On relieving crankcase pressure, PCVs, catch cans, breathers and whatnot...

#41

Pardon my noobishness, but in subaru land every catch can, AOS, PCV vent setup all needed a constant vacuum source pre-turbo. Non of the proposed setups I've seen do that, they rely on the intake manifold for vacuum and look like they would be back feeding the catch can and pressurizing the crankcase under boost.

#42

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,031

Total Cats: 6,596

Pardon my noobishness, but in subaru land every catch can, AOS, PCV vent setup all needed a constant vacuum source pre-turbo. Non of the proposed setups I've seen do that, they rely on the intake manifold for vacuum and look like they would be back feeding the catch can and pressurizing the crankcase under boost.

Venting the seperator tank into the turbo inlet does improve scavenging efficiency very slightly, and it also decreases emissions a tad. But if any oil mist / vapor is coming out of said tank, it'll wind up condensing inside the intercooler, and that's bad.

For seriously high-rev engines with major blowby concerns, we don't vent into the intake manifold. And even when we do, a PCV valve and / or check valve should prevent positive pressure in the intake manifold during boost from back-feeding into the crank case.

#43

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,609

Total Cats: 567

I just read this, found it in another thread: http://www.shophemi.com/images/media..._ccv_bible.pdf

This guy is pretty adament about there being a slight vacuum source at all time. I will say that since hooking my VC up to the stock PCV setup (with check valve and catch can), and the hotside pre-turbo, It notably helped with oil burning/smells after boosting.

Thinking about trying the setup where you delete the PCV and both lines go catch can then pre turbo. Should put a slight vac on things at all times and keep the engine happy.

This guy is pretty adament about there being a slight vacuum source at all time. I will say that since hooking my VC up to the stock PCV setup (with check valve and catch can), and the hotside pre-turbo, It notably helped with oil burning/smells after boosting.

Thinking about trying the setup where you delete the PCV and both lines go catch can then pre turbo. Should put a slight vac on things at all times and keep the engine happy.

#47

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,031

Total Cats: 6,596

The blowby coming from an engine running under heavy load at high RPM is going to massively exceed the capacity of such a device. Like, by orders of magnitude. The pump would become a restriction to flow.

The slash-cut pipe is a proven, inexpensive, reliable solution to provide forced evacuation of an engine running at high load.

#49

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I am designing a custom breather tank setup per sixshooter's recommendations.

There will be 2 5/8" ID hard lines coming out from the the valve cover; one just behind the oil cap, on top of the vc, and one from the original PCV port location.

Question:

Do I have to weld outlet ports on the valve cover?

Would it be possible to use grommets instead? (If grommets are OK, I will use them on the breather tank, as well.)

Using grommets will make my life much easier.

What do you think?

There will be 2 5/8" ID hard lines coming out from the the valve cover; one just behind the oil cap, on top of the vc, and one from the original PCV port location.

Question:

Do I have to weld outlet ports on the valve cover?

Would it be possible to use grommets instead? (If grommets are OK, I will use them on the breather tank, as well.)

Using grommets will make my life much easier.

What do you think?

#50

I am designing a custom breather tank setup per sixshooter's recommendations.

There will be 2 5/8" ID hard lines coming out from the the valve cover; one just behind the oil cap, on top of the vc, and one from the original PCV port location.

Question:

Do I have to weld outlet ports on the valve cover?

Would it be possible to use grommets instead? (If grommets are OK, I will use them on the breather tank, as well.)

Using grommets will make my life much easier.

What do you think?

There will be 2 5/8" ID hard lines coming out from the the valve cover; one just behind the oil cap, on top of the vc, and one from the original PCV port location.

Question:

Do I have to weld outlet ports on the valve cover?

Would it be possible to use grommets instead? (If grommets are OK, I will use them on the breather tank, as well.)

Using grommets will make my life much easier.

What do you think?

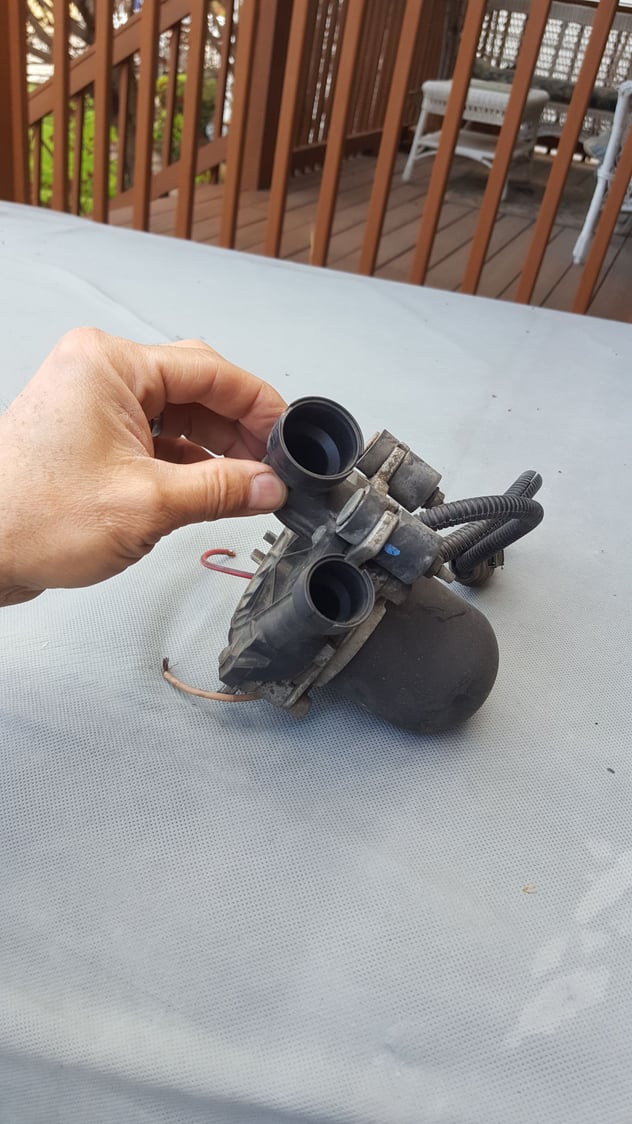

I already did a bunch of this.

1.0 made a venturi, pre turbo- worked great, made a lot of vacuum, filled my intercooler with oil.

2.0 valve cover: welded a bung on one side, other side, made a custom slip fit adapter, 13mm (aprox) that slides into a grommet and has a -10 male on the other end.

3.0 drilled and vented block: one location dumps oil, the other does not.

Ill drop some pics later if wanted.

#51

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,656

Total Cats: 3,011

Grommets might be okay if they are good and tight. You don't want leakage between the grommet and the valve cover or between the grommet and the fitting or you will have oil running down the side of the engine. But it is not a pressurized arrangement, especially with large-diameter hoses or pipes.

#52

I drilled with a 3/4 inch bit and tapped with 1/2 inch NPT. Sealed with JBWeld. Also opened up the valley between chambers, I believe I used 5/16 bit for that?

If I had to do it over again, I might step down to 3/8th NPT on the hot side. That's what I originally drilled/tapped for, the aluminium is too thin in that spot for 1/2 inch hence why it's in there at an angle now. Also had to clearance it to get the baffle cover on it.

Pics here so I don't spam your post

I also drilled/tapped the catch can for the same barbs, they came with 3/8 I believe and I didn't want to reduce flow. No pics of that though - It's not pretty anyways. :P

If I had to do it over again, I might step down to 3/8th NPT on the hot side. That's what I originally drilled/tapped for, the aluminium is too thin in that spot for 1/2 inch hence why it's in there at an angle now. Also had to clearance it to get the baffle cover on it.

Pics here so I don't spam your post

I also drilled/tapped the catch can for the same barbs, they came with 3/8 I believe and I didn't want to reduce flow. No pics of that though - It's not pretty anyways. :P

Last edited by cpierr03; 05-30-2019 at 01:51 PM.

#53

This is not as constructive as it is a history lesson.

Just don't make the same mistakes Mazda did with the MSM.

The MSM air oil separator was connected to top of the oil pan like the OP thought. But it was also connected to the PCV valve, and the cold side vent. MSM owners have had trouble with the oil pan line backing up all the way to the oil separator, then having it get sucked into the intake. Then people added a check valve so it was only good as a drain.

All I can say you right to keep it VTA, this should prevent the problems the MSM had.

Just don't make the same mistakes Mazda did with the MSM.

The MSM air oil separator was connected to top of the oil pan like the OP thought. But it was also connected to the PCV valve, and the cold side vent. MSM owners have had trouble with the oil pan line backing up all the way to the oil separator, then having it get sucked into the intake. Then people added a check valve so it was only good as a drain.

All I can say you right to keep it VTA, this should prevent the problems the MSM had.

#54

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I started building the breather tank system I had outlined here before:

Here:

https://www.miataturbo.net/engine-pe...9/#post1539009

Here:

https://www.miataturbo.net/engine-pe...9/#post1539009

Thread

Thread Starter

Forum

Replies

Last Post

mighty mouse

Engine Performance

52

08-14-2011 12:04 AM