Post your DIY aero pics

#287

Alumalite has a plastic core.

I think thin ply with a reflective material on it and a fully wrapped exhaust would do the job just fine.

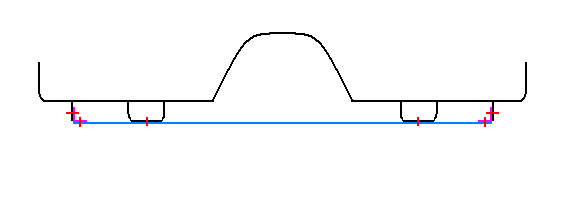

The below pic is a cross section of the MX5 tub. You can see the trans tunnel in the middle, the pinch welds are the vertical lines at the outside and inside them is the frame rails.

The pink represents aluminium angle, the blue is 1/4" ply sheet, and the red are fasteners.

Looks ok?

Anyone think exhaust heat wrap and reflective tape cannot save the timber?

Dann

#289

Supporting Vendor

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

A couple things -

First off, don't wrap your exhaust. The header is one thing, but under the car can easily get soaked with oils if you develop a leak since it is downstream of the engine/trans, and then instant fire. This has happened to people before. Whatever you make the undertray out of needs to be able to handle the heat without needing to add exhaust wrap.

As for my particular design, I'm not using alumalite. I have alumalite in the garage, but after my first version which was made from ABS, I have seen how much heat is under there, and I feel that the core of the alumalite will quickly be compromised by the heat just like the ABS was. I am making version 2 from .030" aluminum, which by itself is quite flimsy, but it's being reinforced with a gridwork of small aluminum angle, and I've worked out a permanent and lightweight way to bond the angle to the sheet.

-Ryan

First off, don't wrap your exhaust. The header is one thing, but under the car can easily get soaked with oils if you develop a leak since it is downstream of the engine/trans, and then instant fire. This has happened to people before. Whatever you make the undertray out of needs to be able to handle the heat without needing to add exhaust wrap.

As for my particular design, I'm not using alumalite. I have alumalite in the garage, but after my first version which was made from ABS, I have seen how much heat is under there, and I feel that the core of the alumalite will quickly be compromised by the heat just like the ABS was. I am making version 2 from .030" aluminum, which by itself is quite flimsy, but it's being reinforced with a gridwork of small aluminum angle, and I've worked out a permanent and lightweight way to bond the angle to the sheet.

-Ryan

#292

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

For an undertray I would rather use rivnuts than Dzus fasteners. If everything under the car is built well, then the undertray will not have to come off often, maybe once a year, and rivnuts/bolts will be a lot stronger.

#294

From a fabrication standpoint, the rivnuts would be a much easier install to boot. You could just drill holes in the frame rails to mount the rivnuts, whereas with dzus fasteners you'd be forced to install dzus plates anywhere you want to install, since you can't access the backside of anything to locate the springs.

#298

What materials are people using for flat underbody's?

Im about to put a front end on an NA the same as the blue car with the big Hoosier sticker, and I have a diffuser to put on the back, I was considering just riveting aluminium angle to the pinch welds and screwing an alumalite panel to it with perhaps a few alluminium angle's running across it for stiffness, and of course the whole exhaust will need to be wrapped.

Is there a foolproof option that wont melt? 1/4 birch seems heavy for an entire undertray.

Dann

Im about to put a front end on an NA the same as the blue car with the big Hoosier sticker, and I have a diffuser to put on the back, I was considering just riveting aluminium angle to the pinch welds and screwing an alumalite panel to it with perhaps a few alluminium angle's running across it for stiffness, and of course the whole exhaust will need to be wrapped.

Is there a foolproof option that wont melt? 1/4 birch seems heavy for an entire undertray.

Dann

#299

Supporting Vendor

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Weld-nuts are better than Riv-nuts. Riv-nuts are great until they come loose, then you can't get your bolt out because the riv-nut is just spinning in its hole, so you have to cut the bolt head off. Weld-nuts won't do this to you.

-Ryan

-Ryan

#300

Supporting Vendor

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Wood is also a bad material for under the car due to oil soak/fire danger. This is why any wood or ply splitter should get a layer of fiberglass laid over the top so it can't absorb oils.