3d printed intake for N/A NA miatas

#121

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I did my first data logging with the new crossover today. The results are kind of mixed. It still heat soaks when you park it, it just takes longer. Today I left the key on so the log could keep running after I parked it took 26 minutes to pick up 60 degrees (which is where it levels out)

For the drive I logged, I started with a fully heat soaked car showing 140f MAT and the ambient temp was 77. The minimum IAT number was 81.2 and I was consistently seeing 82 degrees on the gauge when cruising. 5 degrees over ambient is an improvement. I also noticed that air temps only start to climb again when you are under 25mph or when you have the throttle completely closed. Under 25mph it picked up 1-3 degrees.

I am going to try putting the IAT sensor in the end of the air filter. How do the GM open air sensors react to moisture? Is it going to kill the sensor or throw the reading way off if the filter ingests a small amount of water?

For the drive I logged, I started with a fully heat soaked car showing 140f MAT and the ambient temp was 77. The minimum IAT number was 81.2 and I was consistently seeing 82 degrees on the gauge when cruising. 5 degrees over ambient is an improvement. I also noticed that air temps only start to climb again when you are under 25mph or when you have the throttle completely closed. Under 25mph it picked up 1-3 degrees.

I am going to try putting the IAT sensor in the end of the air filter. How do the GM open air sensors react to moisture? Is it going to kill the sensor or throw the reading way off if the filter ingests a small amount of water?

Last edited by asmasm; 07-19-2014 at 06:18 PM.

#122

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Well I did this and will test it tomorrow:

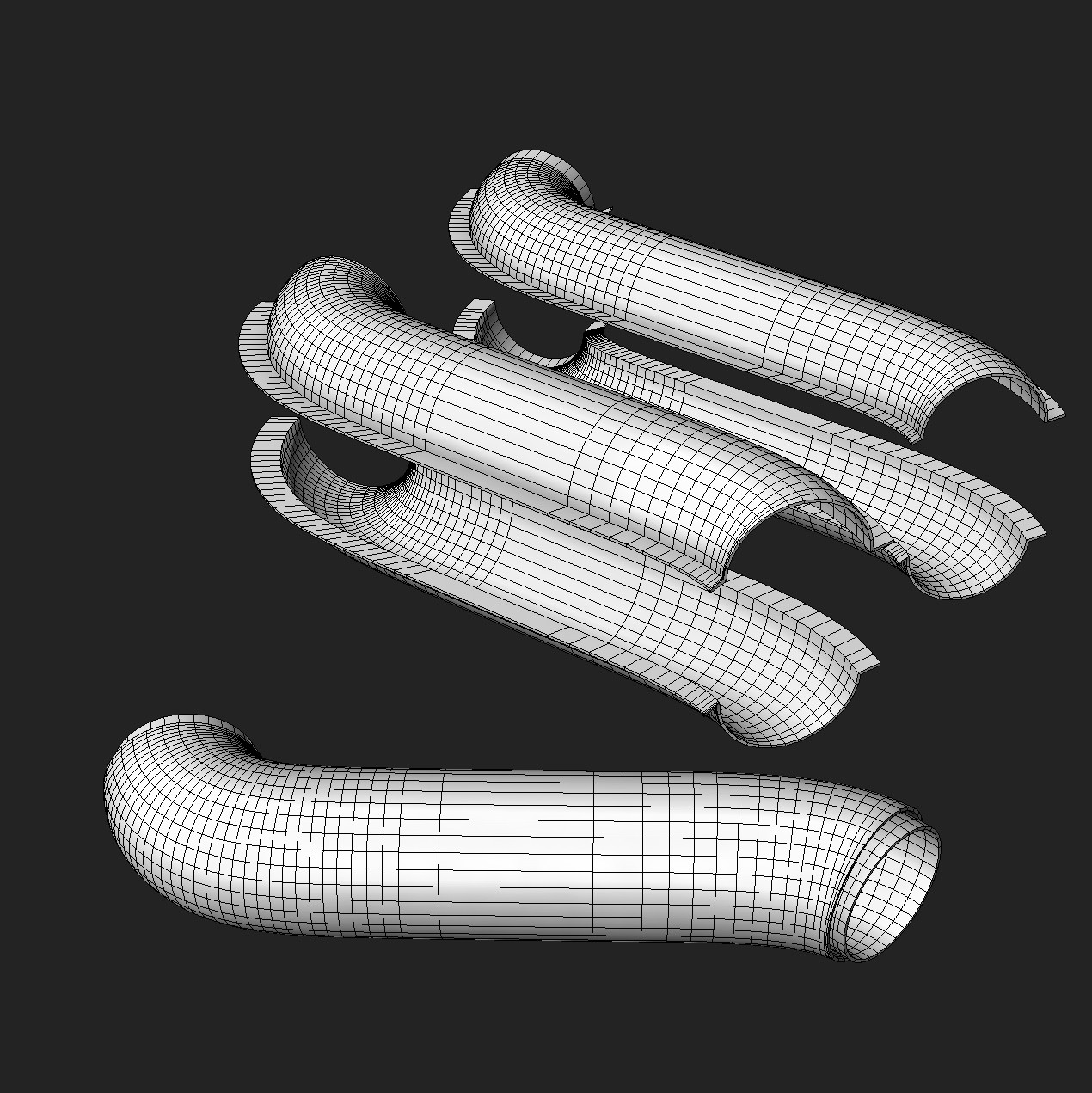

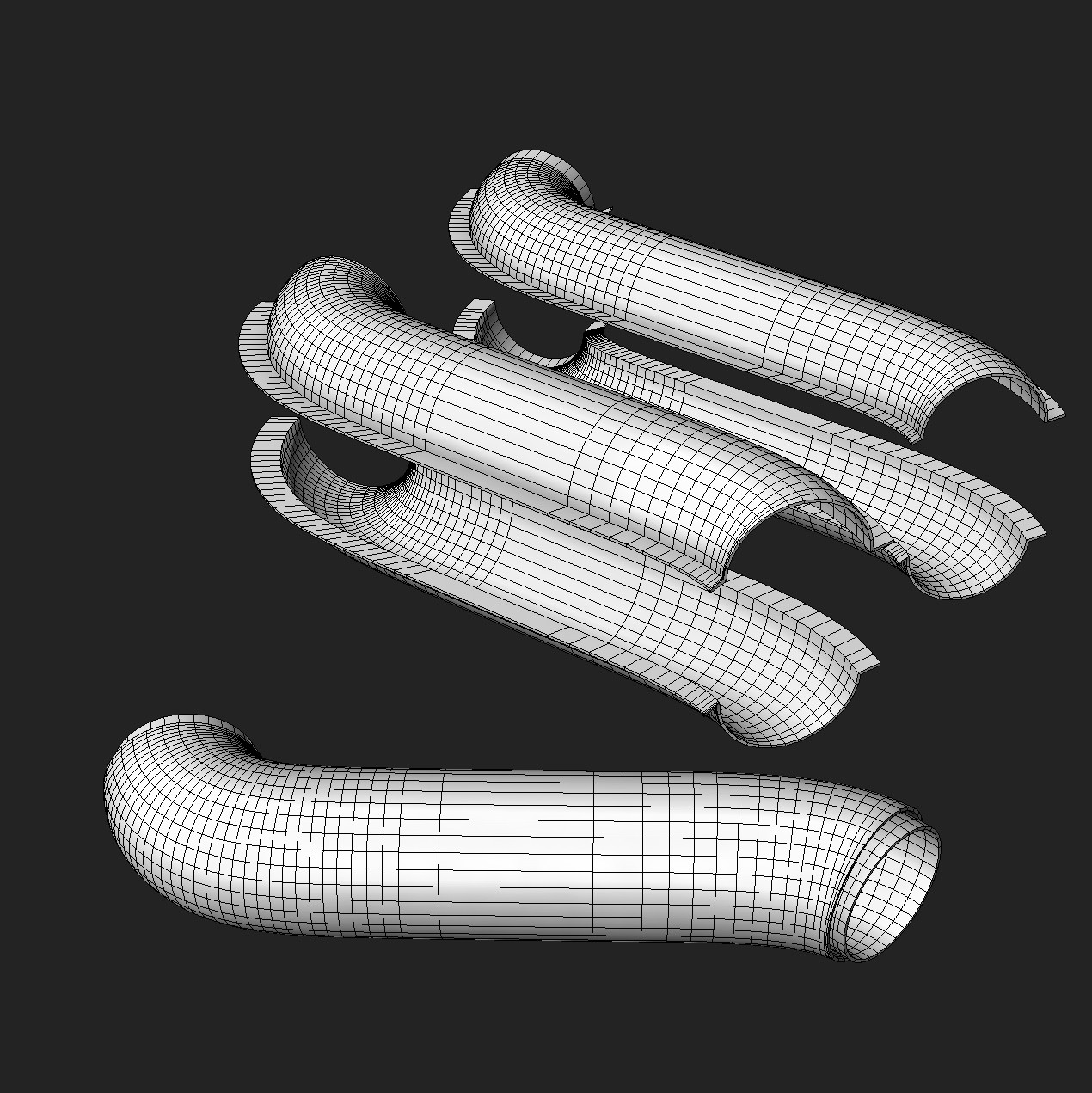

Also, because I can't help myself- I modeled up split molds for a longer dual wall carbon fiber tube that would run from the duct to the throttle body. My idea is to fit a check valve to the outer surface and hook it up to the manifold as a vacuum source. 70% chance it doesn't do anything but once I get an idea like this in my head I have to follow through with it.

Also, because I can't help myself- I modeled up split molds for a longer dual wall carbon fiber tube that would run from the duct to the throttle body. My idea is to fit a check valve to the outer surface and hook it up to the manifold as a vacuum source. 70% chance it doesn't do anything but once I get an idea like this in my head I have to follow through with it.

#123

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,175

Total Cats: 1,129

Looks nifty. Wonder if it could act as a heat shield too? Haven't been keeping up on this, but I like it. My friend's intake by the back of the intake manifold was seeing 120* on a 85* day after being heat soaked. Fully DEI wrapped too.

#124

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I did 30 minute VEAL drive today and it was cooler out than my earlier testing. 30 minutes probably isn't enough to get everything fully heated up but at the end of my drive my cruising IAT was 2.1 degrees above ambient  I still haven't moved the sensor to the filter- I layed up a heat shield today and I want to get that in place before I make the switch. I am pretty confident that the real IAT numbers are close enough to ambient air that measuring the air outside of the car will be most accurate.

I still haven't moved the sensor to the filter- I layed up a heat shield today and I want to get that in place before I make the switch. I am pretty confident that the real IAT numbers are close enough to ambient air that measuring the air outside of the car will be most accurate.

Also, can anyone recommend a good dyno tuner within 100 miles of the RDU area? I want to get the fuel in place myself but I would rather have someone who knows what they are doing figure out spark.

I still haven't moved the sensor to the filter- I layed up a heat shield today and I want to get that in place before I make the switch. I am pretty confident that the real IAT numbers are close enough to ambient air that measuring the air outside of the car will be most accurate.

I still haven't moved the sensor to the filter- I layed up a heat shield today and I want to get that in place before I make the switch. I am pretty confident that the real IAT numbers are close enough to ambient air that measuring the air outside of the car will be most accurate.Also, can anyone recommend a good dyno tuner within 100 miles of the RDU area? I want to get the fuel in place myself but I would rather have someone who knows what they are doing figure out spark.

#126

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I got one of these off of ebay for $50:

Savant VP100 VP 100, Rotary Vane Dual Stage Mechanical Vacuum Pump Rebuilt

Now I can vacuum bag an entire boat! The first project with it is going to be a heat shield. After that I am going to look at making solid carbon versions of the duct.

Savant VP100 VP 100, Rotary Vane Dual Stage Mechanical Vacuum Pump Rebuilt

Now I can vacuum bag an entire boat! The first project with it is going to be a heat shield. After that I am going to look at making solid carbon versions of the duct.

#129

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I finally ran the car with the IAT sensor in the filter. Hot restarts are now nice and smooth. I will try and find the time to do some data logging with it this weekend and I hope to have a heat shield made in the next few weeks.

#131

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I think I am going to try one of these with a 57mm crossover and a 2.5" elbow for the stock TB. It will be interesting to see how much difference it makes on the stock throttle body in a/b testing. Either way it funnels down to 57mm but I think this will make a cleaner transition with the tradeoff of not fitting skunk2 TBs.

#135

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

What is the hottest air temp you expect to see coming out of a turbo setup? 300 degrees? I think I would need a really specialized epoxy and then a controlled oven post cure to make a laminate part that would stay together.

#137

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I just went into the garage and test fit the passenger side hole. It would be doable with crossflow radiator and a redesign of the part. The hot side could be done as well but that would need more equipment.