Build Thread (FE3, RX7 TII, EFR 6258, MS3)

#162

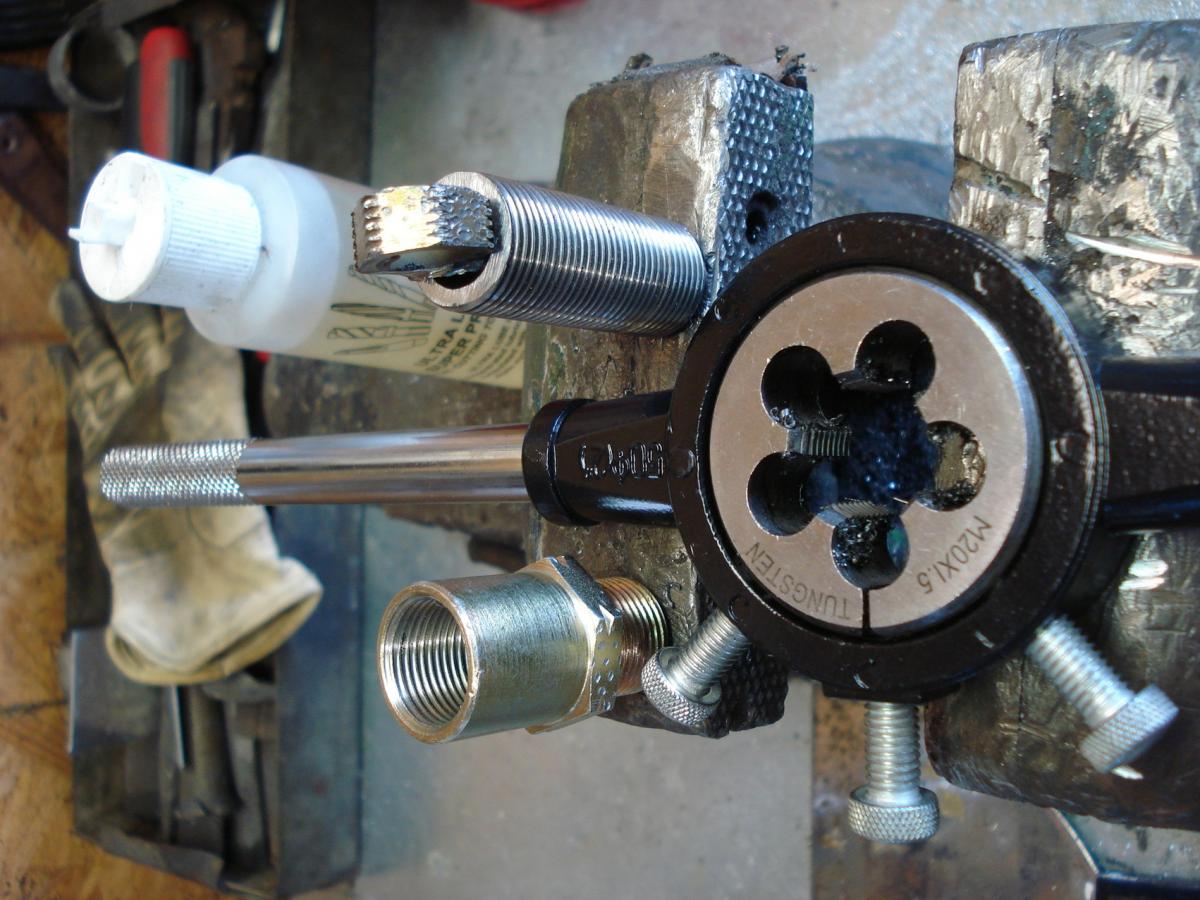

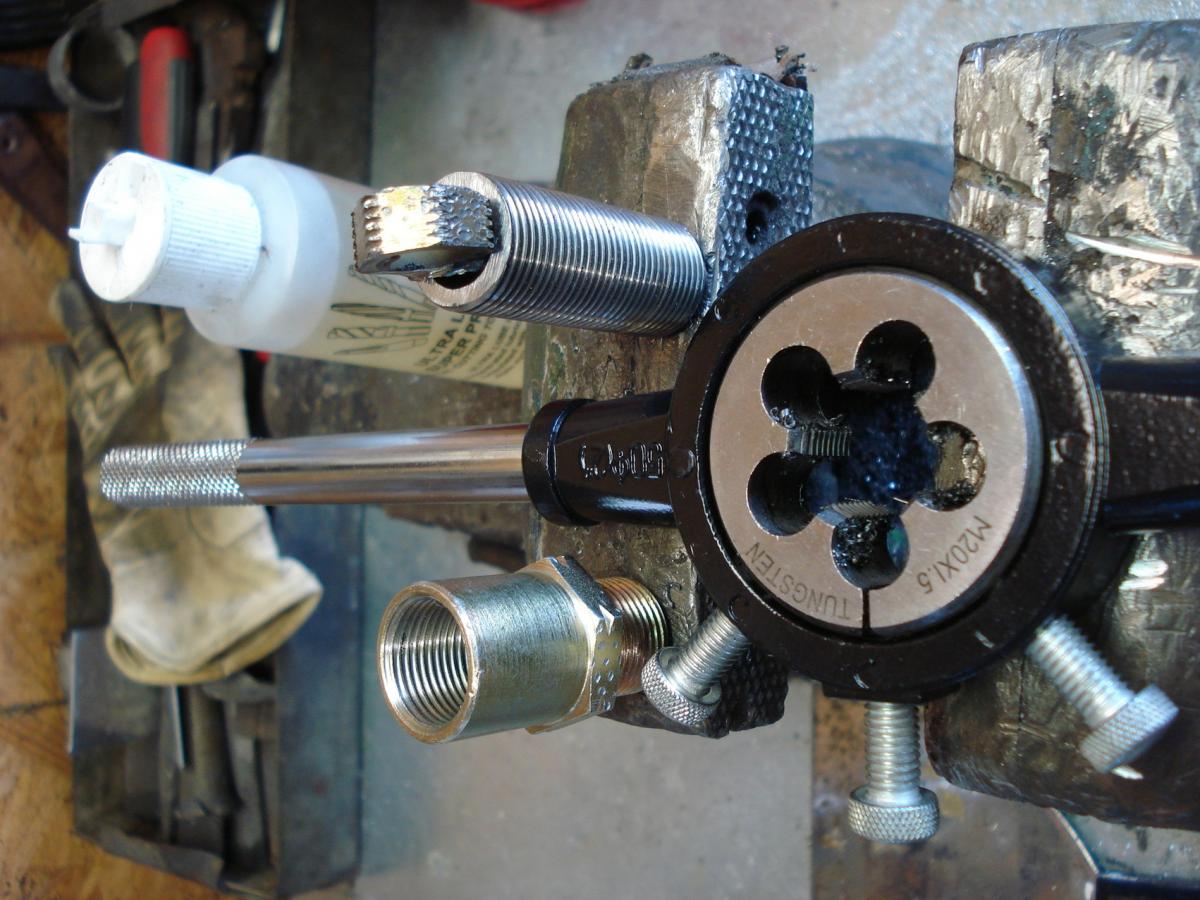

Finally got my sandwich plate issue worked out. I turned down the stock stem, took a die to it and cut off the hex head when i was finished. turned out nice.

Finally got the hubs back from the machine shop today. I had to call my dad and tell him to throw a few beers in the fridge after i paid the bill on it though. $470 for 11.75 hours of labor. granted it took them 3 hours to pull the old miata axles from the spindles but it shouldn't have taken them that long to do the machine work in my opinion. As they were driving in one of the studs one of the holes blew out and they had to re-weld.. kind of worried about the strength of the hubs at this point seeing as they took off some material to re- surface the face of the hub as well..

here is a comparison of the thickness between the stock miata and my modified hubs. (shiny = rx7)

I signed a liability waiver when i paid the bill and he told me to take it easy on them...

... Riiight.

Finally got the hubs back from the machine shop today. I had to call my dad and tell him to throw a few beers in the fridge after i paid the bill on it though. $470 for 11.75 hours of labor. granted it took them 3 hours to pull the old miata axles from the spindles but it shouldn't have taken them that long to do the machine work in my opinion. As they were driving in one of the studs one of the holes blew out and they had to re-weld.. kind of worried about the strength of the hubs at this point seeing as they took off some material to re- surface the face of the hub as well..

here is a comparison of the thickness between the stock miata and my modified hubs. (shiny = rx7)

I signed a liability waiver when i paid the bill and he told me to take it easy on them...

... Riiight.

Last edited by yank; 10-17-2011 at 01:41 PM.

#164

as described in Mightymouses' thread the point of using the rx7 hubs is so that the rx7 axles just slide right into the splined hub. otherwise i would need to come up with a custom axle solution or modify the rear diff to accept the miata axles which are much weaker.

#169

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,184

Total Cats: 1,135

Uh, haven't people been having issues with using the oil pressure sensor on a "T" like that? vibrations will break the T. I believe you have to mount the T somewhere in the engine bay and route a braided line to it.

#172

Yes. Of course i could have bought some less expensive items that would do the job but i tried to make quality and dependability a priority in order to build it right the first time.

I got shafted on a few items

-$240 to shave 3 lbs from the flywheel.

-$470 hub / brake rotor machining.

and i initially bought a few items on craigslist that im not going to end up using due to the integrated features of the EFR.

-Tial Q 50mm BOV (new efficient one)

-Tial V44 wastegate

-boost solenoid

-2" 90deg coupler

I got shafted on a few items

-$240 to shave 3 lbs from the flywheel.

-$470 hub / brake rotor machining.

and i initially bought a few items on craigslist that im not going to end up using due to the integrated features of the EFR.

-Tial Q 50mm BOV (new efficient one)

-Tial V44 wastegate

-boost solenoid

-2" 90deg coupler

#173

I'm with you on this. Granted at the moment it feels really stout there has to be a high stress concentration on the male to male threaded section in the block. I like the idea of the remote mount via flexible line idea. I also considered welding a bracket to the T up to the nearest tapped hole on the block. This option would be free which is good under my current financial circumstances. do you think this would suffice?

#177

well. thinning the hub like that will have a dramatically negative effect upon the brake rotor hat depth/sitting position. you'll have to space your caliper back the same effective distance they shaved.

go buy a digital caliper if you don't already have one-harbor freight has decent ones.

short of that- KYclutch.com Great people insanely cheap pricing. $50 to lighten & resurface your flywheel.

tell them the guys from clubprotege sent you over & they'll take good care of you.

go buy a digital caliper if you don't already have one-harbor freight has decent ones.

short of that- KYclutch.com Great people insanely cheap pricing. $50 to lighten & resurface your flywheel.

tell them the guys from clubprotege sent you over & they'll take good care of you.

#179

well. thinning the hub like that will have a dramatically negative effect upon the brake rotor hat depth/sitting position. you'll have to space your caliper back the same effective distance they shaved.

go buy a digital caliper if you don't already have one-harbor freight has decent ones.

go buy a digital caliper if you don't already have one-harbor freight has decent ones.