TD04/TD05 fitted in place of T25/T28

#41

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

Curly what should I call this........Is it ugly enough to be a Bobbitt horn?

Leafy, I will use 5/4 inch for the runners, joined 6/4 for the merge and 7/4 for the collector, so hopefully flow wont choke. (Even with a td05)

Good point hochkis. I guess I could brace the turbo from outlet flange back to the manifold?

Good point hochkis. I guess I could brace the turbo from outlet flange back to the manifold?

#43

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

Some progress over the w/e...

Made the merge (go easy on me, its the first one I tried!)

And tack welded it together

Jonathan, the frame clearance is about 2". (It could be made bigger if needs be.) Why this position? Turbo piping is straight forward (straight pipe to intercooler under light route), clears power steering, does not clash with coolant return hose, turbos fit with out clocking or wastegate relocation.

Made the merge (go easy on me, its the first one I tried!)

And tack welded it together

#45

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,603

Total Cats: 564

Looks pretty good, mucho better than your last config. However, i'd agree that the turbo will be a "lever" on the manifold and add extra stress. Perhaps you should add some bracing?

Should have made it unequal length for more scoobie rumble

Should have made it unequal length for more scoobie rumble

#46

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

I agree, scoobie rumble sounds glorius. I don't know if it would suit my anemic mx5.

Just curious, has anyone used reversible manifold flanges? Theoretically the same manifold could be used for fwd/rear or low/high turbo placement?

Just curious, has anyone used reversible manifold flanges? Theoretically the same manifold could be used for fwd/rear or low/high turbo placement?

Last edited by sturovo; 02-04-2013 at 01:15 PM.

#48

i'm running a subaru/IHI VF10 turbo on my 1600. its a great turbo. good response and holds boost to redline. the best bit is the suby turbos are dirt cheap compared to the nissan/garret ones.

http://www.cardomain.com/ride/264041...a-mx-5/page-6/

http://www.cardomain.com/ride/264041...a-mx-5/page-6/

#49

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

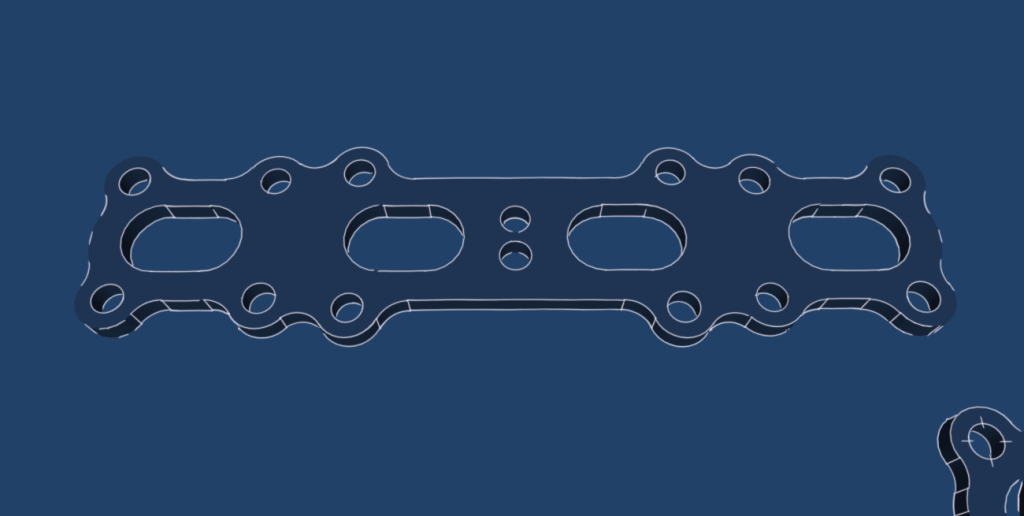

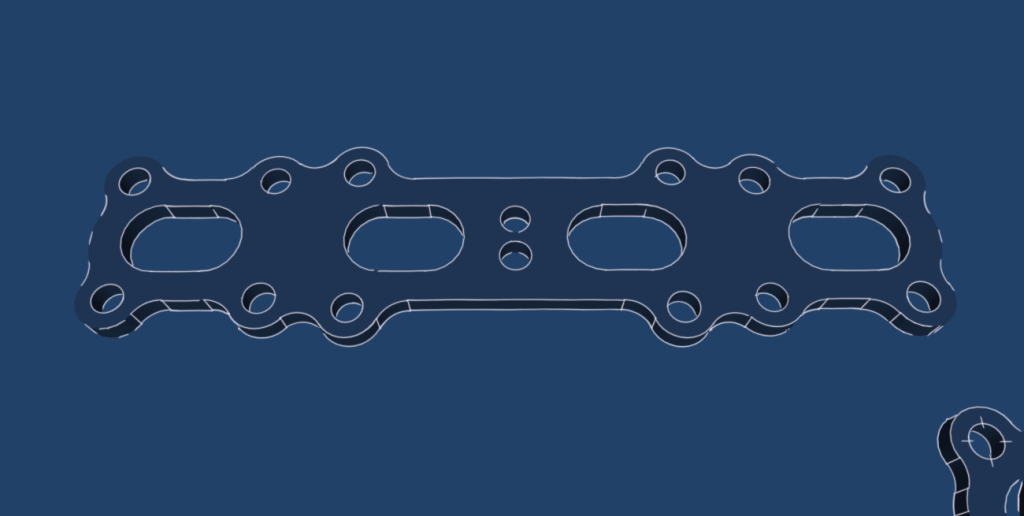

Continuing in the tradition of answering questions that no one is asking I hacked together a reversible manifold suitable for both subaru and t2 flanges. (Mild flanges / stainless elbows.)

Minimal effort involved as the long radius bends line up well and stick welding is hyper fast.

Minimal effort involved as the long radius bends line up well and stick welding is hyper fast.

#52

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

Thanks Jonathan. I learned by watching this video

Rick, I have a basic 100$ inverter. I am no expert but what I have found out so far is that usually spatter is either caused by too much current or drawing too long of an ark.

Controlling slag is the difficult thing with arc welding. I use lighter shade glass as it makes seeing the metal/slag boundary easier. Using gravity is also a big help as is selecting the correct electrodes. There are characteristic sounds for good and bad weld formation.

The stainless steel I used in the manifold is 2mm thick. This is ideal for welding electrode +ve with 1.6mm rods as you can get full penetration on a continuous pass and not get much spatter. I use a chipping hammer and coarse wire wheel to clean the welds. (That's why they look clean

) Safety glasses are a must with stainless electrodes as the slag explodes off the weld when cooling.

) Safety glasses are a must with stainless electrodes as the slag explodes off the weld when cooling.

#56

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

Fabbed a new t25 downpipe elbow from 70mm x 1.5 mm stainless tube and 5mm mild flanges. (The old one was suitable for a horizontally mounted turbo.)

I tried some different electrodes (309 vs 308) which lay smoother beads?

I tried some different electrodes (309 vs 308) which lay smoother beads?

#58

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Martin, Slovakia

Posts: 507

Total Cats: 74

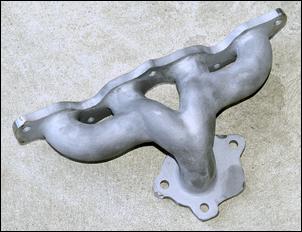

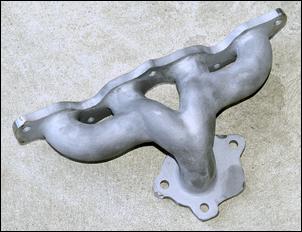

Thanks Jae-Rex for the vote of confidence! If I was thinking about trying a variation of this manifold next....

AutoSpeed - Making Turbo Manifolds, Part 2

AutoSpeed - Making Turbo Manifolds, Part 2

Almost finished the downpipe (70x1.5 304) but ran out of electrodes

Almost finished the downpipe (70x1.5 304) but ran out of electrodes