Godless Commie's ungodly turbo project - R2S Progressive Twin Turbo

#101

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

Just got the turbos back.

Small turbo was in bad shape.

Turbine shaft was badly gouged as if someone had dumped sand in the cartridge through the oil inlet.

So were the bearings...

No gouging or scratches in the big turbo, tho.

So, it must have been an accident / careless handling while the turbo assembly was laying around during the lengthy build process.

Everything in the little guy was replaced, and it is brand new again.

We also decided to replace the turbine wheel on the large turbo.

It had a 44.5 - 50 wheel, we installed a 42 - 50 in there for quicker spool, so the small turbo will not have to run longer to feed it.

I was able to find the proper housing for the new (smaller) turbine, so no machining was needed.

I believe 44.5 - 50 turbine is used in K04-064, and the smaller 42 - 50 is found in K04-015.

(A quick search tells me the larger version is used in Audi RS6 with the 4 liter V8 (twin turbo), and the smaller version is installed on the RS4 (again, twin turbo) 3.7 liter V6)

This operation brought the turbo down to the 1.8 liter territory, such as 1.8T Audi and VW engines.

My hands are tied for at least a week since I will be gone.

So, I will be dropping the car off at the body shop for the week. Trunk lid will be repaired and repainted (my fault), RF fender will be repainted, a few dings will be repaired, surface rust below the RF corner of trunk frame will be dealt with, all four rims will be stripped and repainted, and the whole car will be buffed/polished.

They will also paint the louvers and the frame assembly for the hood. They will be disassembled so they can be painted properly.

All for under $300, so why not...

Small turbo was in bad shape.

Turbine shaft was badly gouged as if someone had dumped sand in the cartridge through the oil inlet.

So were the bearings...

No gouging or scratches in the big turbo, tho.

So, it must have been an accident / careless handling while the turbo assembly was laying around during the lengthy build process.

Everything in the little guy was replaced, and it is brand new again.

We also decided to replace the turbine wheel on the large turbo.

It had a 44.5 - 50 wheel, we installed a 42 - 50 in there for quicker spool, so the small turbo will not have to run longer to feed it.

I was able to find the proper housing for the new (smaller) turbine, so no machining was needed.

I believe 44.5 - 50 turbine is used in K04-064, and the smaller 42 - 50 is found in K04-015.

(A quick search tells me the larger version is used in Audi RS6 with the 4 liter V8 (twin turbo), and the smaller version is installed on the RS4 (again, twin turbo) 3.7 liter V6)

This operation brought the turbo down to the 1.8 liter territory, such as 1.8T Audi and VW engines.

My hands are tied for at least a week since I will be gone.

So, I will be dropping the car off at the body shop for the week. Trunk lid will be repaired and repainted (my fault), RF fender will be repainted, a few dings will be repaired, surface rust below the RF corner of trunk frame will be dealt with, all four rims will be stripped and repainted, and the whole car will be buffed/polished.

They will also paint the louvers and the frame assembly for the hood. They will be disassembled so they can be painted properly.

All for under $300, so why not...

#103

In an effort to prevent future turbo shaft and bearing damage, you may want to reread post #75 in this thread...

Your turbo oil feed lines have Unfiltered Oil.

The feed lined presently pick up the oil between the Oil Pump and the Oil FIlter so, anything floating around in the sump that gets picked up by the pump could end up in the turbos... Kind of hard on journal bearings.

Those ports in the filter adapter are OK for oil pressure or temp sensors but not turbos.

Your turbo oil feed lines have Unfiltered Oil.

The feed lined presently pick up the oil between the Oil Pump and the Oil FIlter so, anything floating around in the sump that gets picked up by the pump could end up in the turbos... Kind of hard on journal bearings.

Those ports in the filter adapter are OK for oil pressure or temp sensors but not turbos.

#105

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

In an effort to prevent future turbo shaft and bearing damage, you may want to reread post #75 in this thread...

Your turbo oil feed lines have Unfiltered Oil.

The feed lined presently pick up the oil between the Oil Pump and the Oil FIlter so, anything floating around in the sump that gets picked up by the pump could end up in the turbos... Kind of hard on journal bearings.

Those ports in the filter adapter are OK for oil pressure or temp sensors but not turbos.

Your turbo oil feed lines have Unfiltered Oil.

The feed lined presently pick up the oil between the Oil Pump and the Oil FIlter so, anything floating around in the sump that gets picked up by the pump could end up in the turbos... Kind of hard on journal bearings.

Those ports in the filter adapter are OK for oil pressure or temp sensors but not turbos.

But, there is evidence of FOD in one turbo. The other one (K04) has no scratches, no gouging.

That pretty much tells me the damage was done way before I even installed them.

I guess I'll order a couple reusable filters and incorporate them in the feed lines. Can't hurt.

#106

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I am back.

A month in Nepal, and another week at home catching up with work related stuff meant no garage time...

I had left al the active hood parts at the paint shop before I left, so I picked them up and did a trial fit last night.

The result is pretty satisfying, so I decided not to remove them and locked everything in place in the open position till I fab and install the actuator mechanism.

Here:

A month in Nepal, and another week at home catching up with work related stuff meant no garage time...

I had left al the active hood parts at the paint shop before I left, so I picked them up and did a trial fit last night.

The result is pretty satisfying, so I decided not to remove them and locked everything in place in the open position till I fab and install the actuator mechanism.

Here:

#111

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

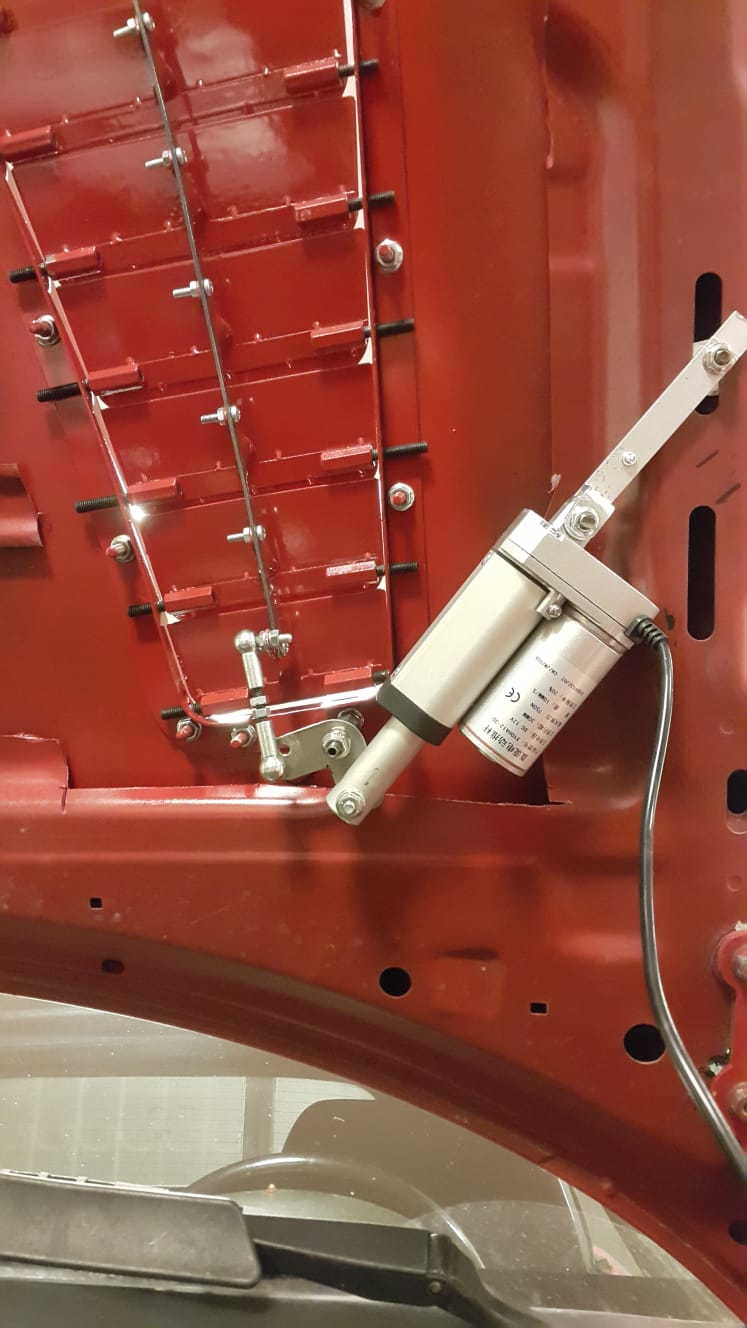

The whole thing evolved into an electric setup. I am using a linear actuator, a couple optocouplers and two delay relays.

The trigger is simple: presence or absence of 12V, borrowed from the alternator signal circuit.

That way the actuation will be based on whether the engine is running, rather than just voltage in the ignition circuit.

#115

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I am excite.

Several hours of head scratching in the garage yielded an 8 second video...

Please note this is very early stages, and I just wanted to see the thing work.

Way too many adjustment points and fiddling around to do yet.

But, turbo not hit block.

Several hours of head scratching in the garage yielded an 8 second video...

Please note this is very early stages, and I just wanted to see the thing work.

Way too many adjustment points and fiddling around to do yet.

But, turbo not hit block.

#120

So far this thread bounces between insainity and total genius.

Thought a small+large turbo setup like this was the best of both worlds but I've never seen them outside of a diesel until tonight. I had a dream about a setup just like this (on a different motor and car) years ago in my sleep but never thought someone would do it.

Thank you for posting.

Thought a small+large turbo setup like this was the best of both worlds but I've never seen them outside of a diesel until tonight. I had a dream about a setup just like this (on a different motor and car) years ago in my sleep but never thought someone would do it.

Thank you for posting.