it down. I would want to use a mill though, not a drill press. TechShop has 'em.

If I still had my old block I'd be tempted to give it a try (I tossed it out when I moved)

--Ian

If I still had my old block I'd be tempted to give it a try (I tossed it out when I moved)

--Ian

#96

Couldn't you use a pretty small bit, like 1/4 ? Since it is only going to feed a turbo, which will then neck down to like .030" . A short bit to start the hole, then finish with something longer. I am by no means a precision machinist, but with a mill, some time spent to level things out, I'd go for it.

#100

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,038

Total Cats: 6,604

It is.

Coming up after the break, we'll show you how one Chantilly man fit an MSM exhaust manifold onto his 1.6 engine. And later, residents are shocked by a gruesome discovery involving a local man, his wife, their cats, and a common household item which may pose a lucking danger for all of us.

Stay tuned.

Coming up after the break, we'll show you how one Chantilly man fit an MSM exhaust manifold onto his 1.6 engine. And later, residents are shocked by a gruesome discovery involving a local man, his wife, their cats, and a common household item which may pose a lucking danger for all of us.

Stay tuned.