Nothing to see here, just project Sisyphus, move along

#1584

You basically walked in here and told me my head was garbage and the machinist was incompetent. If that's not trolling I don't know what is.

I'm glad you have the resources to build these things yourself, I don't. For this reason, I checked what I could and I'm realistic about the tolerances of the tools I have available. Some of us don't have the tools or ability to rip apart an entire cylinder head and check every single clearance on every single mating part. For those things I have to trust that the work was done correctly. To this end I've hedged my bets and purchased a head from a trusted source. Don't assume I don't know what I'm doing just because I didn't do the work myself.

Here's the score:

As I feel Ian correctly pointed out, the next step is to contact the guys from whom I purchased the head and ask their advice. They may tell me "Yeah, we run them tight because X" or "Its assumed you are going to re-shim after X hours on the motor once the valves seat" or even "Dear god that's terrible, the responsible parties will be shot at dawn. Here is our FedEx account number, crate your motor and sent it to us and we'll make it right." For all I know they may not be using OEM specs for what are obviously not OEM parts. I'll never know until I ask.

Also, in the interest of accuracy I need to remember to order a set of feelers that have .0005 steps.

I'm glad you have the resources to build these things yourself, I don't. For this reason, I checked what I could and I'm realistic about the tolerances of the tools I have available. Some of us don't have the tools or ability to rip apart an entire cylinder head and check every single clearance on every single mating part. For those things I have to trust that the work was done correctly. To this end I've hedged my bets and purchased a head from a trusted source. Don't assume I don't know what I'm doing just because I didn't do the work myself.

Here's the score:

- the majority of the lifters are on the "tight" end of the spec

- my feelers are .001 steps

- there could very easily be another .0009 on any of these measurements, I don't have the measurement resolution to confirm or deny

- there is one maybe two that are outside my measurement resolution and OEM tolerance

- this head has never been run, I expect these measurements to change after the valves fully seat

As I feel Ian correctly pointed out, the next step is to contact the guys from whom I purchased the head and ask their advice. They may tell me "Yeah, we run them tight because X" or "Its assumed you are going to re-shim after X hours on the motor once the valves seat" or even "Dear god that's terrible, the responsible parties will be shot at dawn. Here is our FedEx account number, crate your motor and sent it to us and we'll make it right." For all I know they may not be using OEM specs for what are obviously not OEM parts. I'll never know until I ask.

Also, in the interest of accuracy I need to remember to order a set of feelers that have .0005 steps.

I've never trolled you, in this thread alone I've posted things to help you when you asked for advice on various things. (aside from this issue)

I said bad machine work caused the problem, and that sucks. That's LITERALLY the words I wrote. And it's true. You can be offended, call me a troll, whatever. You used good parts, and the tolerances are out on over 1/2 the valves in a short time frame. That's from bad machine work, and I get insulted publicly for telling you this. WTF?

#1586

Call Emilio and ask him. I tend to think that if anything they should be on the loose side, since they will tend to "wear in", and if they're tight already then you'll quickly reach the point of them not fully closing (been there done that, have the tears to show for it)

As for the front routed lines: nothing wrong with it AS LONG as you fasten them down. So like a bracket or two or a strap or something, to make 100% sure that they will never move or rub inside the timing cover.

As for the front routed lines: nothing wrong with it AS LONG as you fasten them down. So like a bracket or two or a strap or something, to make 100% sure that they will never move or rub inside the timing cover.

#1587

Call Emilio and ask him. I tend to think that if anything they should be on the loose side, since they will tend to "wear in", and if they're tight already then you'll quickly reach the point of them not fully closing (been there done that, have the tears to show for it)

As for the front routed lines: nothing wrong with it AS LONG as you fasten them down. So like a bracket or two or a strap or something, to make 100% sure that they will never move or rub inside the timing cover.

As for the front routed lines: nothing wrong with it AS LONG as you fasten them down. So like a bracket or two or a strap or something, to make 100% sure that they will never move or rub inside the timing cover.

I tend to slit rubber hose lengthwise and slide it over stainless lines in order to protect other stuff from them. In this case, though, I'd just run it around the back because it's simpler and the extra couple feet of hose don't really hurt anything.

--Ian

#1588

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

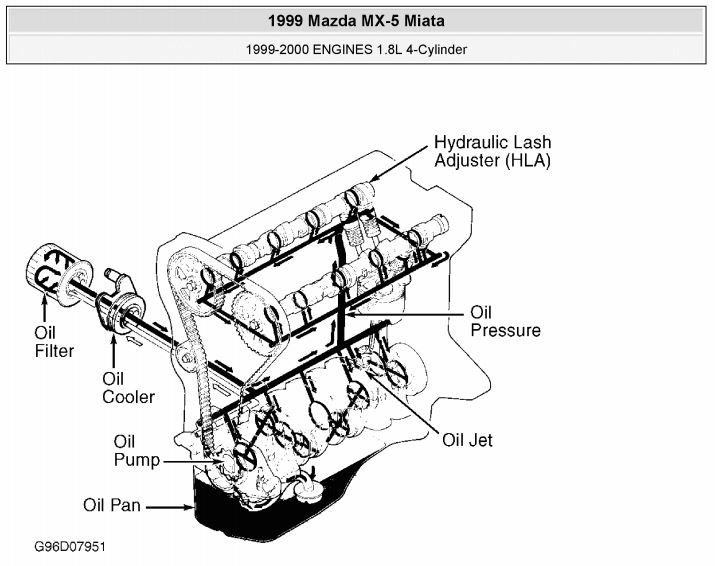

I'm trying to decide if I want to T on the pressure sender or come off a sandwich plate behind the filter. I've not cut my oil filter tube thing yet so I still have some options.

#1589

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I've gone through most of the threads or PMd guys running EFRs here on MT and while damn near everyone is running way longer than 18" very few are actually using -6AN. I can get a -4AN through that space with a piece of rubber hose over it no problem. If I feed it off the sandwich plate rather than T the sender, that's another 8 or so inches of line I can eliminate. I really dislike the T method, but I don't know if I can fit the sandwich and a Mocal thermo plate on there at the same time. I will be eliminating the factory oil cooler/heater so the answer to that question is most likely yes, but I also have not decided if I'm going to keep the sandwich plate. I haven't decided if I dislike the sandwich more or less than the T.

#1597

Hm. I was under the impression that the shim tended to wear faster than the valve seat, so that the tolerances would get larger over time rather than smaller?

I tend to slit rubber hose lengthwise and slide it over stainless lines in order to protect other stuff from them. In this case, though, I'd just run it around the back because it's simpler and the extra couple feet of hose don't really hurt anything.

--Ian

I tend to slit rubber hose lengthwise and slide it over stainless lines in order to protect other stuff from them. In this case, though, I'd just run it around the back because it's simpler and the extra couple feet of hose don't really hurt anything.

--Ian

Valve seat/shim is smaller area, higher pressure, and see's way higher temps with no oil cooling/no oil lubrication. Exhaust valves are hotter still. Thus why 1/2 his exhaust valves are tight, they are wearing away between the seat and valve causing the valve stem to move "up" and thus the tighter measured clearances.

I ran a 4AN on my EFR, never had a problem. It was a 44" line IIRC, no restrictor, VVT oil pump/VVT head.

Regarding oil location, when you're driving the car a lot of oil bypasses the filter anyways, it has a bypass valve inside it. I don't think Teeing off before the filter will matter, but using post-filter oil is technically better.

#1598

The shim has a large surface area, and is cool, and bathed in oil.

Valve seat/shim is smaller area, higher pressure, and see's way higher temps with no oil cooling/no oil lubrication. Exhaust valves are hotter still. Thus why 1/2 his exhaust valves are tight, they are wearing away between the seat and valve causing the valve stem to move "up" and thus the tighter measured clearances.

Valve seat/shim is smaller area, higher pressure, and see's way higher temps with no oil cooling/no oil lubrication. Exhaust valves are hotter still. Thus why 1/2 his exhaust valves are tight, they are wearing away between the seat and valve causing the valve stem to move "up" and thus the tighter measured clearances.

As for shim vs seat wear, the shim has the cam sliding against it, rather than just open/close like the valve. I dunno, I'm a software guy, not a mechanical engineer. This is just what I read somewhere, and it matches up with my experiences of valve clearances getting looser over time rather than tighter.

But yeah, I should go check mine.

--Ian

#1599

Uh. The engine hasn't even been started yet AFAIK, it's still sitting on the engine stand, how has it worn the valve seats?

As for shim vs seat wear, the shim has the cam sliding against it, rather than just open/close like the valve. I dunno, I'm a software guy, not a mechanical engineer. This is just what I read somewhere, and it matches up with my experiences of valve clearances getting looser over time rather than tighter.

But yeah, I should go check mine.

--Ian

As for shim vs seat wear, the shim has the cam sliding against it, rather than just open/close like the valve. I dunno, I'm a software guy, not a mechanical engineer. This is just what I read somewhere, and it matches up with my experiences of valve clearances getting looser over time rather than tighter.

But yeah, I should go check mine.

--Ian

I'll wait for OP to clarify/answer the above questions.

If it's new and set that way........ I'll be surprised if this is the case.

#1600

Uh. The engine hasn't even been started yet AFAIK, it's still sitting on the engine stand, how has it worn the valve seats?

As for shim vs seat wear, the shim has the cam sliding against it, rather than just open/close like the valve. I dunno, I'm a software guy, not a mechanical engineer. This is just what I read somewhere, and it matches up with my experiences of valve clearances getting looser over time rather than tighter.

But yeah, I should go check mine.

--Ian

As for shim vs seat wear, the shim has the cam sliding against it, rather than just open/close like the valve. I dunno, I'm a software guy, not a mechanical engineer. This is just what I read somewhere, and it matches up with my experiences of valve clearances getting looser over time rather than tighter.

But yeah, I should go check mine.

--Ian

On miata motors with solid shims (99-2005) valves typically get tighter as the valve/seat wears. I've torn apart several 99+ heads on miatas and they all had worn exhaust valves, even lower mileage examples showed some wear on stock engines. I've only checked clearances on the heads I've used, but all of the ones I've checked were never loose, always wear tight, especially the exhaust side.

I cut my exhaust seats extra wide to help keep them happy for this exact reason.