turbo manifold design

#81

ITT: Sav installs greddy mani/turbo. Lol.

This is both a joke and a serious note, but I wouldn't want any manifold test bed to have anything but a stock manifold. You might not get the best test results since the intake manifold may stop the turbo manifold from performing at it's best, but 99% of us have a stock intake manifold.

Then have a bunch of people say the results are not relevant because of the supporting mods.

#82

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Curly, you have a point, but the problem is that the stock '99+ IM chokes out at like the 320-330whp mark. I gained 11whp from 3psi with a stock IM (310@18 to 321@21). It's so bad that you may see no gains from a ramhorn and lose spool, but if you stick it on a motor with an IM, you'll see gains because the IM isn't restricting it.

Either way, I expect anyone looking at a ramhorn setup to improve power above ~5000rpm to have an intake manifold in place already. It's a no-brainer at this point.

Either way, I expect anyone looking at a ramhorn setup to improve power above ~5000rpm to have an intake manifold in place already. It's a no-brainer at this point.

#83

I know you have data to back up what you're saying, but I'm still puzzled with the idea of "it chokes out at 320 hp". As I understand the theory, the combo of IM and cam timing doesn't "choke out" at a given hp aka mass flow rate, it drops off a cliff at a given RPM. What this also means is that at say 6500 RPM, as you increase boost, the flow doesn't choke off at some level of boost. The dynamics of the *volume* flow don't change much with boost (density). Remember that as you raise boost, the volume flow downstream of the turbo compressor doesn't change much, the *mass* does. (And of course the volume flow increases *upstream* of the compressor)

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

#85

With the 2.0L I was getting over the 300ft-lb mark by 3800 rpm with 17 lbs of boost. Measured on a Dyno-dynamics Dyno at sea level. It peters out on the top end.

Bob

#86

These guys have to run a restricter that chokes top end power no mater what they do. These manifolds are tuned for mid range torque and throttle response to make performance gains. They still run fairly large turbos. they are not downsizing turbos to get throttle response, spool, or mid range.

Bob

#87

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

A typical manifold for a WRC car.

These guys have to run a restricter that chokes top end power no mater what they do. These manifolds are tuned for mid range torque and throttle response to make performance gains. They still run fairly large turbos. they are not downsizing turbos to get throttle response, spool, or mid range.

Bob

These guys have to run a restricter that chokes top end power no mater what they do. These manifolds are tuned for mid range torque and throttle response to make performance gains. They still run fairly large turbos. they are not downsizing turbos to get throttle response, spool, or mid range.

Bob

more pics of that odd turbo please.

#88

I know you have data to back up what you're saying, but I'm still puzzled with the idea of "it chokes out at 320 hp". As I understand the theory, the combo of IM and cam timing doesn't "choke out" at a given hp aka mass flow rate, it drops off a cliff at a given RPM. What this also means is that at say 6500 RPM, as you increase boost, the flow doesn't choke off at some level of boost. The dynamics of the *volume* flow don't change much with boost (density). Remember that as you raise boost, the volume flow downstream of the turbo compressor doesn't change much, the *mass* does. (And of course the volume flow increases *upstream* of the compressor)

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

You guys are all much more educated than I am when it comes to running boost. I just try to dummy down concepts when I can to help myself grasp the concepts more easily. If I am off base with my thinking please forgive me, and gently set me straight.

#89

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I know you have data to back up what you're saying, but I'm still puzzled with the idea of "it chokes out at 320 hp". As I understand the theory, the combo of IM and cam timing doesn't "choke out" at a given hp aka mass flow rate, it drops off a cliff at a given RPM. What this also means is that at say 6500 RPM, as you increase boost, the flow doesn't choke off at some level of boost. The dynamics of the *volume* flow don't change much with boost (density). Remember that as you raise boost, the volume flow downstream of the turbo compressor doesn't change much, the *mass* does. (And of course the volume flow increases *upstream* of the compressor)

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

The above theory explains the data that even NA cars gain x% above 6000 RPM from an IM, and this x% translates to turbo cars as well. It doesn't explain why at a certain boost level at 6500 RPM, that corresponds to 310 hp, it suddenly "chokes".

So it would be interesting to find corroborating data. Perhaps in Sav's case there was another un-noticed factor on the day he only went from 310 to 321 hp from 18 to 21 psi. One possiblity is that at that mass flow, he was hitting a steep part of the descent of compressor efficiency which was compounding with the increased backpressure required given the drop in VE of the motor >6000 RPM due to the stock IM. So it's not the IM "choking out", it's the combo. Perhaps with a bigger turbo, it wouldn't "choke out" at that RPM/hp combo. Perhaps he could have easily hit 350 hp at 5500 RPM where the IM flows well (massive torque required notwithstanding), and where the compressor would be in a more efficient island (more boost, same mass flow). (But of course a bigger turbo has downsides...)

So... while the IM improves torque > 6000 RPM, I wonder if it gives up torque and thus spoolup at say, 3500-4500, which some would consider important for a street car.

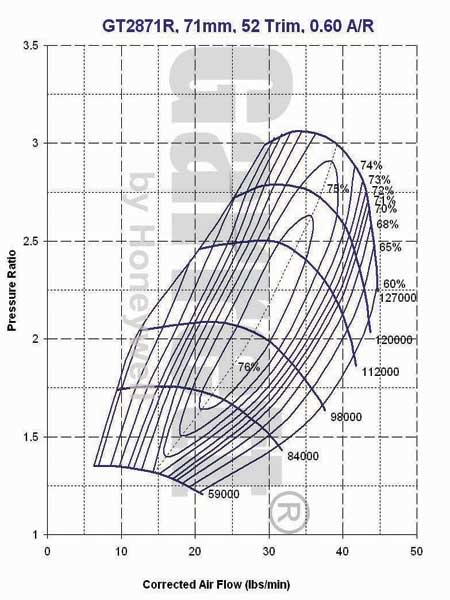

310whp = ~36lb/min

18psi = 2.22 pressure ratio

21psi = 2.42 presure ratio

If anything, the efficiency of that turbo is slightly improving going from 18psi to 21psi at ~36lb/min. The torque was basically unchanged as well, 305tq at 18psi to 306tq at 21psi, which is what leads me to believe that there's some sort of flow limitation to that manifold. You probably understand the theory significantly better than I do, but that's the results I got.

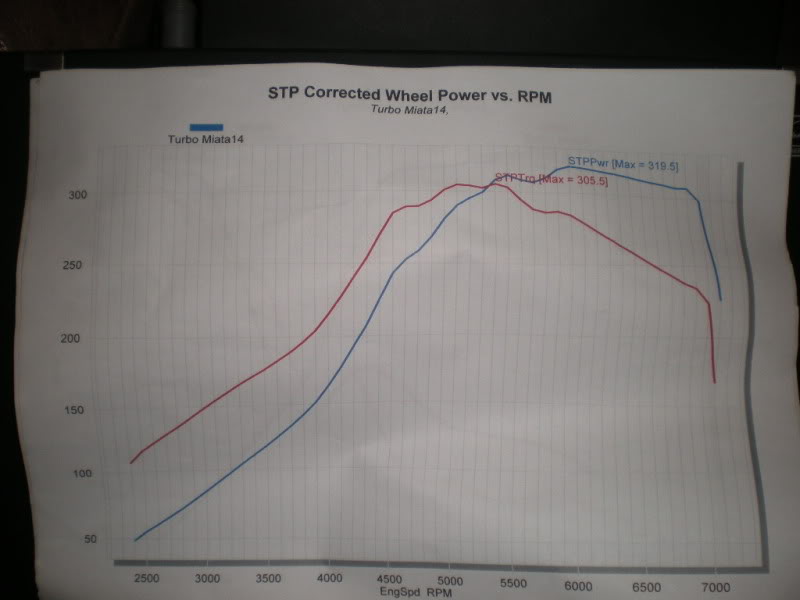

Here's that dyno chart, you can see how the torque just drops like a rock immediately after peak.

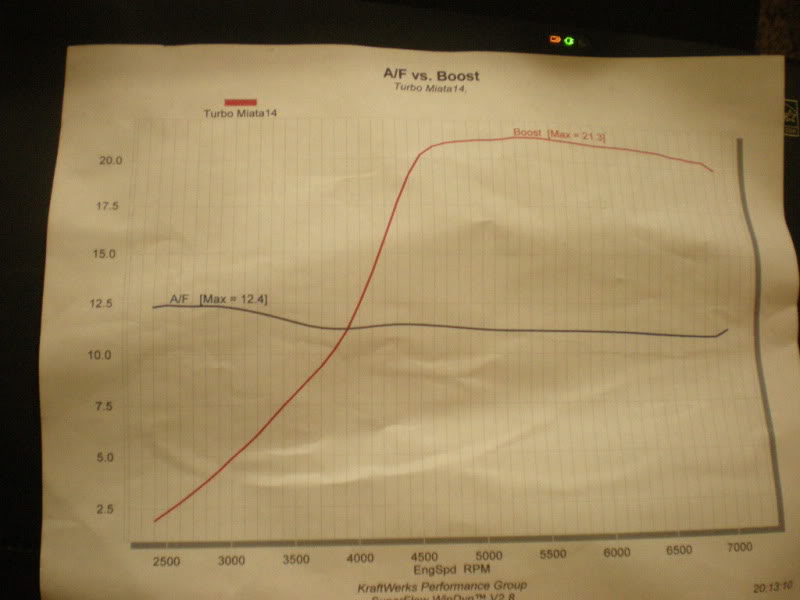

Boost/AFR from those same pulls:

Is there anyone out there making more than ~300tq through a stock '99 intake manifold? I know of a couple people using '94-97 manifolds.

#90

FWIW 18 psi at the IM may be 21-22 psi at the compressor outlet due to pressure drop in the i/c, but that doesn't seem particularly important...

Another possible factor is that it may be the turbine efficiency that's dropping off fast - a turbine inlet pressure reading will show this as a sharp rise in backpressure, resulting in the effect I talk about. Changing the IM to improve the VE of the motor above 5500 RPM may be the removed straw that saves the camel's back if you will.

I know my GT2554 showed it above 6000 RPM at 10 psi. Very sharp rise in TIP. My GT2560 shows it too, to a lesser extent, at the same boost.

If it's indeed the turbine, you will have a new bottleneck at around this new power level or slightly higher, regardless of new cams... unless maybe the new cams work as a kludge to get around the high turbine backpressure.

In any case it's good practice to look at TIP as it will tell you if your turbine is correctly sized.

The shape of your stock IM torque curve resembles my buddy Ian's curve at just 15 psi / 265 whp with a GT2560. I'll bet it's spiking TIP that holds back the breathing, and an IM would probably also just move the "choking" point to maybe 280-290 hp. So it's the system that's choking, and the lack of breathing of the IM > 6000 RPM contributes, but it's not a fixed HP choke point. A bigger turbine would "fix" it too, though the impact on the low end may be worse than that of the IM.

Here are his dyno results

http://www.codrus.com/dyno/bt/

Another possible factor is that it may be the turbine efficiency that's dropping off fast - a turbine inlet pressure reading will show this as a sharp rise in backpressure, resulting in the effect I talk about. Changing the IM to improve the VE of the motor above 5500 RPM may be the removed straw that saves the camel's back if you will.

I know my GT2554 showed it above 6000 RPM at 10 psi. Very sharp rise in TIP. My GT2560 shows it too, to a lesser extent, at the same boost.

If it's indeed the turbine, you will have a new bottleneck at around this new power level or slightly higher, regardless of new cams... unless maybe the new cams work as a kludge to get around the high turbine backpressure.

In any case it's good practice to look at TIP as it will tell you if your turbine is correctly sized.

The shape of your stock IM torque curve resembles my buddy Ian's curve at just 15 psi / 265 whp with a GT2560. I'll bet it's spiking TIP that holds back the breathing, and an IM would probably also just move the "choking" point to maybe 280-290 hp. So it's the system that's choking, and the lack of breathing of the IM > 6000 RPM contributes, but it's not a fixed HP choke point. A bigger turbine would "fix" it too, though the impact on the low end may be worse than that of the IM.

Here are his dyno results

http://www.codrus.com/dyno/bt/

Last edited by JasonC SBB; 08-02-2010 at 04:23 PM.

#91

It is all fluid dynamics, I don't pretend to understand much about it, and I know that this is an over simplification but here is how I see and understand it. A pipe can only flow so much water, you can increase the amount of water flowing through the pipe by adding a pump (turbo) and forcing water(air) through the pipe. However at some point you are going to reach a maximum volume that the system can flow efficiently.

This is the fundamental reason why turbo cars' torque curves remain about the same shape as N/A (once you hit full boost of course). The shape is a mainly a function of the cams and IM.

Last edited by JasonC SBB; 08-02-2010 at 04:27 PM.

#96

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,892

Total Cats: 399

I have little experience but do have theories and can justify why one might be better than the other and vice versa. Both could make sense in my head. The best idea is to make one and find out instead of theorizing. I'm glad I don't have a baby yet.

#100

this one is very interesting. i'm not sure i like the placement of the turbo though. very nice for an ebay many. http://cgi.ebay.com/ebaymotors/BP-BP...Q5fAccessories