Let's discuss spark advance

#81

I'm with Joe. I have more time than money, and I enjoy an EFFECTIVE do-it-yourself approach to tuning. I'm not in a hurry, this is my hobby.

As soon as I get a knock sensor installed, I'll be advancing cell by cell until I detect knock, and then retarding probably 2 degrees from there.

I went through this drill on my Triumph when I Squirted it a few years ago. It really doesn't take THAT long to do if you have either a driver who "gets it" and can do what you ask while you fiddle with the timing table while watching the knock sensor, or a passenger who can be trusted with the software. I think we did it in about 2 hours. Of course, that was on an MS2 with only a 12x12 spark table. Not quite as bad as filling out a 16x16 table.

As soon as I get a knock sensor installed, I'll be advancing cell by cell until I detect knock, and then retarding probably 2 degrees from there.

I went through this drill on my Triumph when I Squirted it a few years ago. It really doesn't take THAT long to do if you have either a driver who "gets it" and can do what you ask while you fiddle with the timing table while watching the knock sensor, or a passenger who can be trusted with the software. I think we did it in about 2 hours. Of course, that was on an MS2 with only a 12x12 spark table. Not quite as bad as filling out a 16x16 table.

#83

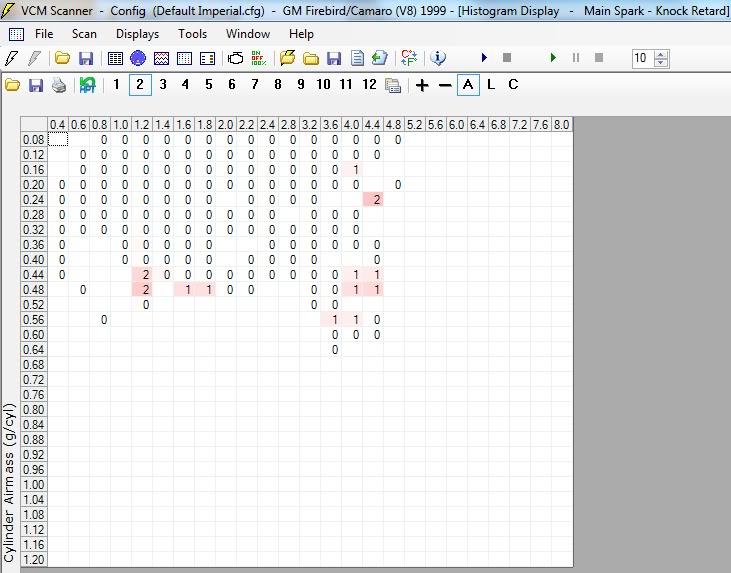

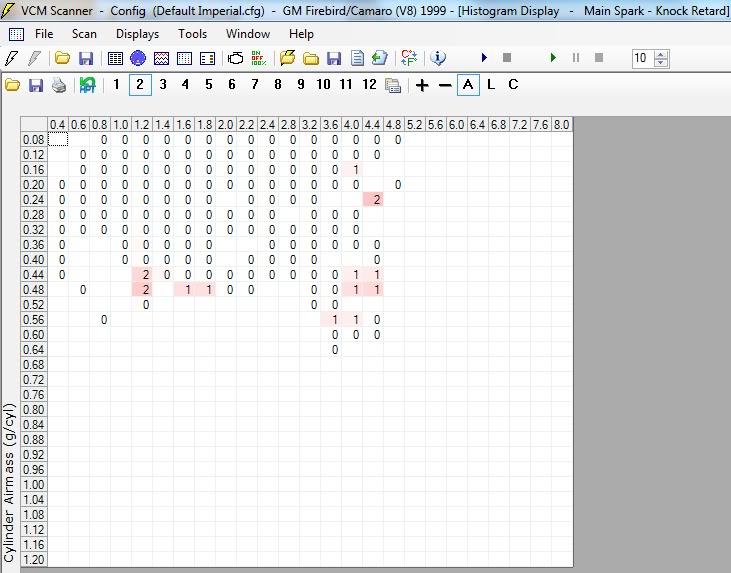

Loren, a lot of cells you wont even knock, and if you hear knock its actually the bearings crying because you're way past MBT. And tuning to knock, with good knock control in the car, you dont even need a 2nd just some good software or well setup spread sheets, you can get something that looks like this.

Literally histogram plot that matches your spark table, except instead of your advance values in the cells you have the peak knock retard value for that cell. Makes spotting the areas you knock a lot easier, though you normally dont have to pull as much timing as the listed KR value since it takes more timing removal to get rid of knock already happening than to prevent it.

Joe, I would look at injector pulse width rather than kpa. I know kpa is a good measure of fuel used, but pulse width should be more accurate. You could also come up with your own variable to track. I dont know if MS lets you make custom calculated variables that calculate in real time, but you could easily come up with a "fuel used per time" variable, just need pulse width, rpm, and map (to estimate fuel pressure). Then you could actually track it in your choice of viewing medium.

Literally histogram plot that matches your spark table, except instead of your advance values in the cells you have the peak knock retard value for that cell. Makes spotting the areas you knock a lot easier, though you normally dont have to pull as much timing as the listed KR value since it takes more timing removal to get rid of knock already happening than to prevent it.

Joe, I would look at injector pulse width rather than kpa. I know kpa is a good measure of fuel used, but pulse width should be more accurate. You could also come up with your own variable to track. I dont know if MS lets you make custom calculated variables that calculate in real time, but you could easily come up with a "fuel used per time" variable, just need pulse width, rpm, and map (to estimate fuel pressure). Then you could actually track it in your choice of viewing medium.

#85

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,024

Total Cats: 6,591

Did you actually look at any of the data which I posted? Every single one has fuel pulsewidth listed, and in post #21, in which I posted the first set of logs, I noted in the conclusion "the most important variable, which is fuel PW, was 16.1% lower." (It was bold in the original post, to emphasize the importance.)

#87

But wrong.

You need to tune to the lower of MBT or knock. On the Miata engine, you usually encounter MBT first. Advancing beyond MBT (even if it's not knocking) does two things:

1. Decreases efficiency.

2. Increases bearing stresses because you are moving the peak pressure point closer to TDC for no good reason.

It takes effort to determine MBT. That's why this is such a PITA and why it took Joe some time to optimize one cell.

As for knock detection, this is what I'm doing:

https://www.miataturbo.net/ecus-tuni...example-61616/

#90

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

I only use the brick on cruise tuning, and only done that once. It worked well though.

#92

Now with part-throttle, holding the throttle trying to maintain a MAP target while the dyno holds RPM, you are then watching 2 things: the MAP readout, and the torque readout. If you are watching the torque readout, looking for 1-2% changes, while playing with timing, and then MAP changes by 1-2%, then you *do not know* if the change in torque was due to the MAP change or the timing change. Thus my desire for a calculated value, torque_divided_by_MAP. All else equal, meaning if your spark map is correctly tuned, small changes in MAP will not change the value of torque_divided_by_MAP. You will only see changes due to timing.

#93

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,024

Total Cats: 6,591

Can we please stop arguing about the best way to dyno-tune a car?

I would really like to know if anyone else out there has actually put a modicum of effort into optimizing their spark table, and if so, what the results were.

I would really like to know if anyone else out there has actually put a modicum of effort into optimizing their spark table, and if so, what the results were.

#94

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

Now with part-throttle, holding the throttle trying to maintain a MAP target while the dyno holds RPM, you are then watching 2 things: the MAP readout, and the torque readout. If you are watching the torque readout, looking for 1-2% changes, while playing with timing, and then MAP changes by 1-2%, then you *do not know* if the change in torque was due to the MAP change or the timing change. Thus my desire for a calculated value, torque_divided_by_MAP. All else equal, meaning if your spark map is correctly tuned, small changes in MAP will not change the value of torque_divided_by_MAP. You will only see changes due to timing.

#96

Ben from DIYautotune carefully dyno tuned his spark table. It is posted here:

https://www.miataturbo.net/megasquir...z-18648/page4/

I am 99% sure that is a stock internal motor which should be relevant. This is the timing table I am using in my MSM.

EDIT: Might I add that it drives smooth and makes great power.

https://www.miataturbo.net/megasquir...z-18648/page4/

I am 99% sure that is a stock internal motor which should be relevant. This is the timing table I am using in my MSM.

EDIT: Might I add that it drives smooth and makes great power.

#97

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,024

Total Cats: 6,591

Ben from DIYautotune carefully dyno tuned his spark table. It is posted here:

https://www.miataturbo.net/megasquir...z-18648/page4/

https://www.miataturbo.net/megasquir...z-18648/page4/

So this is the map that Ben calls "aggressive as ****, and is the key to why my car makes so much power."

I lopped off the boosted rows, so we can compare it to my current map which is "not savagely aggressive"

In the middle RPM columns, I'm running 6-8° more timing in the upper half of the MAP range.

Again, I'm thinking that maybe his map is "aggressive as ****" in the 200 kPa row, but if we're comparing similar engines, it seems to be weaksauce in the vacuum region.

#98

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,603

Total Cats: 564

This thread is great. It makes me realize how untuned my car really is though. It brings me to ask this, what is the main downside of using, say, a mspnp base map (that is very conservative)?

Is it just power/effiency that is left on the table? or is it actually detrimental to the motors lifespan?

Because i cannot see doing this 1 cell at a time using Joe's method, that would take forever, and frankly its like pulling teeth.

I figure if your cruise cells are "good enough", and then you actually tune your in WOT/power cells for MBT, that should be plenty good of a tune for most people - right?

Or how about keeping a conservative timing map, and adding an extra lb of boost or two to reach your desired power goal? It appears to me that's what most on this forum do.

Is it just power/effiency that is left on the table? or is it actually detrimental to the motors lifespan?

Because i cannot see doing this 1 cell at a time using Joe's method, that would take forever, and frankly its like pulling teeth.

I figure if your cruise cells are "good enough", and then you actually tune your in WOT/power cells for MBT, that should be plenty good of a tune for most people - right?

Or how about keeping a conservative timing map, and adding an extra lb of boost or two to reach your desired power goal? It appears to me that's what most on this forum do.

#99

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,024

Total Cats: 6,591

But it's become apparent that we have not been taking ignition advance seriously for quite some time, and that bothers me.

#100

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,024

Total Cats: 6,591

Another question has occurred to me. And this is genuinely more of a "teach me things" post than an "I'm using the Socratic method to make you realize that I'm right" post.

Looking at all of these spark maps, the advance curve in any given row is pretty flat when viewed from left to right. Say we look at Ben's 75 kPa row. At 2,900 RPM (call it 3,000) he's at 31°, and from there until 7,000 RPM it only increases to 33°. This general trend is typical of all rows of most spark tables I have seen.

Are we forgetting something here?

What's the primary reason that we light the fire before TDC? It's because combustion takes time to occur. "Common wisdom" says that to obtain maximum efficiency from the combustion, we want the peak in-cylinder pressure to occur at some "ideal" crank angle, and for the sake of simplicity, we'll use the 15° ATDC number that gets thrown around a lot.

So the ideal moment to set off the spark is one that results in the burning fuel developing peak pressure at 15° ATDC. Don't worry if this figure is exactly accurate, we just need something to use in a comparison.

A number of factors influence the speed at which fuel burns in an engine. AFR is one, fuel composition is another, static compression ratio plays a factor, etc. Fortunately, we can assume that most of these variables are fixed for any given engine, or at least that the variation in them is relatively small.

(amiwrong? dunno.)

So let's just assume for the sake of argument that in Ben's engine, when he's running 3,000 RPM at 75 kPa, lighting the spark at 31° BTDC results in peak cylinder pressure at 15° ATDC, and thus, that cell is optimally tuned.

Now, at 3,000 RPM (which is 50 RPS), the crankshaft is traversing 18,000 degrees of arc per second, which is 5.5 × 10-5 seconds per degree (0.055 milliseconds). From 31° BTDC to 15° ATDC is a total of 46° of crank rotation, and it'll take 2.5 milliseconds for the crankshaft to travel that far.

Thus, we can infer that peak combustion pressure occurs 2.5 milliseconds after ignition, which seems like a reasonable number.

Now, double the speed of the crank to 6,000 RPM. Ignition advance is now 33° BTDC. But the crank is now traversing 36,000 degrees per second, or .027 milliseconds per degree. If we light the fire at 33° BTDC and then wait 2.5 milliseconds, the crankshaft will have traveled 92.5 degrees by the time peak pressure occurs, putting it at 59.5° ATDC.

I have got to be missing something here. I realize that time slows down as you approach the speed of light, but I don't think the pistons are going quite fast enough for special relativity to come into play here.

Looking at all of these spark maps, the advance curve in any given row is pretty flat when viewed from left to right. Say we look at Ben's 75 kPa row. At 2,900 RPM (call it 3,000) he's at 31°, and from there until 7,000 RPM it only increases to 33°. This general trend is typical of all rows of most spark tables I have seen.

Are we forgetting something here?

What's the primary reason that we light the fire before TDC? It's because combustion takes time to occur. "Common wisdom" says that to obtain maximum efficiency from the combustion, we want the peak in-cylinder pressure to occur at some "ideal" crank angle, and for the sake of simplicity, we'll use the 15° ATDC number that gets thrown around a lot.

So the ideal moment to set off the spark is one that results in the burning fuel developing peak pressure at 15° ATDC. Don't worry if this figure is exactly accurate, we just need something to use in a comparison.

A number of factors influence the speed at which fuel burns in an engine. AFR is one, fuel composition is another, static compression ratio plays a factor, etc. Fortunately, we can assume that most of these variables are fixed for any given engine, or at least that the variation in them is relatively small.

(amiwrong? dunno.)

So let's just assume for the sake of argument that in Ben's engine, when he's running 3,000 RPM at 75 kPa, lighting the spark at 31° BTDC results in peak cylinder pressure at 15° ATDC, and thus, that cell is optimally tuned.

Now, at 3,000 RPM (which is 50 RPS), the crankshaft is traversing 18,000 degrees of arc per second, which is 5.5 × 10-5 seconds per degree (0.055 milliseconds). From 31° BTDC to 15° ATDC is a total of 46° of crank rotation, and it'll take 2.5 milliseconds for the crankshaft to travel that far.

Thus, we can infer that peak combustion pressure occurs 2.5 milliseconds after ignition, which seems like a reasonable number.

Now, double the speed of the crank to 6,000 RPM. Ignition advance is now 33° BTDC. But the crank is now traversing 36,000 degrees per second, or .027 milliseconds per degree. If we light the fire at 33° BTDC and then wait 2.5 milliseconds, the crankshaft will have traveled 92.5 degrees by the time peak pressure occurs, putting it at 59.5° ATDC.

I have got to be missing something here. I realize that time slows down as you approach the speed of light, but I don't think the pistons are going quite fast enough for special relativity to come into play here.

Last edited by Joe Perez; 11-28-2012 at 02:03 PM.